Table of Contents

1Notes on the Manual ............................................................................................................................. 6

1.1 Disclaimer.......................................................................................................................................... 6

1.2 Copyright............................................................................................................................................ 6

1.3 Explanation of signs and symbols ..................................................................................................... 6

1.4 Explanations of the Safety Instructions ............................................................................................. 7

1.5 General Safety Instructions ............................................................................................................... 8

1.6 Repairs............................................................................................................................................... 9

1.7 Responsibility of the operating company......................................................................................... 10

1.8 Personnel qualification and target group of this manual ................................................................. 10

2Confirmation Form for the Managing Operator................................................................................ 11

3Technical Data..................................................................................................................................... 12

3.1 Protective Equipment....................................................................................................................... 12

3.2 Gap width......................................................................................................................................... 12

3.3 Degree of Protection........................................................................................................................ 12

3.4 Emissions......................................................................................................................................... 12

3.5 Electromagnetic Compatibility (EMC).............................................................................................. 13

3.6 Rated Power.................................................................................................................................... 13

3.7 Dimensions and Weight................................................................................................................... 13

3.8 Required Floor Space...................................................................................................................... 13

3.9 Feed Grain Size............................................................................................................................... 13

3.10 Grinding chamber volume................................................................................................................ 13

3.11 Degree of hardness of the sample material..................................................................................... 13

3.12 Installation drawing.......................................................................................................................... 14

4Packaging, Transport and Installation .............................................................................................. 15

4.1 Packaging........................................................................................................................................ 15

4.2 Transport.......................................................................................................................................... 15

4.3 Temperature Fluctuations and Condensation ................................................................................. 16

4.4 Conditions for the Installation Site................................................................................................... 16

4.5 Electrical Connection....................................................................................................................... 17

4.6 Type Plate Description..................................................................................................................... 19

5First Commissioning........................................................................................................................... 20

5.1 Installation of the Device.................................................................................................................. 20

5.2 Dust extraction................................................................................................................................. 21

5.3 Lubricating the device when putting it into service for the first time................................................ 22

6Operating the Device .......................................................................................................................... 23

6.1 Use of the Device for the Intended Purpose.................................................................................... 23

6.2 Principle of Operation ...................................................................................................................... 24

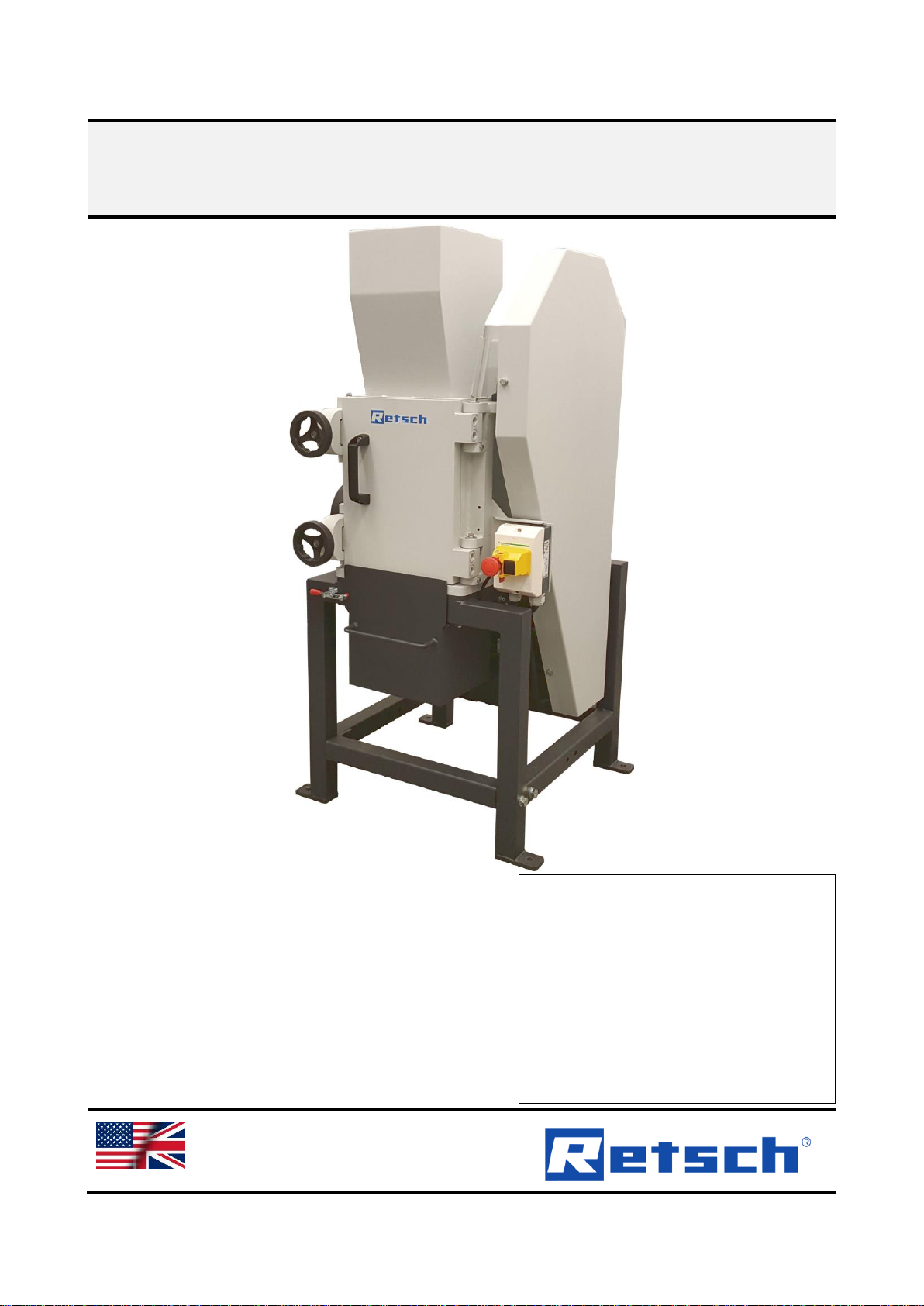

6.3 Views of the Instrument................................................................................................................... 25

6.3.1 Front............................................................................................................................................. 25

6.3.2 Side view...................................................................................................................................... 27

6.4 Switching On / Off............................................................................................................................ 28

6.5 Settings............................................................................................................................................ 29

6.5.1 Adjusting the gap width................................................................................................................ 29

6.5.2 Setting the gap width ................................................................................................................... 30

6.6 Opening and Closing of the Device................................................................................................. 31

6.7 Operation......................................................................................................................................... 32

6.7.1 Starting the crushing process...................................................................................................... 32

6.7.2 Adding sample material ............................................................................................................... 32

6.7.3 Removing sample material after grinding.................................................................................... 33

6.7.4 Stopping the crushing process .................................................................................................... 34

7Cleaning, Wear and Maintenance ...................................................................................................... 35

7.1 Cleaning........................................................................................................................................... 35

7.1.1 Removing and installing the feed hopper .................................................................................... 36