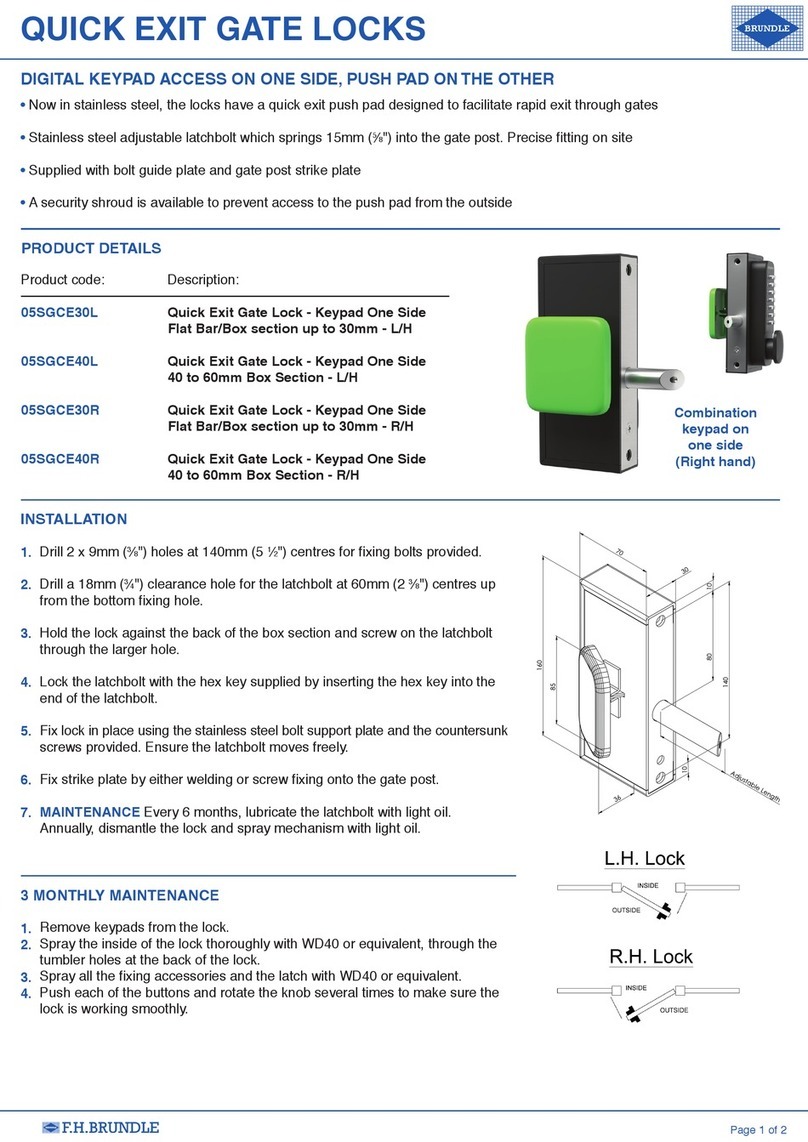

PROMIX Promix-SM104 Series User manual

1

OPERATING MANUAL

Technical description.Installation manual.Certificate.

ПШБА.304268.108 РЭ

PATENT FOR INVENTION

No.2474661

05.04.2019

1.

PURPOSE

Electromechanical locks series Promix-SM104 with a ball locking mechanism and a built-in

pusher (below called the locks) are intended for restriction of access to trade and office furniture,

luggage locker cells, cabinets, chests, various cases and other equipment, which can be opened

remotely by energizing/de-energizing (depending on the version) the lock with DC supply voltage

by means of switches (buttons) or controllers of access monitoring and control systems, audio

and video intercoms, code panels or other devices. The lock makes it possible to eliminate

mounting a handle on the door since, as the lock is opened, the door opens slightly by itself.

