Servitec 35-120 with Touch controller — 06.07.2016 - Rev. B English —

English

Contents

1Notes on the operating manual.....................................................................................................................................................5

2Liability and guarantee...................................................................................................................................................................5

3Safety................................................................................................................................................................................................6

3.1 Explanation of symbols........................................................................................................................................................................6

3.2 Personnel requirements ......................................................................................................................................................................7

3.3 Personal protective equipment..........................................................................................................................................................7

3.4 Intended use..........................................................................................................................................................................................7

3.5 Inadmissible operating conditions.....................................................................................................................................................7

3.6 Residual risks .........................................................................................................................................................................................8

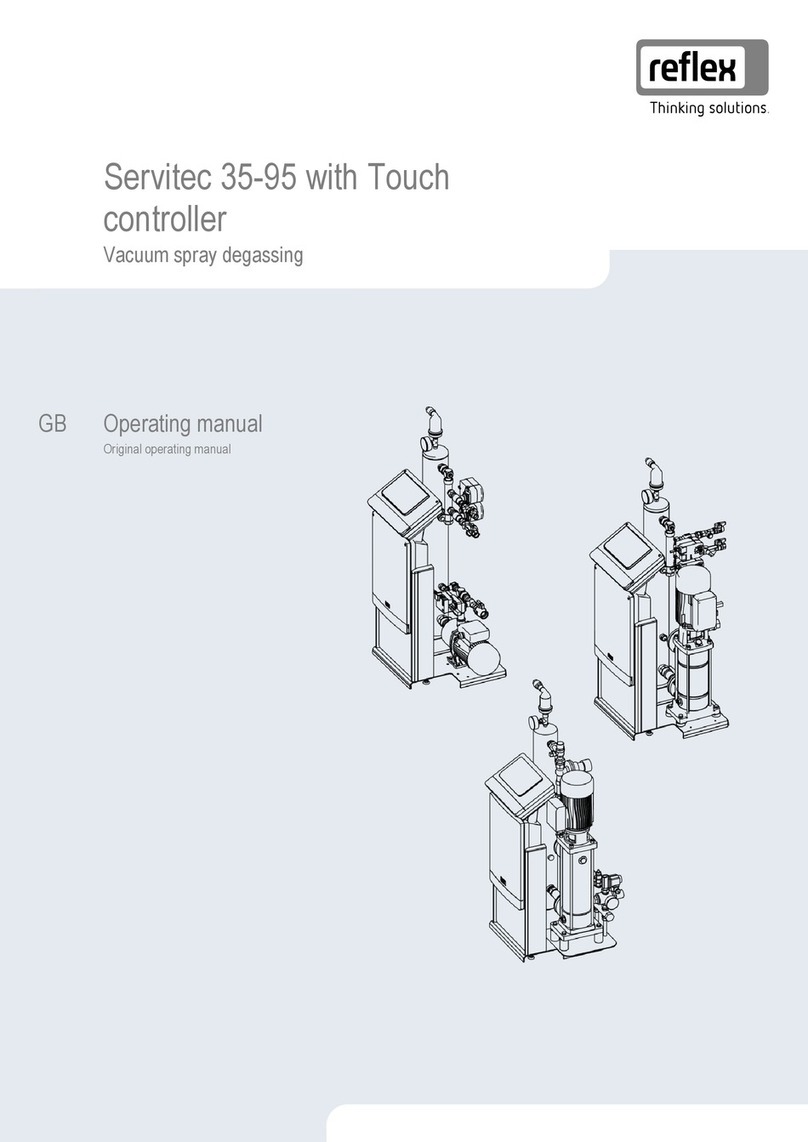

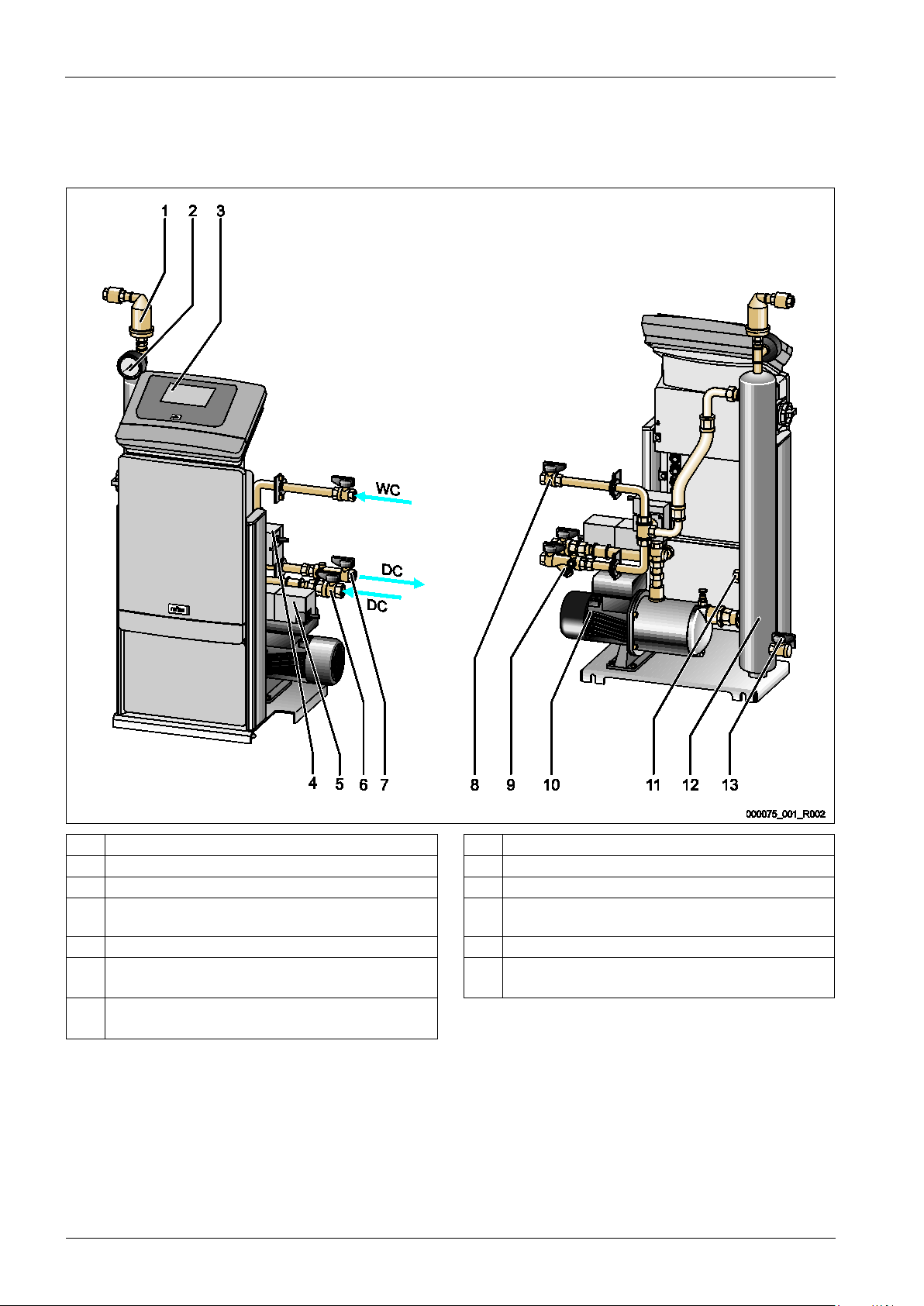

4Description of the device................................................................................................................................................................9

4.1 Description.............................................................................................................................................................................................9

