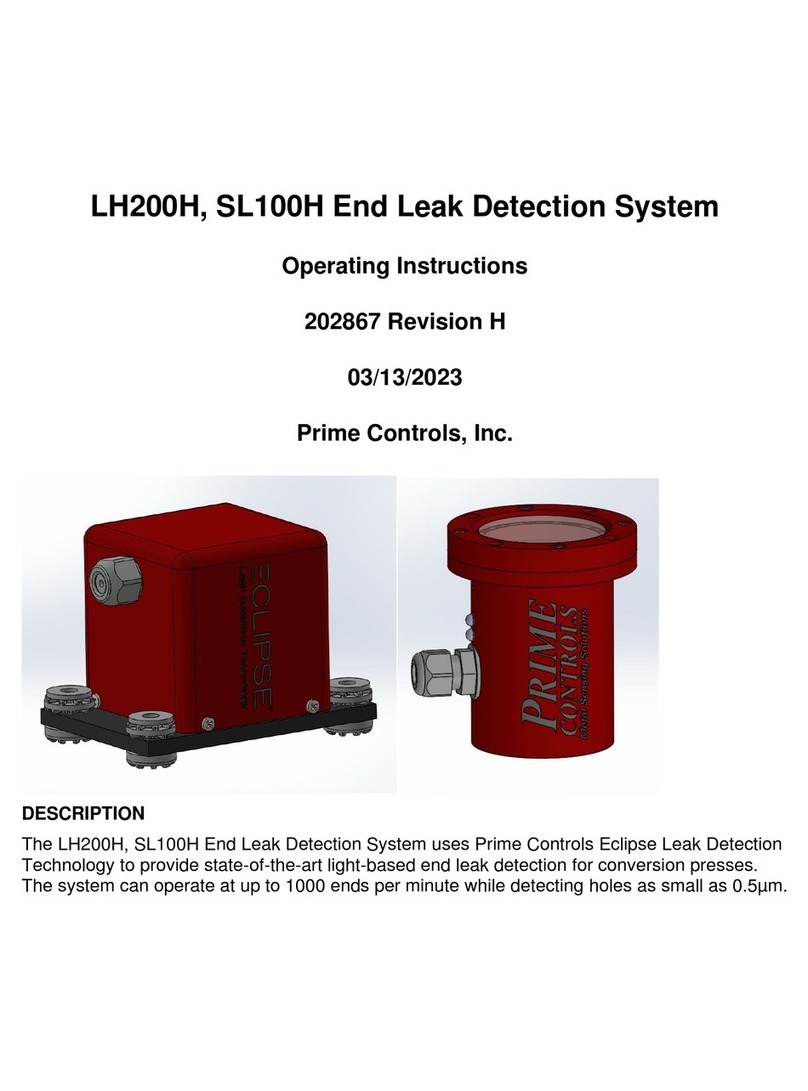

Prime Controls LH200 User manual

LH200 Light Leak Detector

Operating Instructions

Revision D

08/11/2017

Prime Controls, Inc.

DESCRIPTION

The LH200 light sensor is designed to be a component of a light-based inspection system for finding leaks in

container ends and containers. In addition to the LH200, a complete inspection system requires: a controlling

PLC, a Prime Controls SL100 LED Strobe Lamp, and a reject mechanism. If the test system comprises

multiple lanes, where the flash energy from one lane can cross-couple into another lane, the system may

also require the use of the Prime Controls SQ100 sequencer to stagger the triggering of the individual

sensors.

2

OPERATION

Once set up, the operation of the LH200 involves only three control signals, an ENABLE signal from the PLC

or sequencer to start the test cycle, a STROBE output signal to trigger the flash illuminator, and a RESULT

output signal to report the outcome of the test to the PLC.

In general terms, an inspection cycle comprises the following steps:

1. An enable signal is sent to the LH200 to begin the test cycle.

2. The LH200 takes 128 readings and averages them as a dark reference.

3. The LH200 asserts the STROBE signal to trigger the flash illuminator.

4. The LH200 captures the peak signal sensed during the flash.

5. The LH200 assesses the dark level and peak value and reports a leak if either or both signals

exceed their respective test limits.

