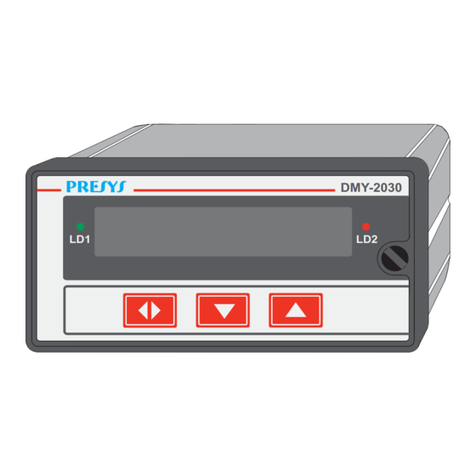

Presys DMY-2015 User manual

Digital Multi-Point Indicator

DMY-2015

Technical Manual

R

presys

EC Declaration of Conformity

We declare under our sole responsability that the CE marked products, are in conformity

with the essential requirements of the following EC Directives when installed in

accordance with the installation instructions contained in the product documentation:

Series

DMY-2015

Description

Digital Mult-Point Indicator

LVD

Low Voltage Directive

2014/35/EC of the European Parliament and of the Council of 12 December 2006 on

the harmonization of the laws of Member States relating to Electrical Equipment

designed for use within certain voltage limits.

EN 61010-1:2011

Safety requirements for electrical equipment for measurement, control and laboratory

use

EN 61010-2:010

Safety requirements for electrical equipment for measurement, control and laboratory

use - Part 2-010: Particular requirements for laboratory equipment for the heating of

Materials.

EMC directive

2004/108/EC of the European Parliament and of the Council of 15 December 2004

on the approximation of the laws of the Member States relating to electromagnetic

compatibility and repealing Directive 89/336/EEC

EN 61326-1:2003

Electrical equipment for measurement, control and laboratory use - EMC requirements

São Paulo, 8 September 2017

Vinicius José Gomes Nunes

Antonio Rafael Sito Antunes

CEO

Engineering Manager

presys

Presys Instruments DMY - 2015

EM0068-01

TABLE OF CONTENTS

Page

1.0 - Introduction...................................................................................... 1

1.1 - Description...................................................................................... 1

1.2 - Order Code..................................................................................... 2

1.3 - Technical Specifications.................................................................. 3

2.0 - Installation........................................................................................ 6

2.1 - Mechanical Installation.................................................................... 6

2.2 - Electrical Installation........................................................................ 6

2.3 - Process Input Signal Connection..................................................... 7

2.3.1 - Thermocouple Input.................................................................. 7

2.3.2 - RTD Input.................................................................................. 9

2.3.3 - Milliampere Input....................................................................... 10

2.3.4 - Volt Input................................................................................... 11

2.3.5 - Connection for Indicators with different input types................... 12

2.4 - Alarm output connection.................................................................. 13

2.5 - Connection diagrams....................................................................... 14

2.5.1 - Indicators with 12 thermocouples, current or voltage inputs

and their combinations......................................................................

14

2.5.2 - Indicators with 8 RTD inputs...................................................... 15

2.5.3 - Indicators with 6 thermocouples, current or voltage inputs

and 4 RTD inputs..............................................................................

16

2.6 - Communication............................................................................... 17

2.7 - Engineering units............................................................................. 17

3.0 - Operation.......................................................................................... 18

3.1 - Normal Operation............................................................................ 18

3.2 - Configuration................................................................................... 18

4.0 - Maintenance..................................................................................... 31

4.1 - Indicator Hardware.......................................................................... 31

4.2 - Snubber use for relays.................................................................... 32

4.3 - Optional module connection............................................................ 33

4.4 - Calibration....................................................................................... 34

4.5 - Hardware maintenance instructions................................................. 38

4.6 - List of components.......................................................................... 40

4.7 - List of recommended spare components......................................... 43

presys

Presys Instruments DMY - 2015

Introduction

Página 1

1.0 - Introduction

1.1 - Description

PRESYS Digital Multi-Point Indicator DMY-2015 is a microprocessor-based

instrument with up to 12 inputs for monitoring process variables found in industrial

plants, such as, flow, level etc., and totalization of voltage and current linear inputs. It

has non-volatile internal memory (E2PROM) to store calibration values. Its accuracy

is warranted by autocalibration techniques based on a high thermal stability voltage

reference.

