Prime Controls FLUXIMITY DS71 User manual

MULTI-FUNCTION

INDICATOR (RED,

GREEN, AMBER)

POWER

INDICATOR

(GREEN)

FLUXIMITY

OPERATING INSTRUCTIONS

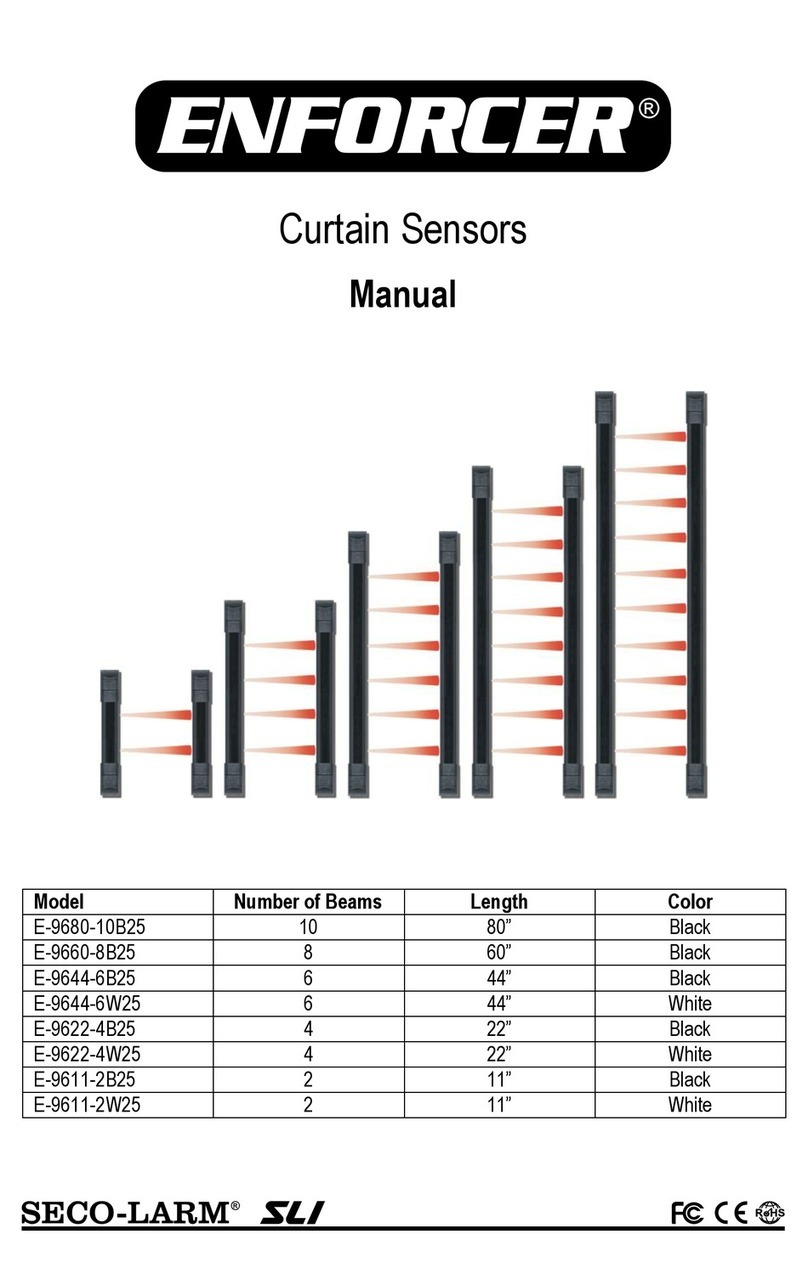

MODEL DS71 or DS72 DOUBLE SHEET CONTROLLER

MODEL PN18 Sensor Probe

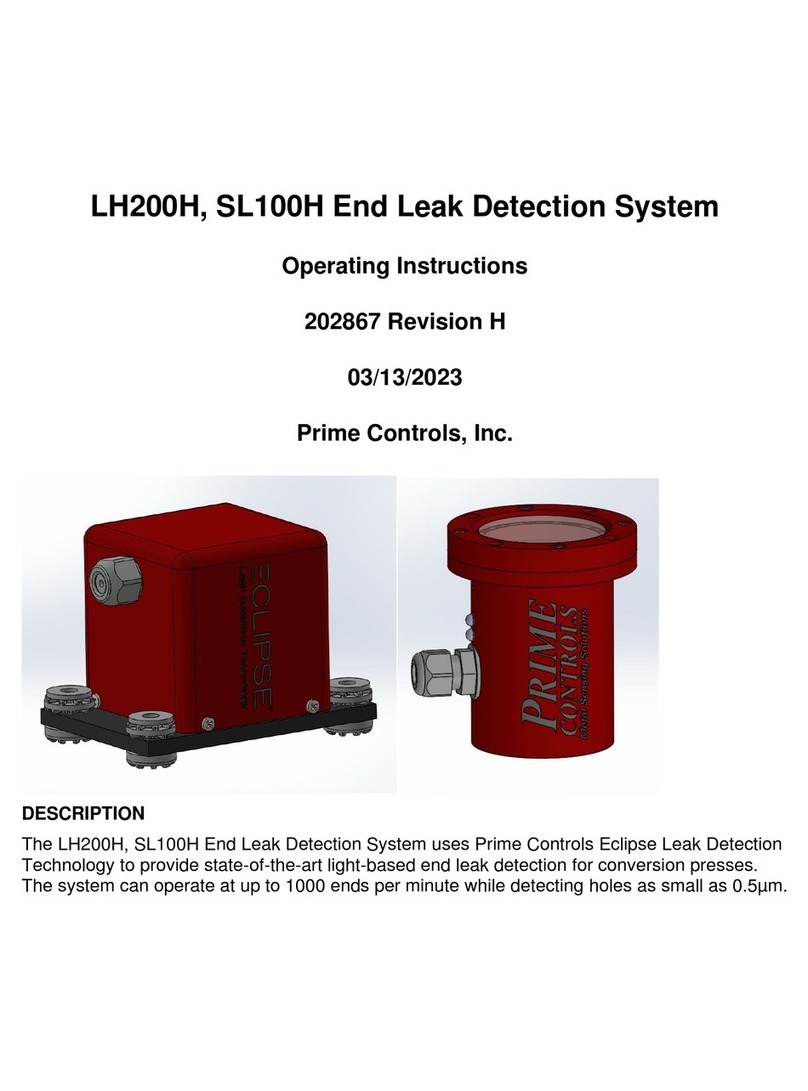

The Fluximity detector is a

unique double metal detection

system that utilizes an external

magnet as the operating signal

to measure metal thickness.

For example it is ideal to use

the magnetic field of a magnetic

conveyor that transports metal

blanks from process to process.

If no magnet is available, one

can be positioned so that the

blank is in contact, while the

Fluximity sensor is in position approximately 12mm away to monitor the strength.

CONTROLLER

There are four Fluximity controllers (DS71 –DS74). Only Models DS71 and DS72

Double Sheet Controllers are explained is this instruction sheet. The Fluximity system

includes a microcontroller based control module in a 18mm threaded aluminum

housing. The Controller is connected to a family of magnetic detection sensors through

an 8mm receptacle on the face of the Controller (depicted above). A four-pin 12mm

connector at the rear end provides connections for power, ground, single output and no-

double output. The Model DS71 provides current

sourcing outputs while the DS72 provides

current sinking outputs; otherwise the two units

are functionally identical. Status and setup

controls on the face include a green power

indicator, a multi-function/multi-color LED indicator

and a pushbutton switch.

The DS71/DS72 requires power that ranges from 12 to 24 DC volts at 40mA for power.

For a Model DS72 add the anticipated output PnP load current to the 40mA when sizing

a power supply. The load current should not exceed 100mA.

2

(Pico Style)

SENSOR PROBE

Currently Prime has only one magnetic probe, the Model PN18 that operates with the

DS71/72. The PN18 is a passive receiver sensor. It requires the operating signal from

an external magnetic source. Ferrous metal from .002 to .100” is detectable with the

PN18, if the external magnetic strength is sufficient to saturate a single blank with

additional magnetic flux available for a double metal blank will cause the sensor to

measure a difference.

INSTALLATION

Installation of the individual components of the DS71/DS72 system is covered in the

following paragraphs:

DS71/DS72 Control Module Installation

