Prime Controls DS1510 User manual

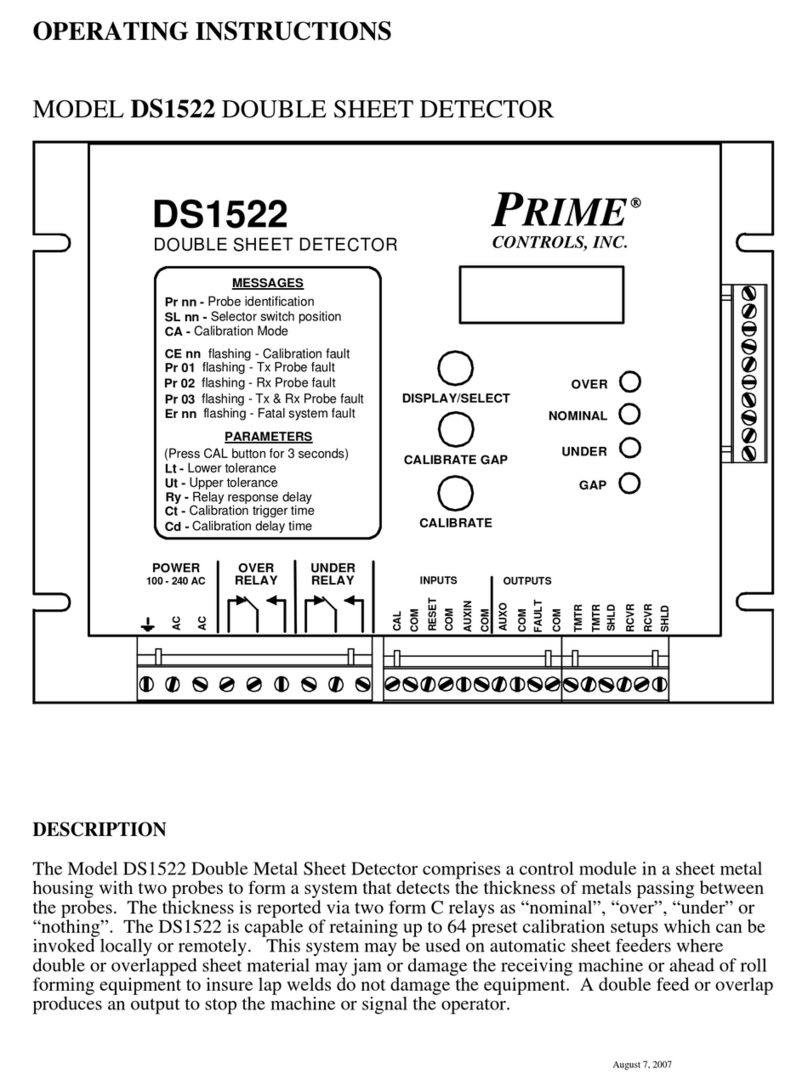

OPERATING INSTRUCTIONS

MODEL DS1510 DOUBLE SHEET DETECTOR

DESCRIPTION

The Model DS1510 Double Metal Sheet Detector comprises a control module in a sheet metal

housing with two probes to form a system that detects the thickness of metals passing between

the probes. The thickness is reported via two form C relays as “nominal”, “over”, “under” or

“nothing”. This system may be used on automatic sheet feeders where double or overlapped

sheet material may jam or damage the receiving machine or ahead of roll forming equipment to

insure lap welds do not damage the equipment. A double feed or overlap produces an output to

stop the machine or signal the operator.

October 3, 2019

CONTROL I/O PROBES

SIGNAL/MESSAGE

MESSAGES

Pr 01 flashing -

Transmitter Probe Fault

Receiver Probe Fault

Pr 02 flashing -

Pr 03 flashing -

Both Probes Faulting

CA - Calibration Mode

CA nn flashing -

Calibration Fault

Er nn flashing -

Fatal System Fault

DS1510

DOUBLE SHEET DETECTOR

NOMINAL

UNDER

OVER

GAP

AC

AC

POWER OVER UNDER

RELAY RELAY

CAL

COM

RCVR

RCVR

SHLD

SHLD

TMTR

TMTR

RESET

COM

AUXIN

COM

AUXO

COM

FAULT

COM

100 - 240 AC OUTPUTS

INPUTS

CALIBRATE

PRIME

CONTROLS, INC.

DESCRIPTION

2

System Features

The DS1510 is a highly flexible gauging system with a variety of features, some of which may be

enabled or disabled through the positioning of DIP switches located beneath the control module

cover. The various features include:

•Accommodates a family of probes allowing double detection on metals, from foil to heavy

plate.

•Manual calibration on single and double thickness for all metals.

•Manual calibration on single thickness for steel.

•Automatic calibration on steel after material absence for a preset trigger time.

•Automatic nominal adjustment for roll stock of varying thickness.

Each of these features is described in greater detail later in this document.

Control Module

The features of the control module include:

•Universal power input accommodates AC voltages from 100 to 240 volts.

•Removable terminal blocks for quick change-out of the control module.

•Separate form C relay outputs for independent reporting of OVER and UNDER conditions.

•LED indicators report the current gage states of NOTHING, UNDER, NOMINAL, and

OVER.

•Automatic setup of system gain and operating parameters.

•External or front panel calibration through a contact closure or the front panel push-button

switch.

•Two calibration memories that are selected through the AUXIN terminal. The memory

contents are retained when power is removed from the unit.

•Latching OVER and UNDER outputs that are cleared by asserting the RESET input.

•A fast, open collector logic output that is ON for nominal readings and OFF for OVER or

UNDER.

•An open collector FAULT output that may be connected to a master controller for monitoring

fault and gauge-not-active conditions.

•Probe fault reporting on the two digit display warns of broken or disconnected probes or

cables.

DESCRIPTION

3

Control Module Indicators

The function of the indicators and display on the DS1510 control module are described in the

following paragraphs:

1. OVER LED is ON whenever the material thickness exceeds the calibrated nominal value by

more than the set tolerance.

2. NOMINAL LED is ON whenever the received signal is within the specified tolerances,

both over and under.

3. UNDER LED is ON whenever there is material between the probes but the material thinner

than the calibrated nominal value by more than the set tolerance.

4. NOTHING LED is ON whenever the received signal goes beyond the measuring range of

the instrument indicating an absence of material between the probes.

