Quick BTAC Series User manual

Other Quick Outboard Motor manuals

Quick

Quick BTAC Series User manual

Quick

Quick BTQ140 User manual

Quick

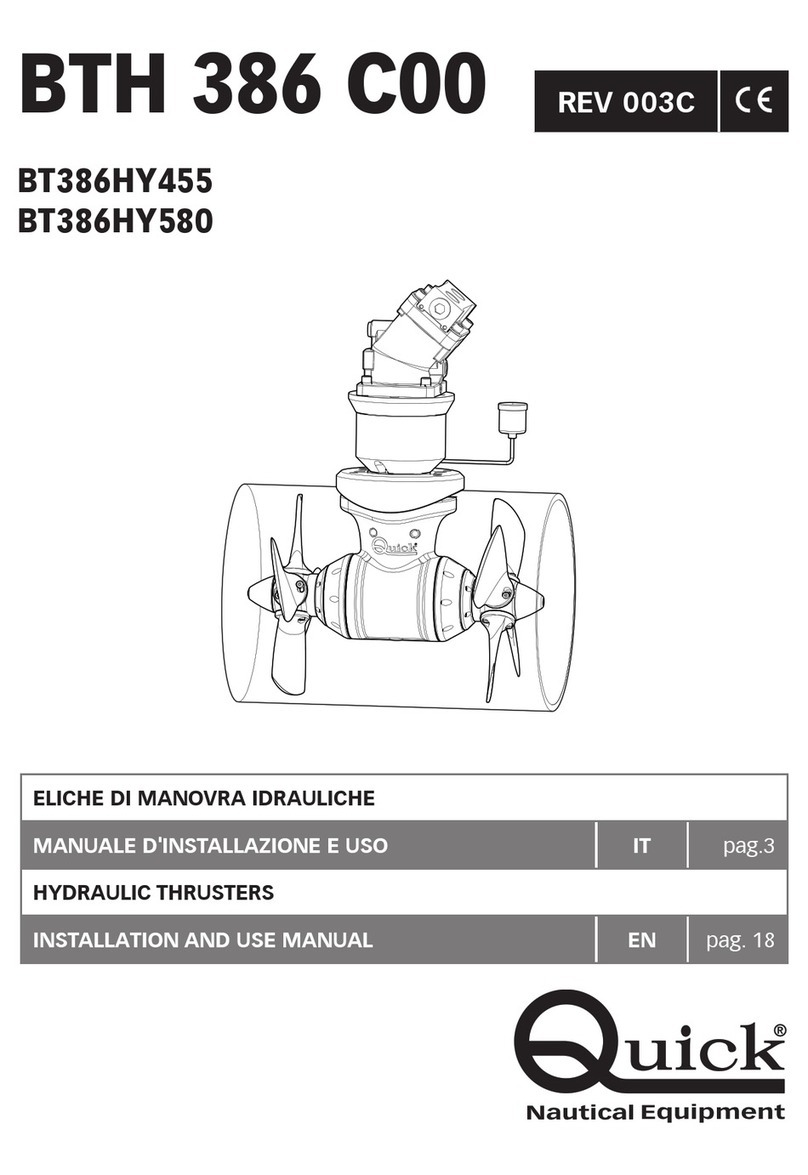

Quick BTH 386 C00 Guide

Quick

Quick BTQ250 Series User manual

Quick

Quick BT386HY455 User manual

Quick

Quick BTQ125 series Guide

Quick

Quick BTR140 Series Guide

Quick

Quick BTR185 Guide

Quick

Quick BTR250 User manual

Quick

Quick BTR1806512 User manual

Quick

Quick BTQR1806512 User manual

Quick

Quick BTQ Series Guide

Quick

Quick BT185HY080 User manual

Quick

Quick BTQ1403012 User manual

Quick

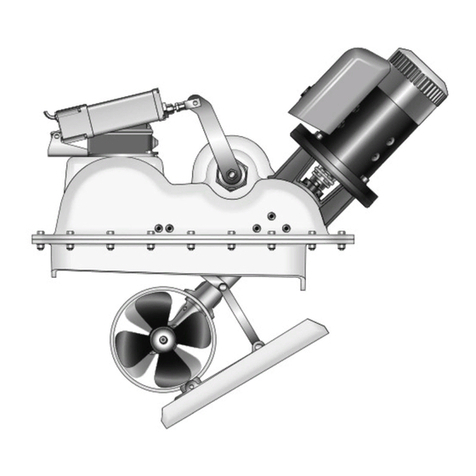

Quick BTH 513 Guide

Quick

Quick BTR Series User manual

Quick

Quick BT386AC420 User manual

Quick

Quick BTQ300 Series User manual

Quick

Quick BTQ110 series User manual

Quick

Quick BTR185 User manual

Popular Outboard Motor manuals by other brands

Mercury

Mercury 8 Bigfoot 4-Stroke Installation operation maintenance warranty manual

Sleipner

Sleipner E-Vision Electric Thruster E300 installation guide

Suzuki

Suzuki DF40A manual

IST

IST 18.BF200D manual

Side-Power

Side-Power SP 155 TC i Installation and user manual

Mercury

Mercury 40 FourStroke Operation and maintenance manual