RF-SM-1277B1/B2

www.szrfstar.com V1.1 - Oct, 2022

Shenzhen RF-star Technology Co., Ltd. Page 2 of 22

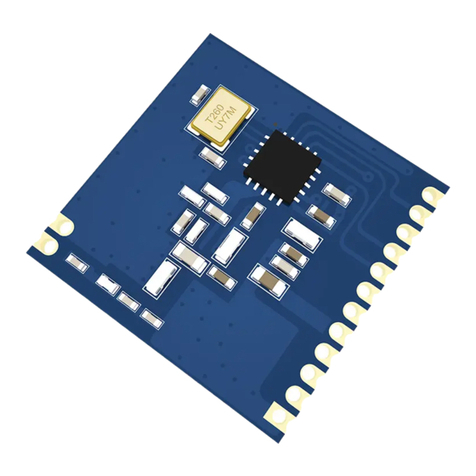

1 Device Overview

1.1 Description

RF-SM-1277B1 and RF-SM-1277B2 are RF modules based on TI CC1312R, which combines a flexible low-power radio

controller ARM® Cortex®-M0 and a powerful 48 MHz ARM® Cortex®-M4F microcontroller supporting multiple physical

layers and RF standards including IEEE 802.15.4g, IPv6-enabled smart objects (6LoWPAN), MIOTY®, Wi-SUN®,

proprietary systems, and the TI 15.4-Stack (Sub-1 GHz). RF-SM-1277B1/B2 integrates a 48.0 MHz crystal, a 32.768

kHz crystal, a balun, a band pass filter, an antenna matching and an option for RF output mode (IPEX antenna connector

and a half-hole interface), which makes the module low cost, low power consumption and long wireless communication

in Sub-1 GHz, also makes it an advanced available in sensing in building security systems, HVAC, smart meters, medical,

wired networking, portable electronics, home theater & entertainment, and connected peripherals markets. For the

working frequency, RF-SM-1277B1 supports 433 MHz and 470 MHz; RF-SM-1277B2 supports 868 MHz and 915 MHz.

1.2 Key Features

•RF Features

- IEEE 802.15.4g

- IPv6-enabled smart objects (6LoWPAN)

- MIOTY®

- Wi-SUN®

- Wireless M-Bus

- KNX RF

- Amazon Sidewalk

- Proprietary systems, including the TI 15.4-Stack

(Sub-1 GHz)

•TX power: up to +14 dBm

•Sensitivity

- Excellent receiver sensitivity: –124 dBm @ long-

range mode, –110 dBm @ 50 kbps

- Excellent selectivity (±100 kHz): 56 dB

- Excellent blocking performance (±10 MHz): 90 dB

•Microcontroller

- Powerful 48 MHz ARM® Cortex®-M4F processor

- EEMBC CoreMark® Score: 142

- EEMBC ULPBench™ score: 158

•Memory

- 352 KB of in-system programmable flash

- 256 KB of ROM for protocols and library

- 8 KB of SRAM for Cache (or as general-purpose

RAM)

- 20 KB of ultra-low-leakage SRAM

•Wide Operation Range

- Power supply: 2.2 V to 3.8 V

- Operating temperature: -40 °C to +85 °C

- Storage temperature: -40 °C to +125 °C

•On-Chip Internal DC/DC Converter

•Ultra-Low-Power Sensor Controller

•Wide Operation Range

- 2-pin cJTAG and JTAG debugging

- Supports over-the-air (OTA) update

- Can run autonomously from the rest of the System

- 16-bit architecture

- 2 KB of ultra-low-leakage SRAM for code and data

•Peripherals

- All digital peripheral pins can be routed to any

GPIO

- Four general-purpose timer modules (eight 16-bit

or four 32-bit timers, PWM each)

- 12-bit ADC, 200 ksamples/s, 8-channel analog

MUX

- Continuous time comparator