5. The OVER, NOMINAL, UNDER, and NOTHING LEDs flash in succession when the

system is in calibrate mode.

6. Numeric Display indicates the level of the signal from the receiving probe and reports error

or status conditions. During gauge operation the value on the display reflects the strength of

the signal from the receiving probe. Thicker materials reduce the level of the signal

reaching the receiving probe, consequently the displayed value is lower for thicker material

and higher for thinner material.

Control Module Calibrate Push Button

The push-button switch on the front panel of the control module serves to initiate the

calibration process and to make adjustments to two numeric parameters, the automatic

calibration trigger time (Ct), and the calibration delay time (Cd). The trigger time is adjustable

from 0.1 minutes (6 seconds) to 25 minutes. The calibration delay is adjustable from 0 seconds

to 9.9 seconds. The calibration delay is not available in units with firmware version numbers

smaller than 3.9.

To initiate calibration, simply press the push button and release it within 3 seconds.

To view the current value of a parameter, press the push button and hold it for more than 3

seconds until the appropriate parameter identifier appears on the digital display. After the

parameter identifier appears, release the push button and the current value of the parameter

displays for 5 seconds. To retain the current value of the parameter, simply allow the 5 second

display interval to elapse. The display reverts back to displaying signal strength.

To change the value of a parameter, press the push button and hold it for more than 3 seconds

until the appropriate parameter identifier appears on the digital display. After the parameter

identifier appears, release the push button and the current value of the parameter displays.

Press the push button while the parameter is displaying and the value increments, first slowly

then more rapidly. For more precise control of the value adjustment, simply tap the push button

repeatedly until the desired value is displayed. All parameters roll back to their minimum

values after reaching the maximum value. To retain the adjusted value of the parameter, simply

allow the 5 second display interval to elapse. The display reverts back to displaying signal

strength.

DESCRIPTION

4

Control Module Configuration Switches

An eight position DIP switch is located beneath the front cover on the main control circuit

board to the left of the displays These switches must be set to enable the features of the system

that are appropriate to your application. Any time a switch setting is changed, the control

module must be powered down and back up to install the change. The switches are read only at

power up.

The functions of the switches are as follows:

Switches 1 & 2 Set the relay response time

SW 1 SW 2 Effect

OFF OFF Minimum delay

ON OFF 100 millisecond delay

OFF ON 500 millisecond delay

ON ON 1 second delay

Switch 3: OFF Calibrate on single and double.

ON Calibrate on single only.

Switch 4: OFF Disable reference tracking.

ON Enable reference tracking.

Switch 5: OFF Probe and gap assessment occurs every time the system is powered up.

ON Probe and gap assessment is bypassed at power-up if the AUXIN input is

high. If AUXIN is held low (connected to COM), probe and gap

assessment occurs at power-up.

Switch 6: OFF Disable automatic calibration trigger.

ON Enable automatic calibration trigger.

Switch 7: OFF AUXO is ON for OVER and for UNDER, otherwise OFF

ON AUXO is ON for OVER, NOM, UNDER, OFF for NOTHING

This option not available for Versions 4.5 or lower.

Switch 8: OFF: The state of the relays for NOTHING in the gap is the same as for the

NOMINAL state.

ON: The state of the relays for NOTHING in the gap, is OVER for the OVER

relay and UNDER for the under relay.

Control Module Polarity Jumpers

Each of the logic inputs (CAL, RESET, and AUXIN) to the DS1510 has associated with it a

two position jumper plug located under the front cover and immediately behind its associated

connector. These jumpers allow the inputs to be driven by a sinking or sourcing device. When

the jumper plug is installed on the pins closest to the connector, the input is set up for a

sourcing driver. When installed on the two pins farthest from the connector, the input is set up

for a sinking driver, or dry contact between the input and COM.

Whether set for sinking or sourcing drivers, the input is active (ON) when the signal at the

terminal is low (at COM).

APPLICATION CONSIDERATIONS

5

APPLICATION CONSIDERATIONS

Choice of Probes

The DS1510 accommodates a number of Prime probes but is most often used with the P1000B,

P70A, and P70CS probes. The P70A and P1000B probes are potted and completely sealed

units with permanently attached cables. The P70CS probes are potted with connectors for easy

removal. The same probe type is used for transmitter and receiver and is not polarized.

The table below provides rule of thumb information for probe selection.

Probe Housing Connection Gap Application

P1000B Aluminum block Cable 0.5” to 1.25” 0.060 and thicker

P70A Threaded steel barrel Cable 0.5” to 0.75” 0.004 to 0.060 steel

P70CS Smooth stainless barrel Connector 0.5” to 3.00” 0.004 to 0.060 steel

Probes with non-ferrous (aluminum and stainless steel) housings offer greater probe separation.

Probes with steel housings are not affected by the material used for mounting. Probes with

aluminum or stainless steel housings are affected by steel near them including mounting clamps.

To realize maximum separation with the P70CS type units, the probes must be mounted in non-

ferrous clamps, e.g. Nylatron or 303 stainless steel.

Prime offers a number of other probes that allow the DS1510 to be applied to a wide range of

materials including magnesium, copper, stainless steel, and aluminum. For more information or

assistance in selecting the appropriate probes, contact Prime Controls.

Calibration Considerations

The DS1510 offers three different modes of calibration.

1. Manual calibration on single and double thickness material (two-hit calibration). In this

mode, a sample of the nominal thickness is placed between the probes and the CAL push

button or optional external cal switch is pressed. Then a second thickness (or multiples of the

original) are placed between the probes and the CAL push button or external cal switch is

again pressed. Calibration is complete.

2. Manual calibration on single thickness steel (single-hit calibration). In this mode, calibration

can be initiated through a press of the CAL push button or an optional external cal switch

prior to material entering the gap between the probes. The DS1510 enters a wait state until

such time as material is fed between the probes. If the calibration delay parameter (Cd) is set

to zero, calibration occurs within 100 milliseconds after material is sensed between the

probes. For slow moving material, this delay can be increased (up to 9.9 seconds) to insure

the material fully covers the probes before calibration occurs. See the Control Module

Calibrate Pushbutton section earlier in this document for the parameter adjustment

procedure.

