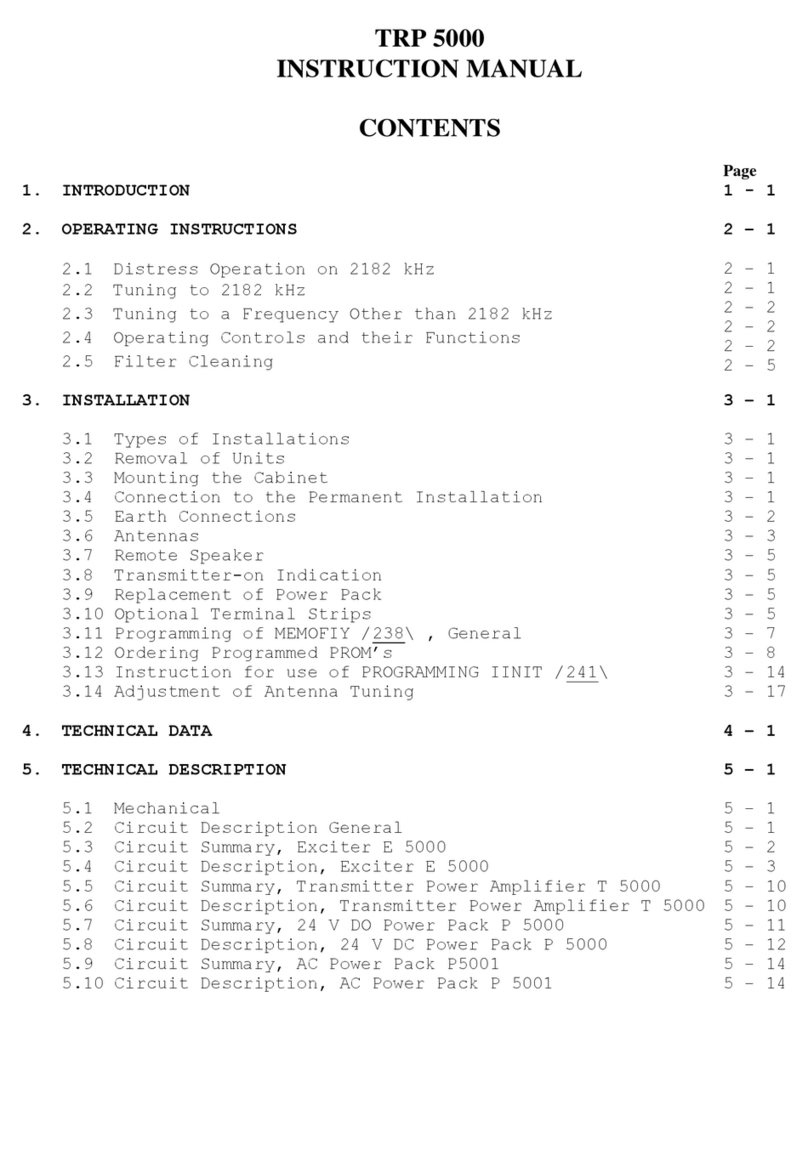

Contents

Contents..........................................................................................................................................................................2