It can communicate with computers by means of an optional communication

module RS-232 or RS-422/485.

The Indicator presents specific models with 12 thermocouples or 8 RTD inputs

for the monitoring of temperature, and 12 current (mA) or 12 voltage (V) linear signal

inputs. There are also available models with two different types of input.

Thermocouples and RTD inputs are linearized automatically by tables stored in the

EPROM memory.

The totalization is performed independently for each channel of up to 8 linear

inputs (mA current and V voltage), configured together with the number of decimals.

The totalization counts do not decrease for signals under the zero scale defined by

the user, and Reset can be applied to the totalization by means of the Indicator front-

panel keys.

All configuration data can be protected by password and are stored in non-

volatile memory in case of an external power failure.

According to modularity design concept, the Indicator accepts up to two output

alarm modules. The types of output are: SPDT relay and open collector voltage.

.

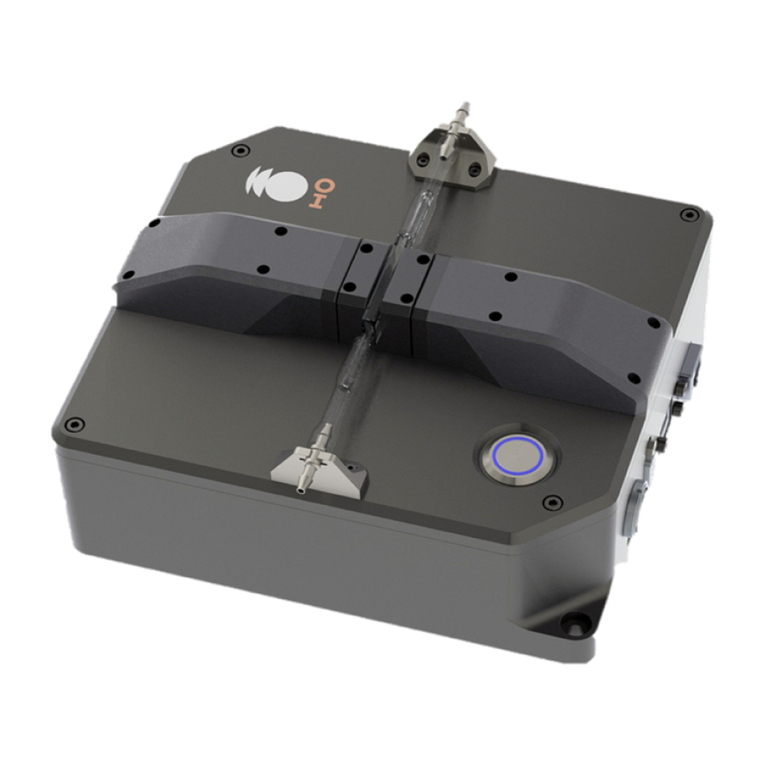

Fig. 1 - DMY - 2015 Indicator front panel

presys

Presys Instruments DMY - 2015

Introduction

Página 2

It accepts 90 to 240VAC or 130 to 340VDC (with any polarity) power supply.

The equipment has an extruded aluminum case which avoids electrical noise,

electromagnetic interference, radiofrequency interference, etc. and its robust

construction makes it tough enough for the most hostile environment.

The front panel has a high visibility display configurable up to 4 digits which

can show the process variable of each channel or a set of selected channels in the

scan mode. During configuration, the display shows mnemonics and parameter

values. The Indicator also presents another two-digit display for identification of the

channel viewed. The leds can be used as a visual indication of alarm for each

channel. The alarm outputs can be configured, independently, to operate with

retention, demanding the operator acknowledge by means of the front panel keys in

order to deactivate them after the process variable returns to normal condition.

