QUIEDAN COMPANY

Overview:

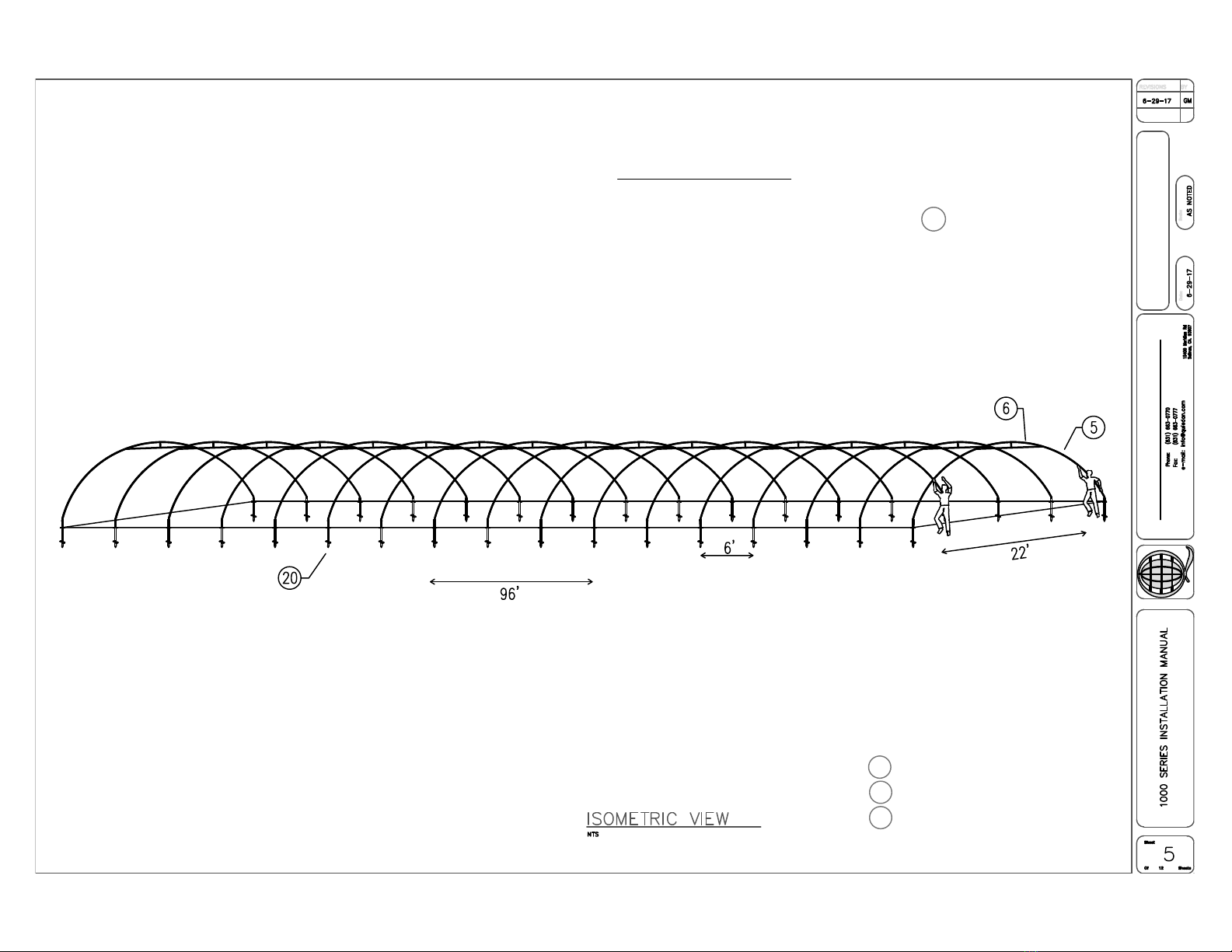

Setting up arc purlins along the exterior sides of

structure, attaching aluminum channel and setting

up front and back enclosures.

