1

DESCRIPTION

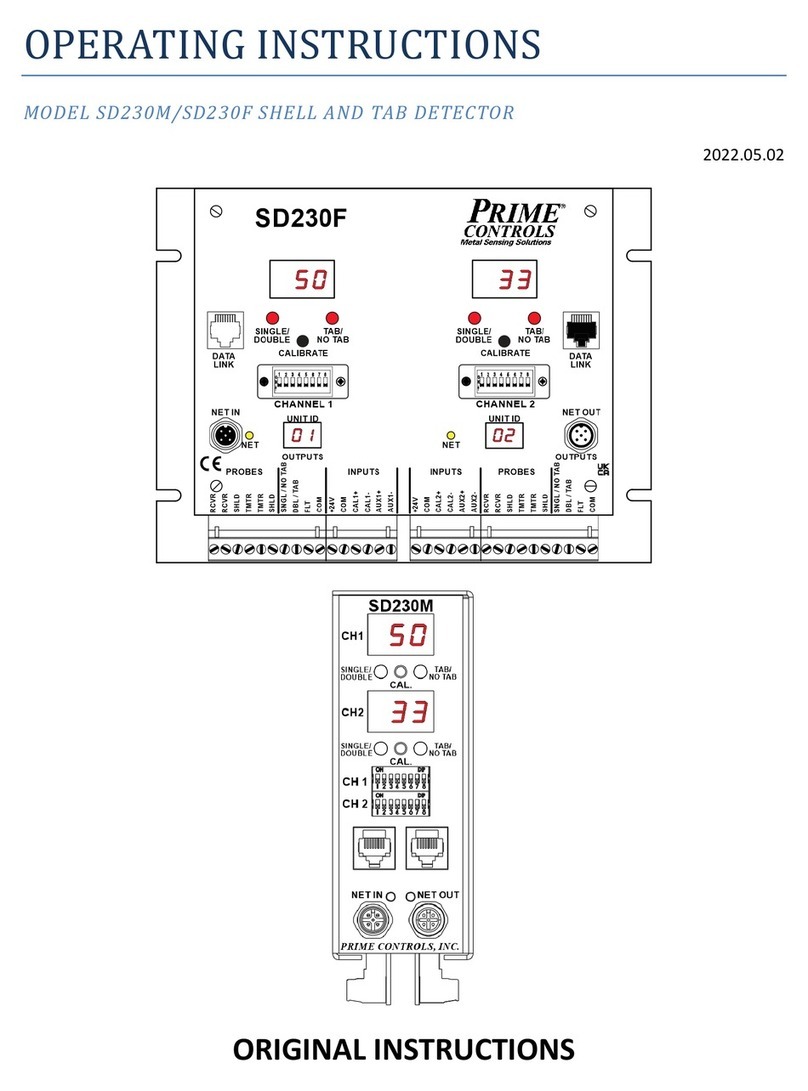

The SD220 Double Shell/Missing Tab Detector and the SD230 Double Shell/Missing Tab/Leak Detectors

for conversion press applications are rugged but sensitive dual channel instruments designed specifically

to detect and report missing blanks or double blanks at the infeed to a conversion press and to detect

and report ends that exit the press without tabs. The SD220 and SD230 units are identical except the

SD230 supports Modbus Networking capability and TriSense functionality.

A complete system for one lane of a press comprises a control module housed in an aluminum enclosure

and four probes. One transmitting and receiving probe pair senses doubles at the press input while the

second transmitting and receiving pair senses the presence or absence of tabs at the press output.

