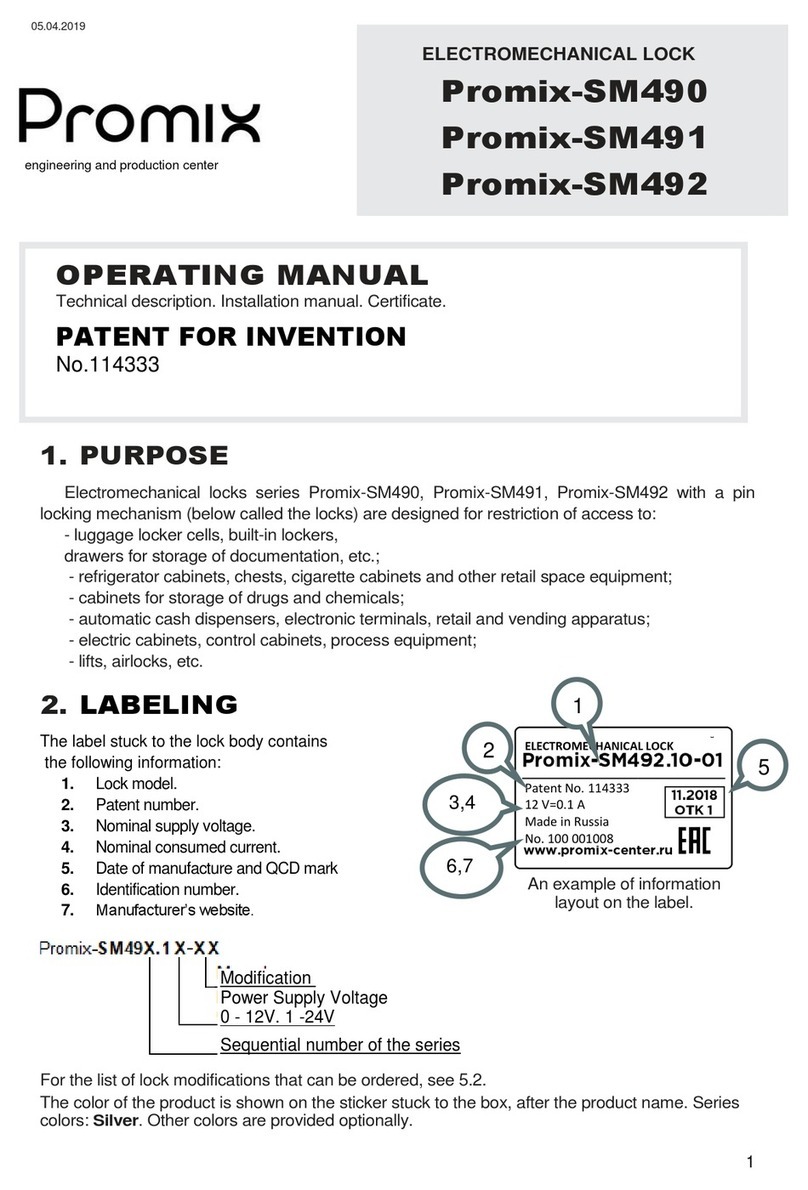

PROMIX SHERIFF-5 User manual

30.08.2017

1

5

2

3

SHERIFF-5

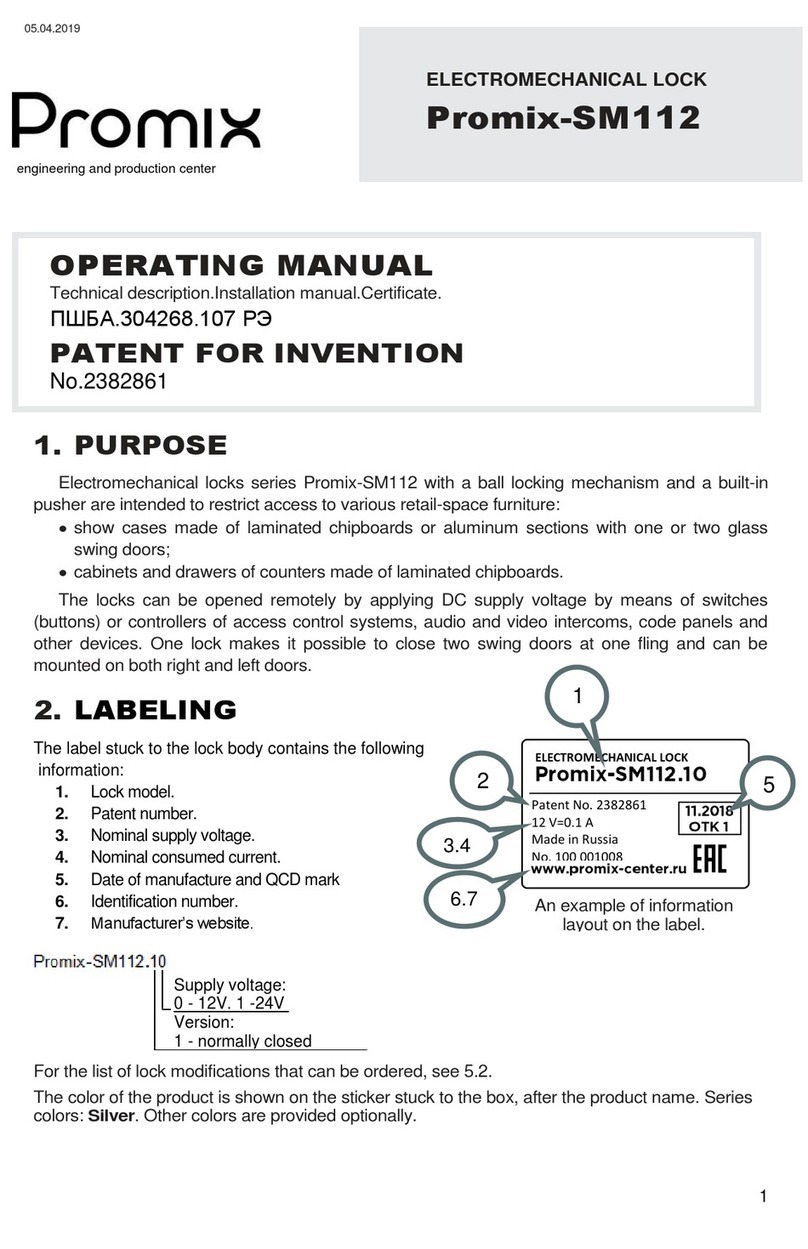

ELECTROMECHANICAL LOCK

FOR PLASTIC DOORS AND WINDOWS

OPERATING MANUAL

TU 3428 – 003 – 80210527 – 14

1. APPLICATION

Electromechanical lock "Sheriff-5" is designed for locking hinged plastic doors and windows, opening inward and outward, with

a possibility of remote opening them with the controllers of access control systems, audio and video door phones, code access

panels. The lock is made in the normally open type (or fail-safe), it is open when the voltage supply is off, and that provides

evacuation during emergencies complied with the power outage. The lock may be installed on doors and windows, both on the right

and the left ones.

