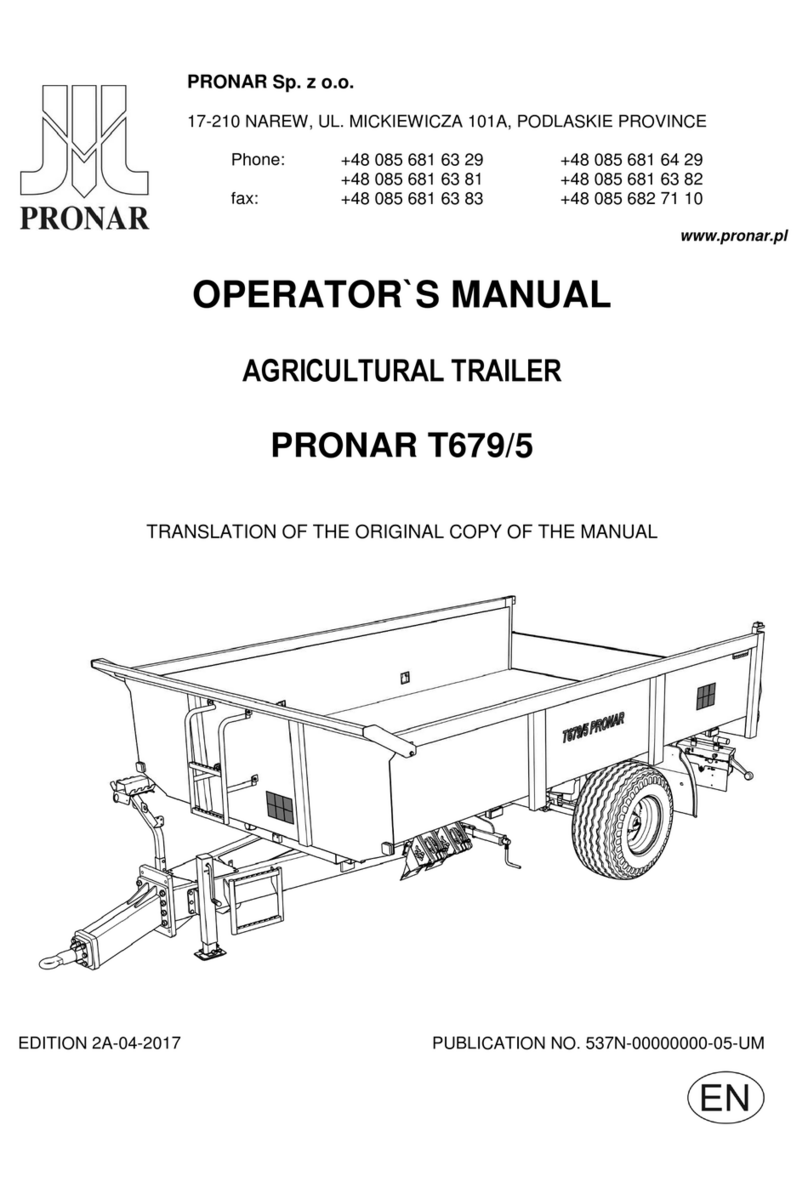

Introduction

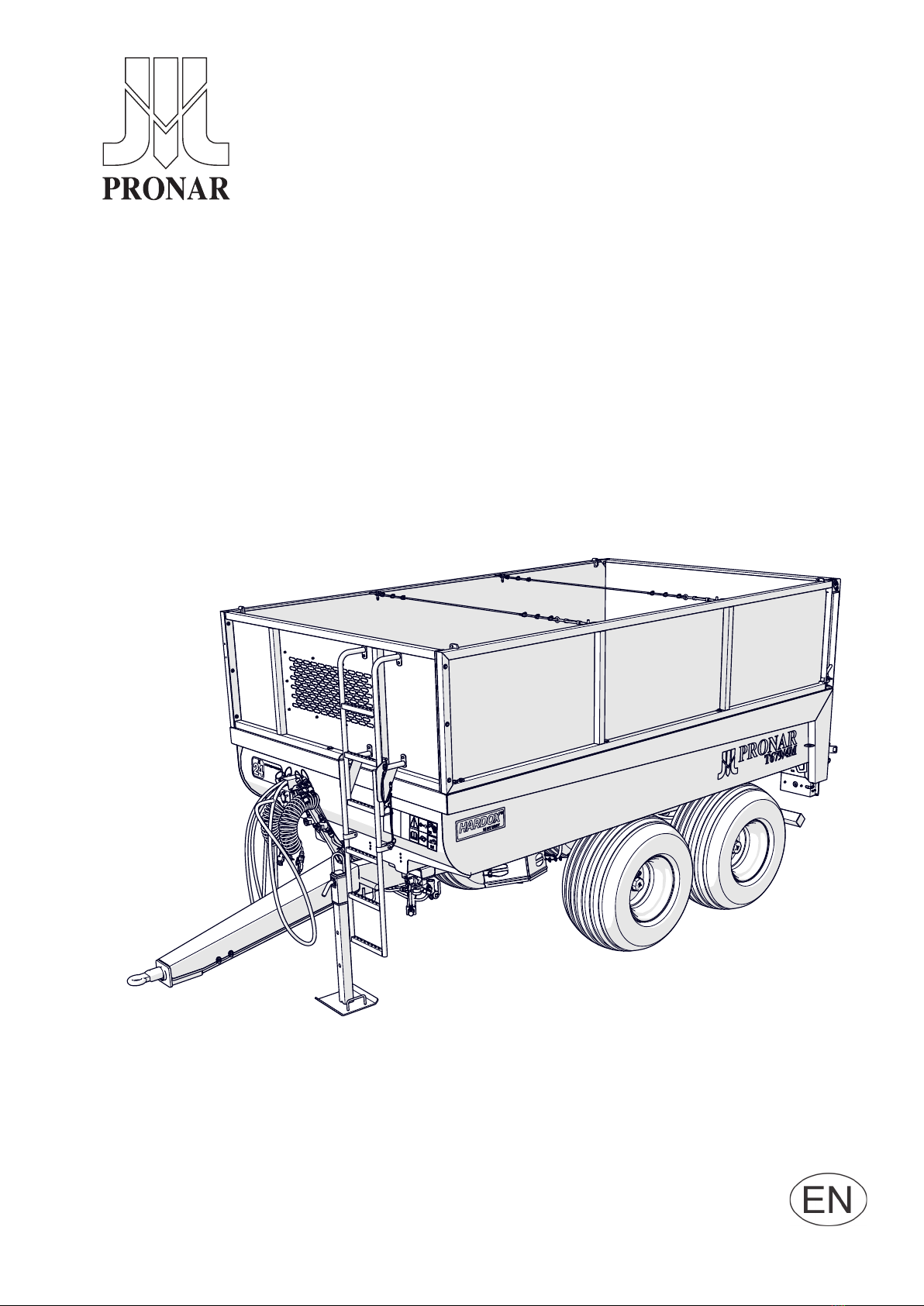

6PRONAR T679/4M

1.5 START-UP OF THE TRAILER

THE SCOPE OF ACTIVITIES

• Read the contents of this OPERA-

TOR'S MANUAL and follow the rec-

ommendations contained therein.

• Adjust the height of the drawbar eye

to the hitch on the tractor.

• Check all trailer lubrication points, if

necessary lubricate machine as rec-

ommended in CHAPTER 5.17.

• Check the tightness of the nuts se-

curing the road wheels.

• Inspect the machine before traveling

in accordance with the guidelines in

CHAPTER 5.8.

• Drain the brake system air tank

(CHAPTER 5.5).

• Make sure that the pneumatic, hy-

draulic and electrical connections on

the agricultural tractor comply with

the requirements, otherwise do not

connect the trailer.

If all of the above activities have been car-

ried out and the technical condition of the

trailer does not raise any objections, con-

nect the machine to the tractor.

Start the tractor, check individual systems

and carry out a test run of the trailer and

perform a test drive without load (without a

loading box). It is recommended that visual

inspection be carried out by two people,

one of them should be permanently in the

tractor's cab. The test run must be carried

out in the order shown below.

• Connect the trailer to the appropriate

hitch on the agricultural tractor.

• Connect the brake, electrical and hy-

draulic system lines.

• By activating individual lights, check

the correct operation of the electrical

system.

• Perform a test tipping of the loading

box.

• Start and check the correct operation

of the rear ap control system.

• When moving off check the operation

of the service brake.

• Perform a test drive.

If during the test trip, disturbing symptoms

CAUTION

The first start-up involves checking the

machine in the presence of the Seller. The

Seller is obliged to carry out training in the safe

and proper operation of the machine.

Training by the seller does not release the user

from the obligation to become familiar with

the contents of this manual and to follow the

recommendations contained therein.

ADVICE

Servicing activities: connecting/disconnecting

from the tractor, adjusting the drawbar position,

tipping the loading box, etc. are described

in detail in the further part of the manual in

CHAPTER 4.