Printed in USA 12/09 © 2009 4 398-513revA-EN

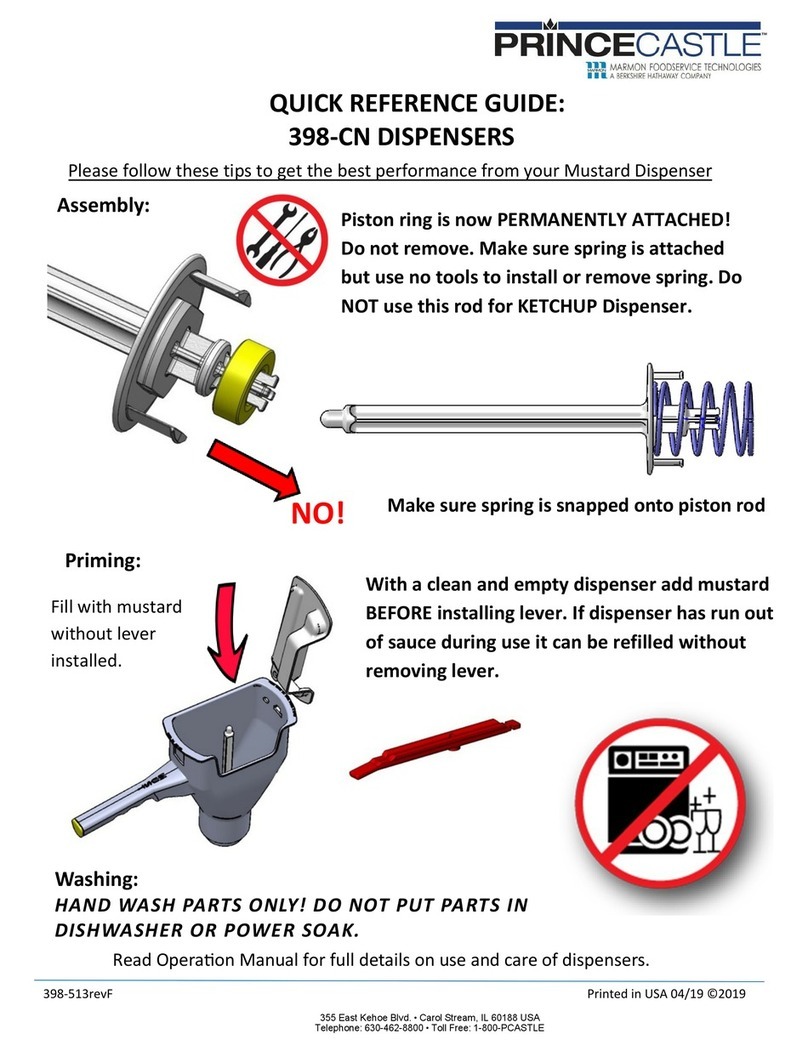

Mustard Dispenser

Model No. 398-CN

Empty mustard from dispenser and discard.

1

Fill dispenser with warm water. Repeatedly press

actuating lever to pump water and flush out dispenser.