The DS71/72 Controller module is designed to mount with a simple bracket, where

convenient, between the probe

and a higher level controller

such as a PLC. Avoid

mounting locations with

excessive heat and vibration.

The control and probe

separation should not exceed

the length of the Model

CBL110-2 cable or two meters.

Any 18mm proximity probe

mounting bracket can be used

to install the controller. Prime’s 18mm right angle bracket model number is BR18SR.

Mount the control so the control face with the LED indicators and pushbutton is in view

and accessible. To connect the DS71/72 into a control system, use Prime Model

CBL104-3 cable/connector. The cable length is 3 meters. Prime can manufacture a

CBL104 cable/connector with additional length. The special order may take one week

to complete.

3

Probe Installation

Mount the probe so that the metal passes between the probe face and the magnetic

source (conveyor). We recommend the initial probe gap to conveyor belt should be

12mm (.5”) or less. Do not hard mount the probe bracket at this time. With no metal

present the probe must detect at least 100 gauss from the magnetic conveyor. It is wise

to leave the probe mounting loose until the ideal location is determined using the Meter

Mode feature cover on page 5.

The Models DS71 and DS72 with the Model PN18 Single probe Double Sheet Detector

can operate without the probe touching the target metal. It uses the residual magnetic

field that attracts the metal to the conveyor. The magnet acts like a transmitter in a dual

probe detector. The Magnetic field will permeate through the metal blank. The

thickness of a non metallic belt will not adversely affect the magnetic strength as long as

it is blank is held closely to the belt surface. The unit must be calibrated after the gap is

established. If the gap is too large, the unit will not calibrate. Use the meter mode

(page 5) to determine the maximum gap.

We recommend you always locate the sensor to achieve maximum coverage of the target metal

blank when calibrating. Calibration at a location where the maximum field is not blocked may

cause false doubles. During production the metal may move to a point where more flux is

covered. This is especially true when the shape of the blank varies. Typically the blank should

cover the magnetic to the PN18 for approximately 50 mm (2”). If the target is smaller than

50mm, then locate it where the maximum coverage is located using the meter mode. Calibrate at

that position.

