Probewell MT-1/WT3 User manual

MT-1/WT3

USER GUIDE

HIGH ACCURACY THREE-PHASE

WIRELESS WATTHOUR METER TESTER

MT-1/WT3

User Guide

Version 2.2 –October 2020

IT IS ESSENTIAL THAT THIS INSTRUCTION BOOK BE READ THOROUGHLY BEFORE

PUTTING THIS PRODUCT INTO SERVICE.

© Copyright 2020 by Probewell Lab Inc. Printed in Canada.

All rights reserved, including those to reproduce this manual or parts thereof, in any form

without the express written permission of Probewell Lab Inc.

Probewell Lab Inc.

Page •2

Limited Warranty

Your MT-1/WT3 comes with a two-year hardware warranty. Probewell Lab Inc.

(Probewell) warrants this MT-1/WT3 against defects in material and workmanship

for a period of two (2) years from the date of purchase from Probewell. This warranty

applies only to the original purchaser of the MT-1/WT3 and is not transferable.

All accessories come with a two-year hardware warranty. Probewell warrants all

accessories against defects in material and workmanship for a period of two (2) years

from the date of purchase from Probewell. This warranty applies only to the original

purchaser and is not transferable.

This warranty does not cover any damage caused neither by negligence, non-

authorized modifications, or parts installed without prior written permission from

Probewell.

This warranty does not apply if the product has been damaged by accident, abuse,

misuse, or misapplication, nor as a result of service to the product by anyone other

than Probewell.

PROBEWELL IS NOT RESPONSIBLE FOR ANY LOST PROFITS, LOST SAVINGS OR OTHER

INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE, OR INABILITY

TO USE, OF THIS PRODUCT. THIS INCLUDES DAMAGE TO PROPERTY AND DAMAGES

FOR PERSONAL INJURY. THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES

INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

Disclaimer

Probewell Lab Inc., (Probewell) reserves the right to make changes to this document

and the products which it describes without notice. Probewell shall not be liable for

technical or editorial errors or omissions made herein; nor for incidental or

consequential damages resulting from the furnishing, performance, or use of this

material.

Features and specifications are subject to change without notice.

MT-1/WT3 User Guide

Page • 3

Table of contents

Introduction............................................................................................................... 7

MT-1/WT3 Overview ............................................................................................. 7

Description ................................................................................................................ 9

MT-1/WT3 Socket.................................................................................................. 9

