SAFETY FIRST !

WARNING

WARNING INDICATES A POTENTIALLY

HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH, SERIOUS

INJURY OR MAJOR PROPERTY DAMAGE.

This instruction manual contains very important information for you to know and understand. This

information is provided for your safety and to help prevent equipment problems from occurring. Please

observe all safety information labeled danger, warning and caution.

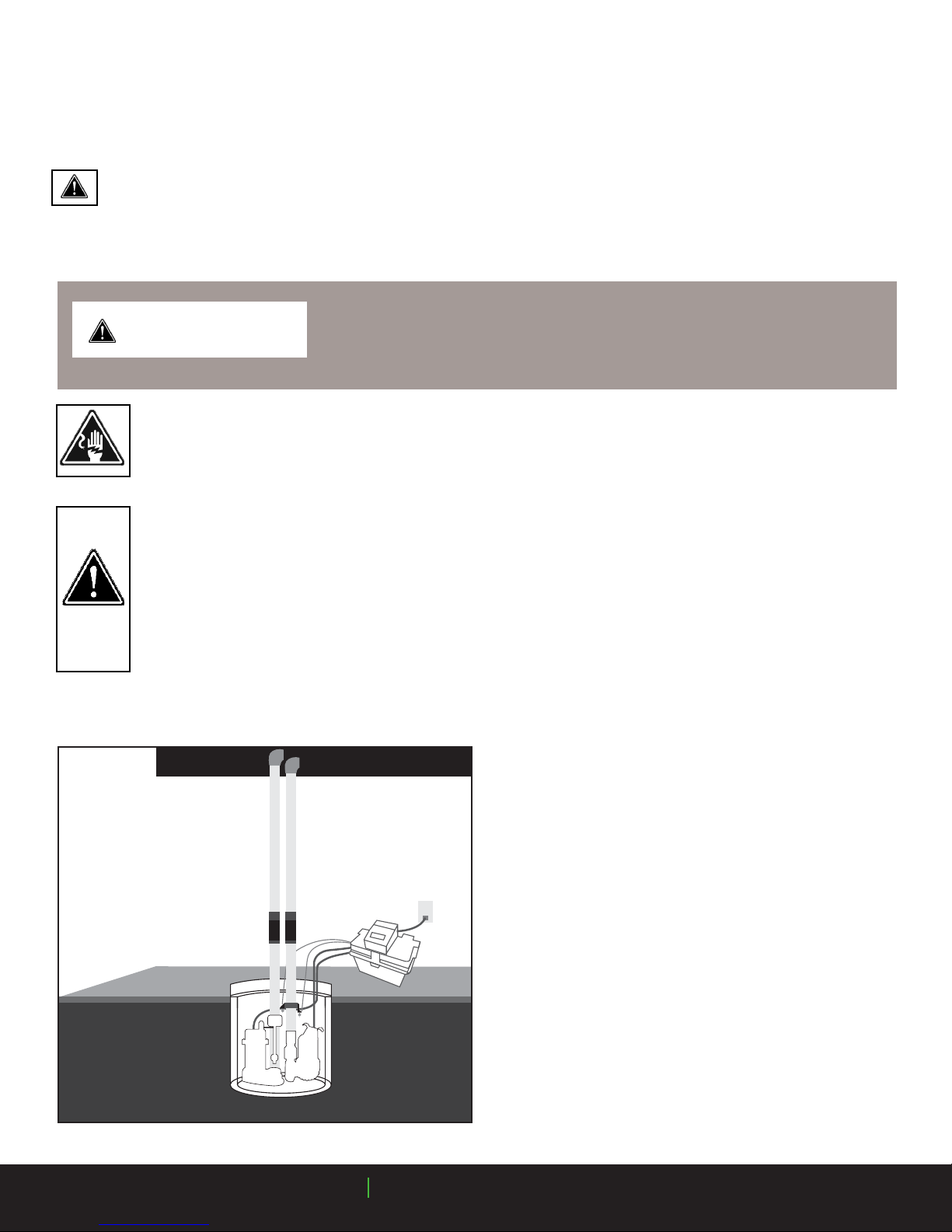

RISK OF ELECTRIC SHOCK.TO REDUCE THIS RISK, OBSERVE THE FOLLOWING

WARNINGS:

WARNING! To reduce the risk of electrical shock, this system must be properly grounded in accordance with

the National Electric Code (NEC) and all applicable state and local codes and ordinances.The receptacle should be

protected with a Ground Fault Circuit Interrupter (GFCI).

WARNING! To reduce the risk of electrical shock, always disconnect the pump / system from the power source and

battery BEFORE handling or servicing.

WARNING! Never remove the ground prong from the plug, or use an adapter that eliminates the ground prong.

WARNING! Never plug this pump system into an electric outlet while standing on a wet surface.

WARNING! Cables should be protected at all times to avoid punctures, cuts and abrasions that may result in exposed

wiring. Never handle connected power cords with wet hands.

WARNING! The PumpSpy™System has not been investigated for use in or around swimming pools, marine areas,

recreational water installations, decorative fountains or any installation where human contact with the pumped uid is

common.

WARNING! Do not use an extension cord. Extension cords could present a safety hazard if not properly sized,

become damaged or the connection falls into the sump pit. Do not attempt to disassemble the PumpSpy controller or

Backup Pump. There are no eld serviceable parts or repair options!

RISK OF EXPLOSION. TO REDUCE THIS RISK, OBSERVE THE FOLLOWING

WARNINGS:

WARNING! Do not use to pump ammable or explosive liquids such as gasoline, fuel oil, kerosene, etc.

WARNING! Do not use in a ammable or explosive atmosphere.

NOT SUITED FOR POTABLE WATER APPLICATIONS.

WARNING! Do not use this pump to transfer water that will be used for potable (drinking) water. This pump is only

to be used in applications for which it is designed.

CAUTION INDICATES A POTENTIALLY HAZARDOUS

SITUATION WHICH, IF NOT AVOIDED, MAY RESULT IN

MINOR INJURY OR PROPERTY DAMAGE.

CAUTION

TO REDUCE THE RISK OF HAZARDSTHAT CAN CAUSE INJURY OR PROPERTY

DAMAGE, OBSERVE THE FOLLOWING WARNINGS:

CAUTION! Do not use discharge hose. Discharge hose may whip under pressure. Use rigid piping and ttings to

secure the pump in the sump basin to reduce movement.

CAUTION! Do not install the pump if it has been damaged in any way.

CAUTION! Do not carry or lift the pump by the power cord. Use the pump’s lifting handle.

© PumpSpy Technology, LLC Questions? Call Tech Support: 515.999.6935