Electrical Wiring

The connection between the probe and the controller requires a Prime Controls adapter

cable model CBL110-2. The cable has a connector at either end and does not require

external wiring. Probe and control separation should be within the 2 meter cable length.

Power to the controller and the outputs connect through an industrial standard male,

four-pin, 12mm connector. For noise immune connection use Prime Controls specified

Model CBL104-3 cable.

The CBL104-3 pin-out is as follows and the connected individual wire colors:

Pin 1 - Power Brown wire on standard cable

Pin 2 - Single Output White wire on standard cable

Pin 3 - Common Blue wire on standard cable

Pin 4 - No-double Output Black wire on standard cable

Cable shields should not be strip from wires more than 50mm or 2 inches to maintain

noise immunity. Route the cables away from any high power wiring and machinery to

maintain noise immunity. Make sure the Pin 3 Common (blue) is uninterrupted to the

common of the source power supply.

4

MULTI-FUNCTION

INDICATOR (RED,

GREEN, AMBER)

POWER

INDICATOR

(GREEN)

Apply Power

When power is applied, the green LED indicator is continuously ON.

When initially powered up, the DS71/DS72 controller displays the firmware version

number by flashing the multi-function/multi-color LED indicator, first red then green

(See FIRMWARE VERSION later in this document on page 8). When troubleshooting

with Prime Controls, it is helpful to know the version number. The controller then

checks for a valid probe. If a fault is detected, it could be one of the following problems:

a) the probe is not connected; b) there is an open connection in the cable to the probe;

c) weak or no magnetic signal present. The multi-function indicator will flash red at a

rate of 10Hz until the fault is cleared. If no fault is detected the controller goes into

normal the sensing operation. Normal indicator colors are covered on page 8. If the

magnetic field signal is strong the multi-function indicator will be off. (this assumes the

probe face was mounted within 50mm of the magnetic conveyor.)

PUSHBUTTON OPERATION

The small pushbutton mounts flush with the

face of the unit to insure no inadvertent

bumping can cause a calibration mistake.

In addition to calibration, the pushbutton is

used to control two other operational modes.

They modes are:

1. During operation, pressing and holding the pushbutton for three seconds more,

initiates meter mode.

2. From meter mode, pressing the pushbutton once exits meter mode.

3. From error mode, pressing the pushbutton once retries calibration.

4. From calibration mode, pressing and releasing once within 3 seconds, initiates

calibration on a single thickness of metal.

5. From calibration mode, pressing the pushbutton twice within 1.0 second, initiates

two-sample calibration mode and records the first point. A third tap records the

second calibration point, installs the new calibration and exits calibration mode.

5

MULTI-FUNCTION

INDICATOR (RED,

GREEN, AMBER)

POWER

INDICATOR

(GREEN)

METER MODE

The DS71/DS72 Controller provides a

feature for determining the magnetic

source strength detected by the

sensor. Mount the sensor face

pointing at the magnetic (conveyor

source. We suggest approximately

12mm or .5 inches to start. After

power is applied activate the “meter”

mode by pressing the calibration

pushbutton switch for three (3) or

more seconds. When the switch is released, the multi-function indicator begins flashing

at a rate inversely proportional to the strength of the detected magnetic signal.

One of the following examples will occur:

For minimum or no signal, the flash rate is approximately <25 Hz and the color is red.

For nominal or maximum signal, the flash rate is 1 Hz and the color is green.

There is a transition point where the indicator is amber.

In order for the detector to work it must sense sufficient magnetic strength to penetrate

(saturate) an inspected single metal blank and have additional magnetic flux for a

double blank thickness to block the signal. The Fluximity operates best if the magnetic

strength is >100 gauss. Gauss (G) is a unit of measurement for magnetic field strength

or flux density.

For example: approx. 1 gauss from earth’s magnetic north aligns a compass needle in

its direction. When the flux is measured at 100G or greater the indicator will begin to

flash green at a rate of approximately 1 Hz or 1 per second. This indicates the signal is

strong enough to detect double metal. For weak flux, under 100 gauss, the indicator

flashes amber slowly (<25 Hz) and then red as the magnetism is weaker. The red

flashes rapidly or at maximum rate (25 HZ) if no flux is detected.

Locate Nominal Signal

With no metal on the conveyor, move the probe around while observing the indicator

flash rate and color. Any position or gap where the indicator is green and flashes at 1

Hz is a good location (>100G). The metal blanks must consistently pass this point

between the probe and magnet. Mount the probe there.

To deactivate the Meter Mode, press and release the pushbutton once. The multi-

function indicator reverts to the setting from the previous calibration. If this is the first

time these settings are from the factory and do not apply to your installation. Calibration

for this installation should follow.

6

CALIBRATION

The DS71/DS72 Controller offers two modes of calibration or “teach”, a one-sample

mode and a two-sample mode. Both are invoked through the pushbutton on the face of

the unit.

The one-sample mode simply sets the gauge threshold at 125% of the signal present at

the time the pushbutton switch is pressed. The two-sample mode sets the gauge

threshold halfway between the readings from the two-sample calibrations.