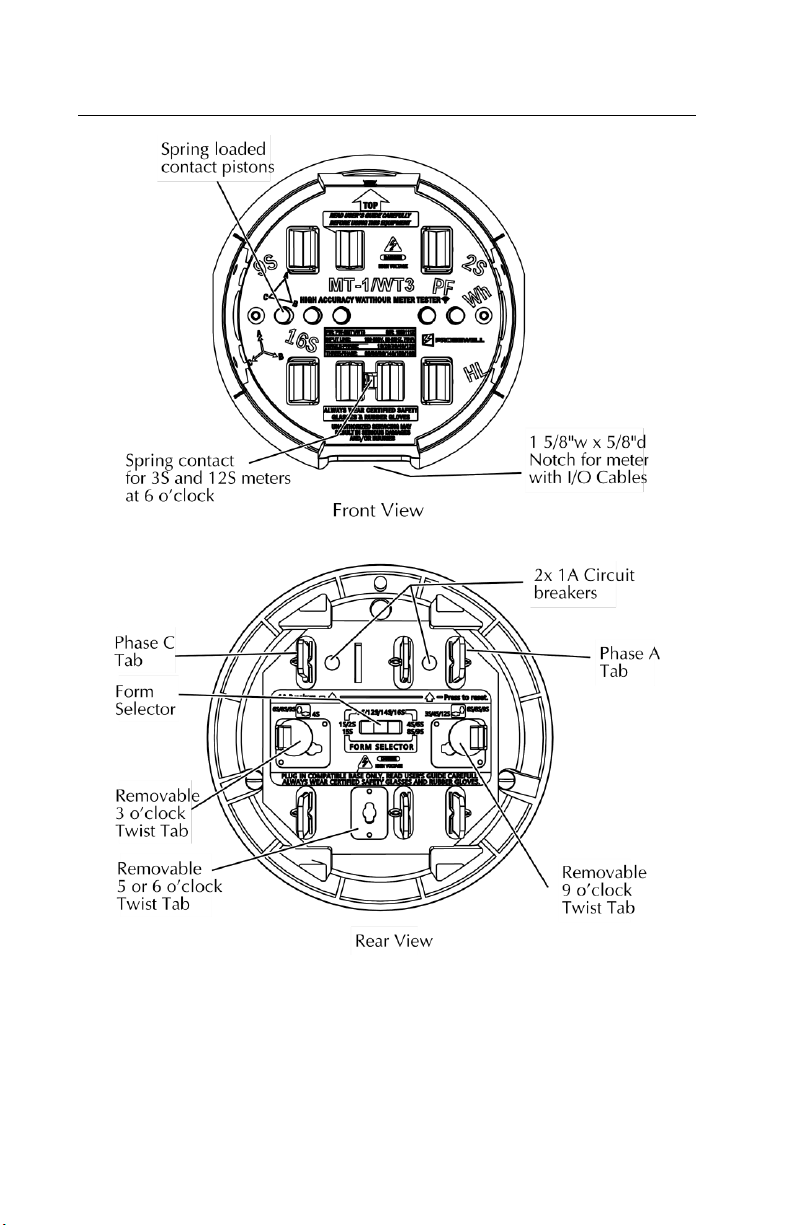

Front/Rear View of the Socket ........................................................................ 10

Side View of the Socket ................................................................................... 11

Functioning Theory.............................................................................................. 13

Meter Testing .................................................................................................. 15

Accessories .......................................................................................................... 17

Metercam ........................................................................................................ 17

Optical Pickup.................................................................................................. 18

Meter Adapters ............................................................................................... 19

Operations............................................................................................................... 21

Summary.............................................................................................................. 22

Installation of the Socket..................................................................................... 23

Connecting to the MT-1/WT3.............................................................................. 25

Running the application....................................................................................... 25

Tests available ..................................................................................................... 26

Test Examples...................................................................................................... 27

Example 1: Quick Test - Solid-state 9S meter .................................................. 28

Example 2: Custom Test - Solid-state 9S meter............................................... 30

Example 3: Tracking Test - 12S(N) meter......................................................... 31

Example 4: Custom Test - 2S electromechanical meter................................... 33

Example 5: kW Demand Test –Electromechanical 14S meter ........................ 35

Example 6: Full Test –Solid-state 8S Fitzall meter........................................... 37

Example 7: Four-Quadrant Test –Solid-state 9S meter................................... 39

Example 8: Meter tested in the meter shop.................................................... 41

Appendix A

Specifications........................................................................................................... 43

Appendix B

Compatible Meter Forms......................................................................................... 47

Form 1S................................................................................................................ 48

Form 2S................................................................................................................ 49

Form 3S................................................................................................................ 50

Form 4S................................................................................................................ 51

Form 5S, 35S & 45S Fitzalltm (3 2CT).................................................................. 52

Form 5S, 35S & 45S Fitzalltm (3 2CT 2PT) ........................................................... 53

Form 5S, 35S & 45S Fitzalltm (N 2CT).................................................................... 54

Form 5S, 35S & 45S Fitzalltm (N 2CT 2PT) ............................................................. 55

Form 5S, 35S & 45S Fitzalltm (Y 3CT)..................................................................... 56

Form 5S, 35S & 45S Fitzalltm (Y 3CT 2PT).............................................................. 57

Form 5S, 35S & 45S Fitzalltm (Y 2CT)..................................................................... 58

Form 5S, 35S & 45S Fitzalltm (Y 3CT 2PT).............................................................. 59

Probewell Lab Inc.