Instructions

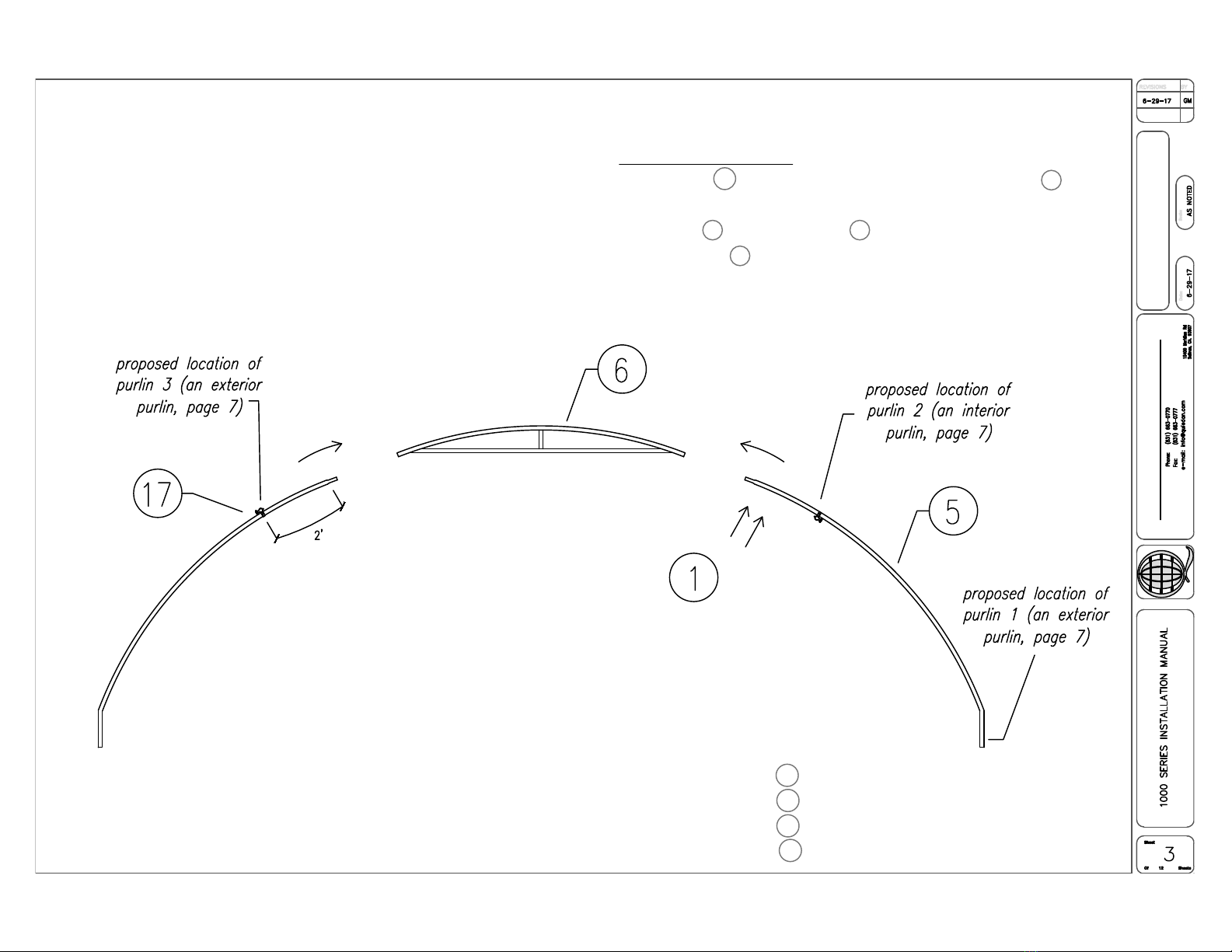

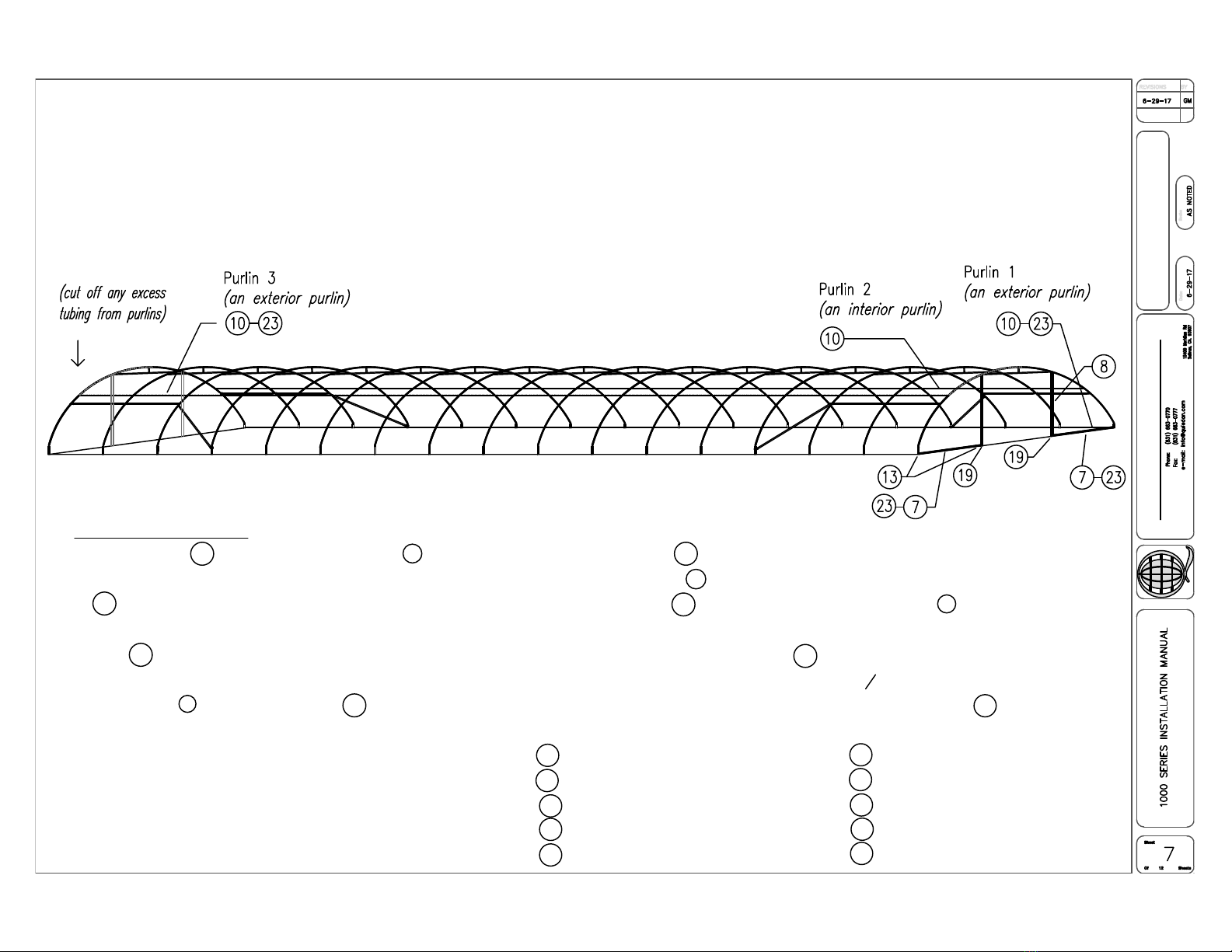

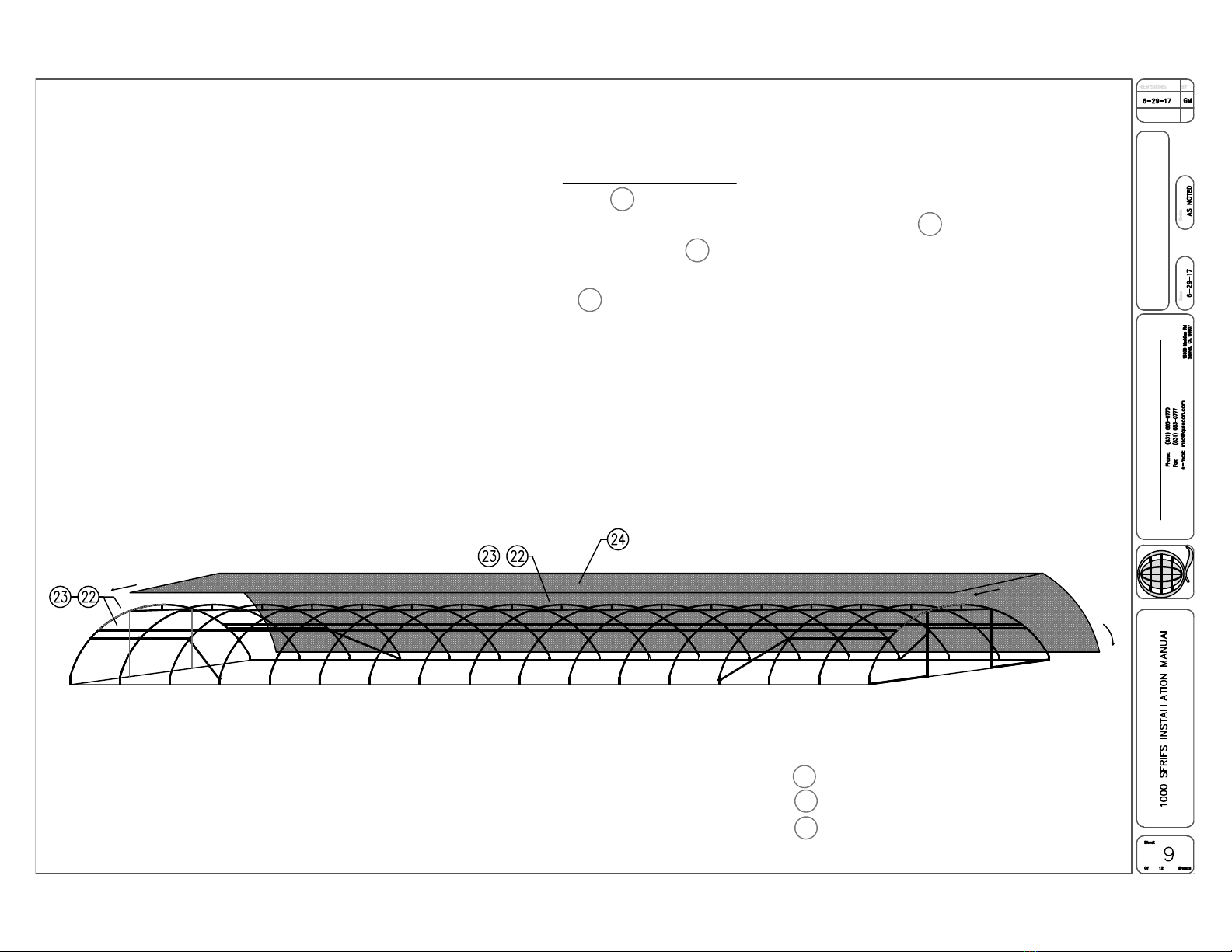

1. Connect nine 10 10' swaged tubes and one 7 6' tube together (drill

in two screws at the unions to hold tubes together) and use

17 33/33 double-hinged clamps to attach this newly created purlin

to arcs as shown. Three purlins total. See page 3 for purlin positioning.

2. Drill 23 aluminum channel along the top side of the first and last

arcs as well as on the exterior purlins as shown.

3. Gather four 7 6' tubes and drill on 23 aluminum channel to the

tubes beginning at 12" in from both ends.