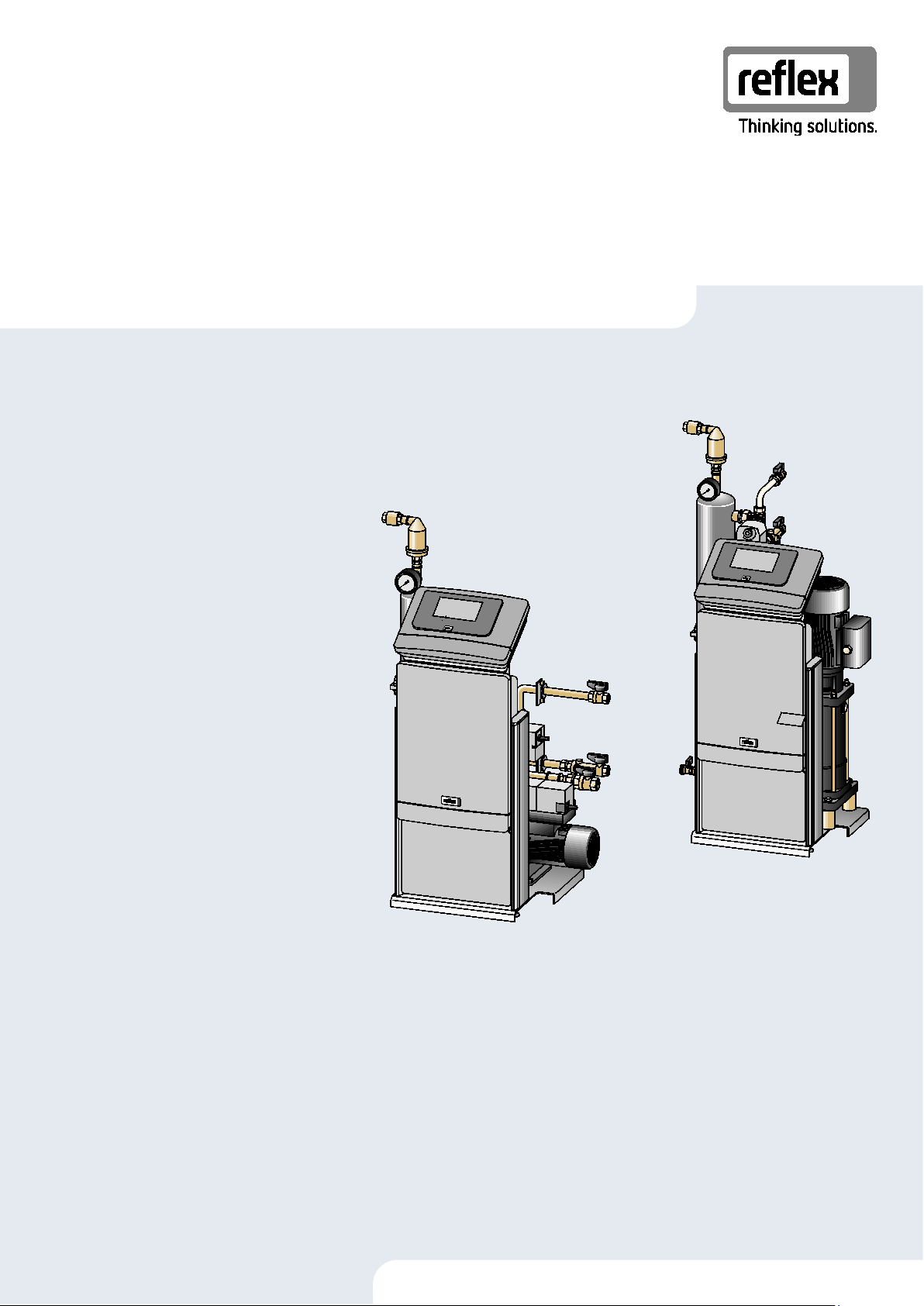

4.2 Overview ..............................................................................................................................................................................................10

4.3 Identification .......................................................................................................................................................................................13

4.3.1 Nameplate........................................................................................................................................................................13

4.3.2 Type code..........................................................................................................................................................................13

4.4 Function ...............................................................................................................................................................................................14

4.5 Scope of delivery.................................................................................................................................................................................17

4.6 Optional equipment and accessories ..............................................................................................................................................17

5Technical data ...............................................................................................................................................................................18

5.1 Electrical system..................................................................................................................................................................................18

5.2 Dimensions and connections............................................................................................................................................................18

5.3 Operation .............................................................................................................................................................................................19

6Installation.....................................................................................................................................................................................20

6.1 Installation conditions .......................................................................................................................................................................21

6.1.1 Incoming inspection .......................................................................................................................................................21

6.2 Preparatory work ................................................................................................................................................................................21

6.3 Execution..............................................................................................................................................................................................22

6.3.1 Fitting the add-on components....................................................................................................................................22

6.3.2 Floor mounting................................................................................................................................................................23

6.3.3 Wall mounting .................................................................................................................................................................23

6.3.4 Hydraulic connection......................................................................................................................................................24

6.4 Switching and make-up variants......................................................................................................................................................27

6.4.1 Pressure-dependent "Magcontrol" make-up mode...................................................................................................27

6.4.2 Level dependent "Levelcontrol" make-up mode .......................................................................................................28

6.5 Electrical connection ..........................................................................................................................................................................30

6.5.1 Terminal plan, connection component........................................................................................................................32

6.5.2 Terminal plan, operating unit........................................................................................................................................34

6.5.3 RS-485 interface...............................................................................................................................................................35

6.6 Installation and commissioning certificate.....................................................................................................................................35

7Commissioning..............................................................................................................................................................................36

7.1 Checking the requirements for commissioning.............................................................................................................................36

7.2 Setting the minimum operating pressure for Magcontrol...........................................................................................................37

7.3 Modifying the controller's start routine ..........................................................................................................................................39

7.4 Filling the device with water and venting ......................................................................................................................................39

7.5 Vacuum test.........................................................................................................................................................................................41

7.6 Hydraulic equalisation .......................................................................................................................................................................42

7.7 Use the device to fill the facility system with water......................................................................................................................45