Page •4

Form 5S, 35S & 45S Fitzalltm (4 3CT 2PT) ........................................................... 60

Form 5S, 35S & 45S Fitzalltm (4 3CT).................................................................. 61

Form 6S (36S, 46S) (Y 3CT)................................................................................... 62

Form 6S (36S, 46S) (Y 3CT 2PT)............................................................................ 63

Form 6S (36S, 46S) Fitzalltm (Y 3CT)...................................................................... 64

Form 6S (36S, 46S) Fitzalltm (Y 3CT 2PT)............................................................... 65

Form 8S (4 3CT)................................................................................................. 66

Form 9S (4 3CT)................................................................................................ 67

Form 9S (Y 3CT) ................................................................................................... 68

Form 9S (Y 3CT 3PT)............................................................................................. 69

Form 12S (25S) (3N)............................................................................................. 70

Form 12S (25S) (3)............................................................................................. 71

Form 14S (4Y)s..................................................................................................... 72

Form 15S (4)...................................................................................................... 73

Form 16S (4Y) ...................................................................................................... 74

Appendix C

Form Configurations................................................................................................ 75

Appendix D

Troubleshooting ...................................................................................................... 77

Appendix E

Parameters for Data Logging Option....................................................................... 79

Appendix F

Customer Service..................................................................................................... 81

Appendix G

Recommendations................................................................................................... 83

MT-1/WT3 User Guide

Page • 5

List of Abbreviations

Abbreviation

Complete Term

A

Ampere

Amp

Ampere

AC

Alternating Current

AP

Access Point

ATK

Accuracy Testing Kit

CFM

Cubic feet per minute

CL

Class

CSV

Comma Separated Value

CT

Current Transformer

DSP

Digital Signal Processor

HL

High Load (Full Load)

Kh

Watthour constant. The number of watthours represented by

one revolution of the disk. Also, called disk constant.

Kt

Test constant. For electronic (no disk) meter, the amount of

energy represented by each calibrated pulse of the LED.

kW

Kilowatt

Lb

Pound

LL

Light Load

NIST

National Institute of Standard and Technology

PF

Power Factor

PPI

Pore per inch

Rev

Revolution, number of revolutions

RMS

Root mean square

TA

Test Ampere

THD

Total Harmonic Distortion

V

Volt

VA

Volt-Ampere

VAC

Volt Alternating Current

VARh

VARhour (Volt Ampere Reactive Hour)

Vdc

Voltage direct current

VT

Voltage Transformer

W

Watt

Probewell Lab Inc.

Page •6

Abbreviation

Complete Term

Wh

Watthour

WiFi

Wireless Fidelity

WLAN

Wireless Local Area Network

WWW

World Wide Web

µWh

Micro-Watthour

µVARh

Micro-VARhour

MT-1/WT3 User Guide

Page • 7

Chapter 1

Introduction

The Probewell Lab MT-1/WT3 is a portable three-phase meter tester with built-in

WiFi technology.

MT-1/WT3 Overview

The MT-1/WT3 test socket adapter weighs only 6.4 lb which makes it the ideal tool

for field testing. Within a few minutes, a residential, commercial or industrial

electricity meter can be accurately tested on site by meter shop technicians.

The MT-1/WT3 can be set to test all three phases simultaneously in one step (Quick

Test) or set to do the three phases simultaneously followed by each element

separately (Full Test). The MT-1/WT3 provides measurements for active and reactive

energy with forward and reverse flow testing capability.

The MT-1/WT3 has a built-in three-phase phantom load made of synthesized 50A

current sources and a three-phase electronic standard with a typical accuracy of

±0.02% and a guaranteed accuracy of ±0.05%. It comes with a complete calibration

report certifying measurement accuracy across its entire operating range.

The MT-1/WT3 comes with a shock resistant carrying bag. The bag has individual

compartments for the test socket, the pickups and the User's Guide. There is also

enough space for small accessories such as the magnetic adapter for the optical

pickup, seals, pliers, etc.