APPLICATION CONSIDERATIONS

6

3. Automatic calibration on single thickness steel. In this mode, calibration process is the same

as for the manual single-hit calibration except that the calibration process can be initiated by

the expiration of a timer within the DS1510. The timer (Ct) can be set to a value from 0.1

minute (6 seconds) to 25 minutes. When the DS1510 detects the absence of material between

the probes, the timer count-down begins. If the count-down expires before material is sensed,

the DS1510 enters calibration mode, waiting for material to be fed. If the calibration delay

parameter (Cd) is set to zero, calibration occurs within 100 milliseconds after material is

sensed between the probes. For slow moving material, this delay can be increased (up to 9.9

seconds) to insure the material fully covers the probes before calibration occurs. See the

Control Module Calibrate Pushbutton section earlier in this document for the parameter

adjustment procedure.

NOTE

The adjustable calibration delay parameter (Cd) is only available in systems with firmware

version 3.9 or higher. Older systems can be upgraded at the factory for a nominal fee. See

Firmware Version section later in this document for determining the firmware version of your

system.

The choice of calibration mode is application dependent since each mode has its advantages and

disadvantages. Two-hit calibration offers the possibility of discriminating changes in metal

thickness that are far less than 2 to 1 since the system is calibrated on samples of the thickness

range to be discriminated.

Relay Response Time

For most applications it is desirable that the OVER relay respond as quickly as possible. For

thinner materials the response time is as fast as 3 milliseconds. For very thick metals the

response time can be as long as 40 milliseconds.

If very fast response times are undesirable, the action of the relays can be delayed through the

setting of DIP switches 1 and 2 as described under “Control Module Configuration Switches”

earlier in this document.

Tracking Nominal

The tracking nominal feature of the DS1510 (Switch 4 ON) is typically used on roll-fed material

that varies in thickness over its length. The unit keeps a slow average of the thickness and

gauges relative to the average rather than relative to a fixed nominal calibration value. The

average is referred to as the tracking nominal. The tracking nominal is allowed to shift by as

much as 50% in thickness in either direction from the calibrated nominal.

Whenever no material is sensed between the probes, the calibrated nominal is reinstated

regardless of the final thickness of the previous material.

APPLICATION CONSIDERATIONS

7

Gauge and Fault Monitoring

The open collector FAULT output provides a means for monitoring the status of the DS1510

to insure that all material passing between the probes is checked for doubles. When the DS1510

controller detects a fault from a probe or from within the controller itself, the FAULT output

turns OFF. Since the OFF state is the fault state, a loss of power at the DS1510 is, by default,

reported as a fault.

With firmware Version 3.6 and later, the FAULT output also turns off whenever the controller is

not in gauge mode, i.e. whenever the unit is in setup (SU) or calibration (CA) mode.

INSTALLATION AND SETUP

8

INSTALLATION

The installation of the components of the DS1510 system is covered in the following

paragraphs:

DS1510 Control Module

The control board is designed to mount on the back panel of an electrical enclosure using the four

mounting slots at the edges of the enclosure. The footprint is 8.25 inches (210 mm) by 6.25

inches (159 mm) with mounting slot locations on a rectangle 7.625 inches (194 mm) in the

horizontal and 4.0 inches (102 mm) in the vertical. Insure that the mounting screws make good

electrical contact between the module housing and the control enclosure back panel.

Avoid mounting locations with excessive heat and vibration.

Probe Mounting

See instructions specific to the probes supplied with your system.

Electrical Wiring

All wiring for the DS1510 connects to removable terminal blocks at the bottom of the control

enclosure as described in the following paragraphs.

1. Connect 100 to 240 VAC, 50-60 Hz. power (15 watts) to the terminals labeled AC on the

leftmost terminal block.

2. Connections to the control circuit of the machine are made through the OVER and UNDER

form C relays as required. These relays are powered in the NOMINAL condition and the

diagram on the DS1510 front panel reflects the NOMINAL state. As shipped from the

factory, the NOTHING state places the relays in the same state as NOMINAL. DIP switch

8, beneath the cover of the DS1510, when ON, causes the NOTHING condition to place the

OVER and UNDER relays in the over and under states simultaneously.

3. The shielded cables from the probes to the board should be run in conduit. The receiver

probe is connected to terminals labeled RCVR on the rightmost terminal block and the

transmitter probe to the terminals labeled TMTR on the same terminal block. Since the

probes are non-polarized, the order of lead connection is not important and since the probes

are identical, it does not matter which is the transmitter and which is the receiver. Connect

the shield leads (drain wires) from the probe cables to the terminals labeled SHLD.

4. The OVER and UNDER relays may be operated in a "follower" mode or a "memory" mode

depending upon the wiring of the RESET input. The operational modes and required

connections are described below.

a) For "follower" mode, jumper RESET and COM together on the center terminal block. In

this mode, when an OVER or UNDER condition occurs, the appropriate relay drops out,

and the OVER or UNDER LED comes on. After the fault condition is corrected, the relay

returns to the normally energized condition and the LED goes out. Automatic reset is

normally selected to control the operation when the fault condition is automatically

removed or the DS1510 is wired into the stop circuit of the machine.

INSTALLATION AND SETUP

9

b) For "latch" mode, wire the RESET and its associated COM terminal to the normally open

contacts of a switch, relay, or controller output. In this mode, when a fault condition

occurs, the relay drops out and the OVER or UNDER LED comes on. After the fault

condition is corrected, the contact must be momentarily closed to energize the relay.

5. If gap assess bypass is not selected (SW 5 OFF), a switch or contact may be connected

between AUXIN and COM to allow selection of two different calibration memories.

Calibration data is stored in the memory that is selected at the time calibration occurs.

Switching between calibration memories can be done at any time during DS1510 operation.

6. Optionally, the open collector FAULT output may be connected to a master system

controller or to an indicator that warns of error conditions within the DS1510 system. This

output is normally ON and turns OFF when an error condition is detected. Thus if the

DS1510 loses power, the FAULT output reports an error condition by default.

With firmware Version 3.6 and later (see Firmware Version at the end of this document),

the FAULT output turns OFF any time the DS1510 is not gauging the metal between the

probes. In addition to error conditions, setup (SU on the display) and calibration (CA on

the display) cause the fault output to turn OFF. This allows the unit to be monitored for

non-gauge conditions.

INITIAL SETUP

Probe and Gap Assessment

The startup process of the DS1510 commences immediately after power up and includes

several processes which are transparent to the user except for the sequence of characters that

appear on the two digit display.