Calibration information is stored in non-volatile memory and is restored at power-up.

One-sample Calibration

1. Place a single thickness of the metal to be sensed on the magnetic conveyor in

front of the probe face.

2. Press the calibration pushbutton once.

If successful the multi-function LED indicator turns off momentarily, and then flashes

amber 4 times in succession at a 5 Hz rate then turns solid green.

If calibration is not successful, the indicator flashes amber at a 10 Hz rate for 15

seconds or until the pushbutton is pressed again. The previous calibration values are

re-installed if 15 seconds elapses with no press of the pushbutton.

The detector has a standby calibration feature that permits calibration while the metal is

moving. Press the pushbutton once with no metal between the magnet field and probe.

The indicator will flash amber at a 2.5 Hz rate until metal is moves in front of the probe.

The controller will sense the effect the metal has on the magnetic field. It delays the

measurement for half (.5) second to allow full coverage of the metal over the

background magnetic field. If successful the indicator flashes green 4 times and

remains solid if metal remain present or off if no metal is present.

Two-sample calibration

Two-sample calibration may be used to tightly set the gauge tolerances. Two-sample

calibration places the gauge threshold at the midpoint between the two recorded

samples. Whereas the one-sample calibration always discriminates on a >25% change

in signal relative to the sample point. The separation of sample points in the two-

sample mode may be varied according to the user’s needs.

When calibrating in two-sample mode, the order of sampling the thicker and thinner

material makes no difference. The controller sorts out the order and sets the threshold

the same either way.

7

The calibration procedure is as follows:

1. Place the first material sample centered in front of the probe face.

2. Tap the pushbutton twice in succession within 1.0 second. The first sample is

taken and the indicator will flash amber at a 2.5 Hz rate for up to 25 seconds.

3. Within 25 seconds, place the second material sample centered in front of the

probe face.

4. Tap the pushbutton once more. The second sample is taken, the new threshold

installed, and the indicator flashes amber four times at a 5 Hz rate and then

reverts to following the outputs.

5. If 25 seconds elapses before the press of the calibration pushbutton, the

controller aborts calibration and re-installs the previous calibration values.

6. If the thickness of the two samples is too close for reliable gauging, the indicator

flashes amber at a 10 Hz rate for up to 15 seconds or until the pushbutton is

pressed again. After 15 seconds, it returns to the previous calibration settings.

OPERATION

As metal passes the sensor the LED multi-function indicator and the two outputs

respond as shown in the chart below:

Single No-Double

Probe Detects Output Output LED

No Metal OFF ON OFF

Single Thickness ON ON Green

Double Thickness OFF OFF Red

The DS71/DS72 controller constantly monitors the current draw of the attached probe.

If the measured current goes out of specification for whatever reason, the multi-function

indicator flashes red at a 10 Hz rate until the problem is corrected or the power is

removed.

The output logic is designed for fail-safe operation. If the controller looses power or an

output line is disconnected, the unit reports a double by default.

8

TROUBLESHOOTING HINTS

NORMAL: When power (12 to 24 volts dc ) is applied, the POWER LED should be ON

solidly green

PROBLEM: If the POWER LED remains off with power applied, check the cable

connections and the integrity of the cable.

PROBLEM: It is important to remember that when powering up the DS71/DS72, metal

should not be present on the magnetic surface and in front of the probe face. The

controller reads the probe signal at power-up to determine the minimum signal level of

the probe.

The flash pattern and color of the multi-function LED on the DS71/DS72 can be helpful

in the diagnosis of problems with your installation. Check the following:

Immediately After Power-up

1. NORMAL: The multicolor LED flashes red then green at a 2.5 Hz rate to indicate

firmware version then turns off.

2. PROBLEM: The LED flashes green then red at a 2.5 Hz rate to indicate firmware

version number and then begins flashing red rapidly (10 Hz). This can indicate a)

there is metal present b) the probe is disconnected, or c) the cable to the probe has

an open, or d) the probe is faulty.

During Single-Hit Calibration

1. NORMAL: The LED constantly flashes amber at a 2.5 Hz rate. This is normal if no

metal is present in front of the probe face. It is a standby mode waiting on metal.

2. PROBLEM: Persistence of the above pattern with metal present can indicate a) the

metal is non-ferrous, b) the metal is too thin for the probe, or c) the probe is faulty.

During Two-Sample Calibration

1. NORMAL: After the pushbutton switch is pressed twice in less than 1 second, the

LED flashes amber at a 2.5 Hz rate. This is normal; the controller is waiting for the

second thickness of metal to be placed against the probe and the pushbutton to be

pressed once again.

2. PROBLEM: After the third press of the pushbutton (to record the second thickness),

the LED flashes amber at a rapid (10 Hz) rate. This indicates the two samples were

so close in thickness that the difference cannot be reliably discriminated.

9

While Gauging

1. PROBLEM: The LED flashes red rapidly (10 Hz). The probe is either faulty or

disconnected. Check the cabling and probe.