Optional: A handheld remote is available for the MT-1/WT3, having a keypad and an

LCD display and weighing only 0.6 lb.

Probewell Lab Inc.

Page •8

MT-1/WT3 User Guide

Page • 9

Chapter 2

Description

The first part of this chapter describes the MT-1/WT3 socket. The second part

explains the functioning theory of the tester.

MT-1/WT3 Socket

The MT-1/WT3 socket is cylinder-shaped, designed to be easily inserted in both

ringless and ring-type meter bases. A latch with a quick release mechanism is

available as an option for ring-type meter bases.

The socket contains three 50A synthesized AC current sources to simulate resistive

and reactive loads, a high accuracy three-phase electronic standard and a WiFi

communication controller.

The rear of the socket has six standard fixed tabs with bypasses and two removable

twist-tabs, with twist and lock mechanism. The socket obtains its power directly from

these back tabs and accepts an input voltage from 100 to 600VAC.

The twist-tabs can be placed at 3, 5, 6 and 9 o'clock position as required by the meter

base where the test is conducted. The twist-tab at 3 o'clock can be inserted at two

different positions to hold either forms 6S, 8S, 9S or form 4S. The twist-tab at 9

o'clock can be inserted at two different positions to hold either forms 6S, 8S, 9S or

forms 3S, 4S, 12S. One of the twist-tab can be positioned at 5 o'clock for some 3S or

12S meter bases or positioned at 6 o'clock for 14S, 15S, 16S meter bases. See

Appendix C for all twist-tab configurations.

The front of the socket has seven jaws and five spring loaded contact pistons. The

pistons are actuated by the middle lugs of the meter. A spring contact at 6 o'clock is

also provided for 12S meters. The meter under test is entirely controlled by the

socket. No setup wiring is needed.

The socket has a dead front design for safer operation. The front jaws of the socket

become live only when a meter is inserted. See Appendix A for all technical

specifications.

Probewell Lab Inc.

Page •10

Front/Rear View of the Socket

Fig. 2.1 –Front and Rear View of the Socket

Fig. 2.1 shows the removable twist-tabs which do not require any tools to be moved

from a position to another. The above illustration shows only the twist-tab

positioned at 3 and 9 o’clock.

MT-1/WT3 User Guide

Page • 11

Side View of the Socket

Fig. 2.2 –Side View of the Socket

Probewell Lab Inc.

Page •12

Identification

Description

Rear Tabs

The rear tabs connect the socket to the front jaws of the

meter base. The socket gets its power directly from the

meter base (100-600VAC) circuit. The service current

shorting bars (bypasses) are rated for high capacity

amperage.

Removable Tabs

These tabs can be positioned at 3, 5, 6, or 9 o'clock

position as required by the meter base where the test is

conducted. See Appendix C.

Form Selector

In position 1S, 2S, and 15S, the unit is powered from the

two upper tabs. In position 3S, 12S, 14S and 16S, the unit

is powered from the Phase C and the neutral tab. In

position 4S, 6S, 8S and 9S the unit is powered from the 3

and 9 o'clock tabs.

Circuit Breakers

Protection for the MT-1/WT3 and the meter. Two circuit

1A breakers which can be reset by pressing a spring-

loaded button.

Power Switch

Socket's main power on/off switch.

Front Jaws

The front jaws are controlled by internal relays allowing

to test meters. The front jaws become live only when a

meter is inserted. The voltage on the front jaws is current

limited for additional protection.

Pistons

These are actuated by the small lugs on the back of the

meter when inserted for testing.

I/O Connector

Isolated full-duplex communication port. It also provides

an isolated and current limited low voltage supply for the

accessories (optical pickup and metercam) and the

optional handheld remote control.

QR Code Sticker

The QR code sticker contains the access point

information to be scanned for a mobile device as well as

the MAC address.

LED

Socket Status Indicator.

Magnetic Switch

Switch for any manual entry using a magnet.

Air Vent(1)

Warm air exit. A 5 CFM miniature fan forces air

circulation inside the socket.