When the unit first powers up, the several different sequences of characters may appear on the

two digit display depending upon which options are currently active. Typically, if probe gap

assessment is not bypassed, the startup display sequence includes momentary flashing of SU,

followed by momentary flashing of the probe identifier (PR 15, PR70, or PR 1H.), followed by

momentary display of the selected memory identifier, e.g. SL 01. When probe gap assessment is

bypassed (Switch 5 ON) the typical startup sequence includes momentary flashing of SU by,

followed by momentary flashing of the probe identifier, e.g. PR 70. If the probes are faulty,

disconnected, or cannot be identified, the controller flashes PR 01 indefinitely.

After the probes have been identified, the sensing system is characterized and the spacing

between the probes is determined. For this assessment there must be no material between the

probes. Switch 5 ON causes the controller to bypass this assessment unless a contact is closed

across AUXIN. However, it is essential that this process be completed at least once after

initial installation or whenever the physical arrangement of the probes is changed. If

assessment process is bypassed, the system flashes SU by on the two digit display during

startup.

When the operating conditions have been established, the two digit readout displays a numeric

value representing the receiver signal strength.

CALIBRATION

10

CALIBRATION

The DS1510 offers three modes of calibration: 1) manual calibration on single and double

material samples, 2) manual calibration on a single thickness material sample, and 3) automatic

calibration on material coming between the probes after a period of not material between the

probes.

Calibration on Single and Double Thickness

For highest gauging precision, the double sheet detector must be calibrated on both a single and

a double thickness of the material to be monitored, any time prior to running. This mode of

calibration is selected when Switch 3 is OFF. Calibration values are retained even when power

is removed from the DS1510. Depending upon selected options, the system can retain one or

two different calibration settings in non-volatile memory.

1. Place a single sheet of the thickness to be gauged in the probe gap and press the CAL push

button or close a contact across the external CAL input. If the calibration on single is

accepted, the unit displays alternately "CA" and "2" indicating readiness to calibrate on a

double thickness. If the calibration is not successful, the unit displays alternately "CE" and

a number. Calibration may be attempted again immediately.

2. Place a double thickness of material to be gauged in the probe gap and press the CAL push

button or close a contact across the external CAL input. If the calibration is successful, the

unit resumes display of the signal strength. If the calibration is not successful, the unit

displays alternately "CE" and a number. If this occurs, reinsert the single thickness and

begin calibration again.

Manual Calibration on Single Thickness

Manual calibration on single thickness is selected when Switch 3 is ON and Switch 6 is OFF. If

you change the switch settings, be sure to power the unit down and back up to activate the new

settings. The switches are read only at power-up.

When calibrate on single is selected, the calibration process may be triggered in two ways: by

the press of the front panel push button, or by a 30 millisecond or longer contact closure between

the external CAL input and COM.

Place a single sheet of the material to be gauged in the probe gap and press the CAL push

button or close a contact across the external CAL input. If the calibration on single is accepted,

the unit displays alternately "Fr" and a number indicating the frequency selected for operation.

The displayed number has no meaning except for factory troubleshooting.

If the control senses no material between the probes when the CAL push button is pressed or

the external CAL input is activated, it enters a wait state, flashing “CA” on the display until

material is brought between the probes. An additional calibration delay can optionally be

introduced through the calibration delay parameter (Cd). If not zero, this delay holds off the

calibration process for the specified delay time after material comes between the probes to

insure the material fully covers the probes during calibration. The additional delay may be

required with slow-moving material. See the Calibration Delay Time section later in this

document for the parameter adjustment procedure.

CALIBRATION

11

Gauging commences immediately after calibration but only if the push button is released and

the contact across CAL and COM is released. If either of the calibration initiating signals

persists, the unit hangs in a wait state.

Automatic Calibration on Single Thickness

Two switches must be properly set to enable automatic calibration. The system must be enabled

for calibrate on single (Switch 3 ON) and automatic calibration must be enabled (Switch 6 ON).

These switches must be set prior to powering the unit since they are read only at power-up.

Automatic calibration provides a time-based trigger that starts the calibration process. Whenever

there is no material between the sensing probes for a time equal to or greater than the stored

trigger interval (see Auto-cal Trigger Time later in this document), the DS1510 enters a wait

state in preparation for calibration when material comes between the probes. The display flashes

alternately “CA” and blank and the LEDs flash sequentially. The wait for material can be

indefinite.

When material enters the gap between the probes, if the calibration delay parameter (Cd) is set to

zero, calibration occurs within 100 milliseconds. For slow moving material, this delay can be

increased (up to 9.9 seconds) to insure the material fully covers the probes before calibration

occurs. With no programmed delay, typical calibration time is 300 milliseconds, total. See the

Calibration Delay Time section later in this document for the parameter adjustment procedure.

NOTE

The adjustable calibration delay parameter (Cd) is only available in systems with firmware

version 3.9 or higher. Older systems can be upgraded at the factory for a nominal fee. See

Firmware Version section later in this document for determining the firmware version of your

system.

If material comes between the probes before the trigger interval times out, the timer is reset to its

programmed value.

When automatic calibration is enabled, the calibration process may still be initiated by a press of

the CALIBRATE push button or a contact closure between CAL and COM. Actual calibration

will begin only when material is sensed between the probes and the calibration delay has timed

out..

CALIBRATION

12

The Auto-cal Trigger Time

The trigger time interval for automatic calibration can be set by the operator through the

CALIBRATE push button on the front panel of the DS1510 control unit. The interval is set in

increments of 6 seconds (0.1 minutes) from 0 to 3 minutes, in increments of 12 seconds (0.2

minutes) from 3 to 5 minutes, in increments of 30 seconds (0.5 minutes) from 5 to 10 minutes,

and in increments of 1 minute from 10 to 25 minutes. To set the trigger time interval, do the

following:

1. Insure that the unit is not attempting to calibrate (no “CA” flashing on the digital display). If

“CA” is flashing, place a piece of material between the probes and allow the calibration

process to be completed. Calibration and time parameter adjustment are mutually exclusive

processes.

2. Hold the CALIBRATE push button in for approximately 6 seconds or until “Ct” appears on

the digital display. WARNING: If the push button is released before 3 seconds, the DS1510

begins the calibration process.