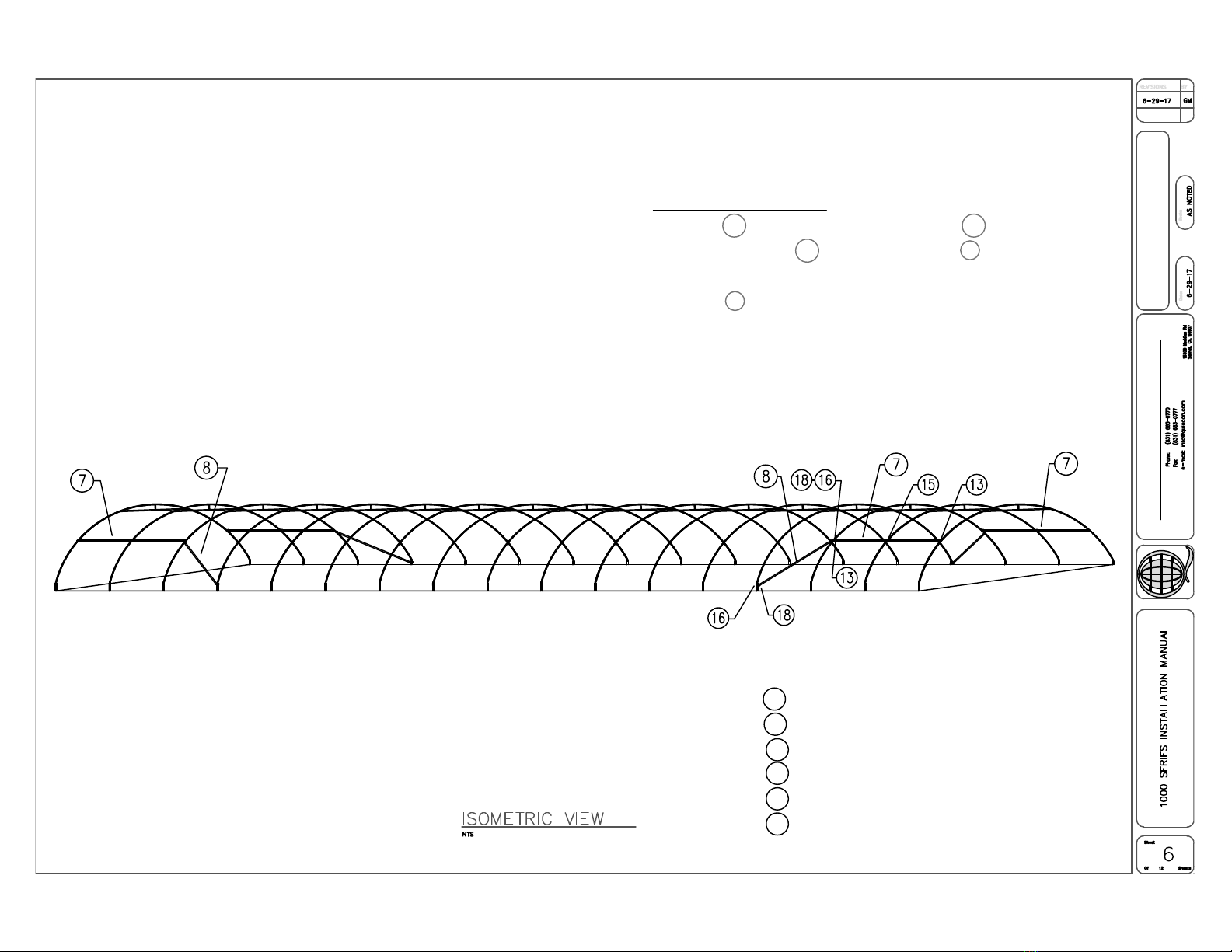

4. Using 13 straight clamp 33/33mm, connect

prepped 7 6' tubes to the first and last pairs of leg sections.