The test cycle is described in greater detail later in this document. See TEST CYCLE DETAIL

USER INTERFACE

The LH200 may be connected to a terminal, laptop, or personal computer for user access to configuration

parameters. Set the serial connection parameters to 34800 baud, 8 data bits, 1 stop bit, no parity and no

handshake. When the connection has been established, enter a question mark, “?” to display the command

menu:

Commands:

A– Auto Adjust, 0/1

B– Bias

C– Cal Offset

F– Free Run

D– Dark Limit

G– Gain

S– Spread Limit

L– Leak Limit

R– Reports

V– Version

?– Menu

Note on Parameters:

In most user applications, it will not be necessary to adjust the available parameters. The default values were

determined by testing in a typical, real world installation. However it may be necessary to adjust the Leak

Limit and Dark Limits based on ambient light intrusions and desired leak reject levels.

A- Auto Adjust

The “A” command allows the user to enable and disable the auto adjust feature. “A” has only two values, 0

and 1. Zero disables the auto adjust feature and 1 enables it. The default is 1, enabled.

The auto adjust mechanism monitors the average of the internal bias readings taken during the dark period

of the test cycle and adjusts an internal offset to maintain the dead-band as specified by the “B” setting. This

insures constant sensitivity through a wide range of temperatures. It is recommended to leave this setting

enabled for most installations.

3

The auto adjust setting is recorded in non-volatile memory and is retained through power cycling of the

LH200.

B- Bias

Displays and opens the bias value for change. If the displayed value is to be retained, simply press ENTER

to accept the current value. Otherwise, enter the new value then press ENTER. Acceptable range is 1

through 100. Default is 30. This command cannot be entered when a machine is running (LH200 is receiving

a periodic ENABLE signal).

This value determines the size of the dead-band from complete darkness to a measurable signal. Increasing

this value decreases the sensitivity of the LH200. The smaller the bias value, the more likely extraneous

noise may trigger a leak response from the LH200. In most instances, adjusting the Bias is not necessary.

NOTE: The bias value should only be changed when the sensor is in complete darkness since a change to

the bias value automatically initiates a re-calibration of the LH200. Calibration may also be initiated through

the “C” command.

The bias value is recorded in non-volatile memory and is retained through power cycling of the LH200.

C– Cal Offset

Initiates calibration of the internal offset voltage required to maintain the bias as specified through the “B”

value. The gain setting does not affect this operation. NOTE: For meaningful calibration, the face of the

LH200 must be in complete darkness. This command cannot be entered when a machine is running (LH200

is receiving a periodic ENABLE signal).

D– Dark Limit

Displays and opens the dark limit value for change. If the displayed value is to be retained, simply press

ENTER. Otherwise, enter the new value then press ENTER. Acceptable range is from 1 to 4000. The

default is 30. This parameter determines how much light leakage is allowed after the test cycle has begun

and before the flash has been triggered. If the average of the dark readings during a test cycle exceeds the

dark limit, the report LED is set to amber and the RESULT output is turned off (reject state).

The dark limit is recorded in non-volatile memory and is retained through power cycling of the LH200.

F- Free-Run Mode

The LH200 is set to free-run mode by entry of the “F” command through the serial port. Free-run mode

cannot be entered if the machine is running (LH200 is receiving a periodic ENABLE signal). The operation

of the LH200 in free-run mode is as follows:

1. The ENABLE signal is ignored.

2. A cycle begins immediately after entry of the “F” command. The results of the test are reported on the

RESULT output, on the result LED, and the serial output.

3. The cycle repeats every 100 milliseconds until a character comes in from the serial port. Any character

from the terminal or PC terminates the free-run mode.

Note that in the free-run mode, the results are held on both the LED and the reject output until the next

inspection cycle while in normal press operation, the reject output is unconditionally set to the reject mode

when the enable signal is removed.

4

G– Gain

Displays and opens the gain value for change. If the displayed value is to be retained, simply press ENTER

to accept the current value. Otherwise, enter the new value then press ENTER. Acceptable range is 10

through 100. Default is 100. The gain value specifies the gain as a percentage of maximum sensitivity. 100

is maximum sensitivity, 10 is 10% of maximum sensitivity.

A change in gain affects both the dark reading sensitivity and the peak reading sensitivity.

The gain value is recorded in non-volatile memory and is retained through power cycling of the LH200.

L– Leak Limit

Displays and opens the leak limit value for change. If the displayed value is to be retained, simply press

ENTER. Otherwise, enter the new value then press ENTER. Acceptable range is from 1 to 4000. The

default is 500. If the peak signal that occurs during the flash period exceeds the leak limit, the report LED is

set to red unless the LED is already amber from the reporting of a dark fault. The RESULT output is turned

off (reject state).