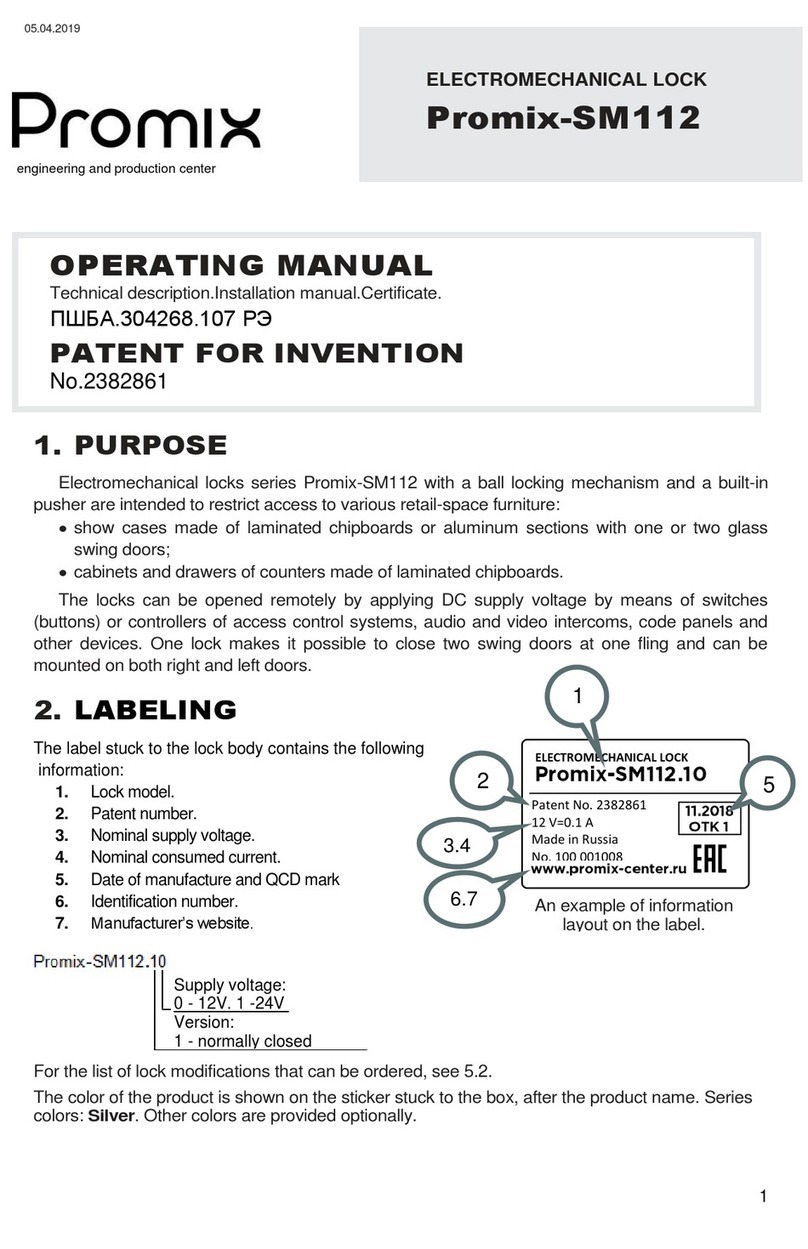

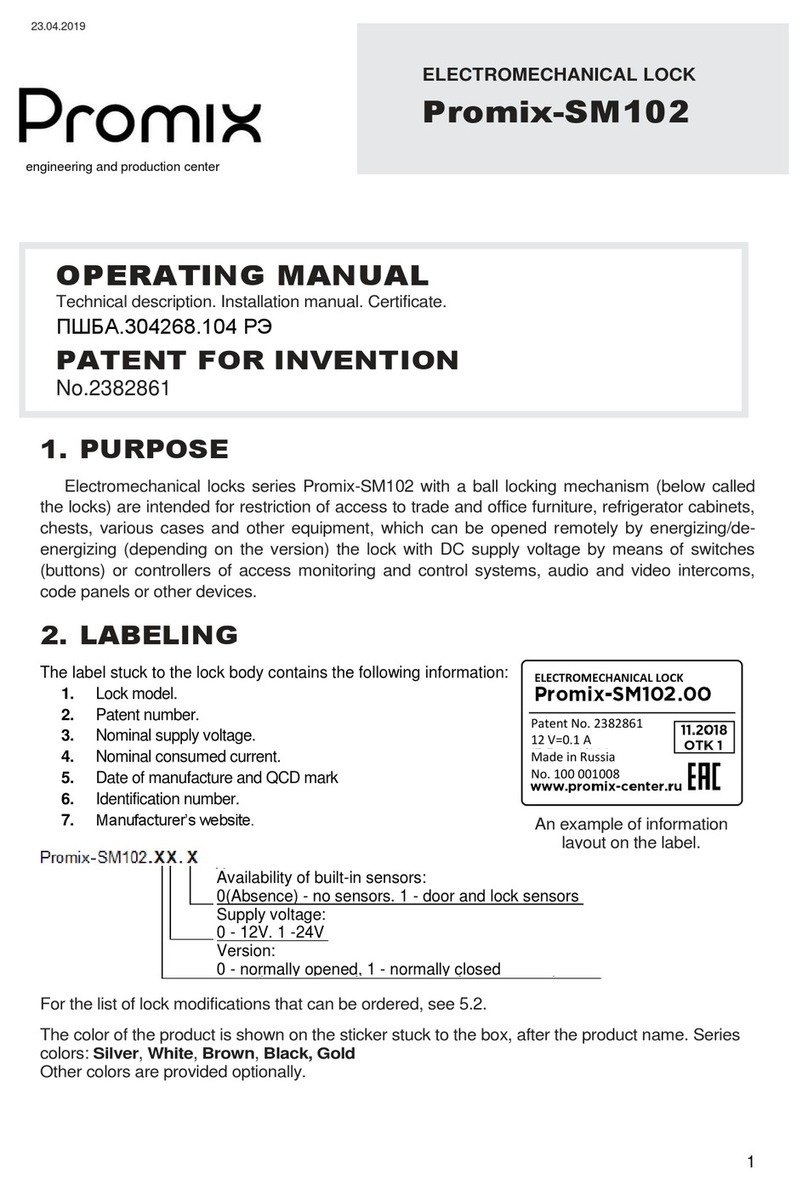

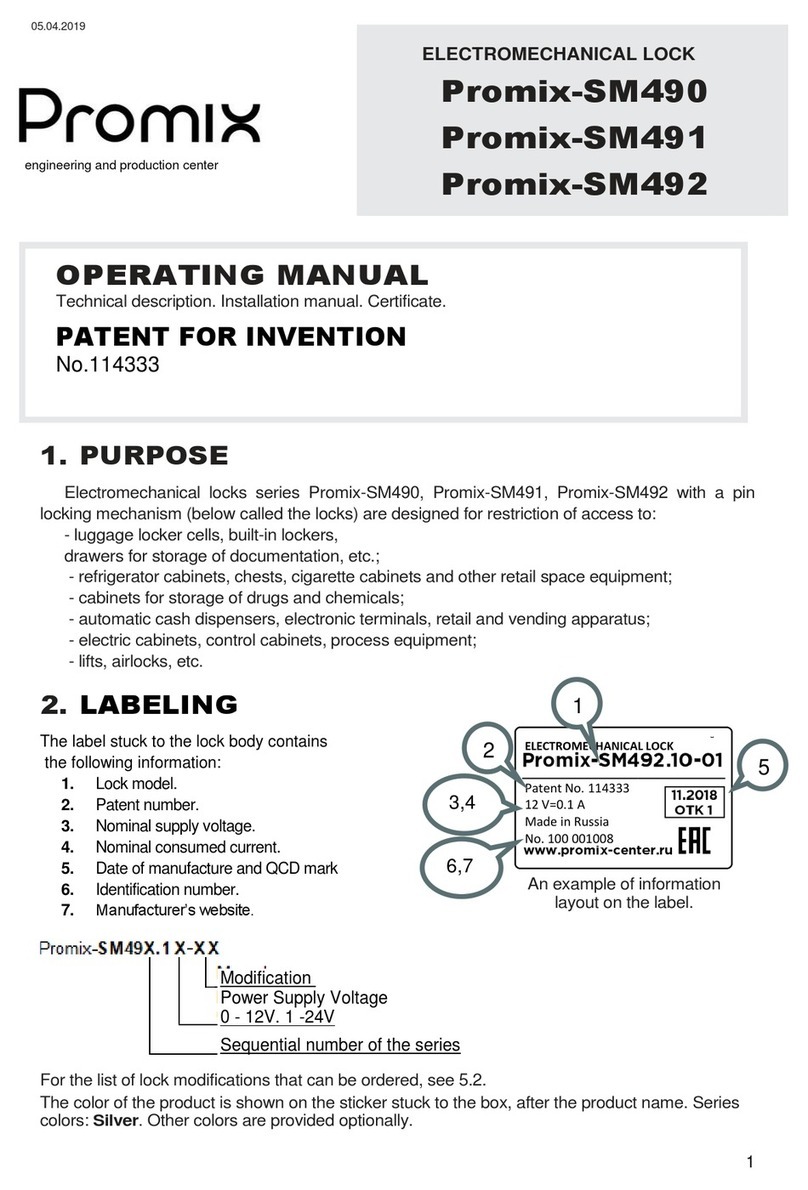

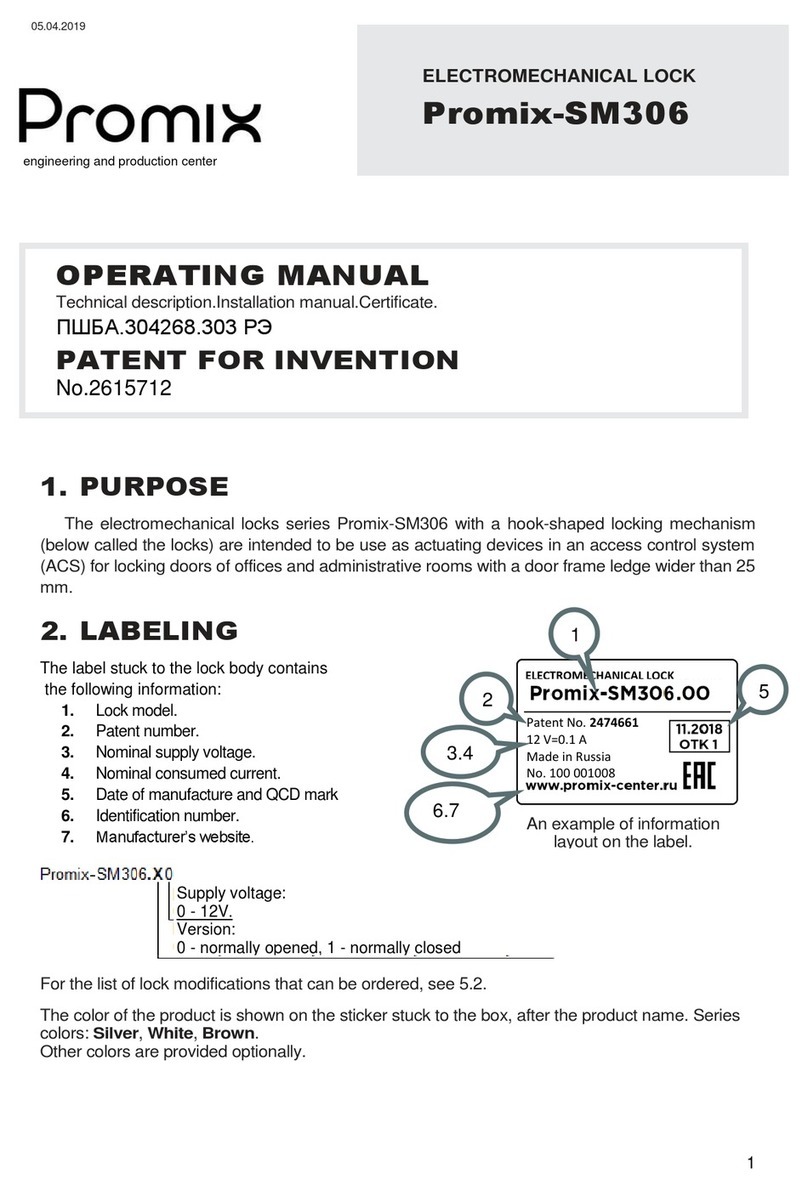

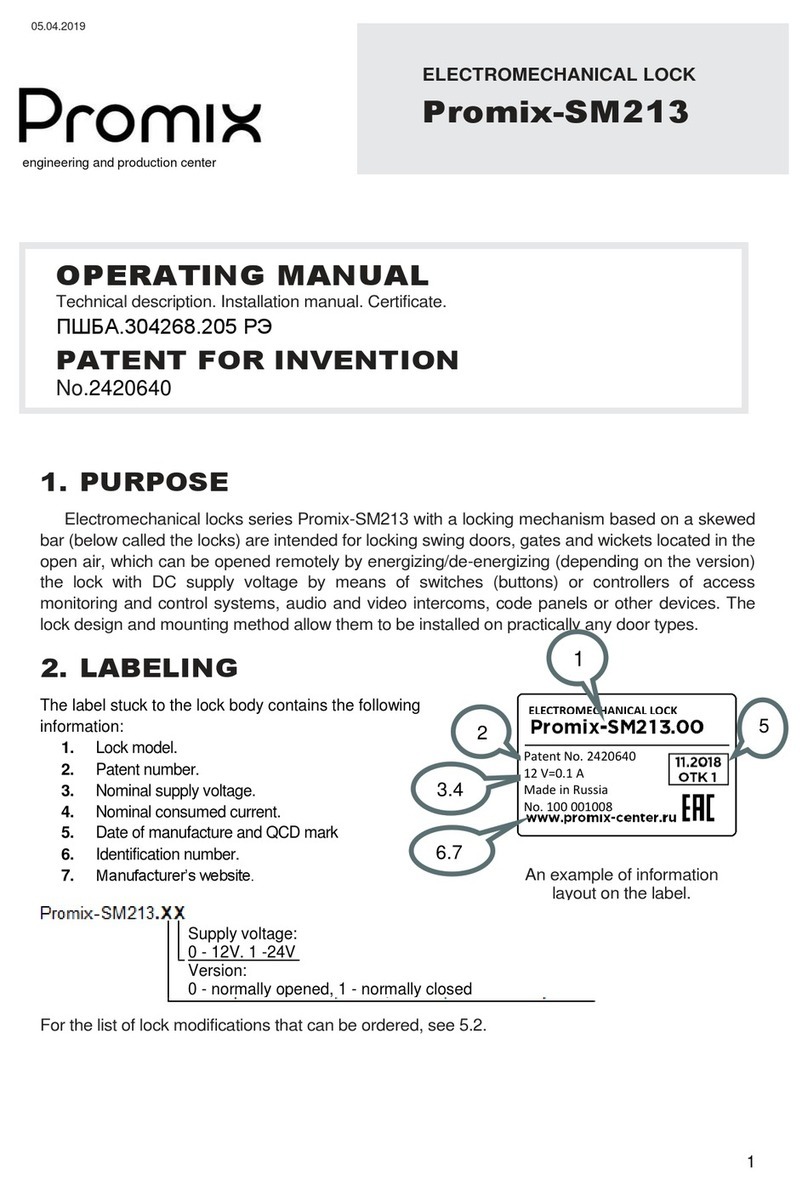

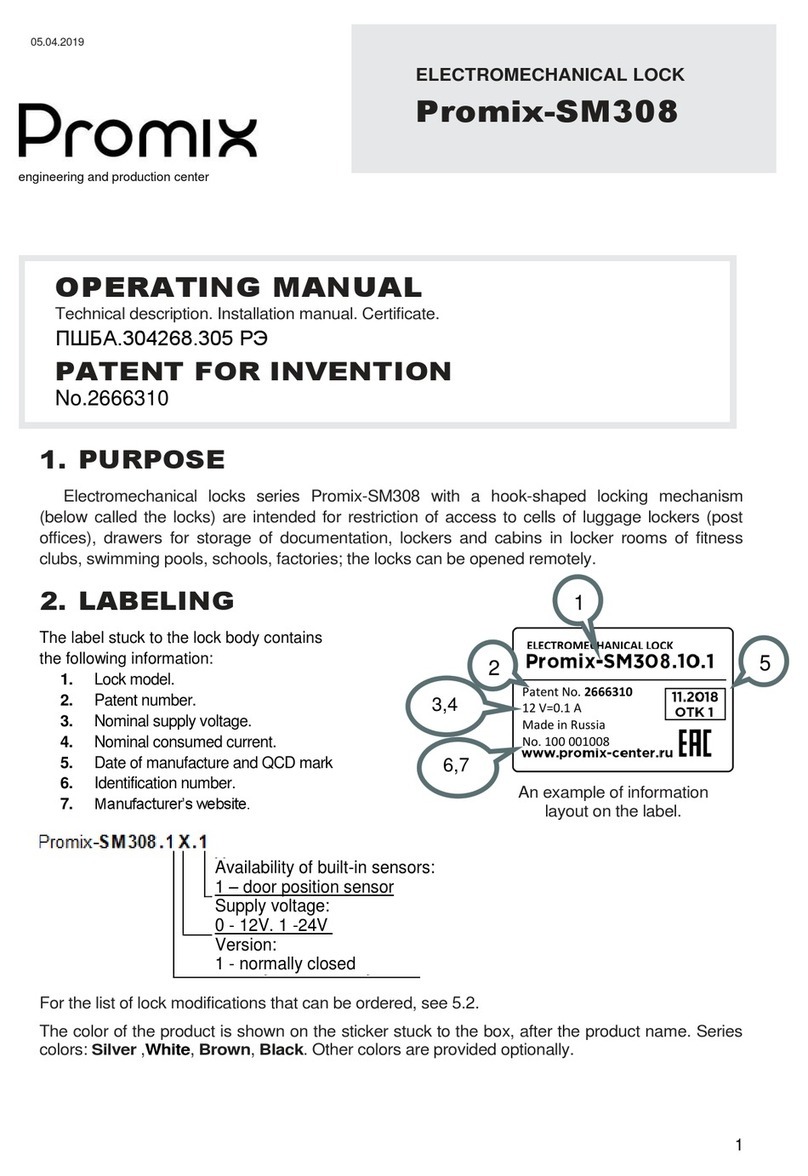

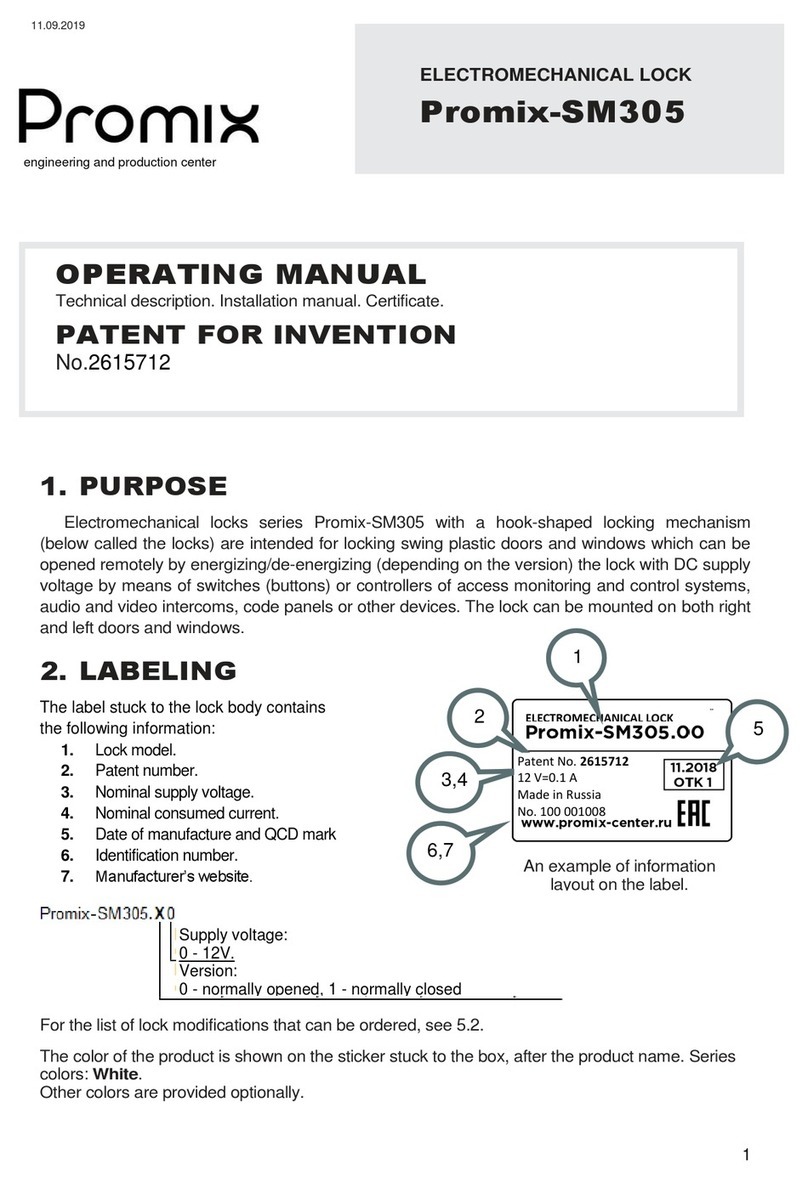

2.

LABELING

The label stuck to the lock body contains the following

information:

1. Lock model.

2. Patent number.

3. Nominal supply voltage.

4. Nominal consumed current.

5. Date of manufacture and QCD mark

6. Identification number.

7. Manufacturer’s website.

For the list of lock modifications that can be ordered, see 5.2.

ELECTROMECHANICAL LOCK

Promix-SM104

2

5

3.4

6.7

An example of information

layout on the label.

ELECTROMECHANICAL LOCK

Patent No. 2474661

12 V=0.1 A

Made in Russia

No. 100 001008

Availability of built-in sensors:

0(Absence) - no sensors. 1 - door and lock sensors

Supply voltage:

0 - 12V. 1 -24V

Version:

0 - normally opened, 1 - normally closed

engineering and production center

1

Promix-SM104

2

Check completeness of the lock set when buying! After buying, the

manufacturer will not accept claims related to incomplete set.