2. OPERATING CONDITIONS

Climatic operating conditions:

- ambient air temperature: from -40 to +50°С;

- relative air humidity not more than 95% at +35°Сand with lower temperatures without condensation and frost formation;

- installing indoors in any type of doors;

- resistance to the environmental exposure complies with GOST 15150-69:UHL2.

Operation of the lock at low temperatures is possible when most of the time the lock is open (voltage supply is on).

During the operation, prevent the ingress of water and dust into the lock.

3. DELIVERY SET

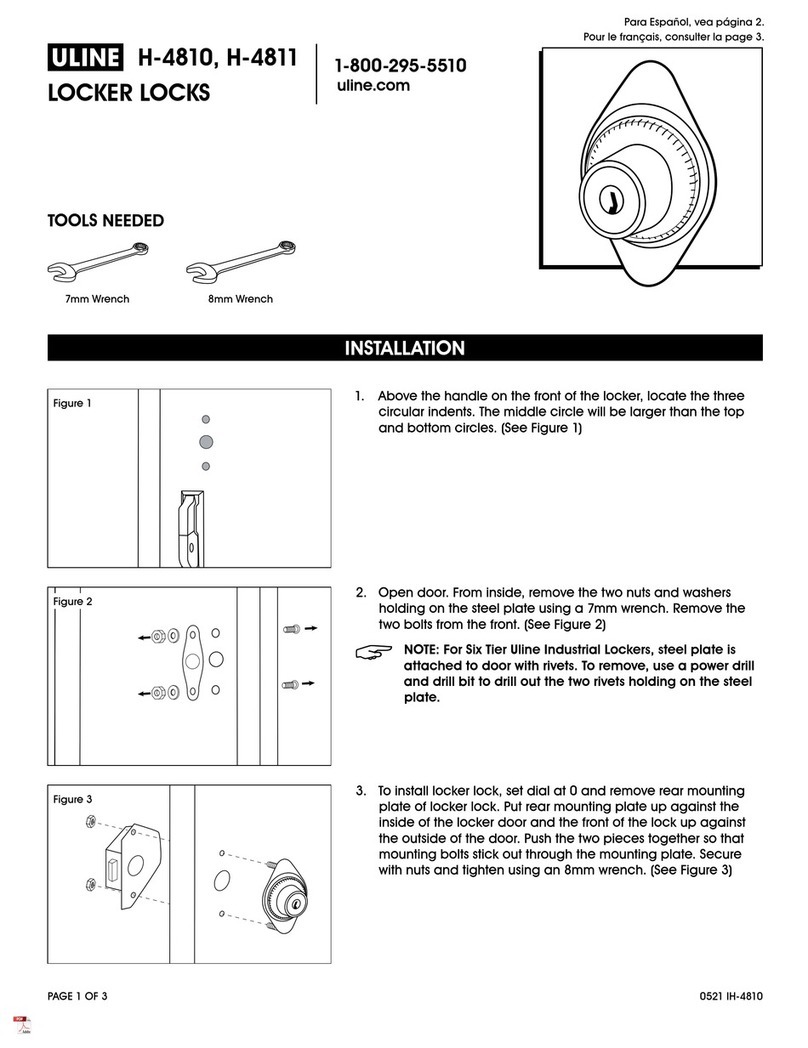

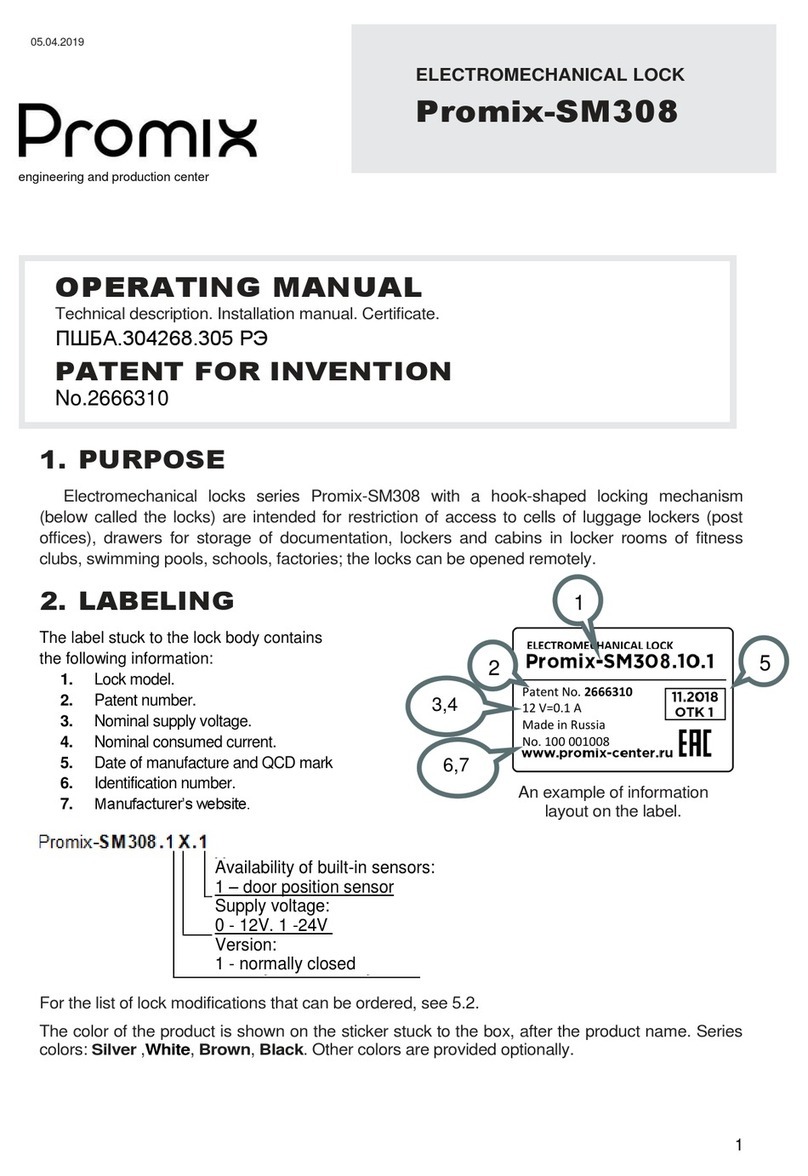

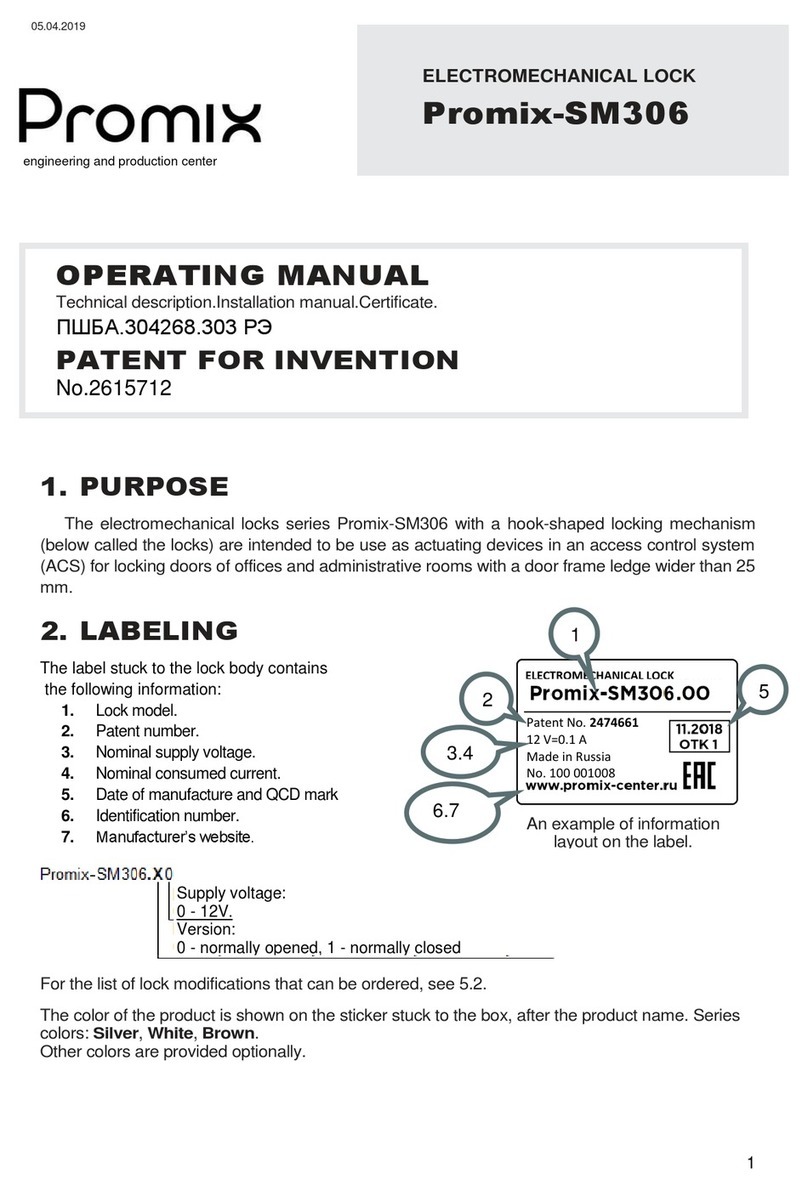

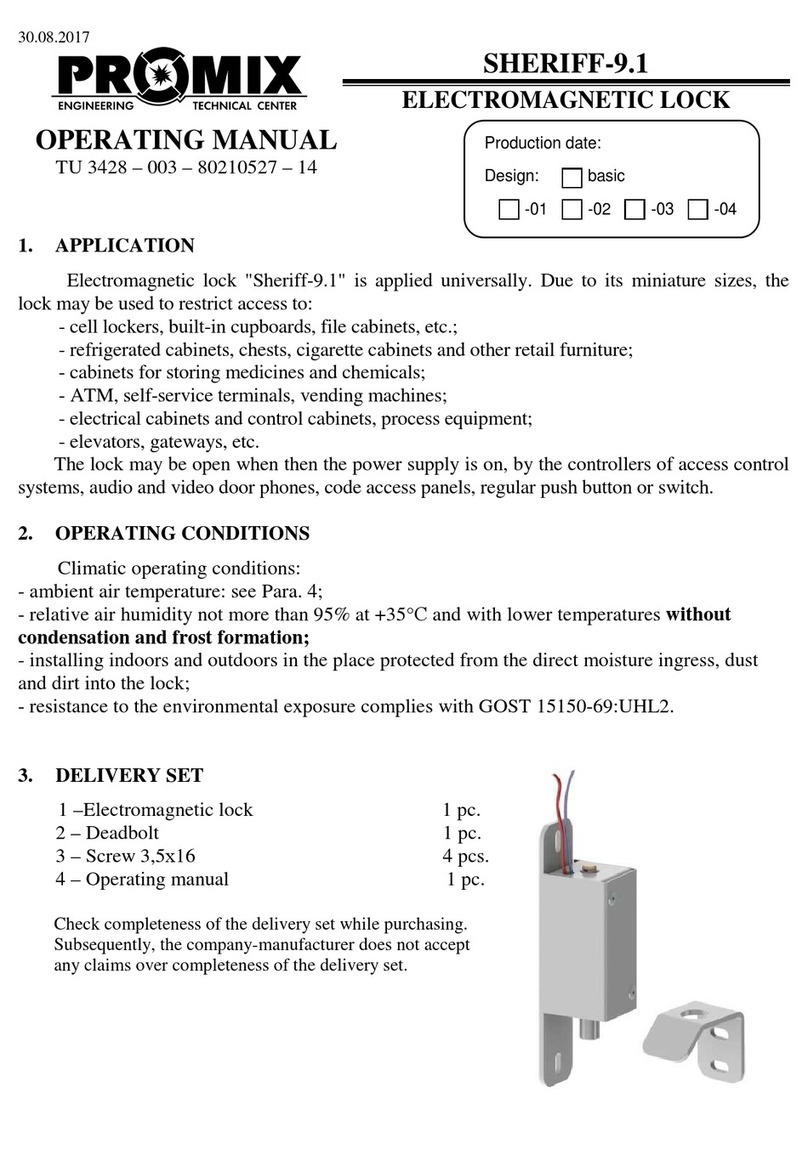

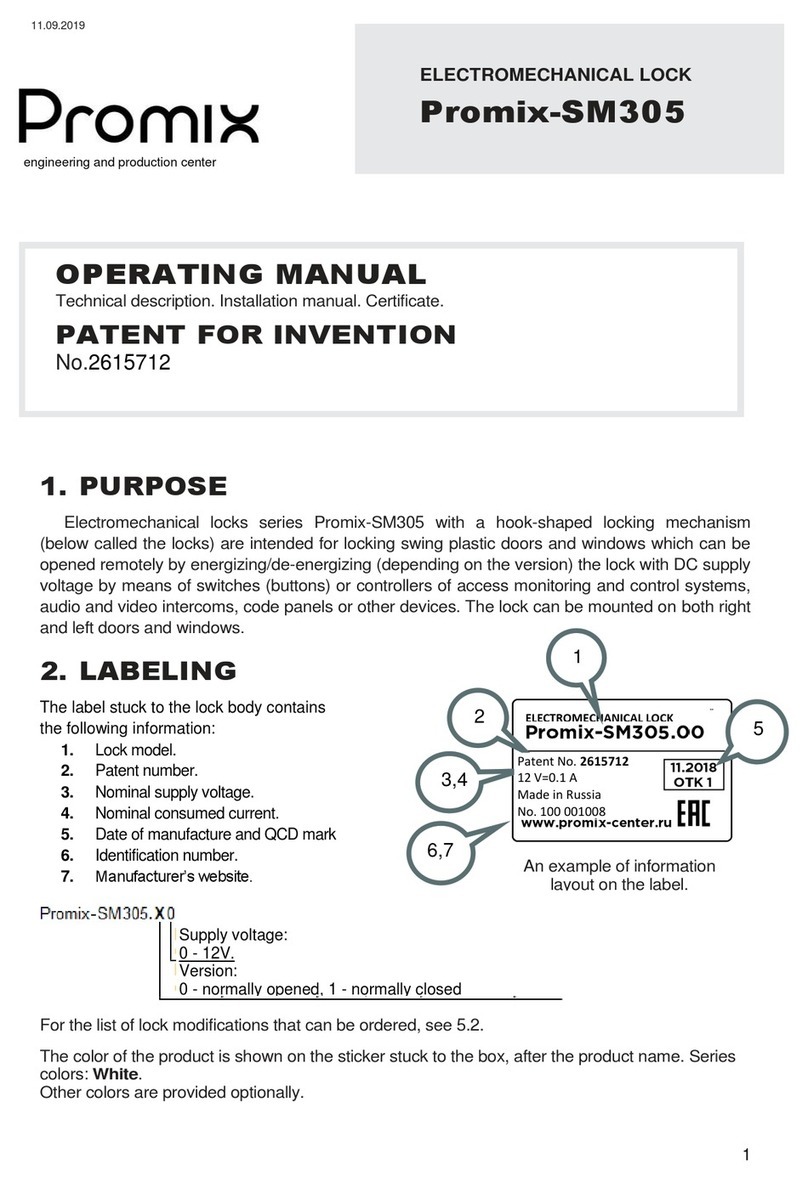

1 Electromechanical lock 1 pc.

2 Deadbolt assembled with the plate 1 pc.

3 Gasket 3 pc.

4 Screw 3х30 for lock fixing 4 pcs.

5 Self-drilling screw 3.5х25 for deadbolt fixing 2 pcs.

Check completeness of the delivery set while purchasing.