If the peak signal does not exceed the leak limit and neither the dark average nor the dark spread exceed

their respective limits, the LED is set to green and the RESULT output is set high.

The leak limit is recorded in non-volatile memory and is retained through power cycling of the LH200.

R– Reports

The “R” command displays the currently enabled reports to be output for display over the serial port. The

value of each enabled parameter is displayed at the end of each test cycle. The parameters display in the

order in which the reports are listed when “R” is entered.

After the enabled reports are listed, the LH200 asks if the user wishes to change the selection of enabled

reports: Change? (Y/N). If “N” is entered, no change is made to the enabled list. If “Y” is entered, the list of

available reports is displayed, one at a time, to allow the user to enable the report (enter “Y”) or disable the

report (enter “N”). A typical scenario might be as follows:

Dark Average (Y/N) Yes

Dark Spread (Y/N) No

Peak Value (Y/N) Yes

Leak Factor (Y/N) No

Temperature (Y/N) No

Result Flags (Y/N) Yes

*(R command entered here)

Enabled Reports:

Dark Average

Peak Value

Result Flags

Change? (Y/N) (N entered here)

*

The selection of reports is recorded in non-volatile memory and is retained through power cycling of the

LH200.

5

The result flags are D, N and L. Their meaning is as follows:

D – the average dark current exceeded the dark limit

N – the dark spread exceeded the spread limit

L – the peak value exceeded the leak limit

S– Spread Limit

Displays and opens the spread limit value for change. If the displayed value is to be retained, simply press

ENTER. Otherwise, enter the new value then press ENTER. Acceptable range is from 1 to 4000. The

default is 500. This parameter determines how much variation in signal is allowed during the dark interval of

the test cycle. If the spread in dark readings during a test cycle exceeds the dark spread, the report LED is

set to amber and the RESULT output is turned off (reject state). For most applications this test has limited

meaning and may be essentially disable by setting the limit to a high value. Its primary usage is for detecting

electrical noise.

V– Version

Displays the controller firmware version number in the form of 1.01 for example.

?– Menu

Displays the command menu as shown at the beginning of this section.

6

TEST CYCLE DETAIL

The inspection cycle comprises the following steps:

1. The LH200 begins the test cycle by awaiting the assertion of the ENABLE signal from the PLC or the

SQ100 (high on gray wire, connector pin 5).

2. Prior to assertion of the ENABLE signal, the test sample is indexed into position between the sensing

face of the LH200 and the illumination device..

3. The PLC then sends the ENABLE signal to the LH200 or SQ100 sequencer. The sequencer generates

individual ENABLE signals for the LH200 units on each lane of the tester or press. The ENABLE signals

are generated 1 millisecond apart to insure that no two lanes flash at the same time.

4. The ENABLE signal passes from the PLC or SQ100 to the LH200 (high on gray wire, connector pin 5)

indicating the end is in position for inspection.

5. The LH200 responds immediately to the ENABLE signal by turning the report LED off then takes 128

consecutive light readings and averages them as a dark reference. The dark reading interval plus delay

lasts 5.25 milliseconds.

6. After the dark readings are taken, the dark level average is tested against the dark limit and the dark

spread is tested against the spread limit. If either limit is exceeded, the amber LED is turned on.

7. The LH200 awaits the end of the 5.25 mS interval then asserts the STROBE signal, activating the flash

(yellow wire, connector pin 4 set high) and captures the peak light resulting from the flash.

8. When the 1 millisecond peak capture interval has expired, the captured peak value is compared to the

leak limit. If the peak value exceeds the limit but the dark average and dark spread are within limits, the

result LED is set to red. If dark average, dark spread and peak are all within limits, the report LED is set

to green. If either the dark level or the spread of the dark level readings exceeds limits, the report LED

remains amber even if the peak value exceeds its limit.

9. The LH200 delays another 3.5 milliseconds then releases the STROBE signal (yellow wire, connector

pin 4 set low) and, if no leak, sets the RESULT output high (white wire, connector pin 1). The delay

insures a quiet power supply in the flash unit until all later lane inspections have been completed.

10. The LH200 controller then sends the results of the inspection to the serial output (pink wire, connector

pin 6, 38400 baud). This is an RS-232 signal that may be connected to the serial port of a terminal or

computer.

