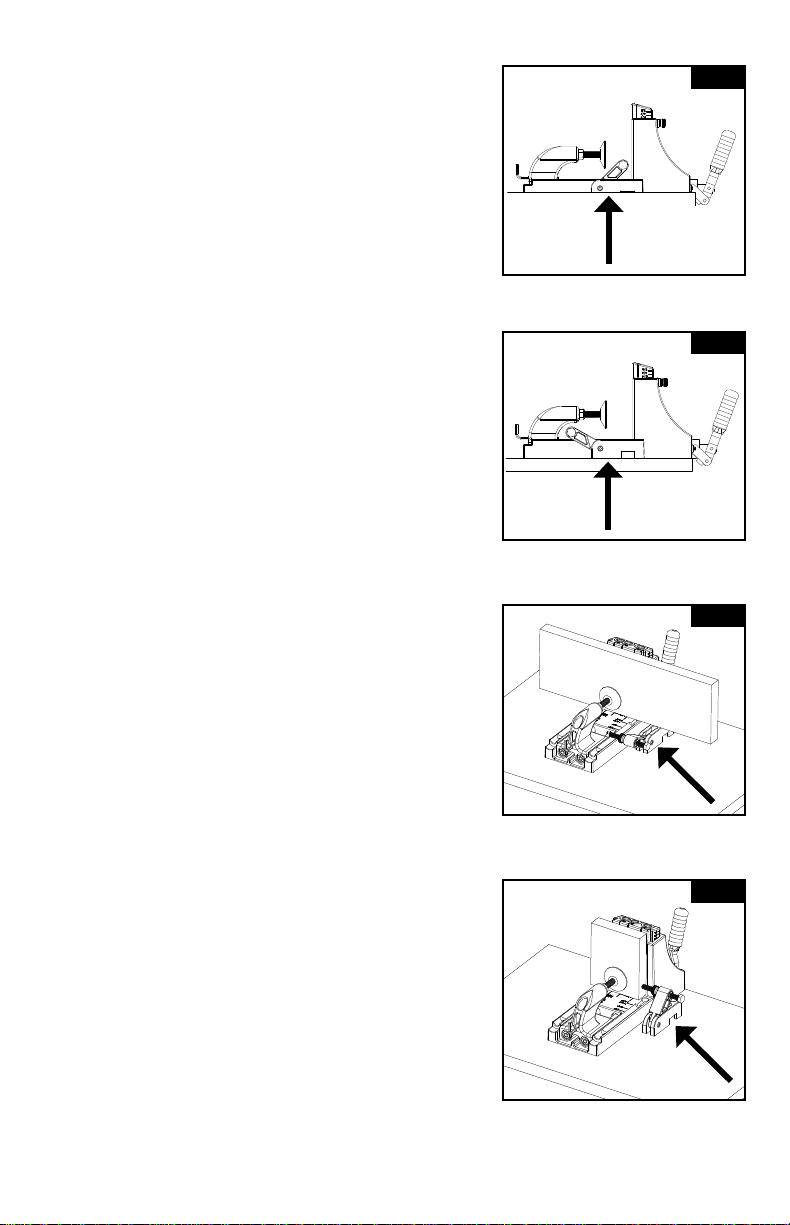

Material Support/Stop (Fig. 2A-D)

The Material Support/Stop is a dual function feature

that both “Supports” large panels to keep them

perpendicular to the base of the jig, and “Stops”

workpieces in a desired position to easily repeat a

2-hole spacing across a rail.

If you intend to use the Support/Stop mainly as

a support, we recommend that you locate it 8-10”

from the base of the jig to provide proper

support across the full width of a panel. Add

multiple Support/Stops to your work surface to

gain more placement versatility (Item# KJSS). Screw

holes are provided to screw mount the Material

Support/Stop to the work surface.