Air Inlet(1)

Cool air input. Filtered through polyurethane foam filter.

(1) Do not block air circulation. Keep away from direct heat or flame.

MT-1/WT3 User Guide

Page • 13

Functioning Theory

MT-1/WT3 applies a load to the meter under test, then measures exactly the

quantity of energy that passes through the meter. After a predetermined number of

disk revolutions, or a minimum time in the case of a solid-state meter, the test will

end, and the application (Probewell Connect) will display the difference between the

meter and the MT-1/WT3's internal electronic standard.

Current Applied to the Meter

The current applied to the meter under test is achieved by three independents built-

in 50A synthesized AC current sources. The current level is adjustable and regulated.

The current sources allow to simulate loads at unity and 0.5 lagging power factor.

They are isolated and form three independent current loads in closed-link

arrangement. This configuration allows to check a meter without the need to open

the potential link of the meter and no wiring setup is necessary.

Voltage Applied to the Meter

The voltage applied to the front jaws is derived from the meter base circuit. For

safety reasons, the voltage is applied to the front jaws only when a meter is inserted.

The voltage is also current limited.

The front jaws of the MT-1/WT3 are controlled by internal relays allowing to test

self-contained and CT rated three-phase and single-phase watthour meter form

configurations without wiring setup.

Built-in Electronic Standard

The built-in electronic standard in the MT-1/WT3 has an exceptional accuracy thanks

to the use of electronic transducers developed by Probewell. These transducers have

an exceptional long-term stability and linearity and are not affected by temperature.

The electronic standard does not contain any potentiometers or other types of screw

adjustment that could become unstable with time. It uses digital technology to

ensure a maximum of reliability over time. A DSP processor measures and calculates

the exact energy, active or reactive, that passes through the meter. This technology

has the advantage of obtaining a more compact and lightweight electronic standard

while minimizing electronic components.

Accuracy Test

The MT-1/WT3's electronic standard is calibrated using a primary standard traceable

to NIST and comes with a complete calibration report certifying measurement

accuracy on both Wh and VARh scales over its entire operating range. Accuracy test

on MT-1/WT3 can be done in your own laboratory using:

Probewell Lab Inc.

Page •14

•An electronic reference standard traceable to NIST. The electronic

standard must have at least 1 isolated current input port of a minimum

capacity of 50A with auto ranging capability and a typical precision of

0.01% or better;

•A laboratory stabilized and isolated AC power source with fundamental

waveform selectable 120V or 240V, 60Hz, rated at least 150VA;

•The Accuracy Test Kit (ATK-3) for three-phase testers.

For more information on socket accuracy test please refer to the ATK and Probewell

Connect for WT series documentations.

MT-1/WT3 User Guide

Page • 15

Meter Testing

Tests performed with a pickup accessory (Optical or Metercam)

Five different tests can be done with optical pickups: Quick, Full, Custom, Four-

Quadrant (WH) and Four-Quadrant (VARH) Test.

Quick Test, Full Test, Four-Quadrant (WH) and Four-Quadrant (VARH) Test are made

up of a predetermined sequence of consecutive steps and tests, all of which are done

in one operation. The sequence is programmable and can be modified through the

Settings tab. By default, the sequence includes one test point with each of the loads:

HL, PF and LL.

In Quick Test,the three phases (ABC) are tested simultaneously in one step.

In Full Test,a Quick Test is performed followed by each phase separately (A, B, and

C). In the Settings tab, there is an option to remove the PF and/or LL for each single

element test.

In Four-Quadrant (WH) Test, the equivalent of a Quick Test is done at various phase

lags between Voltage and Current. This is meant to test the operation of the meter

in all four quadrants of the power vector diagram. For this test, the device expects

the meter to pulse on WH units.

In Four-Quadrant (VARH)Test, the equivalent of a Quick Test is done at various phase

lags between Voltage and Current. This is meant to test the operation of the meter

in all four quadrants of the power vector diagram. For this test, the device expects

the meter to pulse on VARH units.

