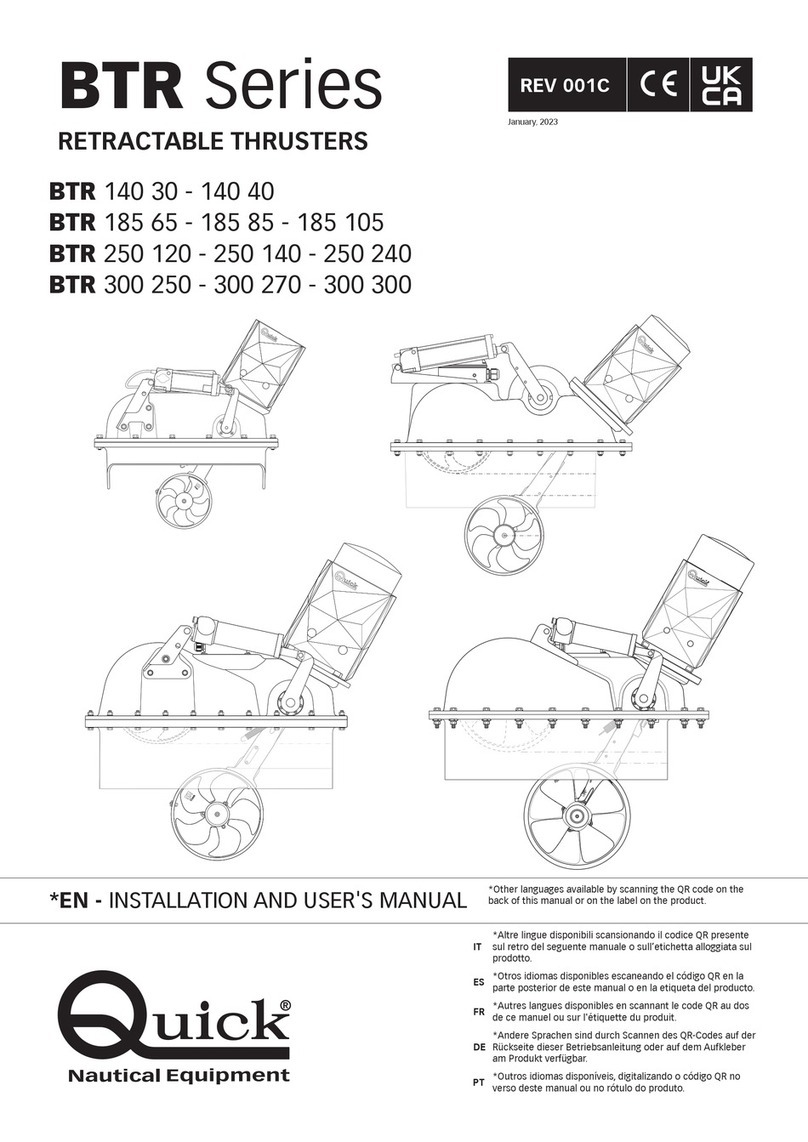

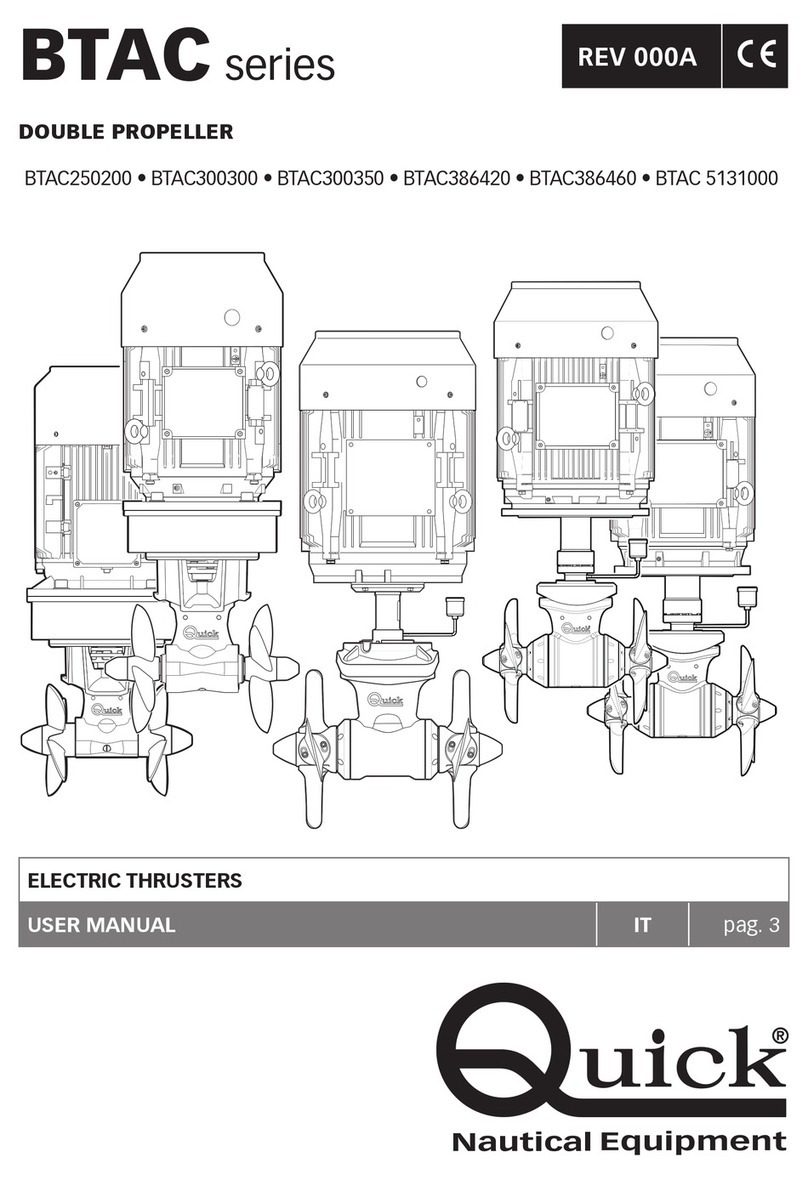

QUICK BTAC SERIES INSTALLATION AND USER’S MANUAL - REV002A

5

READ THIS INSTRUCTION MANUAL CAREFULLY BEFORE USING THE PRODUCT. IF IN DOUBT, CONTACT YOUR QUICK®

DEALER.

QUICK®RESERVES THE RIGHT TO MODIFY THE TECHNICAL CHARACTERISTICS OF THE EQUIPMENT AND THE CONTENTS OF THIS MANUAL

WITHOUT PRIOR NOTICE. IN CASE OF DISCORDANCE OR ERRORS IN TRANSLATION BETWEEN THE TRANSLATED VERSION AND THE ORIGINAL TEXT

IN THE ITALIAN LANGUAGE, REFERENCE WILL BE MADE TO THE ITALIAN TEXT.

1 - Information about the product

1.0 - Technical data

MODELS BTAC250200 BTAC300300 BTAC300350

No. of Propellers 2 counter rotating 2 counter rotating (NIBRAL)

Tunnel Ø 250 mm (9" 27/32) 300 mm (11" 13/16) 300 mm (11" 13/16)

Motor type Electric, 2-poles

Motor power 15 kW 15 kW 22 kW

Voltage 400/960 V 400/690 V 400/960 V

Thrust 200 kgf (441 lbf) 300 kgf (661 lbf) 350 kgf (771 lbf)

Tunnel thickness limit values min. 6,5 mm - max 11 mm

(min. 1/4” - max 7/16”)

min. 9,5 mm - max 13,5 mm

(min. 3/8” - max 17/32”)

Weight 160 kg (353 lb) 167 kg (368.2 lb) 216 kg (476.2 lb)

MODELS BTAC386420 BTAC386450 BTAC386450HD

No. of Propellers 2 counter rotating 2 counter rotating (NIBRAL)

Tunnel Ø 386 mm (15” 13/64)

Motor type Electric, 2-poles Electric, 4-poles