3. When “Ct” displays, release the push button and the trigger time interval is displayed on the

digital readout. If the push button is not pressed again within 5 seconds, the display reverts

back to displaying gauge signal strength and the current time value is retained.

4. Whenever the time interval is displaying, the push button may be pressed to increment the

time to the desired value. The time value is incremented one resolution unit with every press

and release of the push button. If the push button is held in, the value auto-increments at an

ever increasing rate until the push button is released. The value increments up to a maximum

of 25 minutes and then rolls back to 0.1 minutes.

5. When the time has been adjusted to the desired value, it displays for 5 seconds (assuming the

push button is not pressed again) and then is accepted and saved in non-volatile memory.

The display reverts back to displaying signal strength.

CALIBRATION

13

Calibration Delay Time

The “Cd” parameter specifies the duration of a time delay that applies to single sample

calibration, in both manual and automatic trigger modes. The sequencing is as follows:

1. Calibration is triggered, either manually or through trigger time-out.

2. The system waits indefinitely until metal is detected between the probes.

3. When metal is detected, the calibration delay time-out begins.

4. When the calibration delay has timed out, calibration begins.

5. When calibration is complete, gauging begins.

The calibration delay interval can be set to any value between 0.0 and 9.9 seconds. To set the

calibration delay time, proceed as follows:

1. Insure that the unit is not attempting to calibrate (no “CA” flashing on the digital display). If

“CA” is flashing, place a piece of material between the probes and allow the calibration

process to be completed. Calibration and time parameter adjustment are mutually exclusive

processes.

2. Hold the CALIBRATE push button in for approximately 3 seconds or until “Cd” appears on

the digital display. If auto-cal is enabled, prior to displaying “Cd”, the DS1510 displays

“Ct”. WARNING: If the push button is released before 3 seconds, the DS1510 begins the

calibration process.

3. When “Cd” displays, release the push button and the calibration delay time interval is

displayed in seconds on the digital readout. If the push button is not pressed again within 5

seconds, the display reverts back to displaying gauge signal strength and the current delay

value is retained.

4. Whenever the time interval is displaying, the push button may be pressed to increment the

time to the desired value. The time value is incremented one resolution unit with every press

and release of the push button. If the push button is held in, the value auto-increments at an

ever increasing rate until the push button is released. The value increments up to a maximum

of 9.9 seconds and then rolls back to 0.0 seconds.

5. When the time has been adjusted to the desired value, it displays for 5 seconds (assuming the

push button is not pressed again) and then is accepted and saved in non-volatile memory.

The display reverts back to displaying signal strength.

SPECIFICATIONS

14

SPECIFICATIONS

Power Requirements

AC Power, 90 to 240 volts, 15 watts.

Logic Input Electrical Specifications

CAL, RESET, AUXIN: 30 Volts maximum

Upper switch threshold - 6.9 volts

Lower switch threshold - 3.3 volts

When the internal jumper is installed for pull up to accommodate sinking drivers, the input is

pulled to +15 volts through 4700 ohms. When the jumper is installed for pull down to

accommodate sourcing drivers, the input is pulled to common through 4700 ohms.

Logic Output Electrical Specifications

AUXO, FAULT: NPN open collector, 100mA max., 50 volts max.

Output Relay Specifications

Maximum switched voltage: 380VAC

Maximum switched current: 14 amps N.O., 5 amps N.C, AC resistive,

8 amps DC

Maximum switched power: 200W DC, 2,000VA AC.

Minimum required contact load: 12V, 100 mA

Expected mechanical life: 20 million operations

Expected electrical life: 100,000 operations at 8 amps, 240VAC

50,000 operations at 14 amps N.O., 5 amps N.C.,

120VAC resistive

30,000 operations at 7.2FLA, 45LRA, 120VAC

10,000 operations at 5FLA, 30 LRA, 240VAC

TROUBLESHOOTING

15

TROUBLESHOOTING

Should trouble develop, proceed as follows:

1. If no indicators or displays are illuminated, check AC input power to the control module

and the fuse located on the lower left of the chassis.

2. If the unit powers up but hangs displaying alternately “Pr” and “01”, the transmitter probe

is either not connected, is shorted, or has an open in the wiring.

3. If the unit powers up, initializes and the LEDs indicate a response to the material in the gap

but the relays do not switch, check that the relays are set to follow and not to latch (activate

the RESET input to unlatch). For most installations, simply install jumpers between

RESET and COM.

4. IF “PR” and “01” flash alternately on the display, check the transmitting probe for proper

connection and continuity.

5. IF “PR” and “02” flash alternately on the display, check the receiving probe for proper

connection and continuity.

6. IF “PR” and “03” flash alternately on the display, check both probes for proper connection

and continuity.

7. If the unit flashes alternately “Er” and a numeric value between 1 and 8, perform the

corrective action prescribed in the table below. If the error persists, consult the factory.

“Er” Number Fault Description Correction

01 Input shift register failure Reset through power down

02 Output shift register failure Reset through power down

03 Display shift register failure Reset through power down

04 Control shift register failure Reset through power down

05 System configuration data fault Reset through power down

06 Gap assessment data fault Execute gap assess procedure

07 Not used

08 Processor CONFIG register fault Call the factory

8. During manual calibration on single and double, errors may occur that are reported through

the alternate display of “CE” and a numeric value of 1 or 2. These error codes have the

following meanings:

“CE” Number Interpretation

01 The single thickness material is too thin for the system as

configure with the current probes.

02 The material is too thick for the system as configured with

the current probes.

TROUBLESHOOTING

16

Firmware Version

From time to time, as improvements are made to Prime products, the firmware controlling the

units is revised. When setting a unit up or troubleshooting it may be necessary to determine the

version number for the firmware installed in your unit. The version numbers begin with 1.0 and

are incremented either by tenths (1.1, 1.2, etc.) for small revisions or by the integer digit (1.0, 2.0,

etc.) for more significant revisions.

To determine the version of the firmware running in your unit, simply hold the calibration push

button in as power is applied to the unit. The revision number will be displayed on the two-digit

display alternately with the letters “Fr”. For example, Version 1.8 will flash alternately “Fr” and

“1.8”.

For further information or service assistance, contact Prime Controls, Inc., 4551 Gateway

Circle, Dayton, Ohio. Phone: (937) 435-8659. Mention model number and serial number.

