Bulletin 034 Rev. F Page 8 of 8

June 2016 www.reliablesprinkler.com

Installation

Model G5 series sprinklers are intended to be installed in

accordance with NFPA 13 and the requirements of other

applicable authorities having jurisdiction. Model G5 series

sprinklers must not be installed in ceilings with positive

pressure in the space above.

Model G5 series sprinklers are shipped with a protective

cap that should remain on the sprinkler until installed. The

protective cap should be replaced following installation of

the sprinkler and permanently removed only when the

cover plate is installed and the sprinkler system is placed

in service following construction.

Model G5 series sprinkler are installed with the Model FC

wrench. The use of any other wrench to installed Model G5

series sprinklers is not permitted and may damage the

sprinkler. Temporarily remove the protective cap during

installation of the sprinkler. Insert the Model FC wrench

over the sprinkler until the wrench engages the body. Do

not wrench any other part of the sprinkler/cup assembly.

The Model FC wrench is designed to be turned with a

standard 1/2" square drive. Tighten the sprinkler into the

fitting after applying a PTFE based thread sealant to the

sprinkler’s threads. Recommended installation torque is

specified in Table I.

Installation Torque Table I

Sprinkler Threads

Installation Torque

½” NPT or ISO7-1R1/2 8-18 11-24

14-20 19-27

Do not exceed the maximum recommended torque. Ex-

ceeding the maximum recommended torque may cause

leakage or impairment of the sprinkler. Use care when in-

serting or removing the wrench from the sprinkler to avoid

damage to the sprinkler.

Model FC Sprinkler Wrench

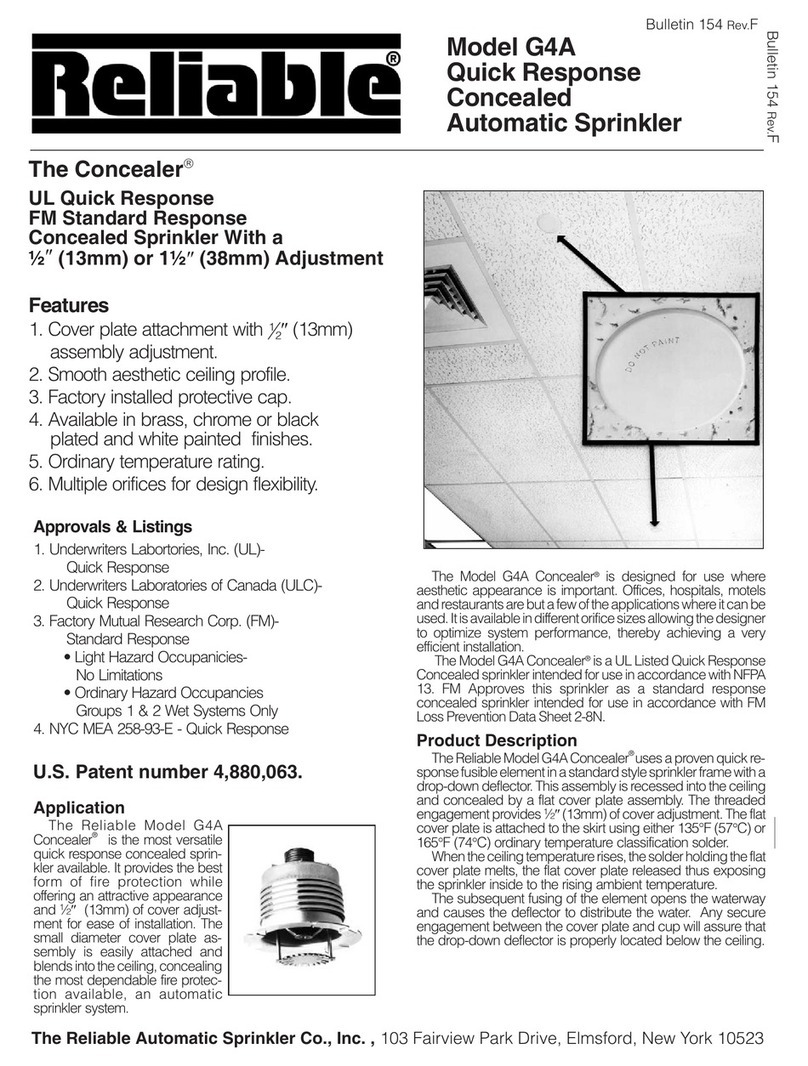

Install the cover plate by hand, turning the cover in the

clockwise direction until it is tight against the ceiling. For

Model G4 QR Gasket and Model G4 SR Gasket cover

plates, the gasket should be attached to the flange of the

cover plate skirt only. Do not glue the gasket in place or

allow the gasket to overlap both the cover plate and the

flange of the skirt.

Maintenance

Reliable Model G5 series sprinkler should be inspected

and the sprinkler system maintained in accordance with

NFPA 25, as well as the requirements of any Authorities

Having Jurisdiction.

Prior to installation, sprinklers should remain in the original

cartons and packaging until used. This will minimize the

potential for damage to sprinklers that could cause im-

proper operation or non-operation.

Do not clean sprinklers with soap and water, ammonia

liquid or any other cleaning fluids. Remove dust by gentle

vacuuming without touching the sprinkler.

Replace any sprinkler or cover plate which has been

painted (other than factory applied). Properly installed

Model G4 cover plates will have an air gap that is required

for proper operation, do not seal the gap or paint the cover

plates. Model G5 series sprinklers have holes in the cup

that must remain unobstructed.

Replace any sprinkler which has been damaged. A stock

of spare sprinklers should be maintained to allow quick

replacement of damaged or operated sprinklers.

Failure to properly maintain sprinklers may result in inad-

vertent operation or non-operation during a fire event.

Guarantee

For the Reliable Automatic Sprinkler Co., Inc. guarantee,

terms, and conditions, visit www.reliablesprinkler.com.

Patents

Model G5 series sprinklers may be covered by one or

more of the following patents:

U.S. Patent 6,554,077, U.S. Patent 7,275,603, U.S. Patent

8,776,903, U.S. Patent 9,248,327

Ordering Information

Specify the following when ordering.

Sprinkler

•Model (G5-28, G5-42, G5-56, G5-56 300, G5-

80)

•Temperature Rating [165°F (74°C) or 212°F

(100°C)]

•Threads (NPT or ISO 7-1)

Cover Plate

•Model (G4 [Solid], G4 Perforated, G4 QR Gas-

ket, G4 SR Gasket)

•Finish (See Table G)

Sprinkler Wrench

•Model FC