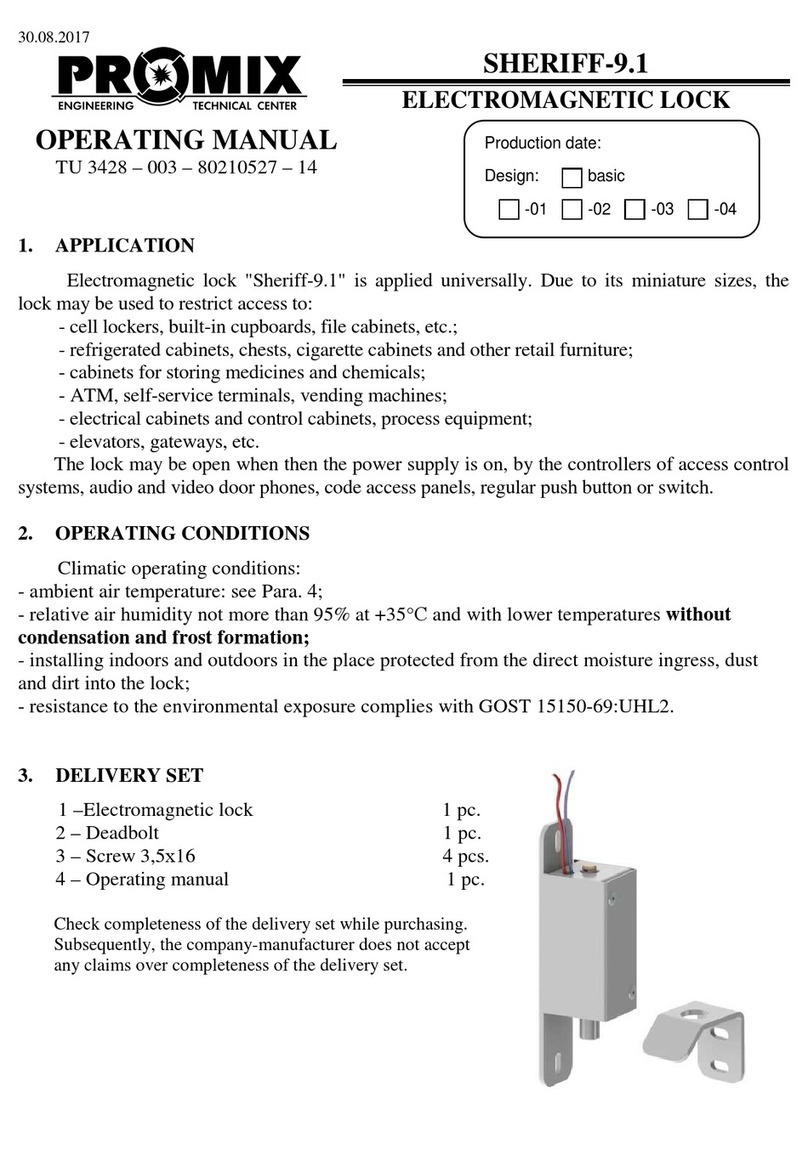

3.

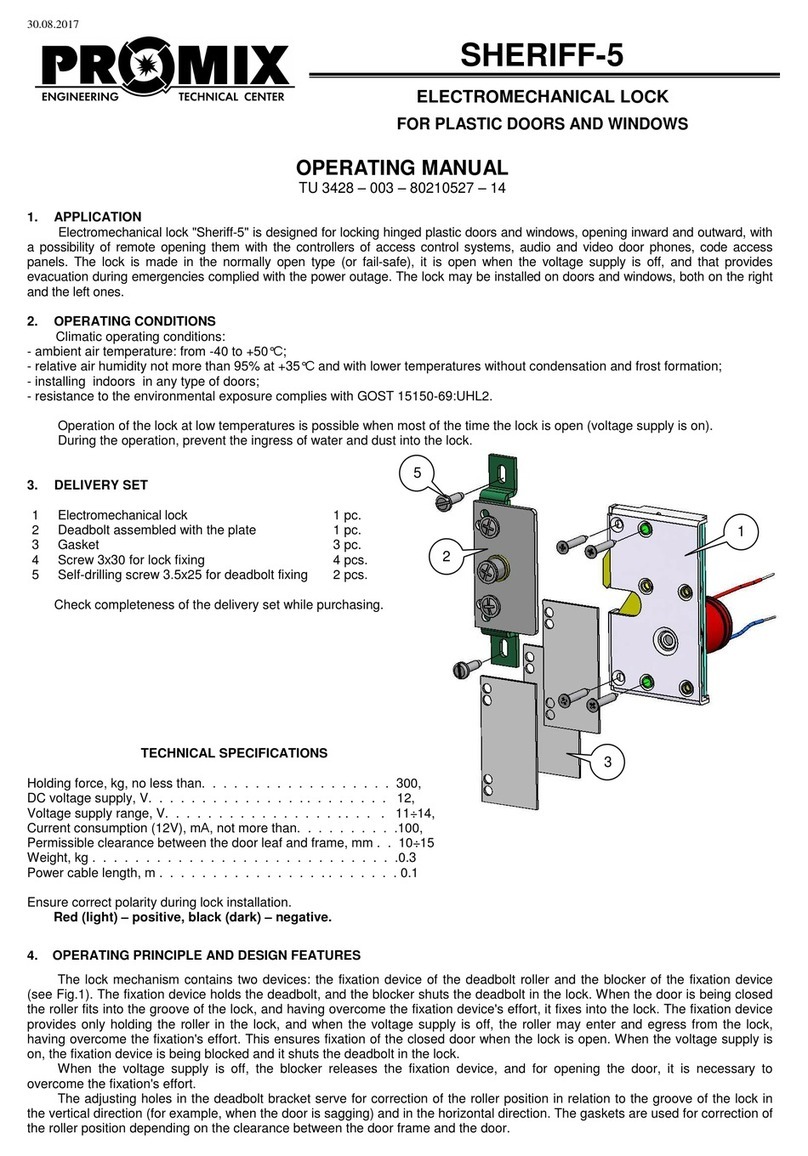

SET OF DELIVERY

4.

DESIGN AND PRINCIPLE OF OPERATION

The locks are manufactured in one version based on the normally closed (NC) principle. NC

lock is in the closed state when the latch is inserted and no voltage is supplied, and in the open

state when the lock is energized. To open the door, the lock must be energized.When opened,

the lock pushes out (shoots off) the latch, which leads to the door opening slightly. The lock

operates as well when the door is in a “tension” condition, i.e., when some external force is

applied to open the door (see 5.2)(e.g., someone pulls the door handle).