2

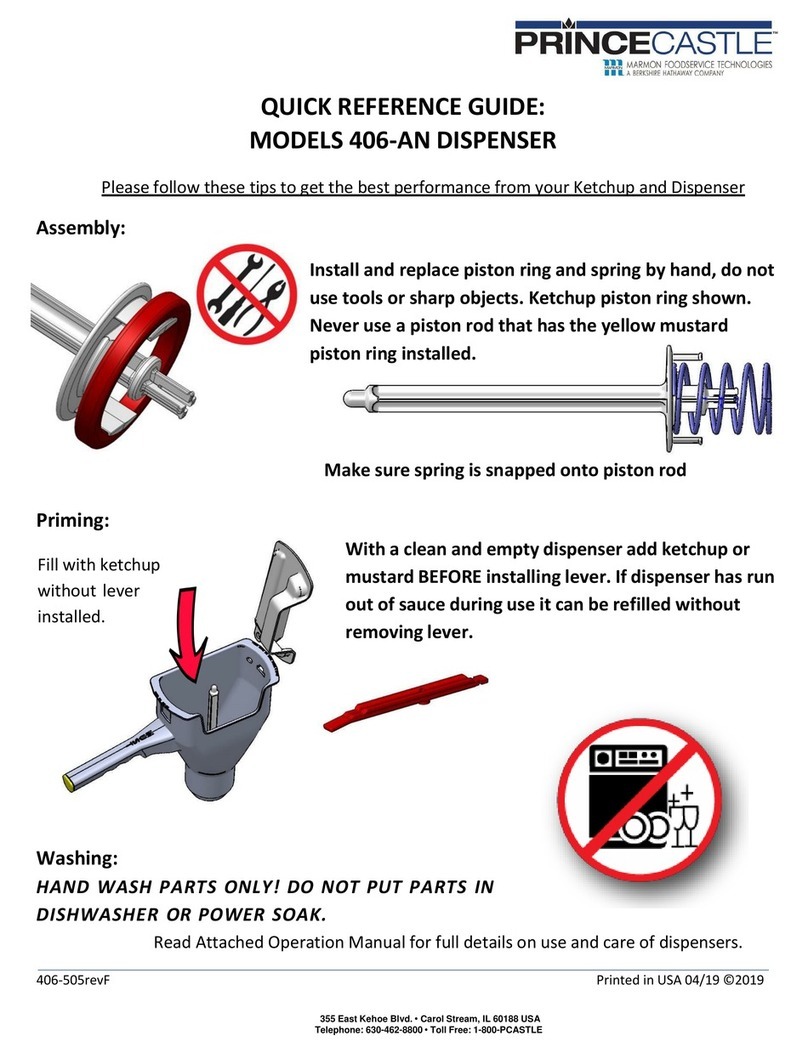

Remove internal parts

from container by

pushing down on the

lever and the piston push

rod. Slide the lever out of

the “T” shaped hole in

the container. Remove

the adjusting cam.

Lift the push rod and the spring assembly straight up

and out of the container.

4

Separate all internal parts to clean thoroughly. Wash

the container and all loose internal parts in a solution of

warm water and All Purpose Concentrate (APC)

(HCS).

5

Rinse all loose parts and the container with running

water.

6

Sanitize dispenser. Use 1 packet of Sanitizer (HCS) to

2-1/2 gallons (8.5 l) of warm water.

7

Let air dry.

Note: Do not reassemble dispenser until it is ready to

be used the next day.

8

PROBLEM PROBABLE CAUSE SOLUTION

Will not dispense Plastic parts broken. Replace broken parts.

Not assembled properly. Assemble properly.

Not primed. See Setup procedure.

Parts missing. Check for proper assembly and placement.

Does not dispense full portion. Out of calibration. Re-calibrate. (See Calibration instructions.)

Mustard pattern is irregular. Diffuser holes plugged in bottom of container. Disassemble and clean diffuser holes by flushing

water through holes.

Does not dispense correct

amount and mustard drips from

dispenser after each shot.

Air pocket in piston spring and cylinder area. Remove lever and cam, gently pull piston push rod

and assembly parts from mustard to release trapped

air. Reassemble. (See Setup.)

Mustard collects on bottom of

dispenser. Bottom of dispenser has made contact with

bun. Wipe off bottom of dispenser with damp cloth.

Ordering/Service Information

WHERE AND HOW TO ORDER REPLACEMENT

PARTS

To order replacement parts, look on the back of your

Prince Castle Price List for the name and phone number

of your local Prince Castle Service Center. You may also

call Prince Castle at 1-800-323-2930 (or fax us at

630-462-1460) for the name of your local service center.

1

PARTS RETURNS

To return parts to your service center for credit, you

must obtain authorization from your center.

Note: All warranty situations should be handled by

your center.

2

PRICES

A. All prices are F.O.B. Prince Castle Service Center

or F.O.B. factory, Carol Stream, Illinois.

B. All prices are subject to change without notice.

These prices are exclusive of all sales taxes or any

special taxes which may be levied by federal,state,

or city governments.

OUTSIDE THE U.S.

Contact your kitchen equipment supplier or designated

repair facility for parts and service.

NON-SCHEDULED MAINTENANCE

Not applicable.

3