17

CONTROL I/O PROBES

SIGNAL/MESSAGE

MESSAGES

Pr 01 flashing -

Transmitter Probe Fault

Receiver Probe Fault

Pr 02 flashing -

Pr 03 flashing -

Both Probes Faulting

CA - Calibration Mode

CA nn flashing -

Calibration Fault

Er nn flashing -

Fatal System Fault

DS1510

DOUBLE SHEET DETECTOR

NOMINAL

UNDER

OVER

GAP

AC

AC

POWER OVER UNDER

RELAY RELAY

CAL

COM

RCVR

RCVR

SHLD

SHLD

TMTR

TMTR

RESET

COM

AUXIN

COM

AUXO

COM

FAULT

COM

100 - 240 AC OUTPUTS

INPUTS

CALIBRATE

PRIME

CONTROLS, INC.

(1.31)

193.7

(7.625)

209.6

(8.25)

101.6

(4.0)

28.6

(1.125)

33.3

(0.60)

15.2

158.8

(6.25)

18

3. MAINTAIN INDEPENDENT SHIELDS

4. POSITION SHIELD TERMINALS BETWEEN

TRANSMITTER AND RECEIVER SIGNAL

TERMINALS

TRANSMITTER

RECEIVER

TRANSMITTER

RECEIVER

FOR MAXIMUM NOISE IMMUNITY, SPLICE

OR TERMINATE CABLES ONLY WHEN

ABSOLUTELY NECESSARY.

WHERE EXTENSION IS NECESSARY,

USE BELDEN 8761 OR EQUIVALENT

SHIELDED, TWISTED PAIR CABLE.

THE DS1510 IS DESIGNED TO PROVIDE

HIGH COMMON MODE NOISE REJECTION.

COMMON MODE REJECTION IS REALIZED

MOST EFFECTIVELY WITH TWISTED PAIR

CABLING.

TO PROBES

SAFETY GND

AC POWER

CONTROL

INTERLOCK

OPEN FOR DOUBLE

CONTROL

INTERLOCK

OPEN FOR UNDER

OPTIONAL

REMOTE CAL

OPTIONAL

OUTPUT LATCH RESET

JUMPER SOLID IF LATCHING

OUTPUT NOT DESIRED

FAULT SIGNAL

NPN, OPEN COLLECTOR

100 mA MAX., OFF = FAULT

HOOKUP IS OPTIONAL

NPN, OPEN COLLECTOR, 100 mA MAX.

OFF FOR OVER OR UNDER, NO DELAY.

FAST RESPONSE OUTPUT

CONTROL I/O PROBES

SIGNAL/MESSAGE

MESSAGES

Pr 01 flashing -

Transmitter Probe Fault

Receiver Probe Fault

Pr 02 flashing -

Pr 03 flashing -

Both Probes Faulting

CA - Calibration Mode

CA nn flashing -

Calibration Fault

Er nn flashing -

Fatal System Fault

DS1510

DOUBLE SHEET DETECTOR

NOMINAL

UNDER

OVER

GAP

AC

AC

POWER OVER UNDER

RELAY RELAY

CAL

COM

RCVR

RCVR

SHLD

SHLD

TMTR

TMTR

RESET

COM

AUXIN

COM

AUXO

COM

FAULT

COM

100 - 240 AC OUTPUTS

INPUTS

CALIBRATE

PRIME

CONTROLS, INC.

MEMORY SELECT or

GAP ASSESS BYPASS

OPTIONAL

19

LIMITATION AND EXCLUSION OF WARRANTIES

All goods purchased from Prime Controls, Inc. shall be free from defects in materials, design and

workmanship under normal conditions of use for one year from the date of shipment. THIS

WARRANTY IS THE SOLE WARRANTY AND IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR

PURPOSE. THE LIABILITY OF PRIME CONTROLS TO ANY PURCHASER SHALL BE

LIMITED EXCLUSIVELY TO THE COST OF REPLACEMENT OR REPAIR OF

DEFECTIVE PARTS, AND SHALL NOT INCLUDE LIABILITY FOR ANY DIRECT,

CONSEQUENTIAL OR INCIDENTAL DAMAGES WHATSOEVER, WHETHER

FORESEEN OR UNFORESEEN, INCLUDING BUT NOT LIMITED TO LOST PROFITS,

LOST SALES, OR INJURY TO PERSONS OR PROPERTY. 10/03/19

Table of contents

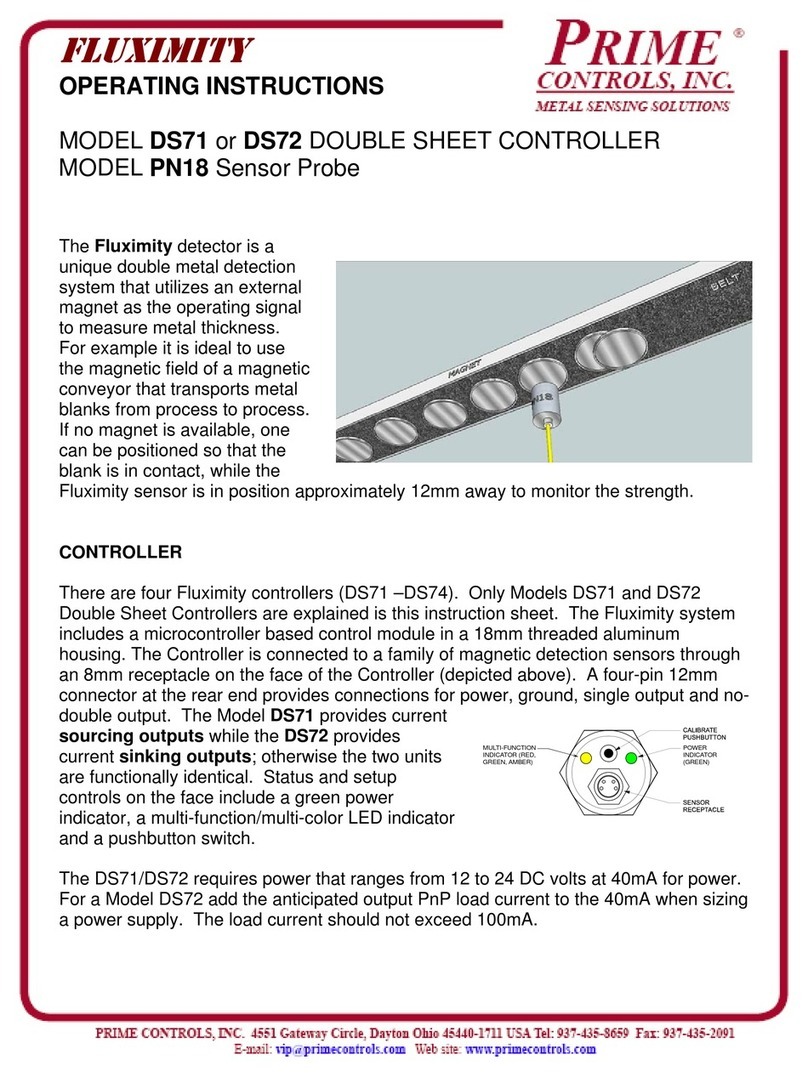

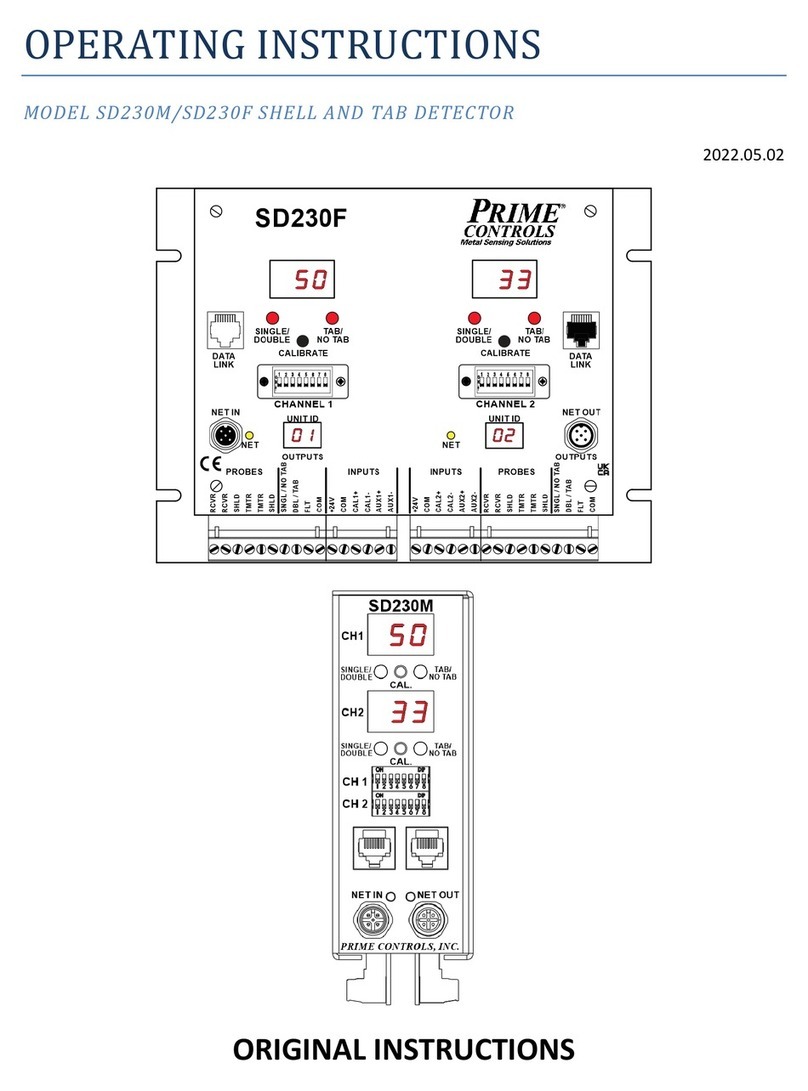

Other Prime Controls Security Sensor manuals

Prime Controls