11. The LH200 then awaits the release of the ENABLE signal (low on gray wire, connector pin 5). When

released, the RESULT output is set low (white wire, connector pin 1) and the cycle begins again at step

1 above.

See Timing Diagram below.

7

TIMING

TEST ENABLE

READ DARK

STROBE

PEAK CAPTURE

DELAY

NO-LEAK RESULT

LEAK RESULT

5.25 mS

1 millisecond

3.5 mS

CONNECTOR PINOUT

Pin Wire Color Signal Direction

1 White Result Out

2 Brown Power (+24V) In

3 Green Serial Data In In

4 Yellow Strobe Trigger Out

5 Gray Test Cycle Enable In

6 Pink Serial Data Out Out

7 Blue Common --

8 Shield Connect to Common --

RS-232 CONNECTION

The illustration below, defines the wiring requirements for accessing the serial port capabilities of the LH200

using the standard 9 Pin Female D Sub Connector (DB9).

12

3

4

5

6

7

89

M12 PIN 3 (CABLE GEEN)

M12 PIN 6 (CABLE PINK)

M12 PIN 7 (CABLE BLUE)

FEMALE CONNECTOR

FRONT VIEW

M12 MALE

1

7

6

5

4

3

8

2

M12 MALE

1

7

6

5

4

3

8

2

8

9

SIGNAL SPECIFICATIONS

Power (Pin 2) 24V DC +/- 10%

ENABLE (Pin 5) Active high, 15 – 24 Volts.

10K ohms input impedance.

Zener limited at 30 volts.

RESULT (Pin1) Sourcing output, active high.

Off: zero volts.

On: supply voltage less 1 volt.

Output impedance: 200 ohms.

STROBE Trigger (Pin 4) Active high.

Off: zero volts.

On: supply voltage less 1 volt.

Output impedance: 1500 ohms

Serial Transmit (Pin 6) RS-232 levels.

Baud rate: 38400

Serial Receive (Pin 3) RS-232 levels

Baud rate: 38400

LH100 AND LH200 DIFFERENCES

From an installation and operational perspective, the LH100 and LH200 are fully compatible. External

hardware differences are detailed below.

Feature LH100 LH200

Report LED (near connector) Off - no leak Off – after power-up, no testing done

Amber – failure Green – no leak

Amber – high dark level or spread

Red – leak detected with flash

Dark Measurement 4 Samples 128 Samples

Dark Threshold Fixed User settable

Spread Threshold Fixed User settable

Peak Threshold Fixed User settable

System Gain Fixed User settable

System Bias Fixed User settable

Invoke free-run mode Connect signal to common Enter “F” through terminal or laptop

Serial communications Logic level signal RS-232 level signals

Out only, 9600 baud Bidirectional, 38400 baud

Serial output data Fixed: Dark Average, Dark Selectable: Dark Average, Dark Spread

Spread, Peak, and Flags Peak Value, Leak Factor, Temperature

and Flags

10

LIMITATIONS AND EXCLUSION OF WARRANTIES

All goods purchased from PRIME CONTROLS, INC. shall be free from defects in materials, design and workmanship

under normal conditions of use for one year from the date of shipment. THIS WARRANTY IS THE SOLE

WARRANTY AND IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED, WARRANTY OF MERCHANTABILITY OF FITNESS

FOR A PARTICULAR PURPOSE. THE LIABILITY OF PRIME CONTROLS TO ANY PURCHASER SHALL BE

LIMITED EXCLUSIVELY TO THE COST OF REPLACEMENT OR REPAIR OF DEFECTIVE PARTS, AND

SHALL NOT INCLUDE LIABILITY FOR ANY DIRECT, CONSEQUENTIAL OR INCIDENTAL DAMAGES

WHATSOEVER, WHETHER FORESEEN OR UNFORESEEN, INCLUDING BUT NOT LIMITED TO LOST

PROFITS, LOST SALES, OR INJURY TO PERSONS OR PROPERTY.

This document is confidential and proprietary. No part of this document may be

disclosed in any manner to a third party without the prior written consent of Prime

Controls, Inc.