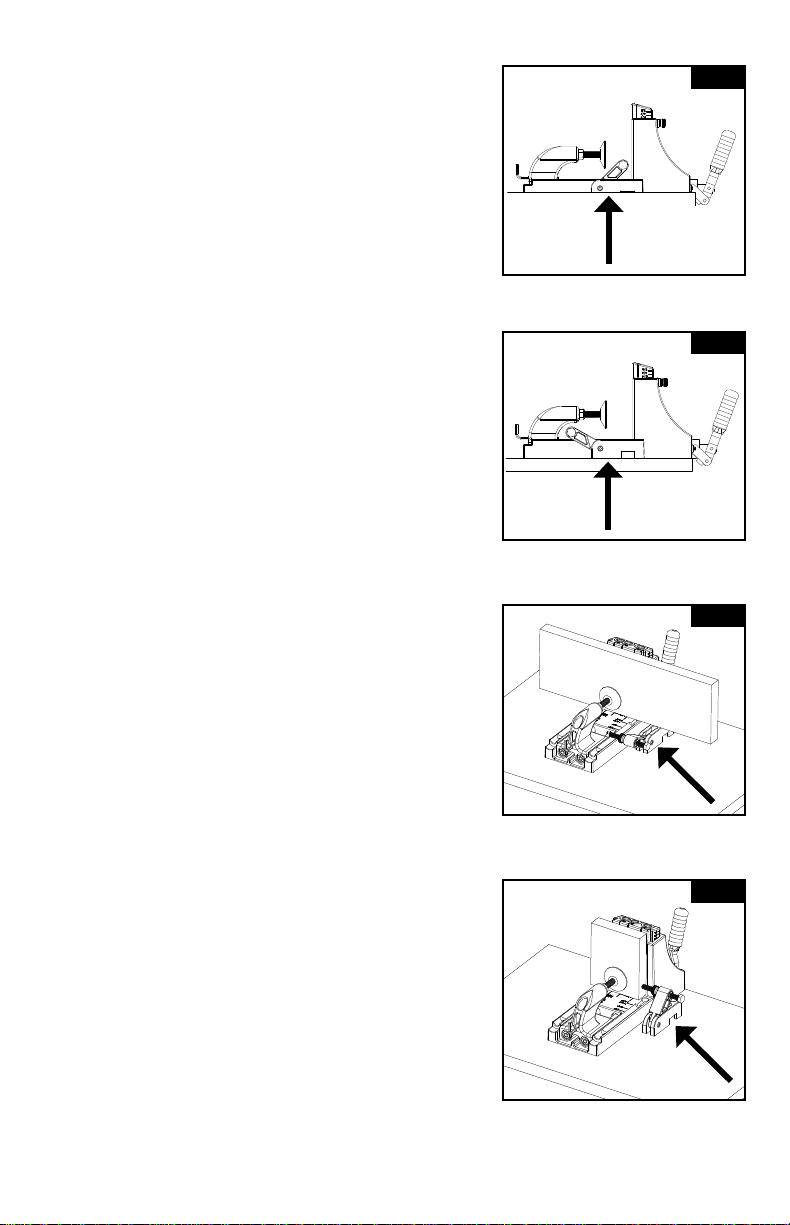

The Material Support/Stop is also designed to

function as a position stop. The end of the Nylon

Stop Bolt is positioned to rest against the workpiece

to “center” the workpiece across the predetermined

2-hole spacing. By locking the Nylon Stop Bolt in

position several pieces of the same width may be

located and drilled quickly to minimize the time

involved in measuring the pocket hole location for

each workpiece. When the stop position is no longer

being used the Material Support/Stop Arm may be

pivoted out of the way to drill panels or large face

frame components. We recommend that you locate

the Material Support/Stop approximately 1/8” to

3/4” from the base of the jig for optimum

performance as a Stop.

You may notice that a notch in the bottom of the

Support/Stop Base is sized to span the profile of

Kreg Mini Trak (sold separately). A special “T”-nut and

#10-32 Machine Screw are included with the Material

Support/Stop hardware pack for mounting to the

Kreg Mini Trak.By adding a length of Kreg Mini Trak

(KMS7506). to either side of the K3 Benchtop Base

an adjustable Support/Stop system may be created

to allow the drilling of several pocket holes across the

width of large panels at repeatable locations. Mini Trak

sold separately.