Please note that with single-phase meters, only the Quick Test, Four-Quadrant (WH)

and Four-Quadrant (VARH) test will be activated as there is no Full Test for single-

phase meters.

Custom Test consists in choosing one of the three loads to apply to the meter: HL, PF

or LL. The disk revolutions or pulses are counted automatically by the pickup. No

critical timing is required to start a test. The test ends automatically.

When testing a three-phase meter, you can also choose to apply the load on all

phases (ABC) at the same time or on each phase individually (A, B or C). The phase

selection is done by selecting the appropriate phase (A, B, C, or A+B+C) in the Select

Active Phase drop down window.

Tests performed without a pickup accessory (Optical or Metercam)

Manual Test is used when the operator counts the disk revolutions manually. A

magnet is used to start and end the test manually by applying it to the side of the

socket (see figure 2.2). The operator can set his own parameters for conducting a

test, such as the number of revolutions and the load to be applied. The load can be

switched dynamically during the test.

Probewell Lab Inc.

Page •16

Please note that without the help of a pickup, if the operator signals the start or the

end of a test too soon or too late using the magnet (magnetic switch), the number

of disk revolutions (a whole number without fraction) might not be accurate and will

affect the precision of the test.

Tracking Test is like the Manual Test except the socket counts the number of

revolutions and displays them on your wireless device. The count is based on the

selected Kh of the meter and the cumulative watthours recorded by the MT-1/WT3

and not the physical count of the disk revolutions. A magnet can be used to start and

end the test.

kW Demand Test allows the operator to perform a kW demand test and the test is

calculated using the following formula:

kW = kWh x 60/T

Where T = Demand interval length in minutes

Note: With solid-state metering, conducting energy and demand tests may be

considered redundant since they are both results of the same measurement.

Set up the meter for a kW demand test following the manufacturer's instructions.

Please note that the kW demand test method varies between manufacturer's

reference technical guide for instructions.

Line monitor Test analyzes the input voltage to determine statistically the line

voltage, frequency fluctuations and its harmonic content (THD) up to the 32nd order.

KYZTest is used to verify the KYZ or KY meter’s output pulses.