This manual suits for next models

1

Table of contents

Other Prime Controls Security Sensor manuals

Prime Controls

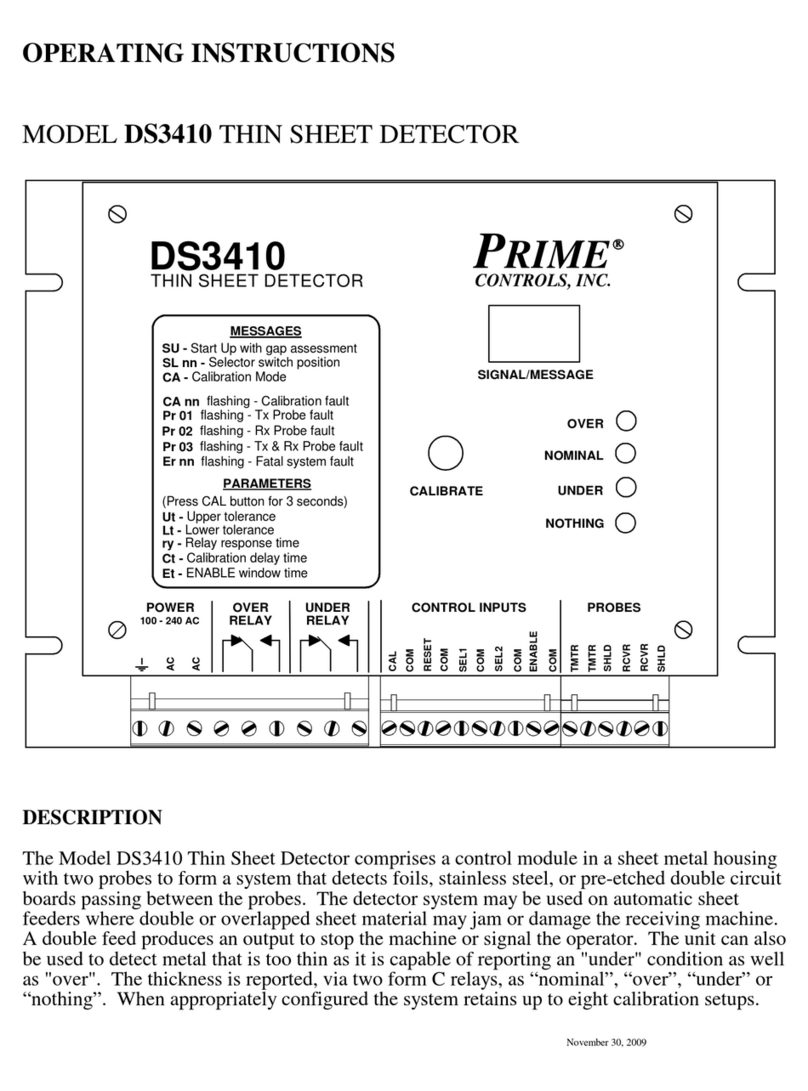

Prime Controls DS3410 User manual

Prime Controls