The Material Support/Stop may also be used with

the K3 Portable Base as a Stop. Mount the Material

Support/Stop adjacent to the Portable Base in a

similar fashion as with the Benchtop Base.

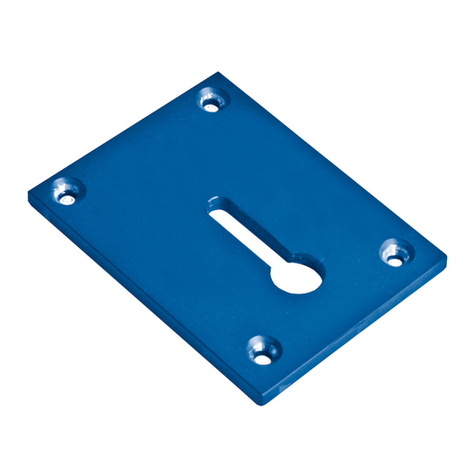

Material Support/Stop shown in

“Stop” position.

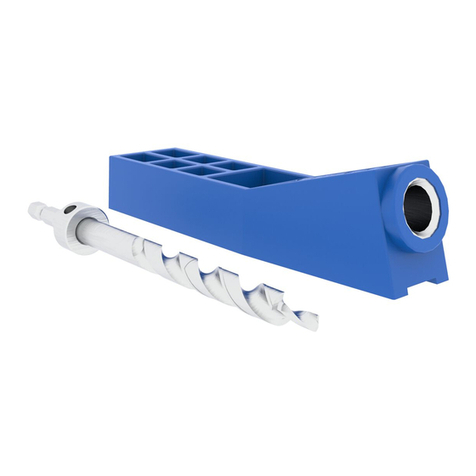

1” tall Material Support/Stop shown

in “Support” position.

Material Support/Stop helping to

balance a panel.

Material Support/Stop positioning

workpiece for proper placement.

Fig.2A

Fig.2B

Fig.2C

Fig.2D

Material Support/Stop (Fig. 2A-D)

The Material Support/Stop is a dual function feature

that both “Supports” large panels to keep them

perpendicular to the base of the jig, and “Stops”

workpieces in a desired position to easily repeat a

2-hole spacing across a rail.

If you intend to use the Support/Stop mainly as

a support, we recommend that you locate it 8-10”

from the base of the jig to provide proper

support across the full width of a panel. Add

multiple Support/Stops to your work surface to

gain more placement versatility (Item# KJSS). Screw

holes are provided to screw mount the Material

Support/Stop to the work surface.

The Material Support/Stop is also designed to

function as a position stop. The end of the Nylon

Stop Bolt is positioned to rest against the workpiece

to “center” the workpiece across the predetermined

2-hole spacing. By locking the Nylon Stop Bolt in

position several pieces of the same width may be

located and drilled quickly to minimize the time

involved in measuring the pocket hole location for

each workpiece. When the stop position is no longer

being used the Material Support/Stop Arm may be

pivoted out of the way to drill panels or large face

frame components. We recommend that you locate

the Material Support/Stop approximately 1/8” to

3/4” from the base of the jig for optimum

performance as a Stop.

You may notice that a notch in the bottom of the

Support/Stop Base is sized to span the profile of

Kreg Mini Trak (sold separately). A special “T”-nut and

#10-32 Machine Screw are included with the Material

Support/Stop hardware pack for mounting to the

Kreg Mini Trak.By adding a length of Kreg Mini Trak

(KMS7506). to either side of the K3 Benchtop Base

an adjustable Support/Stop system may be created

to allow the drilling of several pocket holes across the

width of large panels at repeatable locations. Mini Trak

sold separately.

The Material Support/Stop may also be used with

the K3 Portable Base as a Stop. Mount the Material

Support/Stop adjacent to the Portable Base in a

similar fashion as with the Benchtop Base.

Material Support/Stop shown in

“Stop” position.

1” tall Material Support/Stop shown

in “Support” position.

Material Support/Stop helping to

balance a panel.

Material Support/Stop positioning

workpiece for proper placement.

Fig.2A

Fig.2B

Fig.2C

Fig.2D