2

EN

Contents

1. This manual... ..............................................3

2. Hazard symbols...........................................3

2.1 Levels of danger and signal words........3

2.2 Symbols and depictions used .................3

3. Safety instructions ......................................4

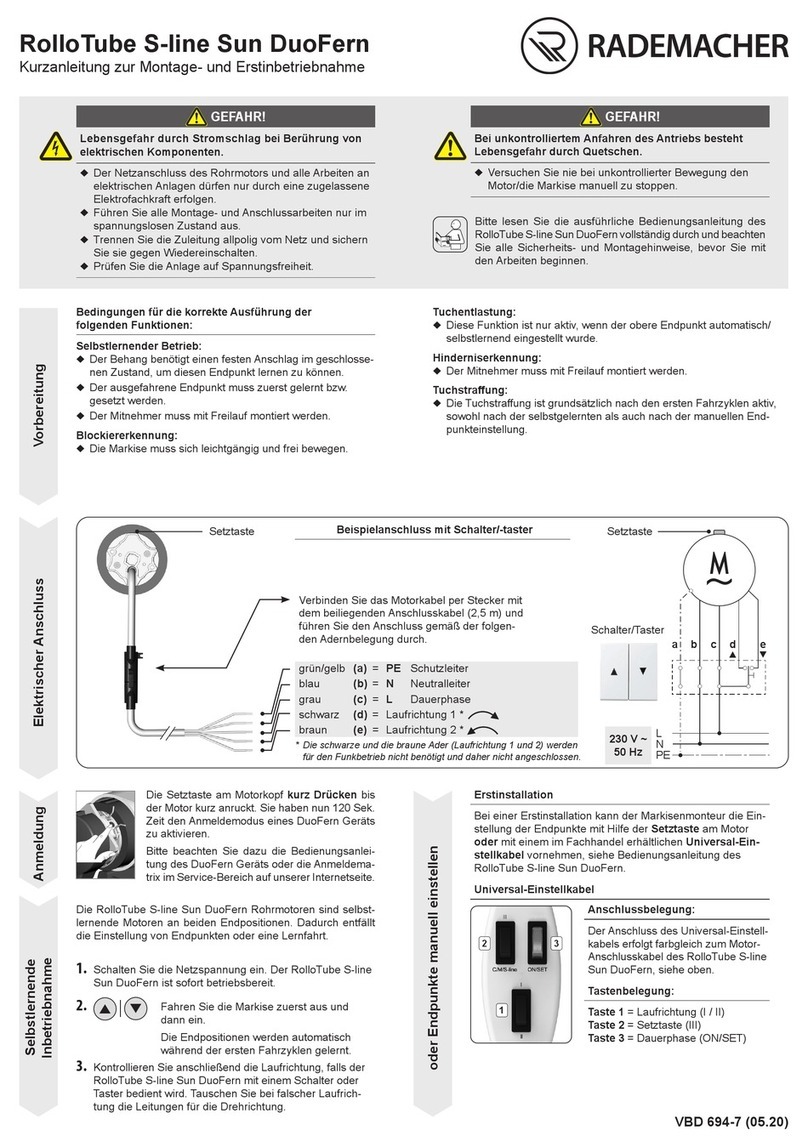

3.1 Intended use / operational

conditions....................................................... 5

3.2 Improper use................................................. 5

3.3 Required expert knowledge of the

installer............................................................ 5

3.4 Glossary - Definition ...................................6

4. Scope of delivery for RolloTube M-line

Small/Medium .............................................7

5. General view of the RolloTube M-line for

Small/Medium .............................................8

6. Functional description................................9

6.1 Blockage detection function................... 9

6.2 Obstacle detection function..................10

6.3 Function of the shutter length

compensation.............................................10

6.4 Functions if the catch has been

mounted without the freewheel

mechanism...................................................10

7. Important installation instructions .........11

7.1 Installation of the tubular motor..........11

7.2 Mounting the bearings............................12

7.3 Determining the length of the

winding shaft (5) ........................................12

7.4 Mounting / dismantling the

adapter (10)..................................................13

7.5 Dismantling the catch (8)........................13

7.6 Mounting the catch (8) with the

freewheel mechanism..............................14

7.7 Mounting the catch (8) without the

freewheel mechanism..............................14

7.8 Sliding the tubular motor (9) into the

winding shaft ..............................................15