2. The LED indicates the expected state of the outputs as follows:

LED State Single Output (pin2) No-Double Output (pin4)

OFF OFF DS71 – low ON DS71 high

DS72 – high DS72 low

GREEN ON DS71 – high ON DS71 – high

DS72 – low DS72 – low

RED OFF DS71 – low OFF DS71 – low

DS72 – high DS72 – high

FIRMWARE VERSION

The format of the firmware version number is of the form 1.2, comprising a single digit

integer part and a single digit fractional part. When first powered up, the controller

displays the version number by flashing the integer digit value in red and the fractional

digit value in green. To determine the version number, count the number of red flashes

and then the number of green flashes immediately after power-up. For example, a

single flash of red followed by a single flash of green indicates a version number of 1.1.

MULTI-FUNCTION

INDICATOR (RED,

GREEN, AMBER)

POWER

INDICATOR

(GREEN)

10

SPECIFICATIONS

Power

Type: DC

V+ Connection: 12 mm Connector, Pin 1

Common 12 mm Connector, Pin 3

Voltage: 10 to 24 volts

DS71 Max Current: 40 milliamps + output loads

DS72 Max Current: 40 milliamps

Protection: Reverse polarity protected.

Transient Voltage Suppress @ 30 Volts

Logic Output Electrical Specifications

DS71 Sourcing Outputs

Connection: 12 mm Connector, Pin 4

Max. source current: 50mA, fuse limited

Output Voltage High: Supply Voltage less 1 volt

Over-current protection: Self-resetting thermal fuse

ESD protection: Transient Voltage Suppressor @ 30 Volts

DS72 Sinking Outputs

Open Drain

Connection: 12 mm Connector, Pin 2

Max. applied voltage: 30 Volts, TVS limited

Max. current, momentary: 40 Amps

Max. current, sustained: 50mA, fuse limited

Max. off state leakage @ 30 V: 25uA

Over-current protection: Self-resetting thermal fuse.

ESD protection: Transient Voltage Suppressor @ 30 Volts

11

DS71 DRIVE CIRCUITRY

CONTROLLER

30V

30V

30V

2

1

4

3

50 mA

50 mA

V+

COM

SINGLE

NO-DOUBLE

DS72 DRIVE CIRCUITRY

CONTROLLER

30V

30V

30V

2

1

4

3

50 mA

50 mA

V+

COM

SINGLE

NO-DOUBLE

12

CONTROLLER DIMENSIONS

LIMITATION AND EXCLUSION OF WARRANTIES

All goods purchased form PRIME CONTROLS, INC. shall be free from defects in

materials, design and workmanship under normal conditions of use for one year from

the date of shipment. THIS WARRANTY IS THE SOLE WARRANTY AND IS

EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED, WARRANTY OF

MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE. THE LIABILITY

OF PRIME CONTROLS TO ANY PURCHASER SHALL BE LIMITED EXCLUSIVELY

TO THE COST OF REPLACEMENT OR REPAIR OF DEFECTIVE PARTS, AND

SHALL NOT INCLUDE LIABILITY FOR ANY DIRECT, CONSEQUENTIAL OR

INCIDENTAL DAMAGES WHATSOEVER, WHETHER FORESEEN OR

UNFORESEEN, INCLUDING BUT NOT LIMITED TO LOST PROFITS, LOST SALES,

OR INJURY TO PERSONS OR PROPERTY

(Pico Style)

