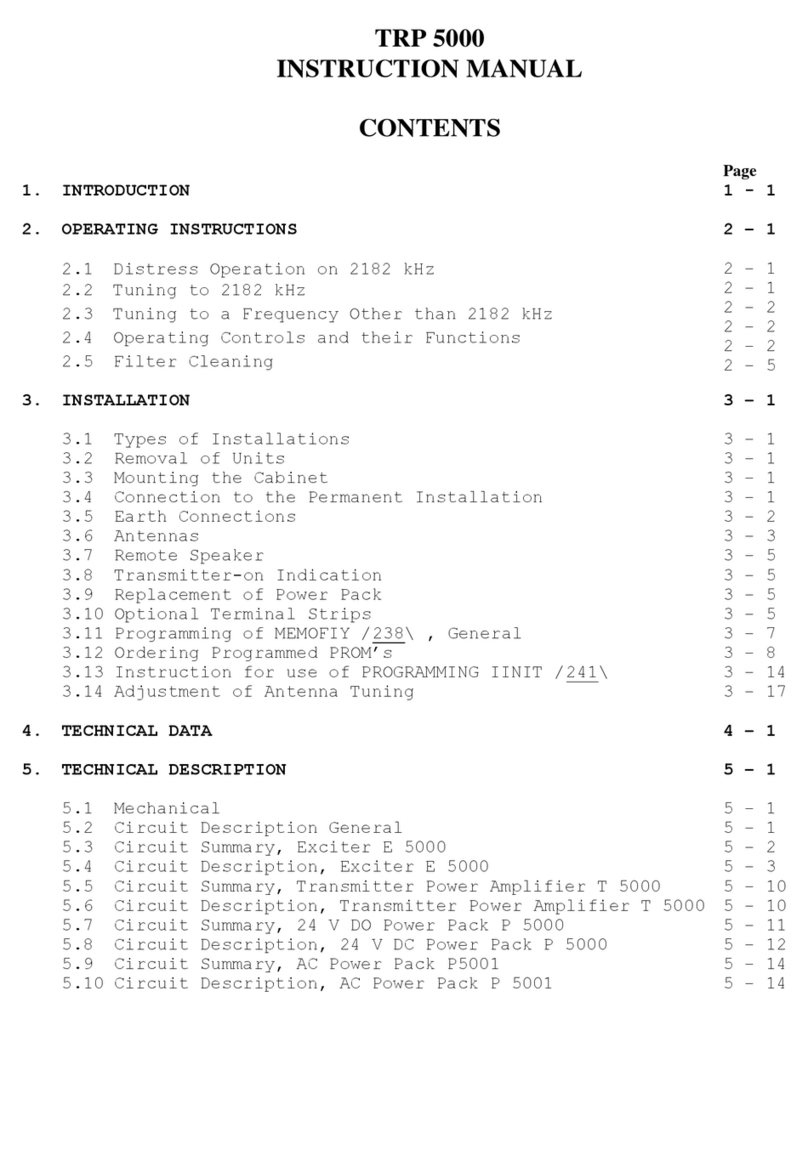

Contents

!"##

$

%&'

(

)*)+,-.$

/)+,/-$

0/)+,/ -$

/$0&12)(

3$/3&12)(

4$

$3 0

)+,-$+ /

534 3

678'!1 4

/678'!1'9$

:$

0;$

//)$

3 $)$

46</00

:=<//

> $$##:3

>1?:4

>@:

%1

%1

0%11

/$2

3)$=5

4 A(0

=($=&$/

1?4

>$$:0

&$0

;$/0

>$:=0

00

/2:B0

3#$ 00

4:>$0

)==00

0/

)$$ 30/

##::2/

&$/

5&C#&:/

0!A#/

2