Page 3 of 24

Table of Contents

Intended Use..........................................................................................................................................4

Packaging Contents..............................................................................................................................4

Technical Specifications......................................................................................................................4

Important Safety Information...............................................................................................................4

Specific Operation Warnings...............................................................................................................6

Grounding..............................................................................................................................................6

Extension Cords....................................................................................................................................8

Main Parts of Breaker Hammer Kit with Cart .....................................................................................9

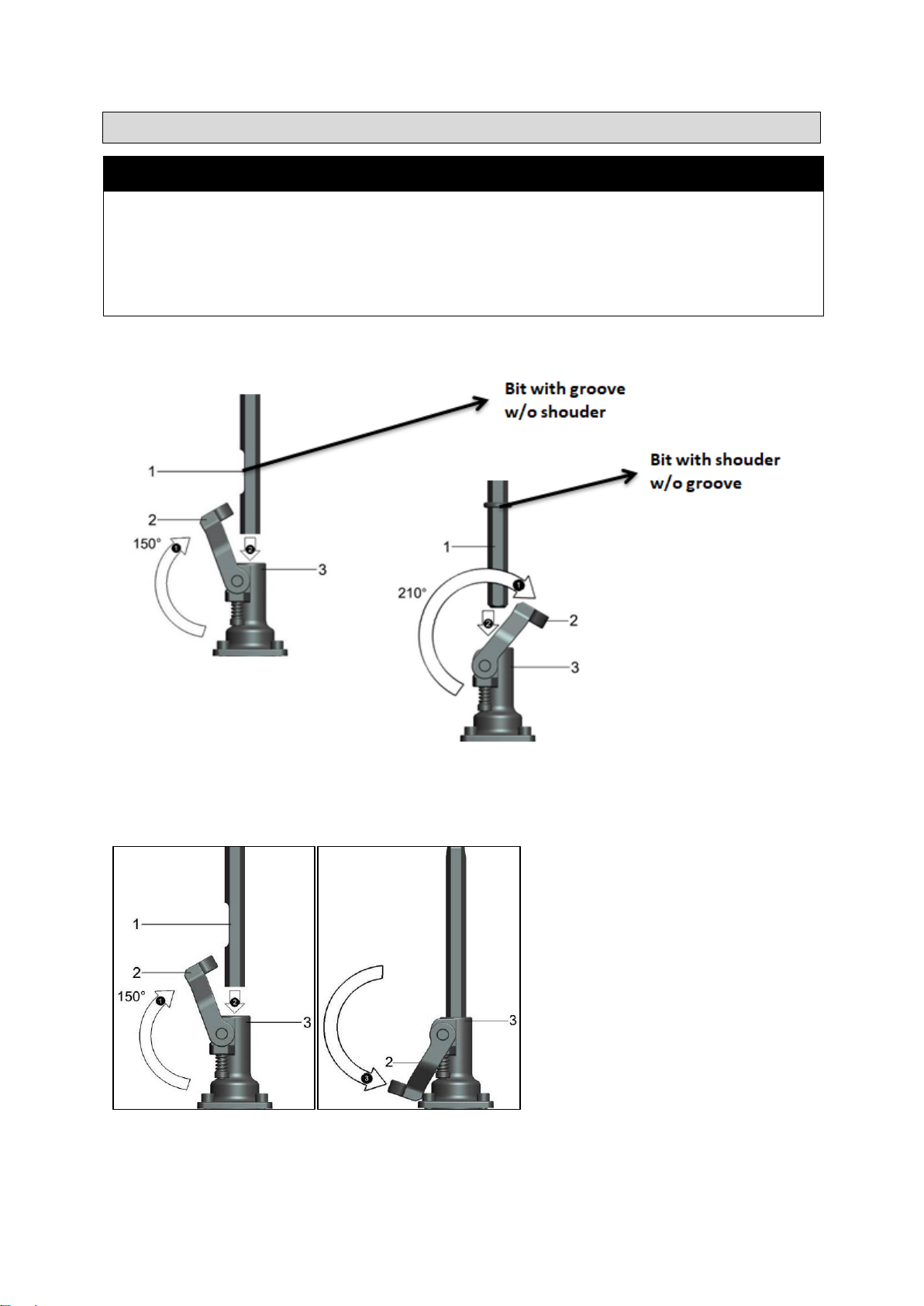

Assembly Instructions........................................................................................................................10

Before Each Use..................................................................................................................................12

Operating Instructions........................................................................................................................12

After Each Use.....................................................................................................................................16

Maintenance ........................................................................................................................................16

Troubleshooting..................................................................................................................................17

Hammer Parts Diagram ......................................................................................................................18

Hammer Parts List ..............................................................................................................................19

Cart Parts Diagram..............................................................................................................................21

Cart Parts List......................................................................................................................................22

Replacement Parts..............................................................................................................................22

Limited Warranty.................................................................................................................................23