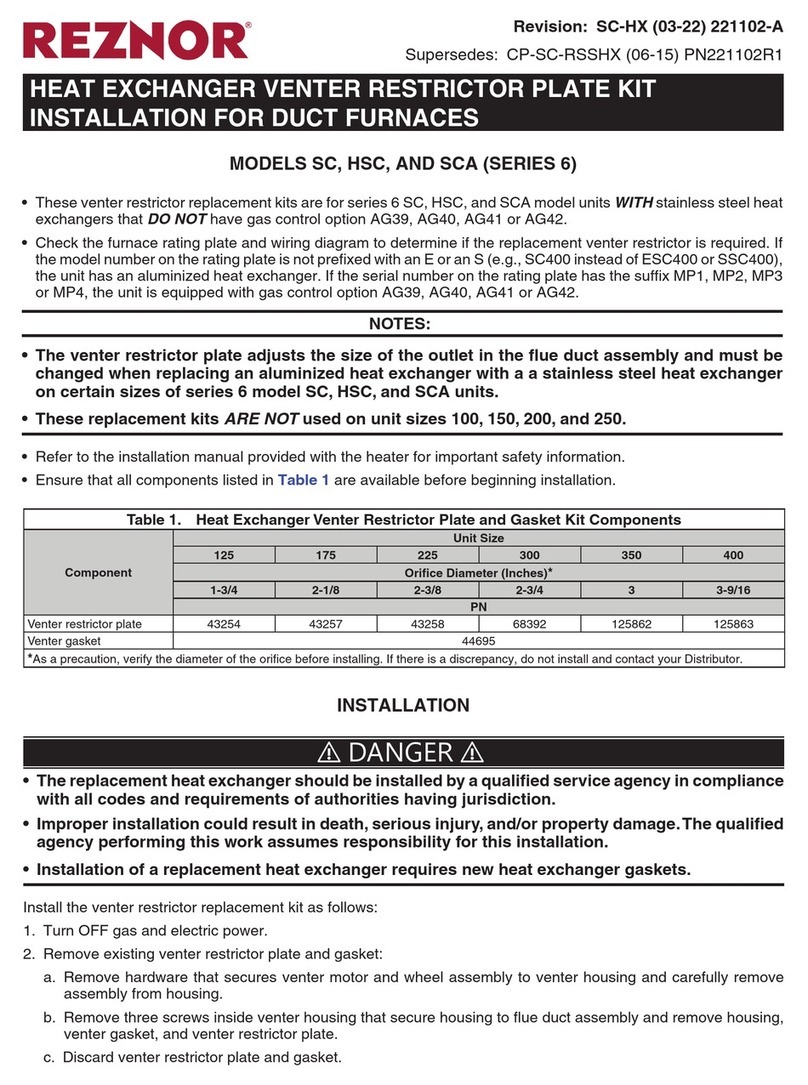

4

2. RECEIVING EQUIPMENT

On receiving your equipment, check the carton visually for

external damage. If the carton is damaged, make a note on

the Bill of Lading when signing for the equipment. Remove

the complete assembly from the carton if it is damaged,

and report the damage to the carrier immediately. Be sure

that you receive the number of packages indicated on the

Bill of Lading. Claims for shortages and damages must be

led with the carrier by consignee.

Purchased parts are subject to replacement only under the

manufacturer’s warranty. Debits for defective replacement

parts will not be accepted and defective parts will be

replaced in kind only per our standard warranties.

When ordering parts, you must specify Model Number of

the unit. When ordering under warranty conditions, you

must also specify date of Installation.

Raypak recommends that this manual be reviewed

thoroughly before installing the D-2 Power Vent. If there

are any questions which this manual does not answer,

please contact your local Raypak Representative.

THIS MANUAL SHOULD BE MAINTAINED IN LEGIBLE

CONDITION AND KEPT ADJACENT TO THE UNIT.