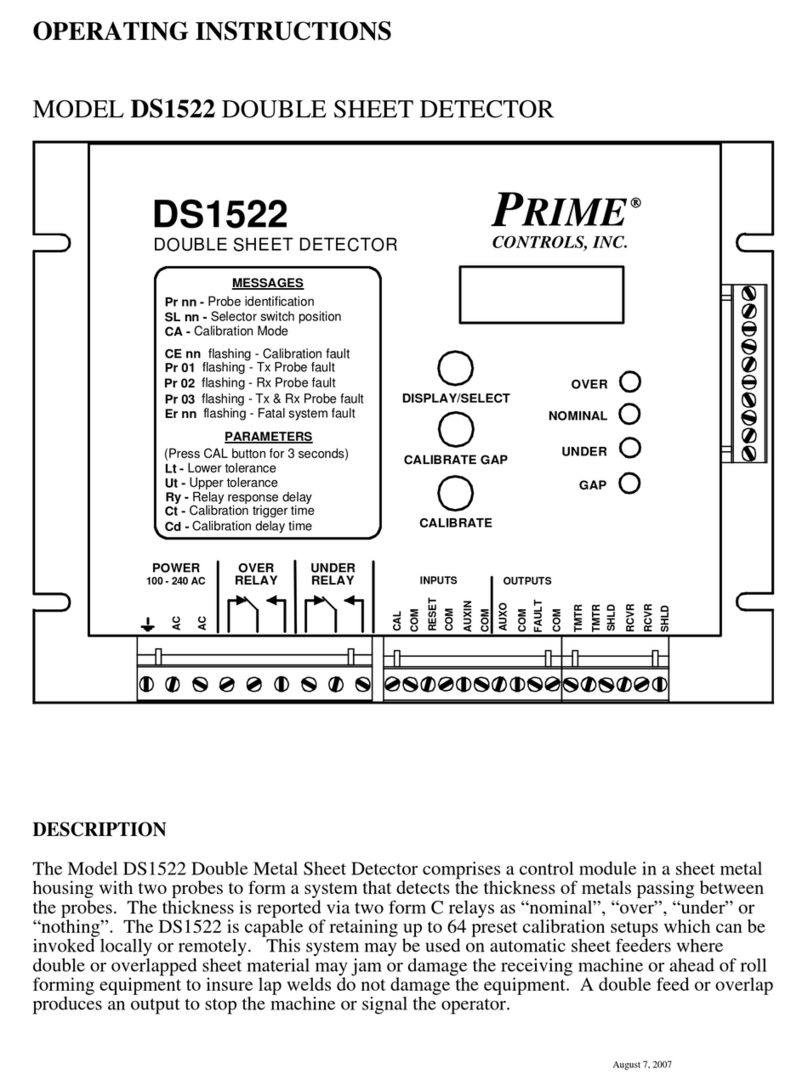

Prime Controls DS1522 User manual

Prime Controls

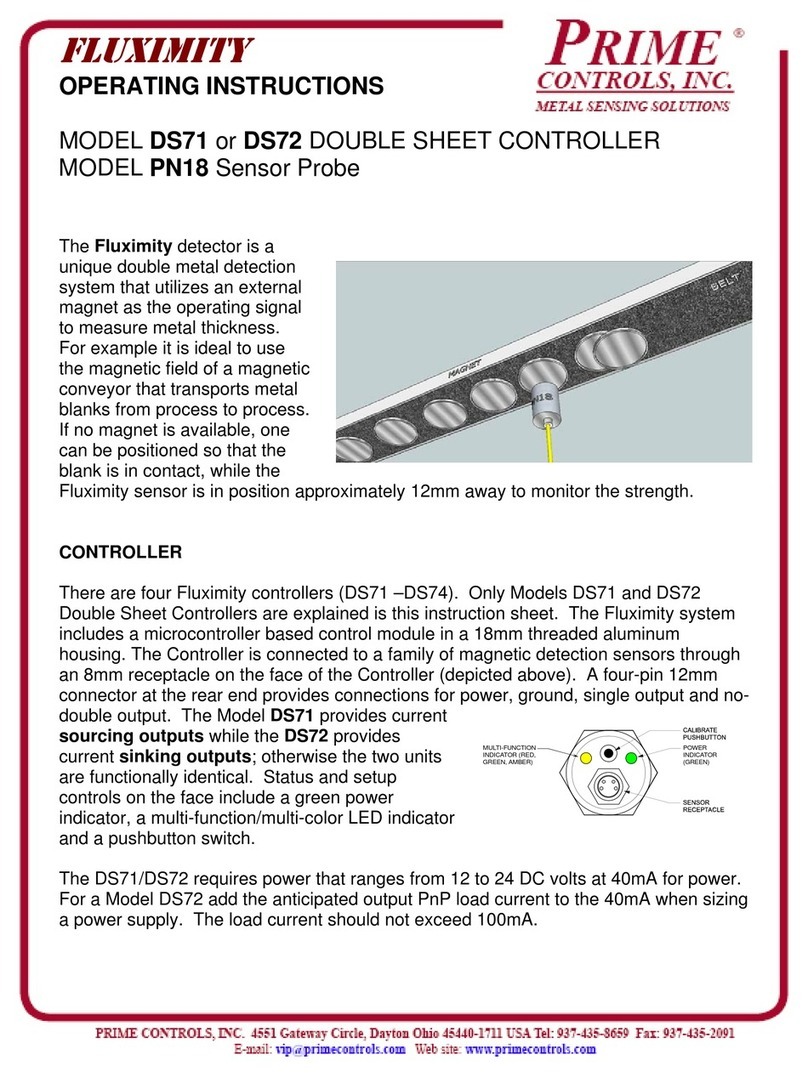

Prime Controls FLUXIMITY DS71 User manual

Prime Controls