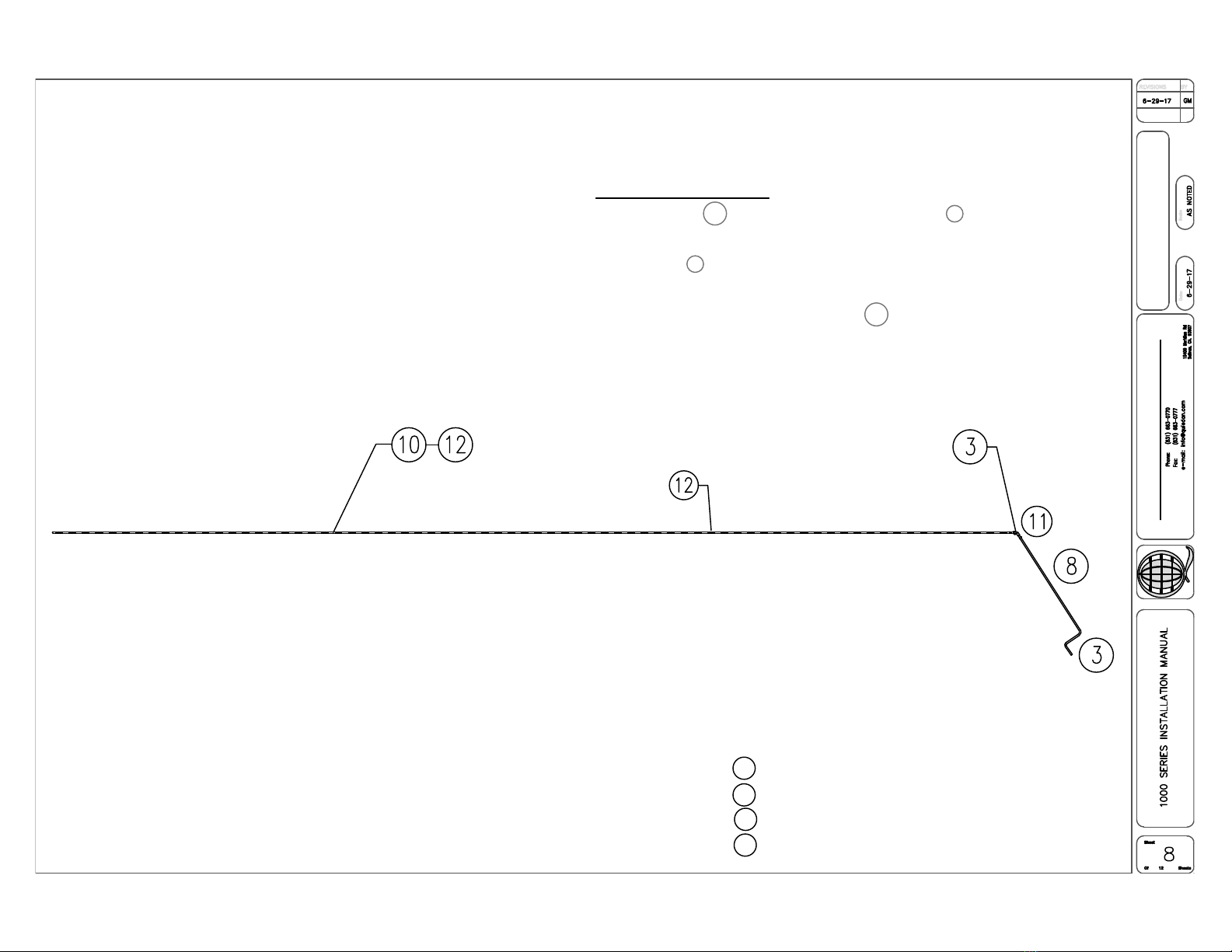

5. Drive 19 prop stops into ground and insert 8 8' tubes at the

appropriate distance so that they can be connected by the

prepped 6' tubes using 13 straight clamp 33/33mm.

6. Cut both 8' tubes approximately 12" below the hoop. Attach

the top of the the 8' tubes to the hoop using the 14 oblique clamps.

Drill on 23 aluminum channel to the 8' tube facing outward.

7 6' tube (7)

8 8' tube (4)

10 10' swaged tube (27)

14 33/33mm oblique clamp

16 33mm one-bolt strap

17 33/33mm double-hinged clamps

18 pivot cap

19 prop stop

22 wiggle wire

23 aluminum channel