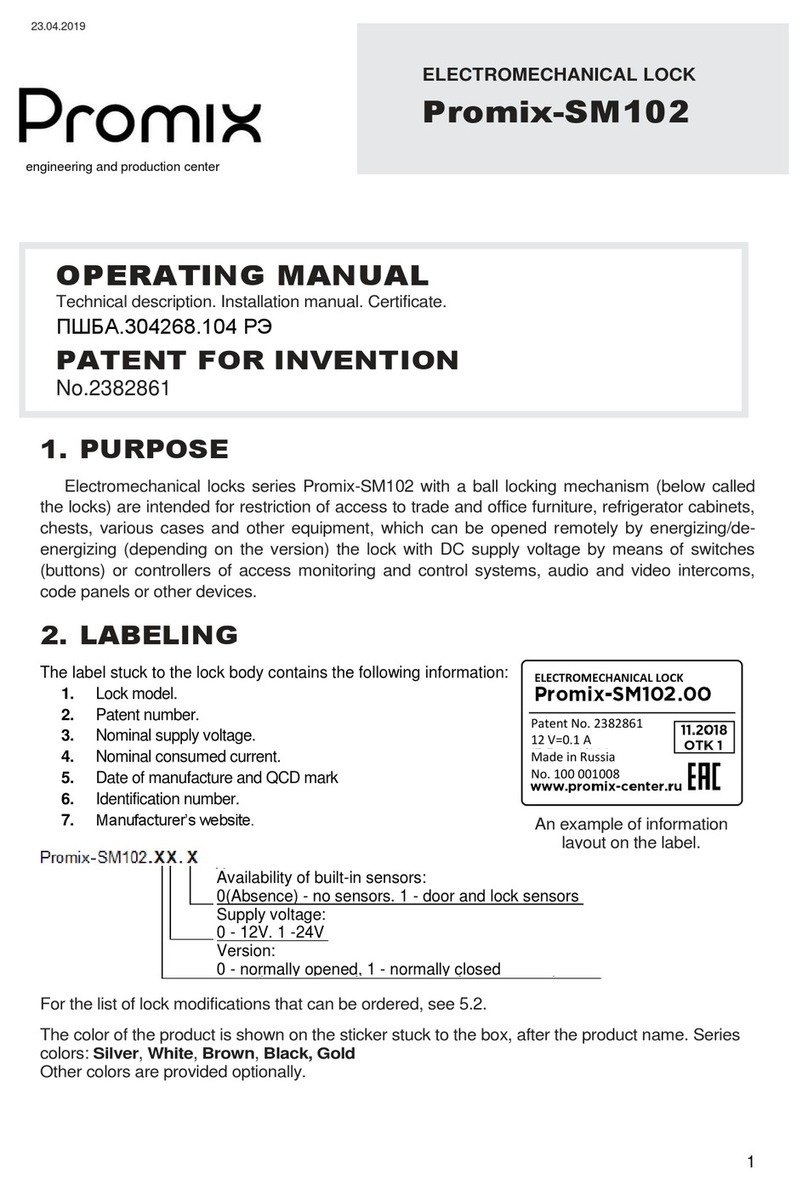

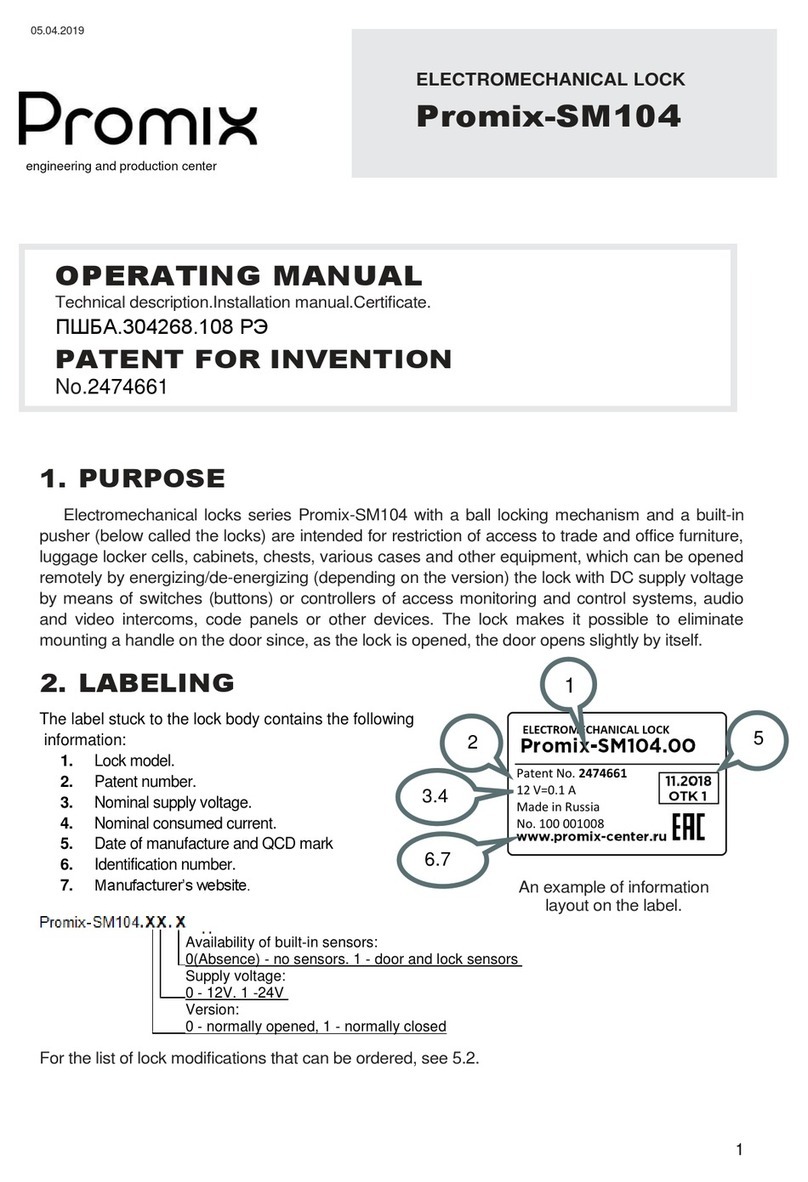

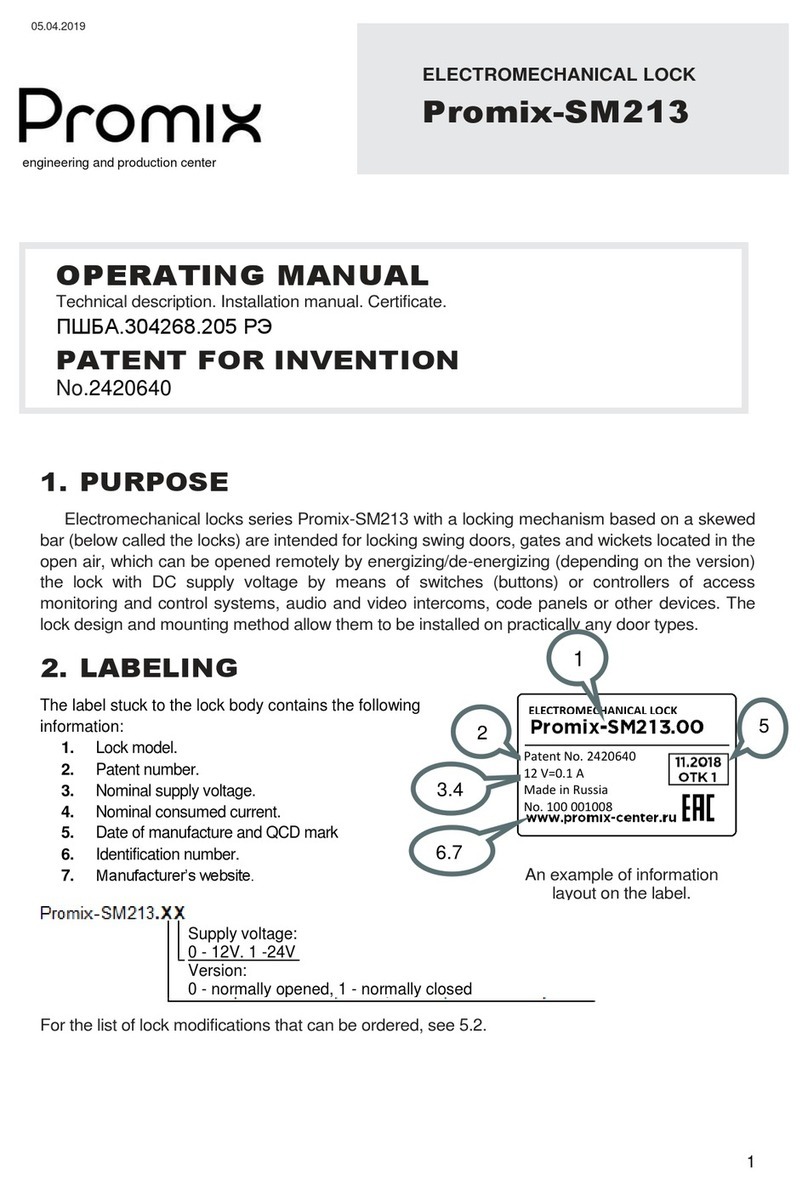

TECHNICAL SPECIFICATIONS

Holding force, kg, no less than. . . . . . . . . . . . . . . . . . 300,

DC voltage supply, V. . . . . . . . . . . . . . . . . . . . . . . 12,

Voltage supply range, V. . . . . . . . . . . . . . . . . . . . . 11÷14,

Current consumption (12V), mА, not more than. . . . . . . . . .100,

Permissible clearance between the door leaf and frame, mm . . 10÷15

Weight, kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.3

Power cable length, m . . . . . . . . . . . . . . . . . . . . . . . 0.1

Ensure correct polarity during lock installation.

Red (light) – positive, black (dark) – negative.

4. OPERATING PRINCIPLE AND DESIGN FEATURES

The lock mechanism contains two devices: the fixation device of the deadbolt roller and the blocker of the fixation device

(see Fig.1). The fixation device holds the deadbolt, and the blocker shuts the deadbolt in the lock. When the door is being closed