The locked may be equipped with a door position sensor. The built-in door position sensor

consists of a magnetically controlled sensor (sealed-contact reed relay) mounted on the lock

body, and a magnet mounted on the mobile sleeve of the lock and displaced by the latch. The

reed relay contacts open when the door is opened (the latch is withdrawn from the lock) and

close when the door is closed (the latch is inserted into the lock to a stop). The sensor is on the

back side of the lock.

5.

TECHNICAL DATA

5.1 OPERATING CONDITIONS

The lock operation environment must be explosion-safe, free of current-conducting dust or

gases that cause metal corrosion and destroying insulation of current conductors and electric

elements, free of current-carrying dust or water vapor, and preventing ingress of water, steam,

fuel and lubricants.

Climatic conditions of operation –У3.1 as per GOST 15150-69 with extended temperature

range:

ambient temperature: from -30 to +50 °С;

Relative air humidity: not higher than 98% at 25°С or lower temperatures without moisture

condensation and hoar-frost formation;

installation indoors or outdoors excluding ingress of moisture, dust, dirt, etc. inside the lock.

1 –Lock

1 pc.

2 –Latch with adjustment plate

1 pc.

3 –Alignment piece

1 pc.

4 –Self-tapping screw 3.5х15 (cup head)

6 pcs.

5 –Operating manual

1 pc.

.

.

1

2

3

4

Promix-SM104

3

5.2 TECHNICAL DATA

Modification

Promix-

SM104.10

Promix-

SM104.10.1

Promix-

SM104.11.1

Promix-

SM104.11

Version

normally closed

Initial latch pushing out

force (not less than), kg

0.7

Maximum “tension” of the

door before opening (not

more than), kg

1.5

DC supply voltage U, V

12±2

24±2

Current consumed, А

0.35 (at 12V)

0.22 (at 24V)

Supply pulse duration (not

more than), s

0.5-3

Minimum pause between

pulses, s

15

Built-in sensors

-

door position sensor

-

Maximum switch current

of the sensor (DC), А:

-

0.5

-

Maximum switch voltage

of the sensor (DC), V:

-

36

-

Sensor output signal type

-

“dry contact”

-

Lock weight (

not more

than

),

kg

0.15

Holding force (

not less

than

),

kg

300

Power wire length, m

0.13

Promix-SM104

4

Lock and latch overall and mounting dimensions.

6.

INSTALLATION AND CONNECTION

6.1 LOCK MOUNTING

Mounting of the lock on a swing door.

Mount the lock on an immobile surface. The

distance between the inner surface of the closed

door to the lock nut must be 10-11 mm, which

guarantees the necessary free movement of the

door within 3-4 mm with the lock closed.

Connect the lock in accordance with 6.2.

1

Sensor fastening

place

Promix-SM104

5

Insert the latch in the lock after prior centering

the latch bar and fitting the alignment piece 3

over the bar (see section 3).

Apply voltage to the lock and make sure that the

latch is pushed out of the lock.

De-energize the lock.

Remove the protective film from the two-sided

adhesive tape on the latch plate and snap the

latch into the lock. Close the door and press it

tightly to the cabinet.

Energize the lock. The door must become

slightly open.

Fasten the latch to the door with self-tapping

screws. Remove the alignment piece. The lock is

ready for operation.

2

3

4

Promix-SM104

6

See operating voltage range in 5.2. Avoid application of a higher voltage or

excessive pulse duration.

Example of lock mounting on a metal cabinet with a swing door.

6.2 CONNECTING PROCEDURE

The lock operation is controlled by means of energizing and de-energizing. For this purpose, a

controller (control board) or a switch (button) is generally used. The controller is mounted in

accordance with its certificate.

Connect the lock power wires adhering to the following polarity:

Red (black with a red stripe) –positive pole of the power supply;

Black –negative pole of the power supply;

Application of voltage of reverse polarity does not provide the lock operability but does cause

its failure.

Connect sensor leads:

Colored wires (yellow, green, etc.) –door position sensor output.

Example of the lock connection to the remote control system Promix-RDS.

Lock

Door

Door

Lock

Cable

channel

Door

Lock

Cable channel

Lock

Controller Promix-CR.RX

Remote control

Promix-CR.TX

~220 V

Promix-SM104

7

Provide a reliable electriccontact. To prevent short-circuit, insulate places of

connection.

7.

SPECIAL ASPECTS OF INSTALLATION AND

OPERATION

1)

The possibility of using of the locks for restriction of access to the premises or to equipment

and the place of installation (outside or inside) are determined by the

installation

organization

on the basis of the design features and the mounting method, room criticality

level, the purpose of the access restriction regime and other factors (the presence of security

providers, video surveillance, etc.).

2) When mounting the lock and the latch, it is necessary to ensure their coaxial alignment within

the latch free movement allowance.

3) When the door is closed, the latch must be inserted in the lock

to stop

. The lock may fail to

open when the door is an excessive “tension” condition, i.e., an excessive external force for

opening is applied (see 5.2).

4) The properly mounted lock provides the necessary free motion (play) of the door of 3-4 mm. If

the free play distance is shorter, the lock may

fail to open

when energized (see section 8).

5) Operation of an installed lock should be tested only if the supply voltage can be applied

thereto.