1.2 - Order Code

DMY - 2015 - ___ - ___ - ___ - ___ - ___ - ___

A B C D E F

Field A Inputs

0 12 thermocouple inputs

1 8 RTD inputs

2 6 thermocouple and 4 RTD inputs

3 12 current (mA) inputs

4 12 voltage (V) inputs

5 6 thermocouple and 6 current (mA) inputs

6 6 thermocouple and 6 voltage (V) inputs

7 6 current (mA) and 6 voltage (V) inputs

8 6 current (mA) and 4 RTD inputs

9 6 voltage (V) and 4 RTD inputs

Field B Output 1

0 Not used

1 SPDT relay

2 Open collector voltage

Field C Output 2

Same code of output 1

Field D Power Supply

1 90 to 240VCA or 130 to 340VDC (any polarity)

2 24VDC

3 12VDC

presys

Presys Instruments DMY - 2015

Introduction

Página 3

Field E Communication

0 Not used

1 RS-232

2 RS-485

3 RS-422

Field F Case Protection Grade

0 General usage, protected place

1 Front aspersion-proof

2 Weather-proof

Note 1 - The indication, relay usage as alarms and alarm points are, among

other things, items that the user can program through a front key (if wanted, specify

these information so that all the configuration can be made by PRESYS).

Note 2 - Hardware and software features are available under previous consult.

Code Example:

1) DMY - 2015 - 0 - 1 - 1 - 1 - 0 - 0

This code defines a DMY - 2015 Indicator for 12 thermocouple inputs with two

SPDT relays which can be used as high and low alarm, 90 to 240VAC or 130 to

340VDC electric power supply, protected field usage.

1.3 - Technical Specifications

Inputs:

Inputs for thermocouple (J, K, T, E, R, S, under ITS - 90).

Inputs for Pt - 100 RTD under DIN 43760.

Inputs for 4 to 20mA. 250input impedance.

Inputs for 1 to 5VDC. Input impedance above 10M.

Table 1 shows the temperature ranges for thermocouples and RTD

and the resolution for linear input sensors.

presys

Presys Instruments DMY - 2015

Introduction

Página 4

Input sensor Measuring Range limits

Thermocouple lower

limit

F

higher

limit

F

lower

limit

C

higher

limit

C

Type J -184.0 1886.0 -120.0 1030.0

Type K -346 2498 -210 1370

Type T -418 752 -250 400

Type E -148.0 1436.0 -100.0 780.0

Type R -58 3200 -50 1760

Type S -58 3200 -50 1760

RTD

Pt-100 2 or 3 wires

-346.0

1256.0

-210.0

680.0*

Linear

Range

Resolution

Voltage 0 to 5V

250V

Current 0 to 20mA

1A

(*) includes wire resistance

Table 1 - Measuring ranges for input sensors

Outputs:

SPDT relays for alarm rated 3A 220VCA, or up to 10A 220VCA under

order, In this case alarm module is not plugged through a connector,

but connected to a base board. It is possible to use up to 2 alarm

modules.

Logic signal, open collector transistor, 24VDC, 40mA max. with

isolation.

Serial Communication:

RS-232 or RS-422/485, with 50VDC isolation, as an optional module

for connection in CPU board.

Indication:

Standard indication in -999 to 9999 range.

Totalization:

Totalization of up to 8 channels for linear inputs (mA current and V

voltage) in 0 to 9999 range, configured with decimal point.

Configuration:

By front panel push-buttons.

presys

Presys Instruments DMY - 2015

Introduction

Página 5

Sampling rate:

480ms sampling rate, for indication of inputs in -999 to 9999 range.

The display is updated each second.

Accuracy:

0.1 % of full scale for TC, RTD, mA, VDC input.