the roller fits into the groove of the lock, and having overcome the fixation device's effort, it fixes into the lock. The fixation device

provides only holding the roller in the lock, and when the voltage supply is off, the roller may enter and egress from the lock,

having overcome the fixation's effort. This ensures fixation of the closed door when the lock is open. When the voltage supply is

on, the fixation device is being blocked and it shuts the deadbolt in the lock.

When the voltage supply is off, the blocker releases the fixation device, and for opening the door, it is necessary to

overcome the fixation's effort.

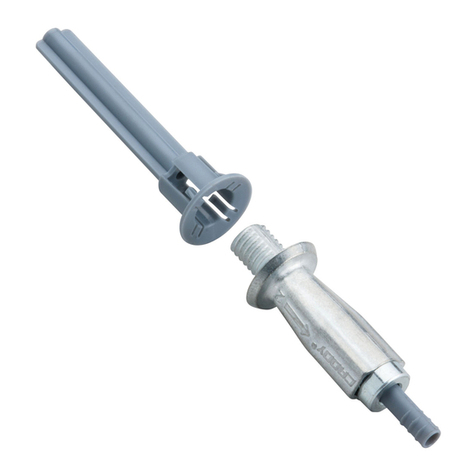

The adjusting holes in the deadbolt bracket serve for correction of the roller position in relation to the groove of the lock in

the vertical direction (for example, when the door is sagging) and in the horizontal direction. The gaskets are used for correction of

the roller position depending on the clearance between the door frame and the door.