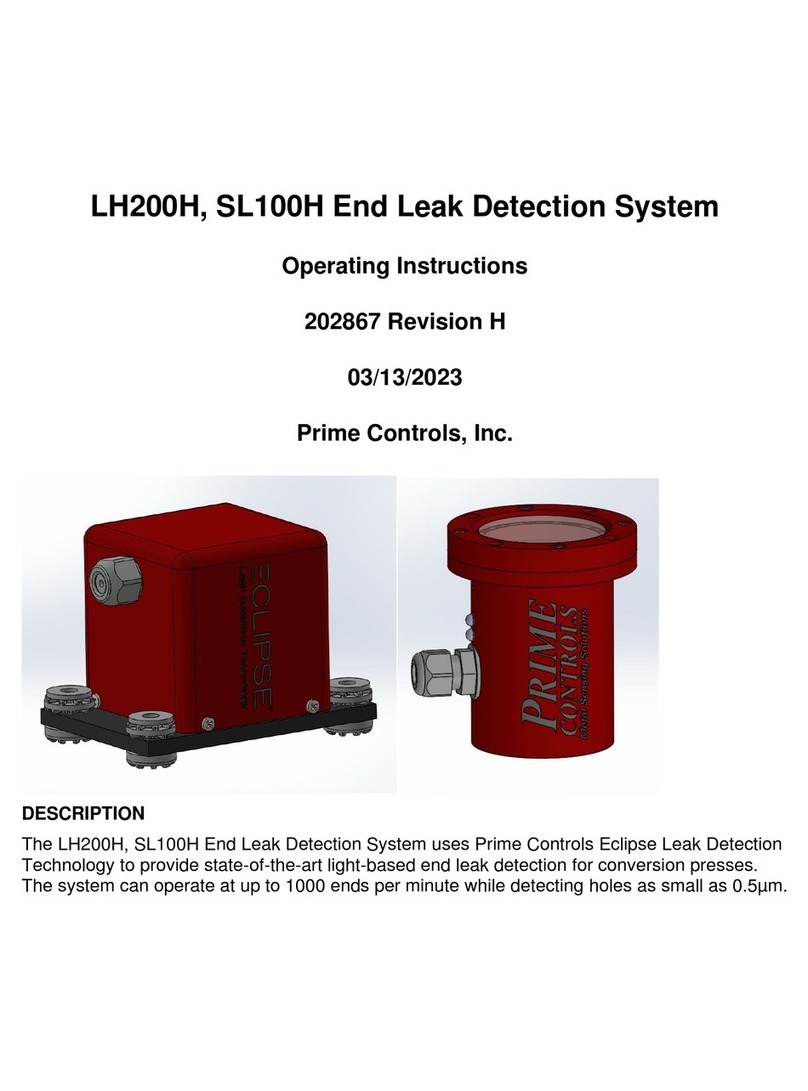

The SD230 when operating in TriSense mode, the controller interfaces to optional LH200 Light Leak

Detector and SL100 LED Strobe Lamp to add leak detection capability to the controller. Status and

configuration data passes through the controller’s Modbus interface through a serial link to the LH200

to provide complete control and monitoring of the Light Leak Detection functionality.

Multiple SD230 units, with or without TriSense functionality may be interconnected through a Modbus

network. See the Modbus Networking section (page 21) for details.

Control Module

The control module allows for fast and easy setup and for quick diagnosis of system errors or problems.

Setup is achieved through the simple press of a push-button switch or an external contact closure. Faults

are reported on digital displays on the control module and through FAULT outputs that may be

connected to a PLC or system controller.

The DOUBLE, SINGLE, NO TAB, TAB and FLT (fault) outputs may be switch selected as sinking or sourcing

drivers. An eight position DIP switch, accessible on the front panel, allows the installer to select a

number of operational options as described in the installation section of this document.

The AUX inputs provide a means to switch between two different setups, such as sensing steel shells

and sensing aluminum shells, without recalibrating or changing the DIP switch settings. This input may

also be used in TriSense mode to provide flash detection.

When the unit first powers up, if probes are properly connected, the digital displays indicate the

operational mode of the unit, i.e. whether set up for sensing Aluminum, Steel, or Aluminum on Steel by

displaying the characters “Al”, “St” or “AS” for a period of approximately two seconds. Which mode

comes up is determined by the setup of the unit through the DIP switches and the state of the AUX

input. See setup (page 6)later in this document.

Calibrate Pushbutton Operation

The push-button switches on the front panel of the control module serve to initiate the calibration

process and to make adjustments for system setup including: set the TriSense mode (tr) (SD230 only),