Linearization:

0.1 C for RTD and 0.2 C for TC.

Square root extraction:

0.5 % of reading, for input above 10 % of span.

Programmable "Cut - off" from 0 to 5 %.

Cold junction compensation:

2.0 C at range from 0 to 50 °C ambient temperature.

Thermal stability:

0.005 % / C of span with reference to 25 C ambient temperature.

Power supply:

Universal 90 to 240 VAC or 130 to 340VDC (any polarity), 10W

nominal; 24 VDC, 12 VDC and other values are optional.

Operating ambient:

0 to 50 °C temperature and 90 % maximum relative humidity.

Dimensions:

1/4 DIN (96 X 96 mm) with 162 mm depth, panel cut of 92 X 92 mm.

Weight:

0.7 kg approx.

Warranty:

One-year warranty.

presys

Presys Instruments DMY - 2015

Installation

Página 6

2.0 - Installation

2.1 - Mechanical Installation

DMY-2015 Indicator front panel has 1/4 DIN size (96 X 96 mm).

It is fixed by the rails which press it against the back side of the panel.

After preparing a 92 X 92 mm cut in the panel, remove the rails from the

Indicator and slide its rear through the cut until its front reaches the panel. Place the

rails again in the Indicator from the back of the panel and tighten the screws as

shown in figure 2.

Fig. 2 - Dimensional drawing, panel cutout and side view

2.2 - Electrical Installation

DMY-2015 Indicator may be powered by voltage between 90 and 240VAC or

130 to 340VDC, any polarity. Remember that the internal circuit is powered

whenever the instrument is connected to the external power supply.

Input and output signals must be connected to the instrument only when it is

turned off.

Figure 3 shows the instrument rear terminals for connection of power supply,

ground, communication, process input and output signals.

Signal wiring must be kept far away from power wires.

Due to its metal case the instrument ground should be connected to earth

ground. Never connect the ground to neutral terminal.

presys

Presys Instruments DMY - 2015

Installation

Página 7

Fig. 3 - Indicator terminals

2.3 - Process Input Signal Connections

The Indicator presents specific inputs for connection of thermocouples, RTD,

current (mA) or voltage (V). See the different types and ranges of input sensors in

table 1, section 1.3 on Technical Specifications.

The connections explained below refer to the different types of input

which exist in the several models of the DMY-2015 Indicator. Make only the

connections allowed by the specific inputs in your instrument.

In order to avoid noise in the wiring, use twisted pair cable and cross sensor

connection wire inside a metallic tube or use shielded cable. Make sure to connect

only one shield wire end either to board terminal or to sensor ground, as shown in the

next items.

WARNING: GROUNDING TWO SHIELD WIRE ENDS MAY CAUSE NOISE IN THE

INDICATOR.

2.3.1 - Thermocouple Input

When using only one thermocouple, connect it to input 1, in order to get a

better precision in the temperature measurement, since the cold junction sensor is

placed near input 1.

In order to reduce the error due to cold junction compensation, use thermal

paste in the rear, at the terminals where the thermocouple is connected to the cold

junction sensor.

presys

Presys Instruments DMY - 2015

Installation

Página 8

Connect the thermocouples to the terminals shown below in table 2 for each

channel:

Channel Terminals

1 1(+) and 2(-)

2 3(+) and 4(-)

3 5(+) and 6(-)

4 7(+) and 8(-)

5 9(+) and 10(-)

6 11(+) and 12(-)

7 13(+) and 14(-)

8 15(+) and 16(-)

9 17(+) and 18(-)

10 19(+) and 20(-)

11 21(+) and 22(-)

12 23(+) and 24(-)

Table 2 - Thermocouple input terminals

Use appropriate compensating cables with the same material of the

thermocouple in order to connect it to the instrument. Check if the thermocouple

polarity is equal to those of the terminals.

Fig. 4 - Thermocouple connection

presys

Presys Instruments DMY - 2015

Installation

Página 9

2.3.2 - RTD Input

Connection is allowed for 2, 3 or 4 wires RTD. All types of connection are

shown in figure 5, and the connection terminals for RTD are described in table 3

below for each channel.