7.9 Preparation for use of the precision

tubes ..............................................................15

7.10 Mounting the roller capsule (4)............17

7.11 Mounting the motor into the

bearings ........................................................17

7.11.1 Mounting into the drive

bearing as a click

bearing (13)..................................17

7.11.2 Mounting in other drive

bearing versions.........................17

7.11.3 Mounting into the counter

bearing (1) ....................................18

7.12 Mounting the roller shutter (17)...........18

7.12.1 Mounting the roller shutter

with rigid shaft connectors ....18

7.12.2 Mounting the roller shutter

with ties .........................................19

8. Safety instructions for the electrical

connection.................................................20

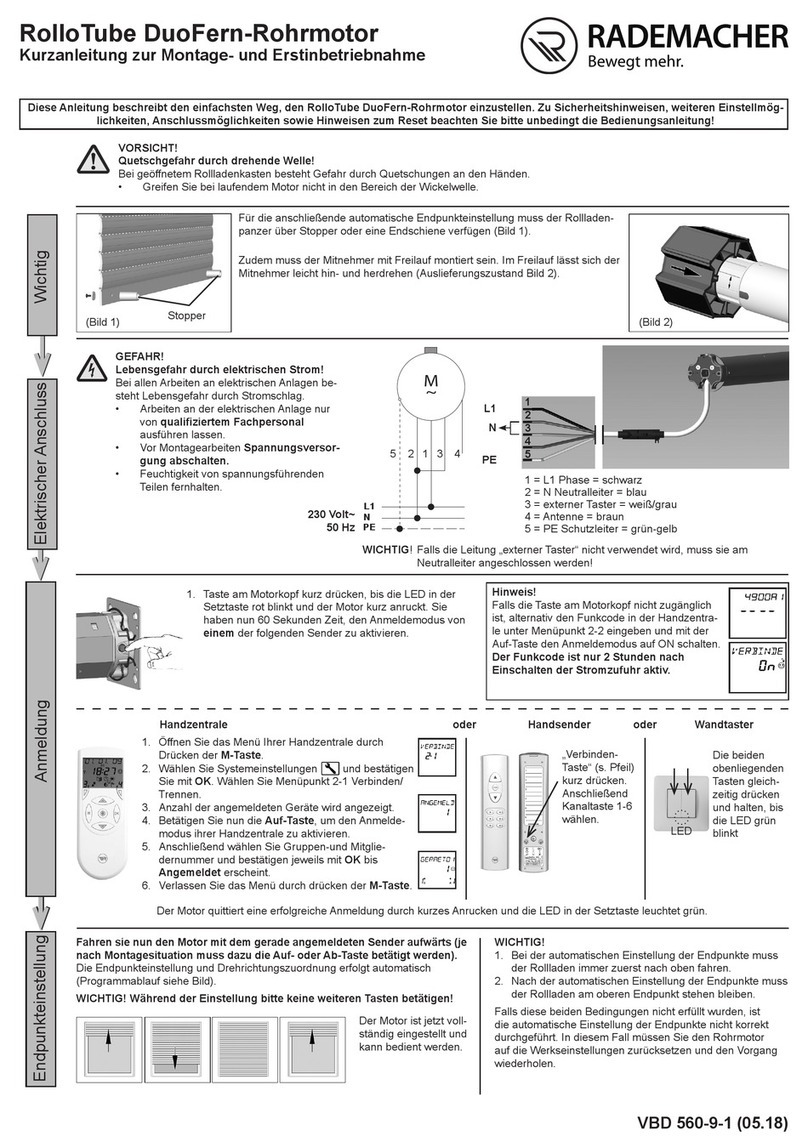

8.1 Connecting the motor cable (15).........20

8.2 Electrical connection of the

tubular motor..............................................21

8.2.1 Control of a drive from a single

point with a 1-pole switch /

button ............................................21

8.2.2 Parallel connection of several

motors............................................21

8.3 Connection of the universal setting

cable for manual end point setting.....22

8.4 Connection of a cord-switch setting

unit for manual end point setting .......22

9. Self-learning mode with smooth stop.....23

10. Manual adjustment of end points ...........23

10.1 Test run / modifying the end points ...25

11. Reloading the factory settings.................25

12. What to do if... ? .........................................26

13. Technical specifications ............................27

14. Configuration of KNX/EIB Venetian blind

actuators for RADEMACHER tubular

motors........................................................27

15. Simplified EU declaration of

conformity .................................................28

i