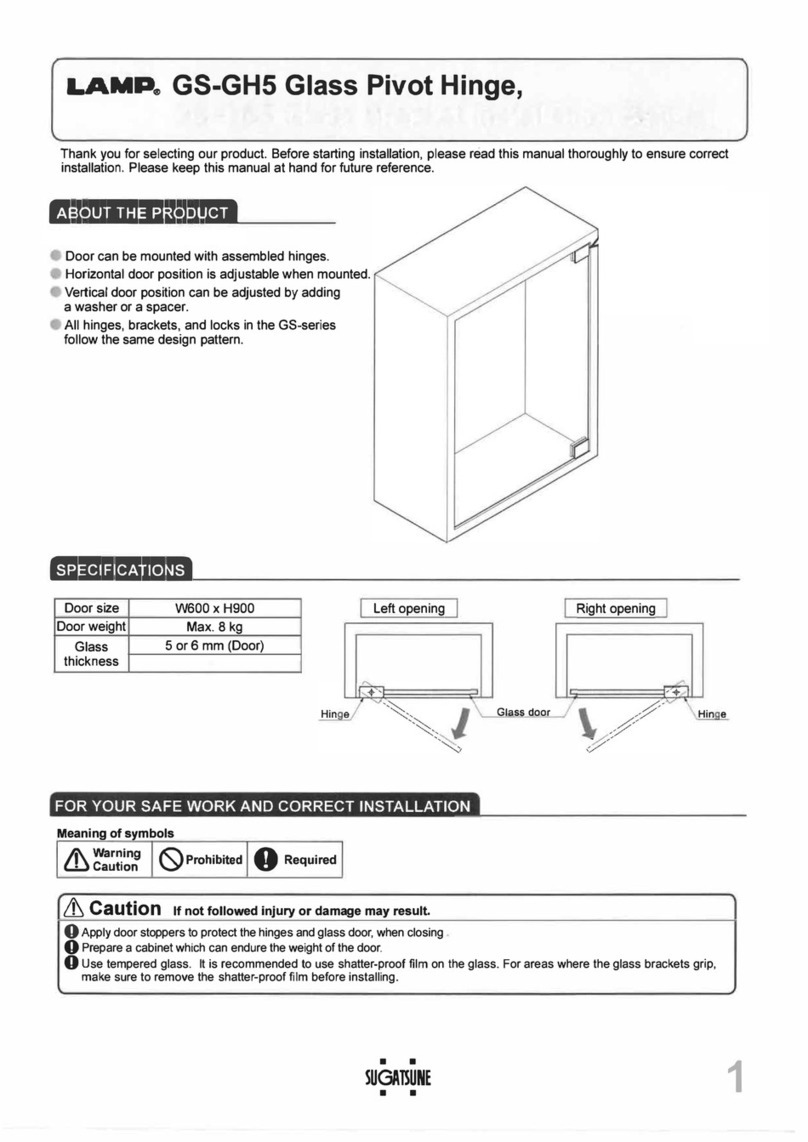

DIMENSIONS AND

MOUNTING

Deadbolt

Fig.1.

Dimensions and mounting dimensions for the

5. INSTALLATION AND ADJUSTMENT

Instruments and equipment for installation

1. Drill or electric screwdriver.

2. Annular Cutter with diameter 25-

26mm.

It is recommended to install the

lock

increases its service life.

5.1. Installation of the lock:

To prevent deformation of the door when one tries to open the door with the closed

deadbolt near the door handle.

1. Mark the center of the hole

for the blocker

2. Drill the through-

hole in the profile with diamet

through the profile

(including the metal frame inside the profile)

Metal objects are not allowed (metal

chips

profile) closer than 10mm from the

end

solenoid.

3. Through the made hole, route

the power cable inside profile's notch or route it outside after drilling the profile.

4.

Make two recesses flush with the drilled surface on the door frame profile (see Fig. 2)

5. Carefully insert the lock blocker 1

into the hole and fixit with screws

6. Mount the deadbolt

assembled with the plate

groove center of the lock and fix it with screws

7. Mark the edges of the deadbolt

plate.

8. Remove the deadbolt

and make the recess with the width 60

9. Mount the deadbolt

into the notch of the door profile

fixation device

2

MOUNTING

DIMENSIONS OF THE LOCK AND THE

DEADBOLT

Lock

Dimensions and mounting dimensions for the

deadbolt

and the lock.

Instruments and equipment for installation

:

26mm.

3.

Drill bits with diameter 2.3 and 3.1mm.

4. Screwdrivers.

5. Knife or chisel.

6. Electrical tape.

lock

in conjunction with a door closer –

it decreases the

To prevent deformation of the door when one tries to open the door with the closed

deadbolt

, it is recommended to mount the

for the blocker

in the distance 29mm from the edge of the door frame

hole in the profile with diamet

er 25-26 mm by the cutter (see F

ig.2). Make sure to drill the hole

(including the metal frame inside the profile)

.

chips

, metal door

end

face of lock's

the power cable inside profile's notch or route it outside after drilling the profile.

Make two recesses flush with the drilled surface on the door frame profile (see Fig. 2)

by the knife or the chisel.

into the hole and fixit with screws

4.

assembled with the plate

2

into the notch of the door profile (Fig. 3), so that the roller be aligned to the

groove center of the lock and fix it with screws

5.

plate.

and make the recess with the width 60

-

70mm in the door profile by the knife or the chisel.

into the notch of the door profile

and fixit with screws 5.

fixation device

Clearance

10 mm

10mm

DEADBOLT

and the lock.

Drill bits with diameter 2.3 and 3.1mm.

it decreases the

impact load on the lock and

, it is recommended to mount the

in the distance 29mm from the edge of the door frame

profile (see Fig.2).

ig.2). Make sure to drill the hole

utterly

the power cable inside profile's notch or route it outside after drilling the profile.

by the knife or the chisel.

into the notch of the door profile (Fig. 3), so that the roller be aligned to the

70mm in the door profile by the knife or the chisel.

blocker

3

Fig.2. Mounting the lock on the door frame profile

Fig.3. Mounting the deadbolt in the notch of the door profile

5.2 Adjusting the deadbolt position:

It is necessary to adjust the deadbolt position in such way that when the door is

closed, the deadbolt roller enters into the lock groove until full operation of the fixation

device.

For adjusting in the vertical direction, loosen the screws 5 and move the deadbolt (see

Fig. 3).

For adjusting in the horizontal direction, unscrew the screws 6, move the deadbolt,

screw the screws 6in the necessary holes.

In case when the clearance between the door and the door frame more than the

standard 12mm (the deadbolt does not reach the lock groove), between the bracket and the

plate of the deadbolt it is necessary to mount one or several gaskets (see Fig.4).

