Fermenting

Fermentation times will vary with how much sugar is used, the ambient temperature you are

fermenting in and if you are using a heater or not.

•6kg of dextrose at 25 degrees will ferment in 48 hours

•9kg of dextrose at 20 degrees will take 10 to 14 days

A fermenting temperature of 20-24 degrees will produce the cleanest wash.

Some points to note:

•When the yeast is first added to the wash in a warm environment, the fermentation is

very active and may blow the water out of the airlock. To prevent a mess, fit the airlock

after 2 days when the fermentation has slowed.

•If the temperature is too low (less than 20 degrees), the fermentation may stop, get the

wash to a warmer position or fit a heater belt or pad, stir well and fermentation should

restart.

•If the temperature is too hot (above 30 degrees), the yeast will become stressed and

produce “off” flavours, if the temperature gets above 35 degrees the yeast will die and

fermentation will stop.

•If fermentation gets “stuck” e.g. fermentation has stopped and will not restart, take a

hydrometer reading:

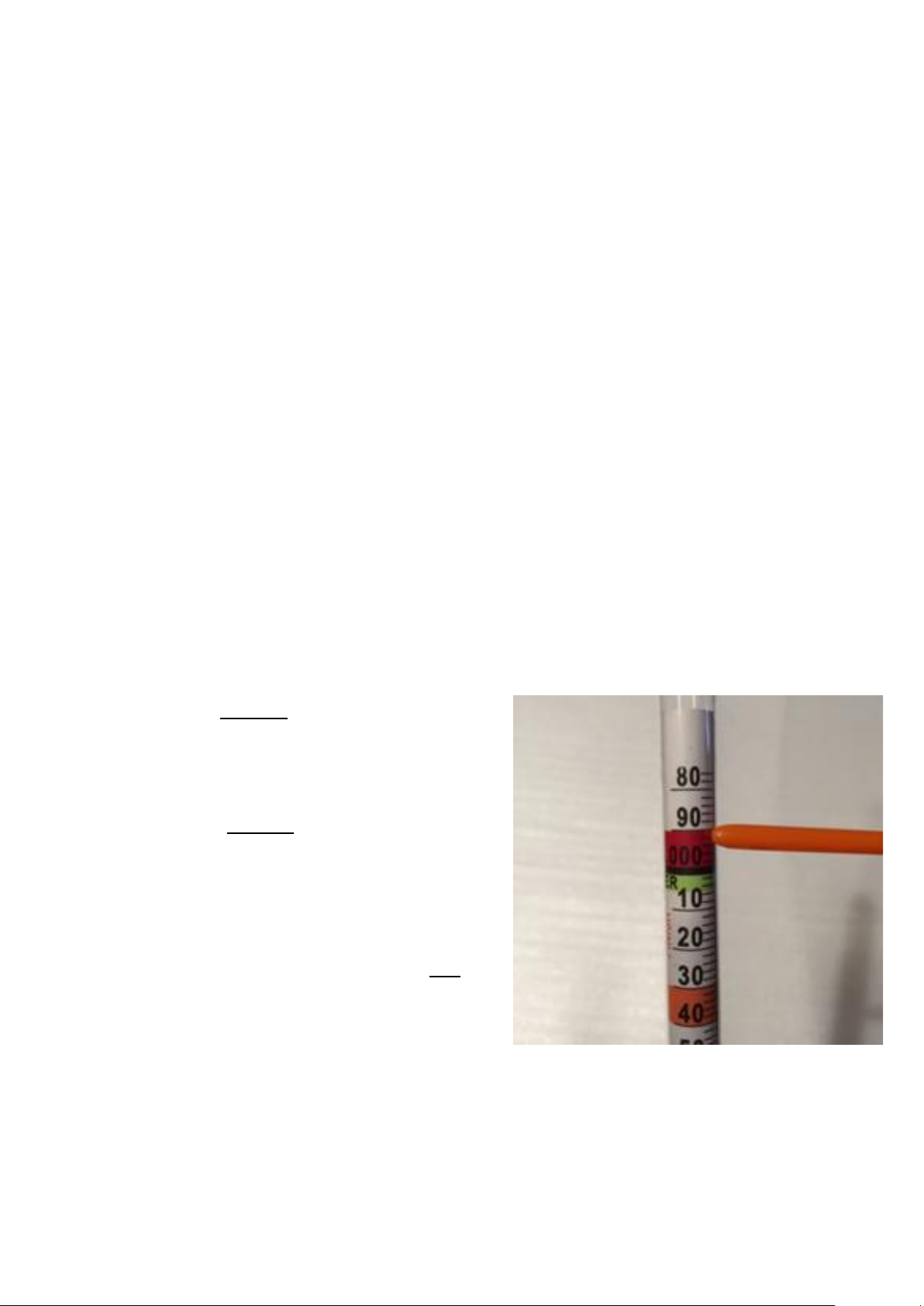

oIf the reading is below or near 0.990

(as shown on the photo) preferably at

the 80, the wash has finished

fermenting.

oIf the reading is significantly higher

than the photo, e.g. above the 1.006

green section, the fermentation is

“stuck”, and remedial action needs to

be taken.

•To restart a stuck fermentation, do not add

another packet of turbo yeast, there is a

measured amount of nutrient in each pack

and adding more increases the pH of the

wash, and unless the pH is lowered the wash can produce a spirit with a blue tinge.

•Use a champagne yeast from your local home brew store, it will take a lot longer to

finish fermenting, up to an additional 10 days.