Prime Controls LH200H User manual

Prime Controls

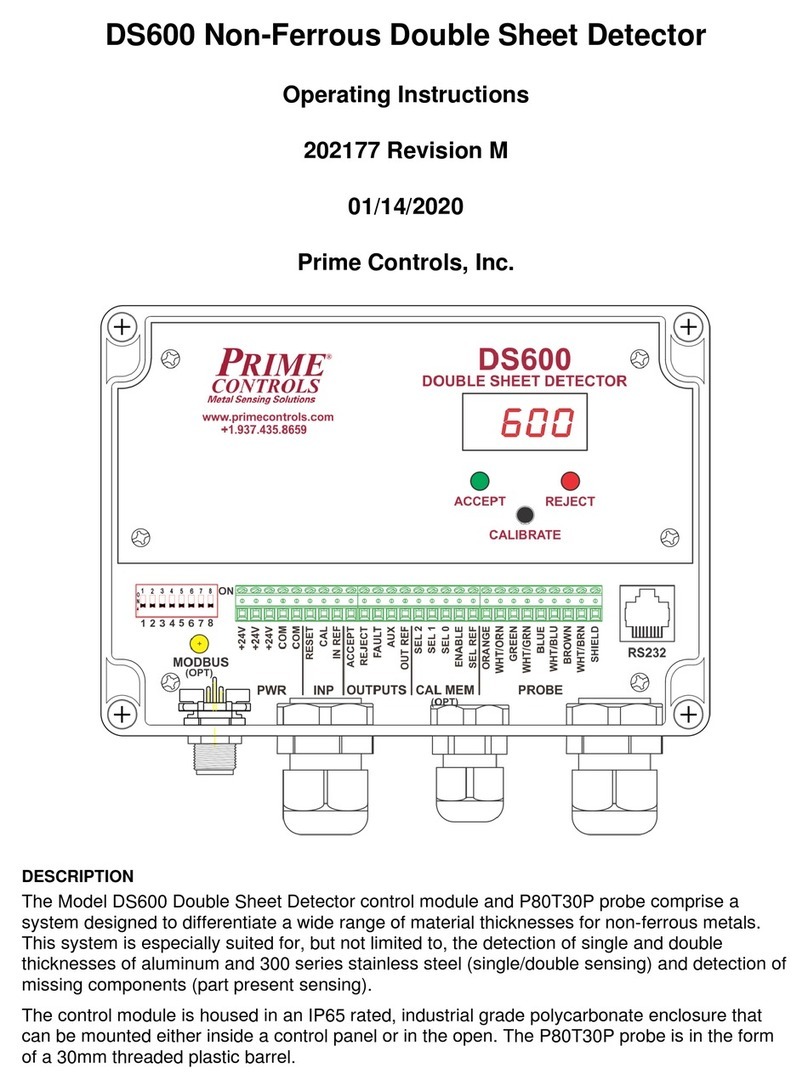

Prime Controls DS600 User manual

Prime Controls

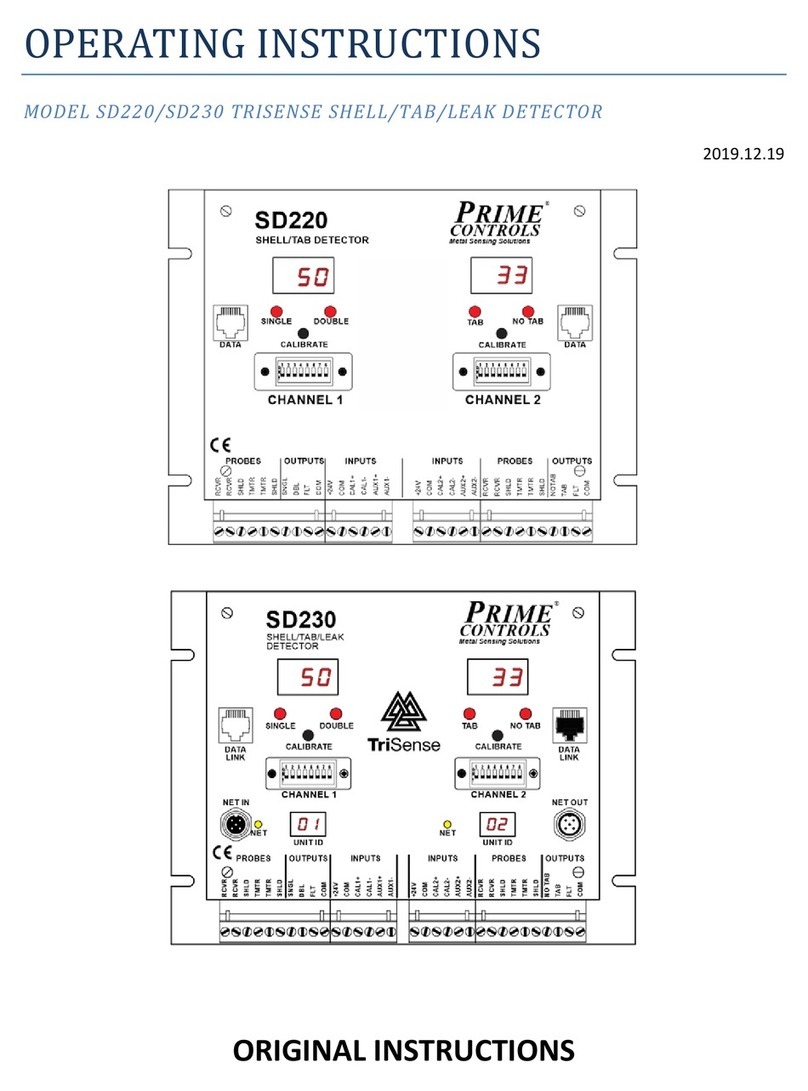

Prime Controls SD220 User manual