Fig.4. Mounting the gaskets

2

5

6

6

5

Gasket

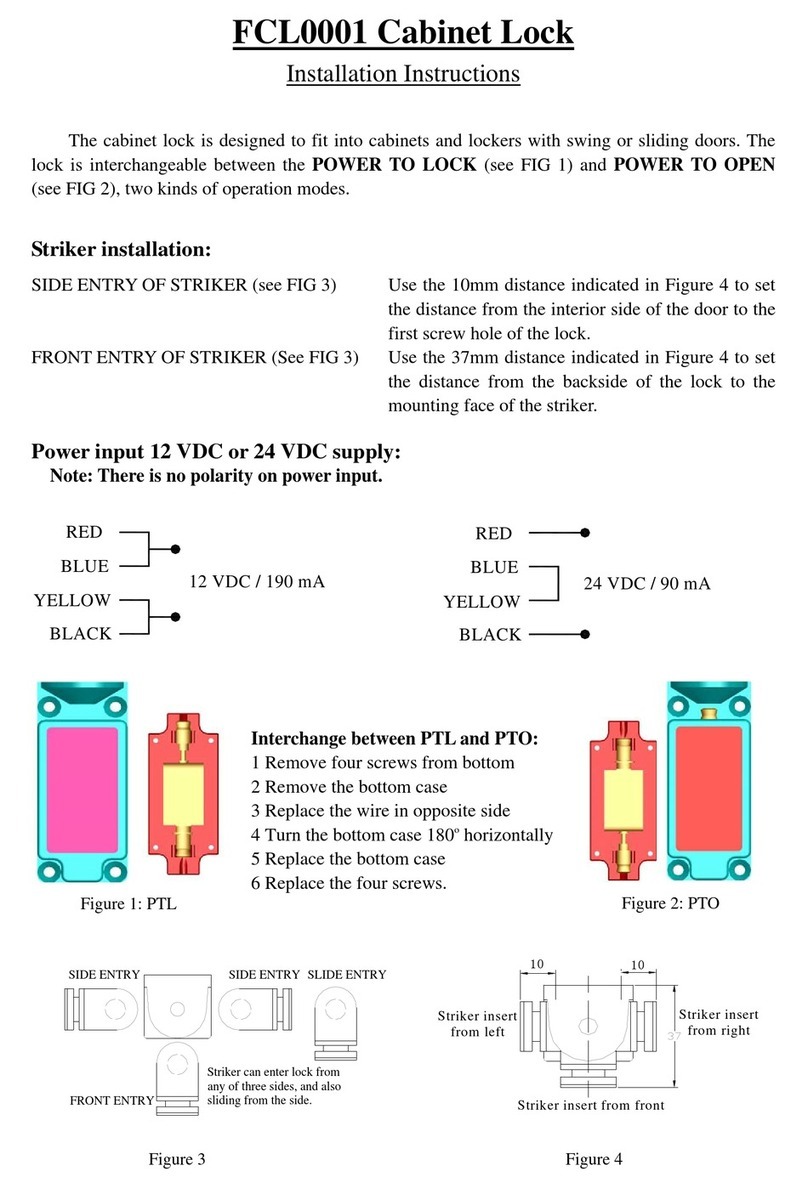

6. WIRING

The lock operates when applying and interrup

switch (button). Controller installation is

done accord

Attention:

power of the lock is supplied by the voltage from 11 to 14 V of the direct current.

Connect the power cable of the

lock in the following

red – positive, black – negative.

(The reverse polarity voltage supply

does

Provide reliable electrical contact. I

solate the connection points to avoid short

ATENTION!!! The possibility to use

based

on the level of premise accountability, assignment of access restriction

7. POSSIBLE FAILURES,

INSTALLATION PROBLEM

Failures

and problems

The lock does not fix the

deadbolt

roller (the door does not fix when it is

closed).

The door does not close fully,

because the deadbolt

does not reach

the lock.

The

deadbolt

roller does not enter, or

it enters with friction into the lock

groove.

When the status of the door is

"open", but the door

does not open.

To open the door needed

to press it

tighter to the door frame.

8. MAINTENANCE

Maintenance of a lock is performed at

least

- Examination of the lock to check

fixation

- Check the locking bolt

correct position

9. MANUFACTURER'S WARRANTY

Engineering & Technical Center PROMIX, LLC guarantees the conformity of

requirements of applicable TU standards under the regulation

The warranty period is 18 months commencing from the date of acceptance by Quality Control Department.

Within the warranty period, Engineering & Technical Center PROMIX, LLC undertakes to re

charge. The shipping cost to the place of repair and back shall be borne by the Buyer.

The warranty shall not cover defects or damages, resulting from:

- improper maintenance by the Buyer;

- using the lock in conditions

that do not conform to the operating requirements;

- mechanical damages or

disassembly of

-

violation of transportation and storage regulations.

PACKING

Electromechanical lock "Sheriff-5"

with the specified date of manufacture is made and accepted in accordance with TU

003–80210527–14

, obligatory requirements of state standards and applicable technical documents, found fit for service and

packed by Engineering & Technical Center PROMI

QCD seal

Engineering & Technical Center PROMIX, LLC

Russia, 214030, Smolensk city,

Krasninskoye Hwy

Tel. (4812) 619-330

www.itc-promix.ru

Please send us all your comments and

suggestions concerning our lock via e

Thank you in advance!

4

The lock operates when applying and interrup

ting the power supply, and for it

is usually used a controller (contro

done accord

ing to the technical data sheet.

power of the lock is supplied by the voltage from 11 to 14 V of the direct current.

lock in the following

polarity:

does

not provide operability of the lock, but does not

damage

solate the connection points to avoid short

-circuiting.

this lock to restrict access to premises is

determined

on the level of premise accountability, assignment of access restriction

and other factors (security,

INSTALLATION PROBLEM

S AND TROUBLESHOOT

Troubleshoot

deadbolt

roller (the door does not fix when it is

Set the lock o

n the "closed" status (turn on the voltage supply of the lock).

Check the polarity and make sure that the

voltage supply corresponds with the

required one.

Make sure that when drilling the hole for the lock, the internal metal frame of

the door profile was drilled either.

Adjust the deadbolt (see Para

. 6.2) in that way when the door is closed the

roller enters

into the lock groove until the full operation of the fixation device.

does not reach

It is possible that the fixation device manually one

moves to the "close" position (not by the

manually or by an external object). Change the

fixation device position to "open", for this turn off the

voltage supply of the lock, and turn the fixation

device.

pull

roller does not enter, or

it enters with friction into the lock

Re

-

establish the door position one changed during operation. If it is impossible

to re-establish it, adjust the deadbolt (see Para

. 6.2).

When the status of the door is

does not open.

to press it

Eliminate the causes of loose fit of the door to the door frame. Adjust the

deadbolt in the horizontal direction.

least

once per two months and includes:

fixation

reliability. If it is necessary, tighten up

fixing elements of the lock and the

correct position

. If it is necessary, adjust the position of the

locking bolt

Engineering & Technical Center PROMIX, LLC guarantees the conformity of

the e

lectromechanical lock "Sheriff

requirements of applicable TU standards under the regulation

s of operation and installation

established in this operating manual.

The warranty period is 18 months commencing from the date of acceptance by Quality Control Department.

Within the warranty period, Engineering & Technical Center PROMIX, LLC undertakes to re

charge. The shipping cost to the place of repair and back shall be borne by the Buyer.

The warranty shall not cover defects or damages, resulting from:

that do not conform to the operating requirements;

disassembly of

the lock by the Buyer;

violation of transportation and storage regulations.

PACKING

AND ACCEPTANCE CERTIFICATE

with the specified date of manufacture is made and accepted in accordance with TU

, obligatory requirements of state standards and applicable technical documents, found fit for service and

packed by Engineering & Technical Center PROMI

X, LLC.

Engineering & Technical Center PROMIX, LLC

Krasninskoye Hwy

, 35

PATENT

suggestions concerning our lock via e

-mail: mail@

itc

is usually used a controller (contro

l board) or a

power of the lock is supplied by the voltage from 11 to 14 V of the direct current.

damage

it).

determined

by the installer company

and other factors (security,

CCTV, etc.).

n the "closed" status (turn on the voltage supply of the lock).

voltage supply corresponds with the

Make sure that when drilling the hole for the lock, the internal metal frame of

. 6.2) in that way when the door is closed the

into the lock groove until the full operation of the fixation device.

It is possible that the fixation device manually one

moves to the "close" position (not by the

deadbolt,

manually or by an external object). Change the

fixation device position to "open", for this turn off the

voltage supply of the lock, and turn the fixation

establish the door position one changed during operation. If it is impossible

. 6.2).

Eliminate the causes of loose fit of the door to the door frame. Adjust the

fixing elements of the lock and the

deadbolt.

locking bolt

(see Para. 6.2).

lectromechanical lock "Sheriff

-5" to the

established in this operating manual.