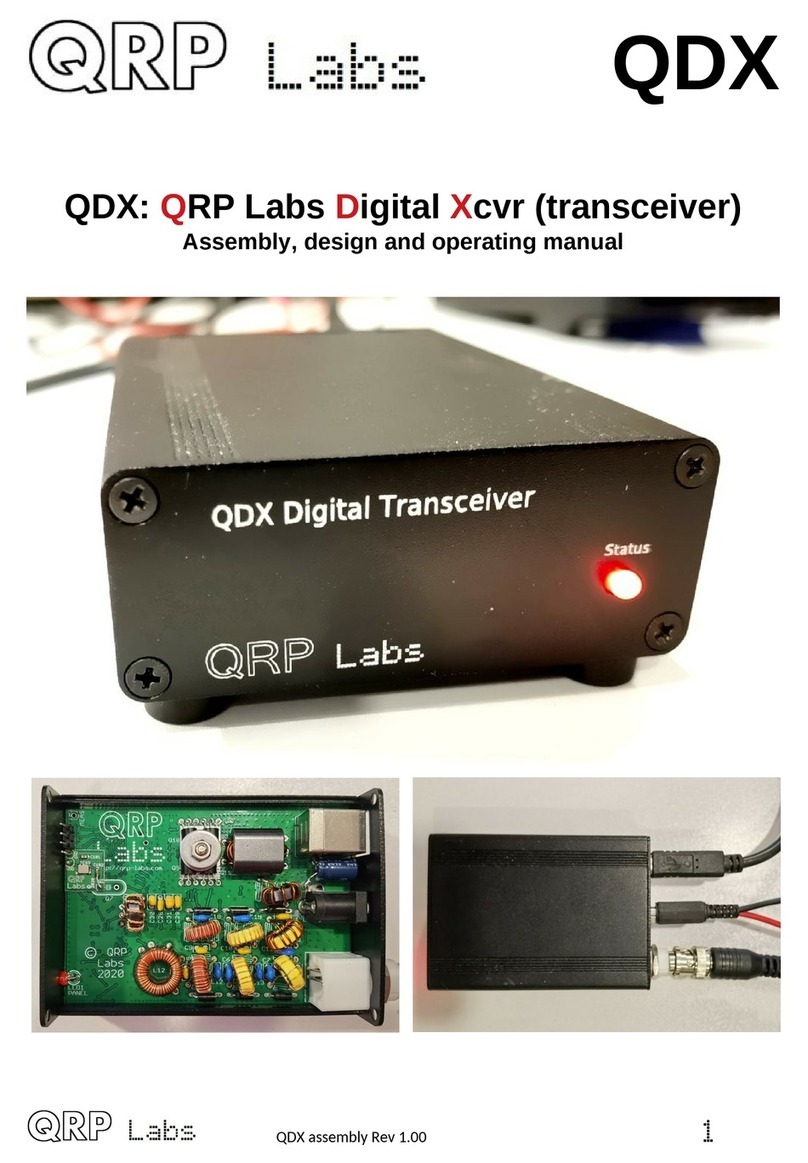

1. Introducon.................................................................................................................................................................3

2. Assembly.....................................................................................................................................................................5

2.1 General uidelines.................................................................................................................................................5

2.2 PCB dia rams (trace, component iden'caon)...................................................................................................9

2.3 Parts list...............................................................................................................................................................17

2.5 Install all the ceramic capacitors..........................................................................................................................23

2.6 Install 1N4007 diodes..........................................................................................................................................24

2.7 Install 47uH inductors..........................................................................................................................................25

2.8 Install BS170 PA transistors.................................................................................................................................26

2.9 Assemble and install transformer T501...............................................................................................................27

2.10 Prepare and install tapped inductor L401..........................................................................................................32

2.11 Wind and install L502........................................................................................................................................35

2.12 Install Low Pass Filter toroids............................................................................................................................36

2.13 Wind and install tri'lar toroid T401...................................................................................................................37

2.14 Wind and install transformer T507....................................................................................................................40

2.15 Install connectors..............................................................................................................................................41

2.16 Install pin header connector sockets (female)...................................................................................................42

2.17 Install power supply boards...............................................................................................................................43

2.18 Install LCD module.............................................................................................................................................47

2.19 Install 2x5-pin and 2x2-pin male pin header connectors...................................................................................48

2.20 Install four 11mm nylon spacers........................................................................................................................48

2.21 Install 20K trimmer potenometer R47.............................................................................................................49

2.22 Install 2x4-pin male header on controls PCB.....................................................................................................50

2.23 Install rotary encoders......................................................................................................................................51

2.24 Install tacle switch bu=ons..............................................................................................................................52

2.25 Install electret microphone...............................................................................................................................52

2.26 Install 11mm nylon hex spacer..........................................................................................................................53

2.27 Fit Controls PCB to main PCB.............................................................................................................................54

2.28 Plu to ether the boards...................................................................................................................................54

2.29 Oponal enclosure............................................................................................................................................56

2.30 QMX GPS interface and PTT output...................................................................................................................59

2.31 FINAL CHECKS BEFORE APPLYING POWER THE FIRST TIME!..............................................................................61

2.32 Connecons for basic operaon........................................................................................................................62

2.33 Firmware installaon.........................................................................................................................................63

3. Resources..................................................................................................................................................................66

4. Document Revision History.......................................................................................................................................66

QMX assembly Rev 1.00e 2