This manual suits for next models

2

Table of contents

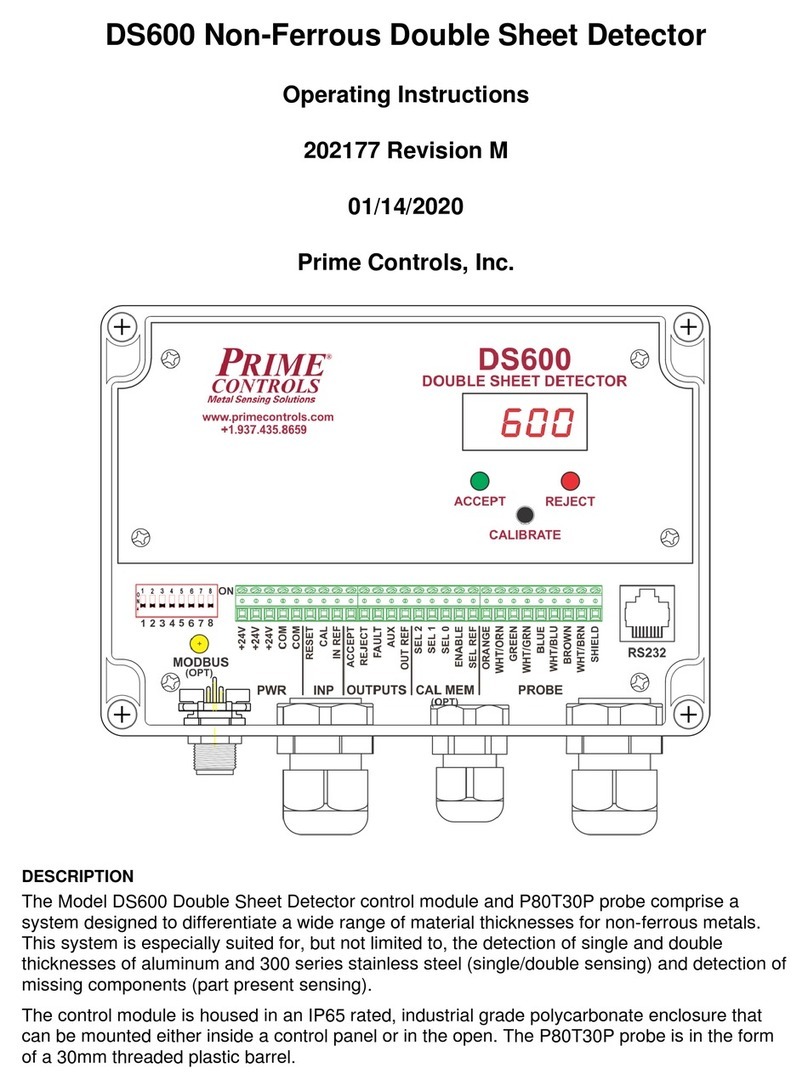

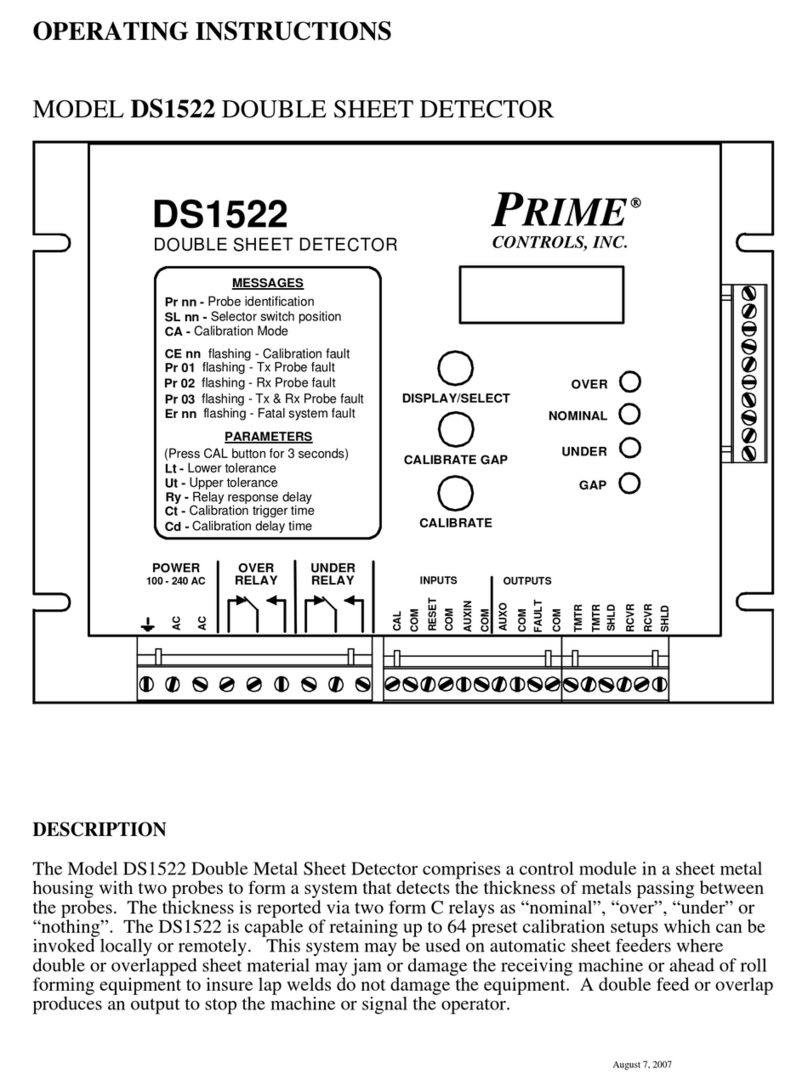

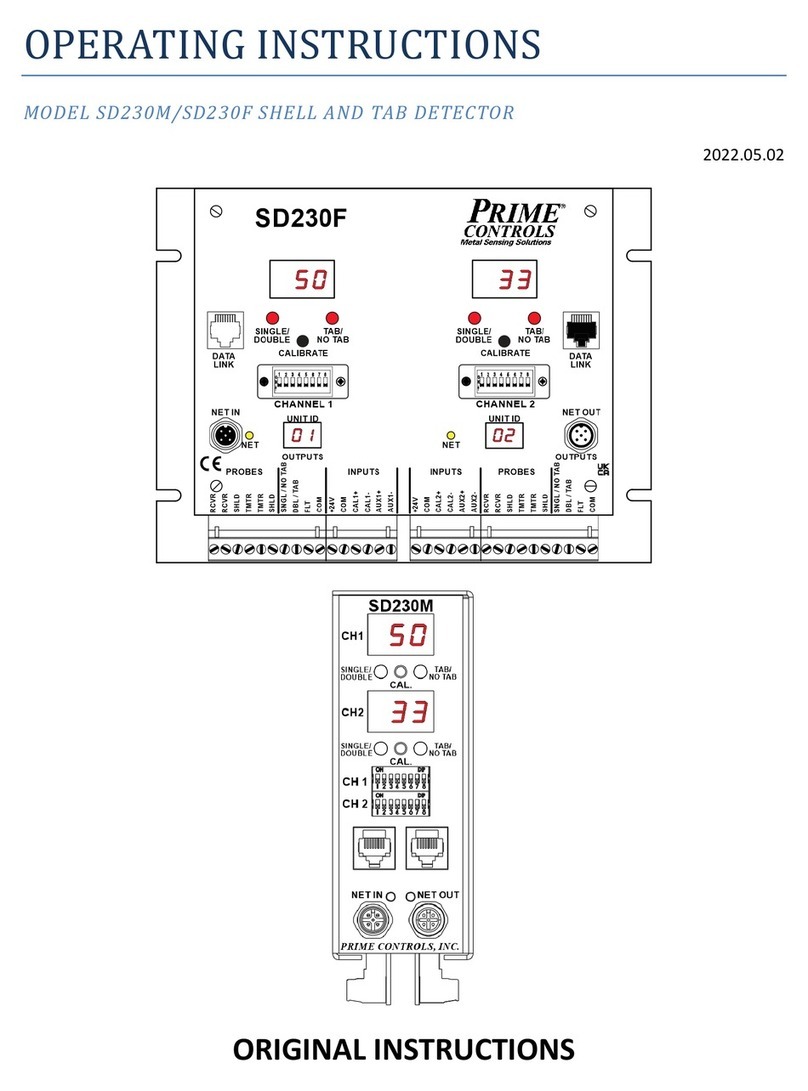

Other Prime Controls Security Sensor manuals

Prime Controls

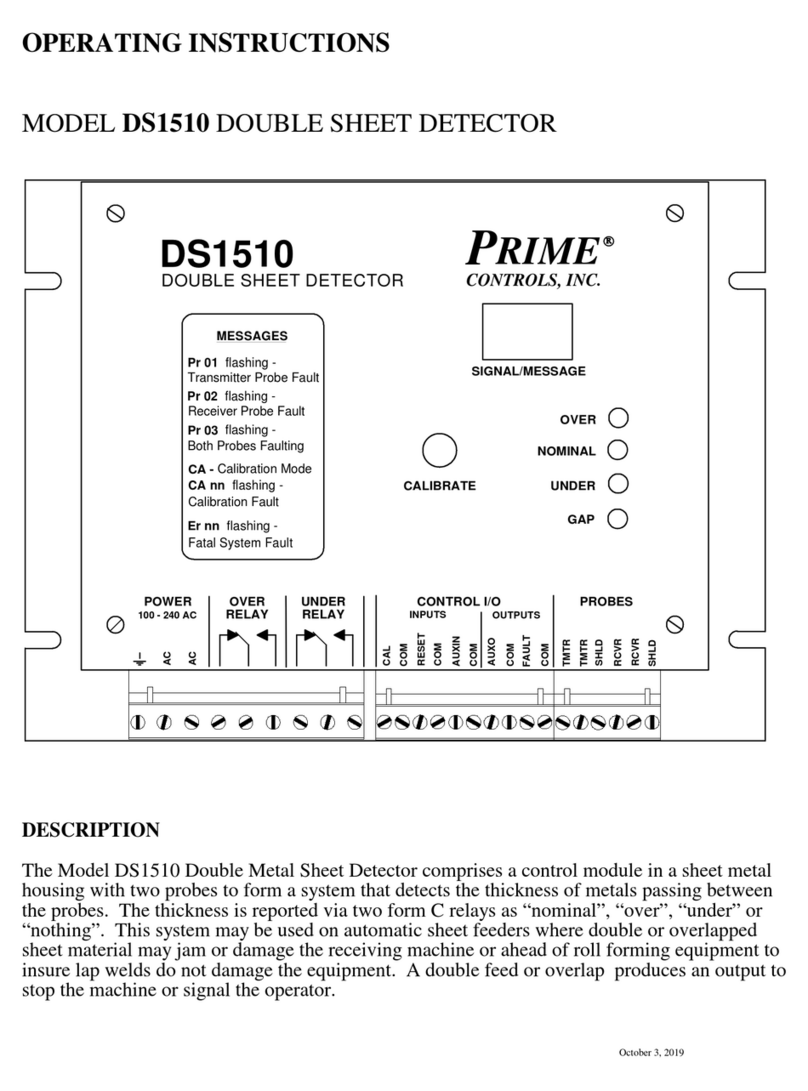