MT-1/WT3 User Guide

Page • 17

Accessories

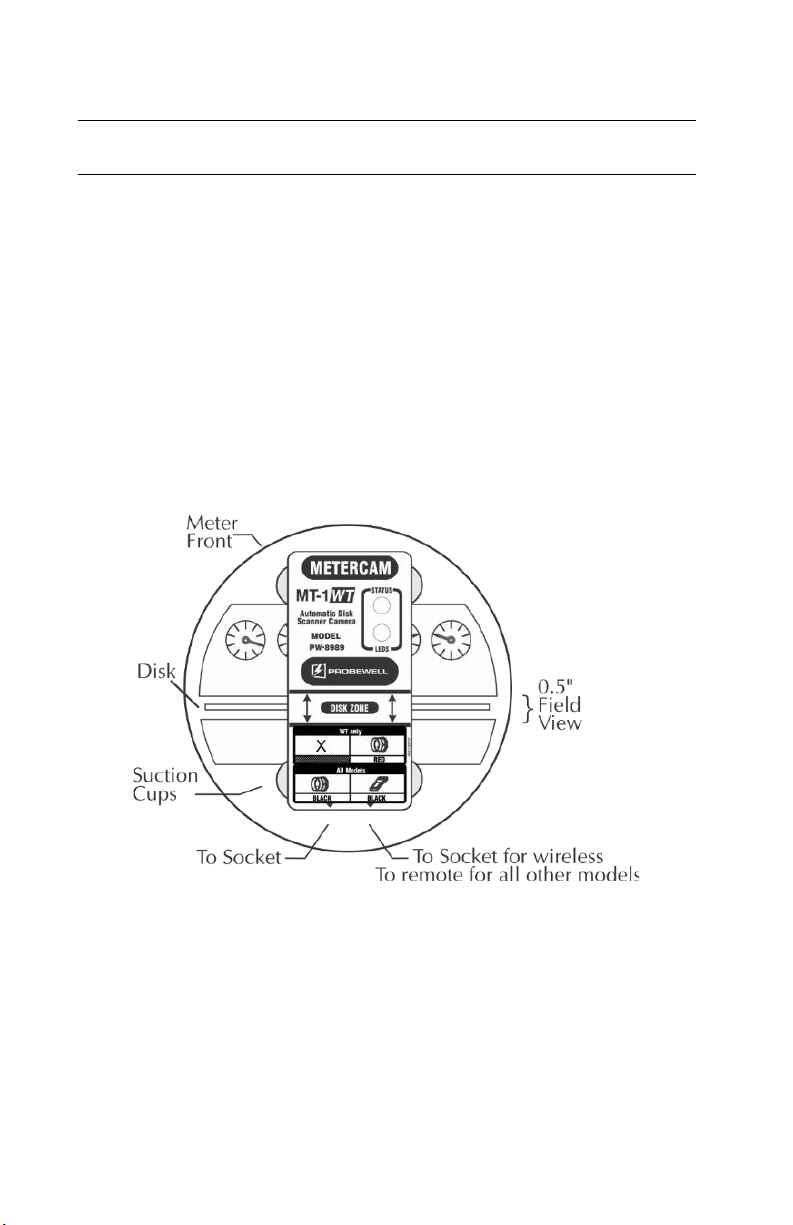

Metercam

The Metercam is used with an electromechanical meter (rotating disk). It is a digital

disk sensor without the many drawbacks found on usual photoelectric sensors, such

as difficulty to align properly and sensitivity to light. With the Metercam, no

alignment is necessary since it detects and picks up the disk by itself. Another feature

is its electronic shutter that makes it insensitive to light variations including bright

sunlight.

The Metercam is built around a miniature digital camera with a ½" field view

combined with a RISC processor that detects the position of the meter disk and locks

automatically on the reference point (black flag).

The Metercam is mounted on four suction cups installed directly on its backside.

For a good and lengthy hold, lightly wet the inside of the suction cups, especially

when field testing in colder weather. Also, keep the inside of the suction cups clean.

Fig. 2.4 –Metercam

Note: For electromechanical meters with a hidden disk, a side-mount Metercam is

available.

Probewell Lab Inc.

Page •18

Optical Pickup

The Optical Pickup is used with solid-state meters. It is mounted with a suction cup

or integrated in a magnetic head that detects infrared light pulses from solid-state

meters. The Optical Pickup uses edge triggering for less sensitivity to changes. On

the top of the head of the pickup, there is a pulse indicator in the form of a visible

red led that flashes when pulses are being received.

Fig. 2.5a –Optical Pickup

Fig. 2.5b –Magnetic Optical Pickup

Adapters

The Focus Adapter is used with the

Optical Pickup for meters with a

protuberant shape over the test pulse.

The Magnetic Adapter is used to install

the suction cup of the Optical Pickup

on meters with a metallic port. Can also

be used a magnet for the magnetic

switch.

MT-1/WT3 User Guide

Page • 19

Meter Adapters

Sensus 3S: This adapter is used to test Sensus’3S meter, without this adapter the

meter will be damaged.

Class 320: This adapter is used to test 4S and 12S meter in a CL320 meter base,

without this adapter the WT3 will not be insertable in the meter base.

Other manuals for MT-1/WT3

1

Table of contents

Other Probewell Test Equipment manuals

Probewell

Probewell ST-3 User manual

Probewell

Probewell MT-1/WT1 User manual

Probewell

Probewell ST-3/XT3 Instruction manual

Probewell

Probewell ATK-3 User manual

Probewell

Probewell MT-1/WT3 User manual

Probewell

Probewell ST-3 Instruction Manual

Probewell

Probewell ST-3 User manual

Probewell

Probewell ST-3/XT3 User manual

Probewell

Probewell ST-3 User manual