The warranty period is 18 months commencing from the date of acceptance by Quality Control Department.

Within the warranty period, Engineering & Technical Center PROMIX, LLC undertakes to re

pair the defective product free of

with the specified date of manufacture is made and accepted in accordance with TU

3428–

, obligatory requirements of state standards and applicable technical documents, found fit for service and

RUSS RU.ММ07.Н00002

PATENT

OF INVENTION №238261

itc

-promix.ru.

Table of contents

Other PROMIX Lock manuals

PROMIX

PROMIX SM101 User manual

PROMIX

PROMIX SM490 User manual

PROMIX

PROMIX SM 323 User manual

PROMIX

PROMIX Promix-SM132 Series User manual

PROMIX

PROMIX Promix-SM308.10.1 User manual

PROMIX

PROMIX Promix-SM306 User manual

PROMIX

PROMIX Promix-SM420 User manual

PROMIX

PROMIX SHERIFF-9.1 User manual

PROMIX

PROMIX SM305 User manual

PROMIX

PROMIX Promix-SM112 Series User manual

Popular Lock manuals by other brands

CODELOCKS

CODELOCKS KL1050 Programming & operating manual

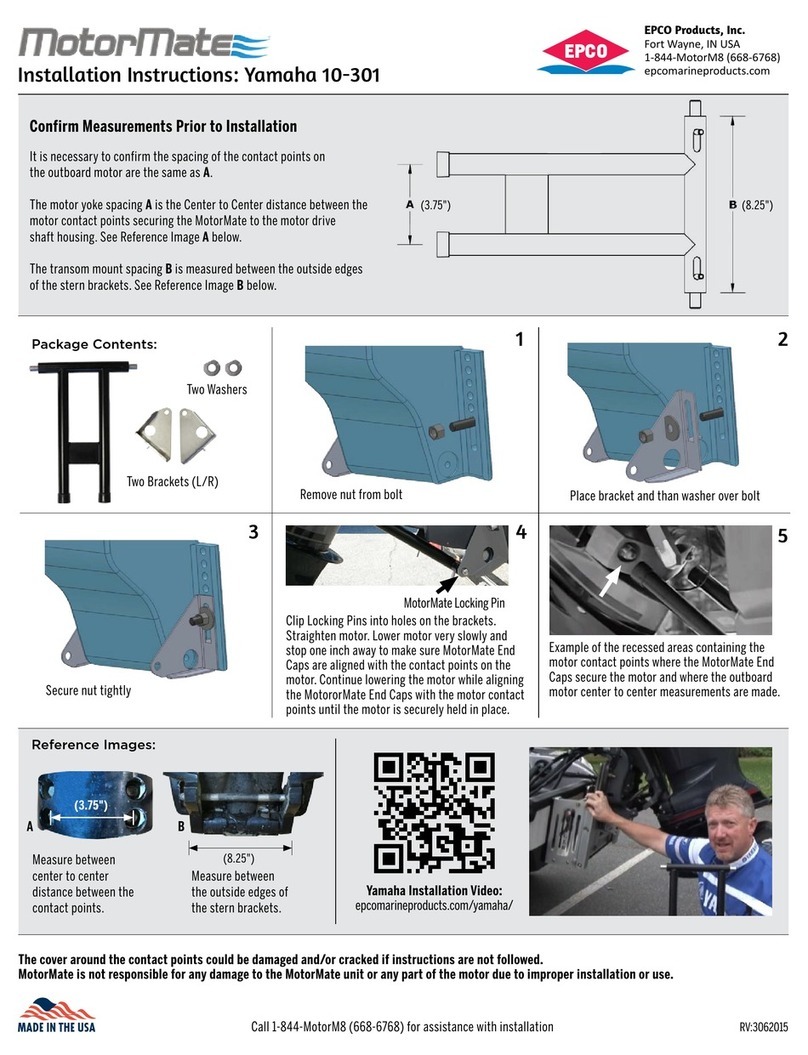

Motormate

Motormate Yamaha 10-301 installation instructions

AmazonBasics

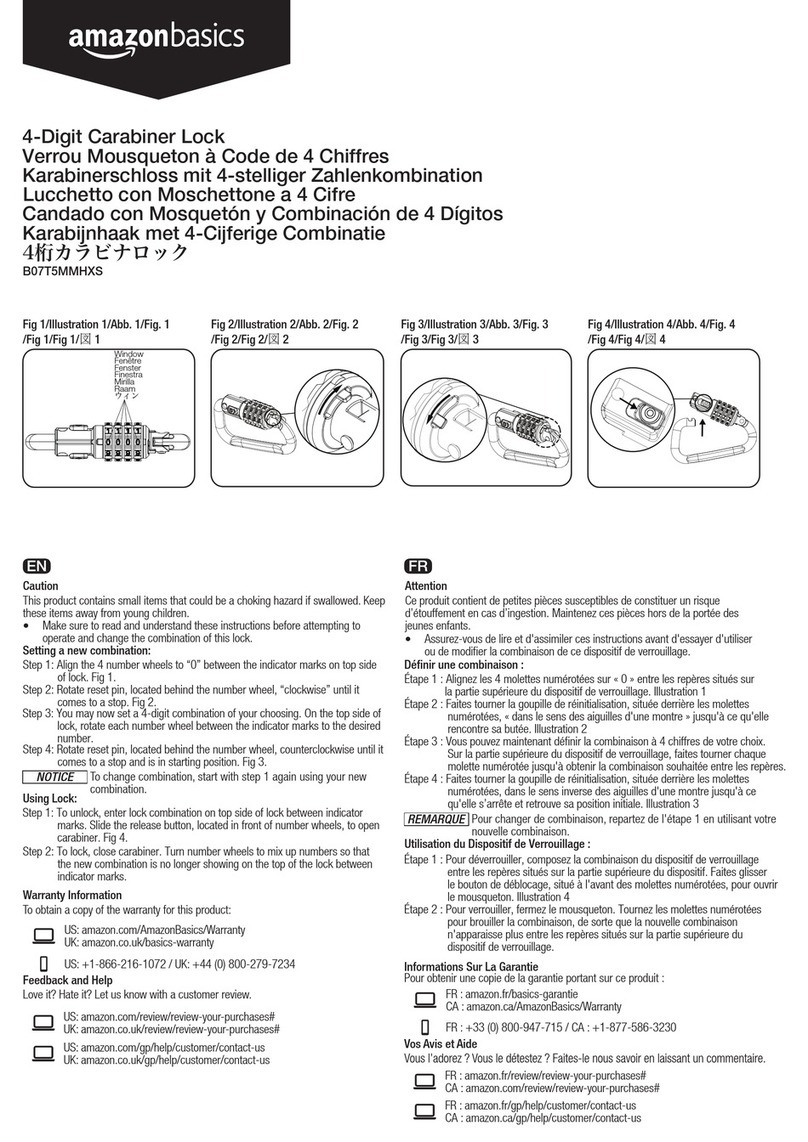

AmazonBasics B07T5MMZ46 quick start guide

Ofs

Ofs carolina Mile Marker StealthLock instructions

Amazon

Amazon B07T5MMHXS quick start guide

Belwith

Belwith FIRST WATCH 1381 instructions