Channel Terminals 3rd wire Terminal

1 1 and 3 2

2 4 and 6 5

3 7 and 9 8

4 10 and 12 11

5 13 and 15 14

6 16 and 18 17

7 19 and 21 20

8 22 and 24 23

Table 3 - RTD input terminals

Fig. 5 - RTD connection

presys

Presys Instruments DMY - 2015

Installation

Página 10

An RTD input device may be a 2-wire, 3-wire or 4-wire RTD.

A 2-wire RTD is connected, for example, to terminals 1 and 3 when using input

1 as shown in Figure 5.

A 3-wire RTD is connected in the same way as explained for a 2-wire RTD,

adding the connection of the compensation wire to terminal 2 for input 1.

Connect a 4-wire RTD as indicated for a 3-wire RTD and keep its forth wire

disconnected. See figure 5.

With a 3-wire RTD one gets a better precision than with a 2-wire RTD.

Use wires of same material, gauge and length on all 3 terminals of each

channel for compensating resistance. The maximum resistance of each connection

wire must be 10 . Use 18 AWG wire (minimum) for distances up to 50 m and 16

AWG for distances greater than 50 m.

2.3.3 - Milliampere Input

Apply 4 to 20mA current signal to the terminals listed below in table 4 for each

channel:

Channel Terminals

1 1(+) and 2(-)

2 3(+) and 4(-)

3 5(+) and 6(-)

4 7(+) and 8(-)

5 9(+) and 10(-)

6 11(+) and 12(-)

7 13(+) and 14(-)

8 15(+) and 16(-)

9 17(+) and 18(-)

10 19(+) and 20(-)

11 21(+) and 22(-)

12 23(+) and 24(-)

Table 4 - Current input terminals

presys

Presys Instruments DMY - 2015

Installation

Página 11

Figure 6 below shows the connections of current sources.

Fig. 6 - Current source connection

2.3.4 - Volt Input

Apply 1 to 5V voltage signal to the terminals listed in table 5 below for each

channel:

Channel Terminals

1 1(+) and 2(-)

2 3(+) and 4(-)

3 5(+) and 6(-)

4 7(+) and 8(-)

5 9(+) and 10(-)

6 11(+) and 12(-)

7 13(+) and 14(-)

8 15(+) and 16(-)

9 17(+) and 18(-)

10 19(+) and 20(-)

11 21(+) and 22(-)

12 23(+) and 24(-)

Table 5 - Voltage input terminals

presys

Presys Instruments DMY - 2015

Installation

Página 12

Figure 7 below shows the connections of voltage sources.

Fig. 7 - Voltage source connection

2.3.5 - Connection for Indicators with different input types

The available models for DMY-2015 Indicator with different types of input are

listed below together with the corresponding terminals and channels for each input.

The connections of the sources or temperature sensors are made according to the

instructions described on sections 2.3.1 to 2.3.4.

Indicator Input Terminals

Type

TC / RTD TC 1 and 2 (CH1), 3 and 4 (CH2), 5 and 6 (CH3),

7 and 8 (CH4), 9 and10 (CH5), 11 and 12 (CH6)

RTD 13 to 15 (CH7), 16 to 18 (CH8),

19 to 21 (CH9), 22 to 24 (CH10)

TC / mA TC 1 and 2 (CH1), 3 and 4 (CH2), 5 and 6 (CH3),

7 and 8 (CH4), 9 and10 (CH5), 11 and 12 (CH6)

mA 13 and 14 (CH7), 15 and 16 (CH8), 17 and 18 (CH9),

19 and 20 (CH10), 21 and 22 (CH11), 23 and 24 (CH12)