In all lock fastening versions, the latch bar length must not exceed 33 mm.The latch length

adjustment is performed as follows: fix the latch support with a wrench, loosen the latch nut,

screw in/out the latch bar to the required length,rotate the latch nutto a stop, and tightenreliably.

Nut

Support

Promix-SM104

8

The lock does not need lubrication!

8.

TROUBLE-SHOOTING

Troubles and problems

Remedies

The lock does not open when supply

voltage is applied.

Using a tester, check integrity of the lock power

circuit.

Close the door, case, etc. tightly and press on it at

the latch fastening place, and apply voltage to the

lock. If the lock does not open, apply an elevated

voltage of 20-30 V (up to 36 V for a 24 V

modification) for a short time.

After the lock opening, increase the latch bar

length. To do this, fix the latch support with a

wrench, loosen the latch nut, screw out the latch

bar, tighten the latch nut.

Excessive free play of the latch (more than

4mm) while the lock is in the closed state.

Decrease the latch bar length. To do this, fix the

latch support with a wrench, loosen the latch nut,

screw in the bar, tighten the latch nut.

A large clearance between the door and the

base as the door is closed (the latch stops

against the inside of the lock).

The lock does not fix the latch (the door is

not closed).

Check polarity and conformity of the lock supply

voltage to the required one.

Check the distance between the latch and the

lock; if necessary, increase the latch bar length.

To do this, fix the latch support with a wrench,

loosen the latch nut, screw out the bar, tighten the

latch nut.

The door has sunk during use (automatic

latch alignment is insufficient), therefore,

the latch does not enter the lock aperture or

hits the lock as enters.

Restore the door position If this is impossible,

dismantle the latch from the door. Fasten the latch

to the door ensuring alignment with the lock

aperture.

9.

MAINTENANCE

Maintenance of the lock is performed at least once every two monthsand includes:

Visual inspection of the lock to check reliability of fastening. If necessary, tighten fasteners

of the lock and the latch.

Check the latch bar length. If the latch bar abuts against the lock body and this leads to

gapping between the door and the door base, or if the latch is not fixed when the door is

closed, adjustthe latch bar length (see section 8).

Promix-SM104

9

The warranted operation period is 12 months from the date of sale but not

longer than 18 months from the day of acceptance by the manufacturer’s QCD.

Faulty products are accepted for repair only together with the latch, on the

obligatory condition that factory labels are retained on the product body.

To improve product quality the manufacturing plant reserves the right to make

modifications to the product design without prior notice.

10.

STORAGE AND TRANSPORTATION

Prior to putting into operation, the locks must be stored in the manufacturer’s packing, in

rooms with an ambient temperature of -30 to +50 °С and a relative humidity not higher than 98%

at 25º С in compliance with storage conditions as per GOST 15150-69.

Locks transportation conditions must comply with group C as per GOST 23216-78 in terms of

exposure to mechanical factors, and Ж2 as per GOST 15150-69 in terms of exposure to climatic

factors.

11.

SAFETY REQUIREMENTS

The design of the locksensures safety of personnel involved in mounting and maintenance.

Due to low DC supply voltage, the products correspond to class III as per ГОСТ 12.2.007.0-

75 and are electrically safe.

Fire safety of the locks is ensured by use of non-combustible or hardly combustible materials,

and low supply voltage.

12.

DISPOSAL

The product is not hazardous for human life and health or for the environment; disposal after

its service life is performed without taking any special measures for environment protection.

13.

WARRANTY LIABILITIES

The manufacturer, ETC PROMIX LLC, warrants conformity of Promix-SM104 locks to

requirements of current Technical Specifications provided that transportation, storage, installation

and operation rules established in this Manual are followed.

Within the period of warranty, ETC PROMIX LLC undertakes to repair defective products free

of charge. Expenses for transporting the product to the place of repair and back will be borne by

the Buyer.

Warranty liabilities do not cover any defects and damages caused by:

Improper maintenance by the Buyer;

Use of the product under conditions that do not comply with the operation requirements;

Mechanical damages or disassembly of the products bythe Buyer;

Non-observance of the transportation and storage rules.

On expiration of the warranty service period, the manufacturer provides after-warranty service

on a contractualbasis.

Promix-SM104

10

14.

ACCEPTANCE AND PACKING

CERTIFICATE

Electromechanical lock Promix-SM104

in quantity of ____ pieces (1 pc. by default)

bearing the

manufacturing date and QCD mark on the body, was manufactured and accepted in compliance

with Specifications ПШБА.304268.001 ТУ, obligatory requirements of state standards and

current technical documentation, recognized as fit for operation and packed by ETC PROMIX

LLC.

PROMIX Engineering and Technical Center LLC

Russia, 214030, Smolensk, Krasninskoye sh., 35, lit. A

Phone: (4812) 619-330

www.promix-center.ru

vk.com/promixcenter

facebook.com/promixcenter

mail@promix-center.ru

This manual suits for next models

4

Table of contents

Other PROMIX Lock manuals

PROMIX

PROMIX SM490 User manual

PROMIX

PROMIX Promix-SM306 User manual

PROMIX

PROMIX Promix-SM213 User manual

PROMIX

PROMIX Promix-SM132 Series User manual

PROMIX

PROMIX Promix-SM308.10.1 User manual

PROMIX

PROMIX SM 323 User manual

PROMIX

PROMIX SHERIFF-5 User manual

PROMIX

PROMIX SM305 User manual

PROMIX

PROMIX Promix-SM420 User manual

PROMIX

PROMIX SHERIFF-9.1 User manual