Prime Controls

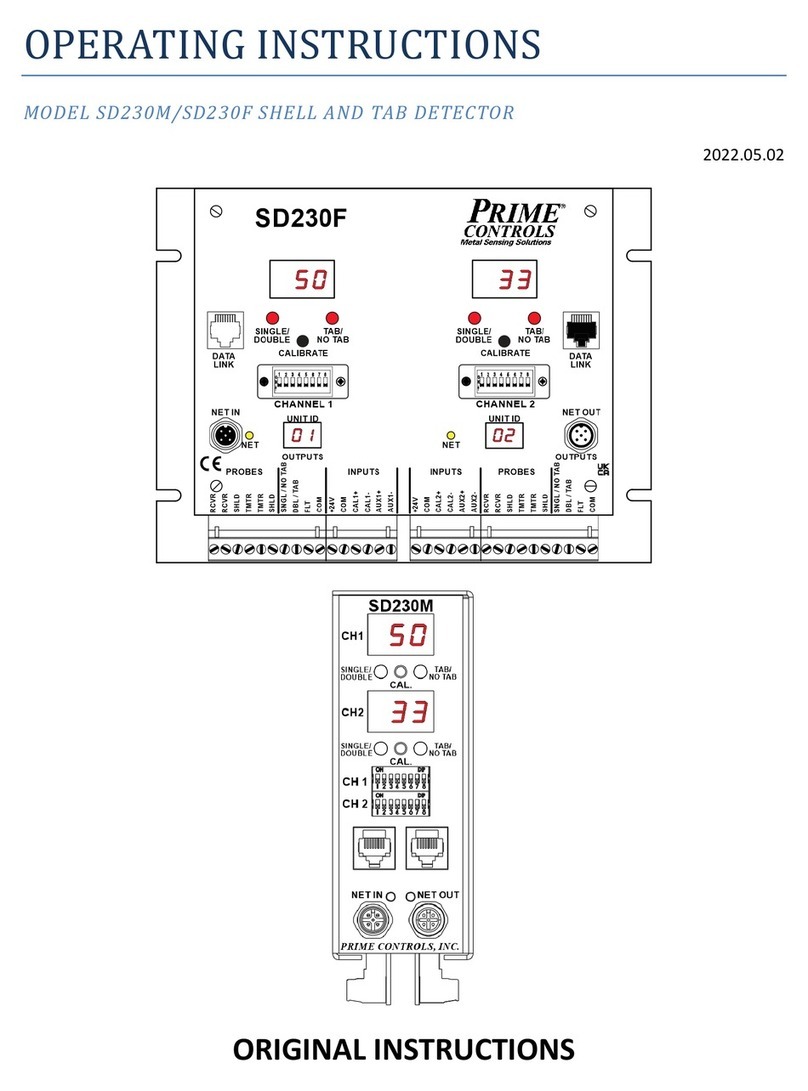

Prime Controls SD230M User manual

Prime Controls

Prime Controls SD220 User manual

Prime Controls

Prime Controls DS1510 User manual