Motor power 30 kW 30 kW 30 kW

Voltage 400/690 V 400/690 V 400/690 V

Thrust 420 kgf (925 lbf) 450 kgf (992 lbf)

Tunnel thickness limit values min. 8 mm - max 15 mm (min. 5/16” - max 19/32”)

Weight 282 kg (621 lb) 300 kg (661lb) 310 kg (683 lb)

MODELS BTAC386520HD BTAC386550HD BTAC386620HD BTAC513750

No. of Propellers 2 Controrotanti 2 Controrotanti (NIBRAL)

Tunnel Ø 386 mm (15” 13/64) 513 mm (20” 13/64)

Motor type Electric, 2-poles Electric, 4-poles

Motor power 37 kW 45 kW 45 kW

Voltage 400/690 V 400/690 V 400/690 V 400/690 V

Thrust 520 kgf (1146 lbf) 550 kgf (1212 lbf) 620 kgf (1367 lbf) 750 kgf (1653 lbf)

Tunnel thickness limit values min. 8 mm - max 15 mm (min. 5/16” - max 19/32”) min.12 - max 22 mm

(15/32” - 55/64”)

Weight 315 kg (694 lb) 385 kg (848 lb) 510 kg (1224 lb) 495 kg (1091 lb)

MODELS BTAC513900 BTAC5131000 BTAC6101200 BTAC6101400

No. of Propellers 2 Controrotanti (NIBRAL)

Tunnel Ø 513 mm (20” 13/64) 610 mm (24” 1/64)

Motor type Electric, 4-poles

Motor power 55kW 75 kW 75 kW 90 kW

Voltage 400/690 V 400/690 V 400/690 V 400/690 V

Thrust 900 kgf (1984 lbf) 1000 kgf (2205 lbf) 1200 kgf (2646 lbf) 1400 kgf (3086 lbf)

Tunnel thickness limit values min.12 - max 22 mm (15/32” - 55/64”) min.14 - max 25 mm (35/64” - 63/64”)

Weight 570 kg (1256 lb) 800 kg (1763 lb) 830 kg (1830 lb) 909 kg (2004 lb)

BTAC Series EN