Prime Controls DS1510 User manual

Prime Controls

Prime Controls SD220 User manual

Prime Controls

Prime Controls LH200H User manual

Prime Controls

Prime Controls LH200 User manual

Prime Controls

Prime Controls DS600 User manual

Prime Controls

Prime Controls DS1522 User manual

Prime Controls

Prime Controls SD230M User manual

Prime Controls

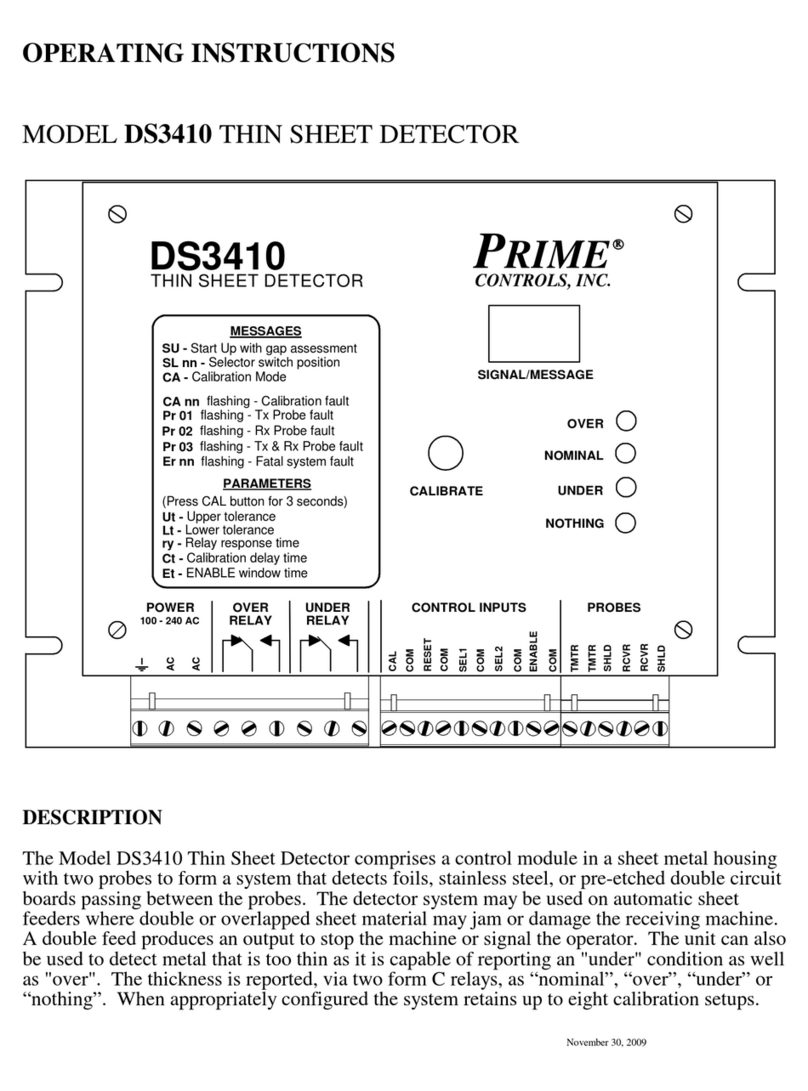

Prime Controls DS3410 User manual

Prime Controls

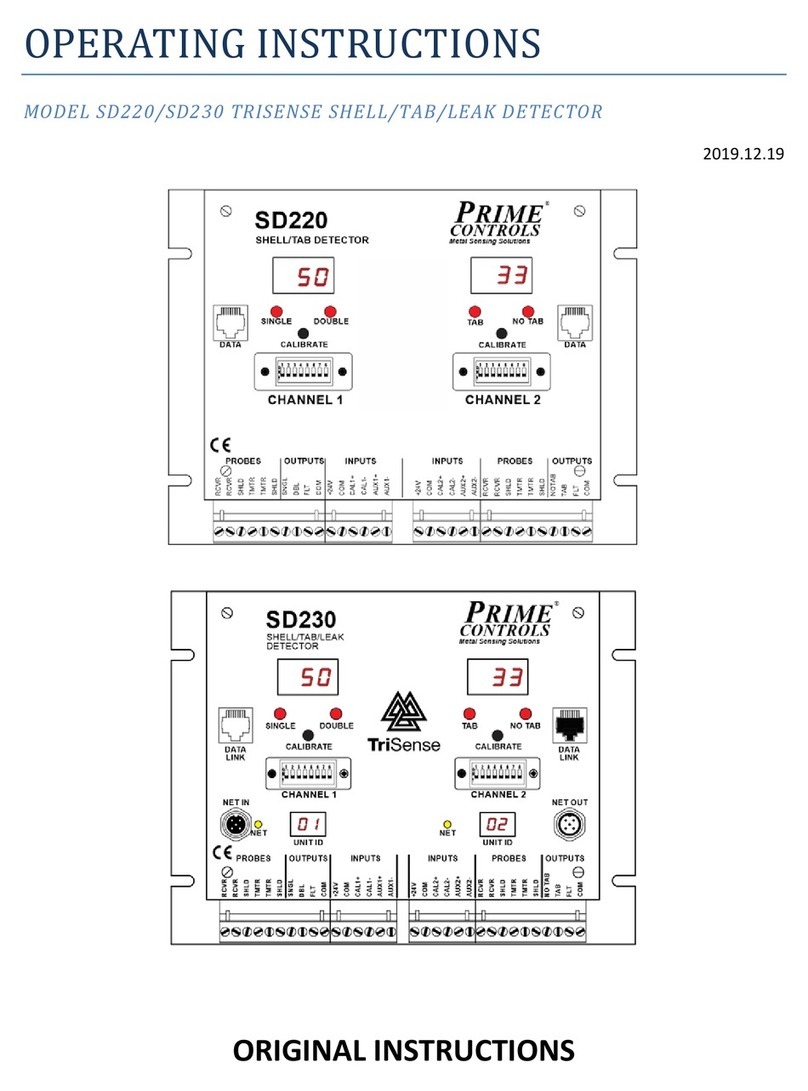

Prime Controls SD220 User manual