TC / V TC 1 and 2 (CH1), 3 and 4 (CH2), 5 and 6 (CH3),

7 and 8 (CH4), 9 and 10 (CH5), 11 and 12 (CH6)

mA 13 and 14 (CH7), 15 and 16 (CH8), 17 and 18 (CH9),

19 and 20 (CH10), 21 and 22 (CH11), 23 and 24 (CH12)

Table 6 - Terminals for Indicators with different input types

presys

Presys Instruments DMY - 2015

Installation

Página 13

Indicator Input Terminals

Type

mA / V mA 1 and 2 (CH1), 3 and 4 (CH2), 5 and 6 (CH3),

7 and 8 (CH4), 9 and10 (CH5), 11 and 12(CH6)

V 13 and 14 (CH7), 15 and 16 (CH8), 17 and 18 (CH9),

19 and 20 (CH10), 21 and 22 (CH11), 23 and 24 (CH12)

mA / RTD mA 1 and 2 (CH1), 3 and 4 (CH2), 5 and 6 (CH3),

7 and 8 (CH4), 9 and10 (CH5), 11 and 12 (CH6)

RTD 13 to 15 (CH7), 16 to 18 (CH8),

19 to 21 (CH9), 22 to 24 (CH10)

V / RTD V 1 and 2 (CH1), 3 and 4 (CH2), 5 and 6 (CH3),

7 and 8 (CH4), 9 and10 (CH5), 11 and 12 (CH6)

RTD 13 to 15 (CH7), 16 to 18 (CH8),

19 to 21 (CH9), 22 to 24 (CH10)

Table 7 - Terminals for Indicators with different input types

2.4 - Alarm Output Connection

The Indicator presents up to two alarm outputs obtained through the

installation of modules with SPDT relay or open collector voltage. Figure 8 illustrates

the Indicator outputs.

See sections 3.2 on Configuration and 4.3 on Optional module

Connection for details on configuration and installation of optional modules.

(*) Relay contact states shown are valid for SAFE option selected (see section 3.2 on Configuration), instrument

powered on and non-alarm condition. Position of the contacts are changed in alarm condition (with SAFE option

selected) or when the instrument is turned off.

Fig. 8 - Alarm output connection

presys

Presys Instruments DMY - 2015

Installation

Página 14

2.5 - Connection Diagrams

2.5.1 - Indicators with 12 thermocouples, current or voltage inputs and their

combinations

presys

Presys Instruments DMY - 2015

Installation

Página 15

2.5.2 - Indicators with 8 RTD inputs

presys

Presys Instruments DMY - 2015

Installation

Página 16

2.5.3 - Indicators with 6 thermocouples, current or voltage inputs and 4 RTD inputs

presys

Presys Instruments DMY - 2015

Installation

Página 17

2.6 - Communication

DMY-2015 Indicator communicates with computers through RS-232 or RS-

422/485 and with use of a MODBUS protocol communication software, when the

optional communication modules are installed and the communication parameters

are configured.

Specific information on communication and signal connection are described in

the communication manual.

2.7 - Engineering units

A label with several Engineering Units is supplied with each Indicator. Select

the one corresponding to the variable shown on the display and stick it to the front

panel of the Indicator.

presys

Table of contents

Other Presys Measuring Instrument manuals

Presys

Presys TA-25NL User manual

Presys

Presys DMY-2030-CC User manual

Presys

Presys TA-60NL User manual

Presys

Presys PROFI BUS DMY-2015-PB User manual

Presys

Presys TE-25N User manual

Presys

Presys DCY-2058 User manual

Presys

Presys DMY-2030 Light User manual

Presys

Presys DMY-2011 User manual

Presys

Presys DMY-2030-F User manual

Presys

Presys DMY-2030 Light User manual

Popular Measuring Instrument manuals by other brands

ADInstruments

ADInstruments AD2821A Operation manual

Hanna Instruments

Hanna Instruments HI 9142 instruction manual

Silex technology

Silex technology WM-100 How to use

David White

David White L6-20 owner's guide

COM-power corporation

COM-power corporation LI-220C instruction manual

Savant

Savant 6710M-32 quick start guide