Prime Controls DS600 User manual

Prime Controls

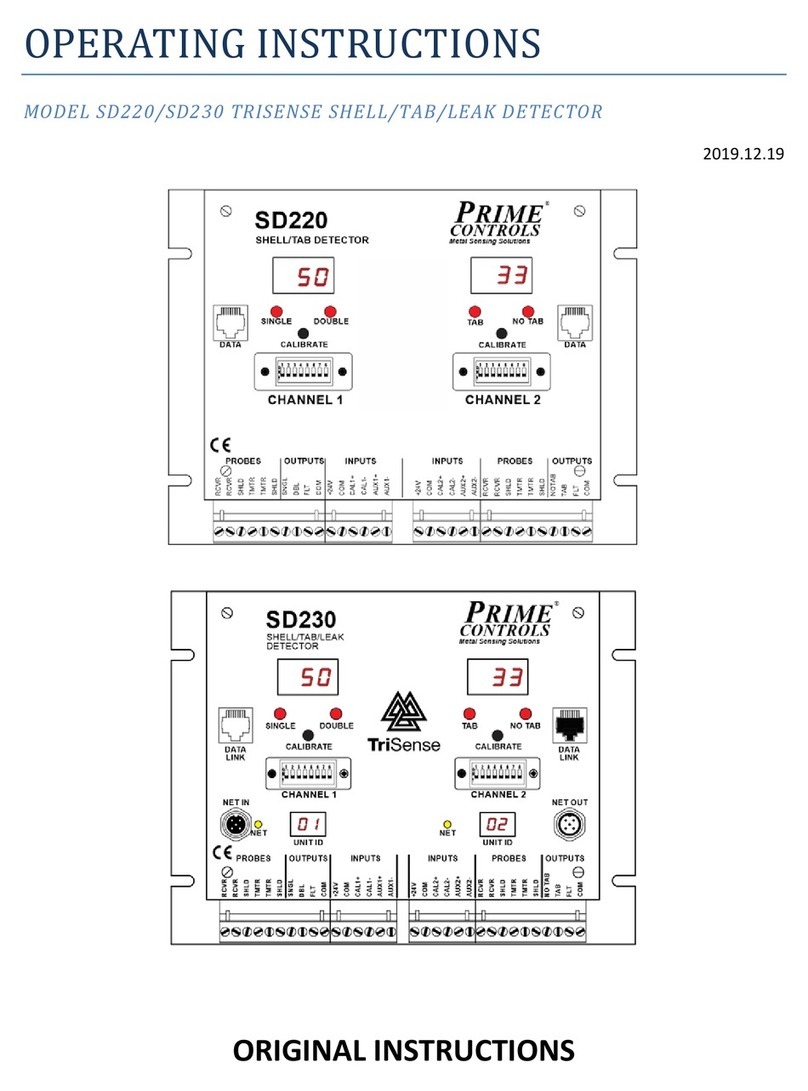

Prime Controls SD220 User manual

Prime Controls

Prime Controls FLUXIMITY DS71 User manual

Prime Controls

Prime Controls SD220 User manual

Prime Controls

Prime Controls DS1522 User manual

Prime Controls

Prime Controls SD230M User manual

Prime Controls

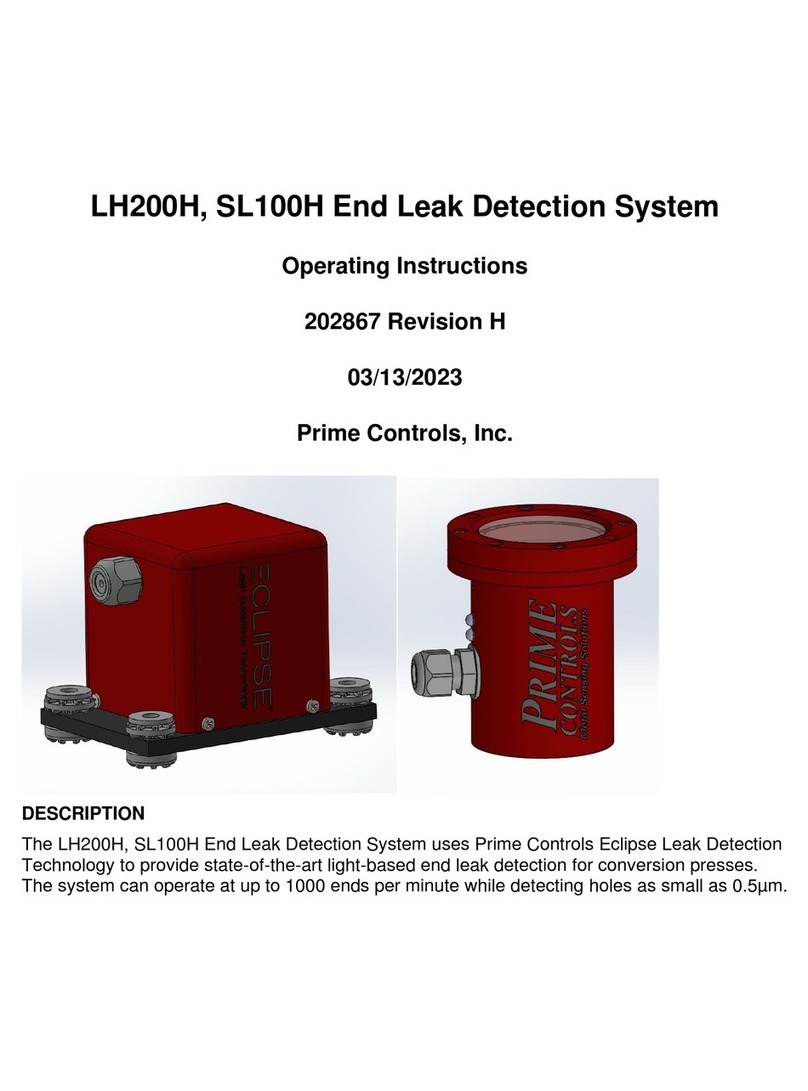

Prime Controls LH200 User manual

Prime Controls

Prime Controls LH200H User manual

Prime Controls

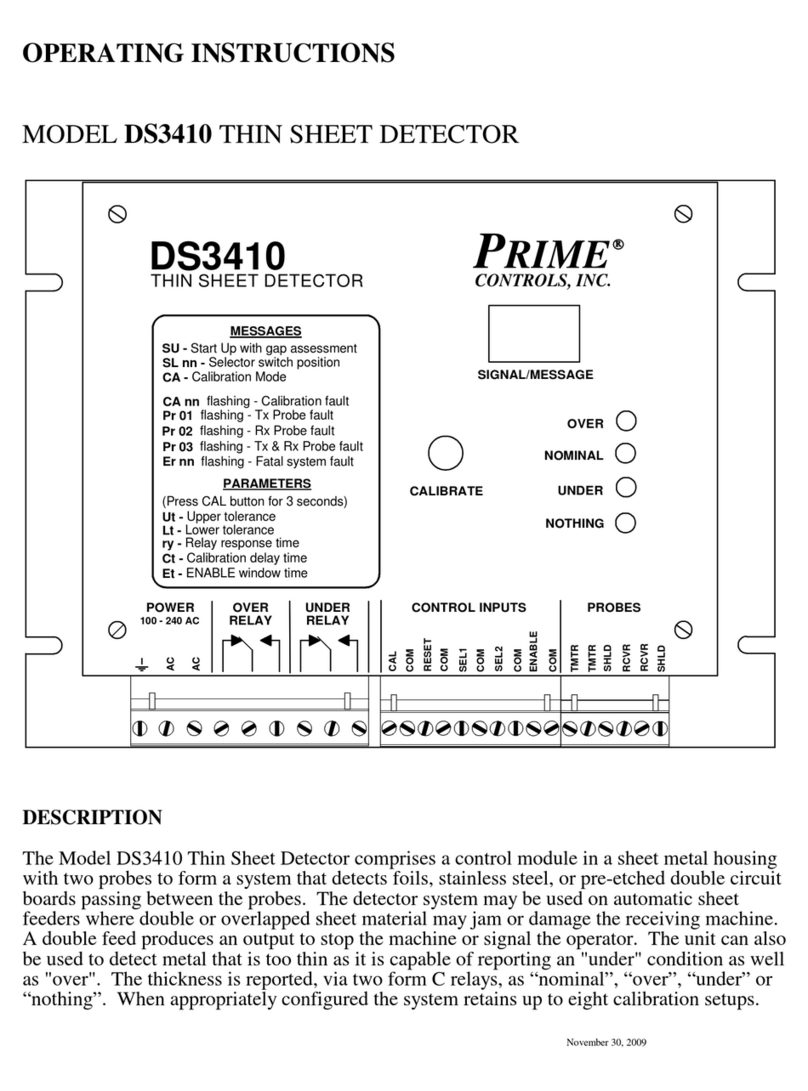

Prime Controls DS3410 User manual