3. GENERAL

SPECIFICATIONS

The D-2 Power Vent Assembly is tested and certied to

the latest edition of the American National Standard ANSI

Z21.10.3 for water heaters and Z21.13 for boilers.

The Power Vent Assembly is a fan-assisted combustion

system designed for application to Raypak Heater Models

182 - 400. The unit, when installed as directed, is capable

of operating in applications such as through-the-wall

venting and reduced horizontal and vertical vent pipe

sizes in new and existing installations.

The ue gases are at a temperature that does not promote

condensation and is under higher pressure than the

ambient air; this denes venting category III. Vent material

certied for cat III usage must be used. Please note that

B-vent does not meet this requirement.

The D-2 Power Vent assembly includes a blower with

a 120/240 volt 60 Hz 1.95/1.0A 3200 RPM motor, a

plenum complete with a draft proving switch and a motor

relay. When provided for eld mounting the assembly is

equipped with a wire harness.

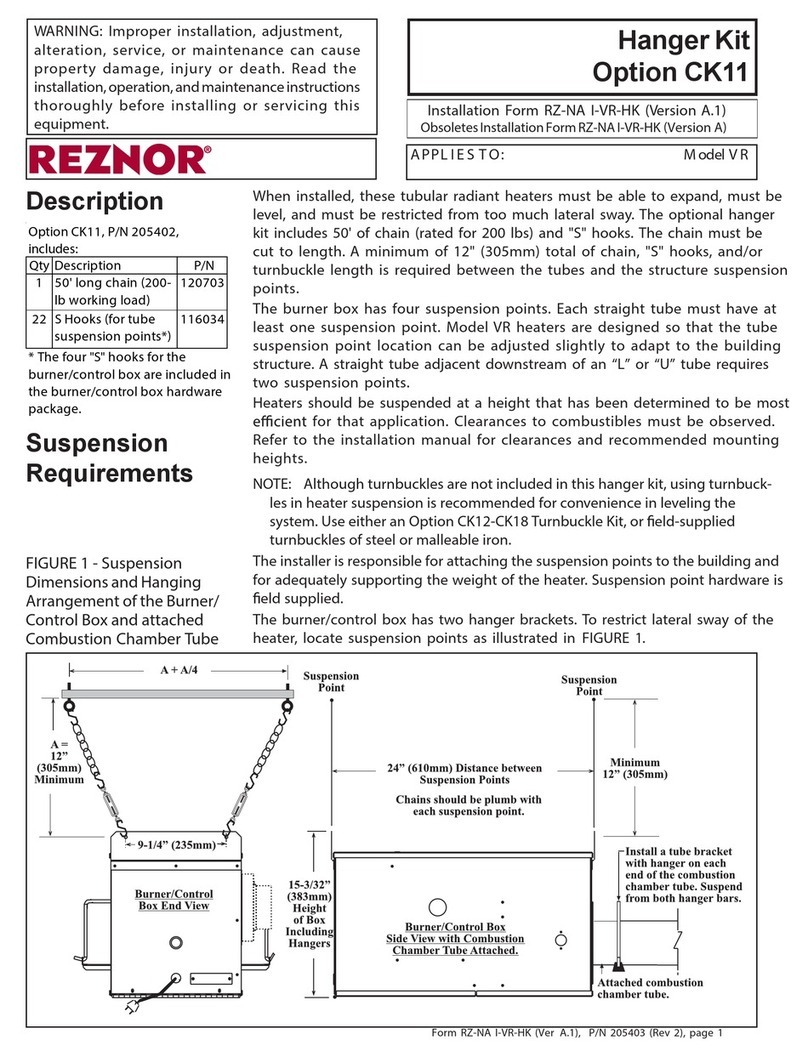

Model No. Discharge

Collar Size

Kit

Number

Factory

Wired

182 4" 008757 120V

260 4" 008757 120V

330 4" 008758 120V

400 4" 008758 120V

Table A. D-2 Kits

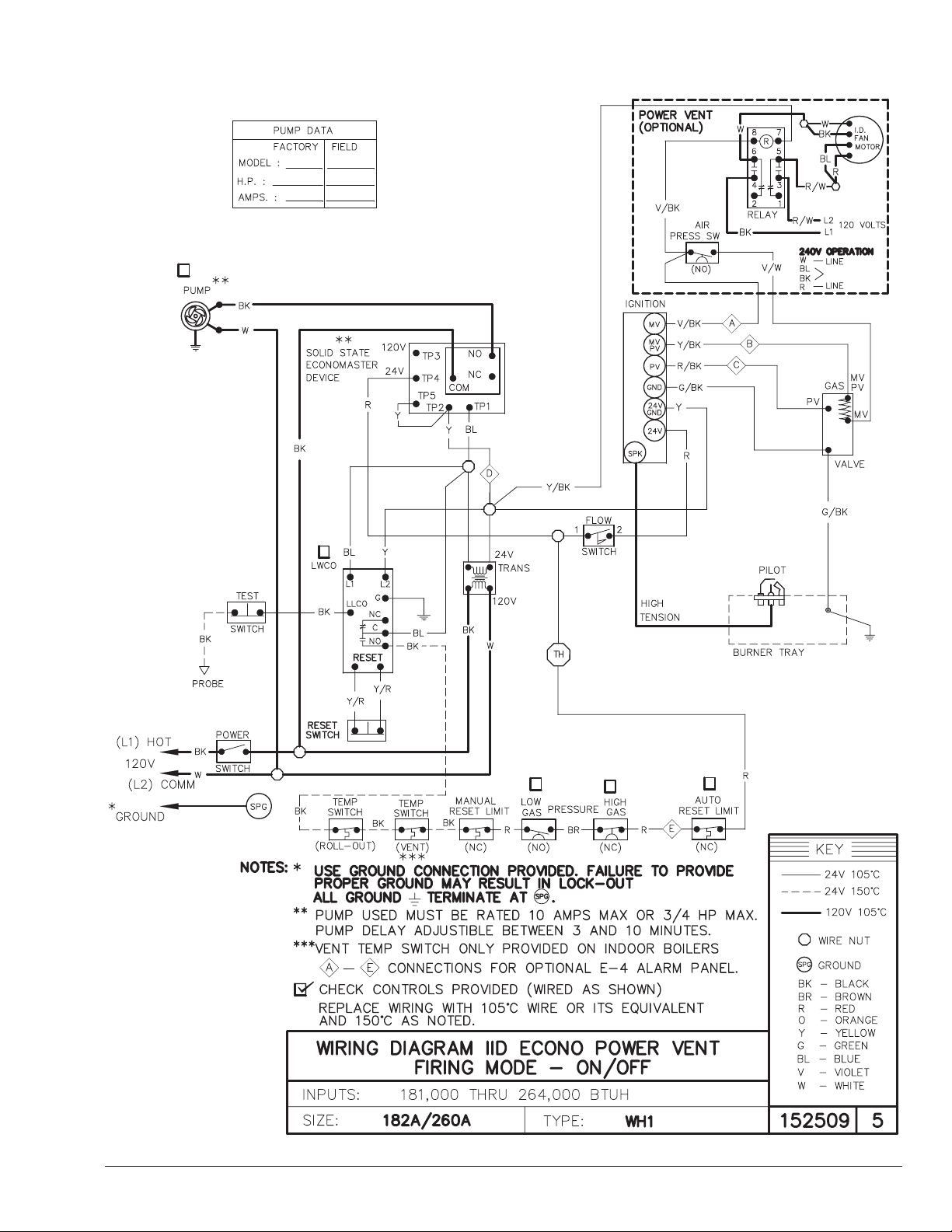

NOTE: The D-2 Power Vent comes factory-wired for

120V, but can be eld-converted for 240V operation.

See wiring diagrams from page 9.

4. INSTALLATION

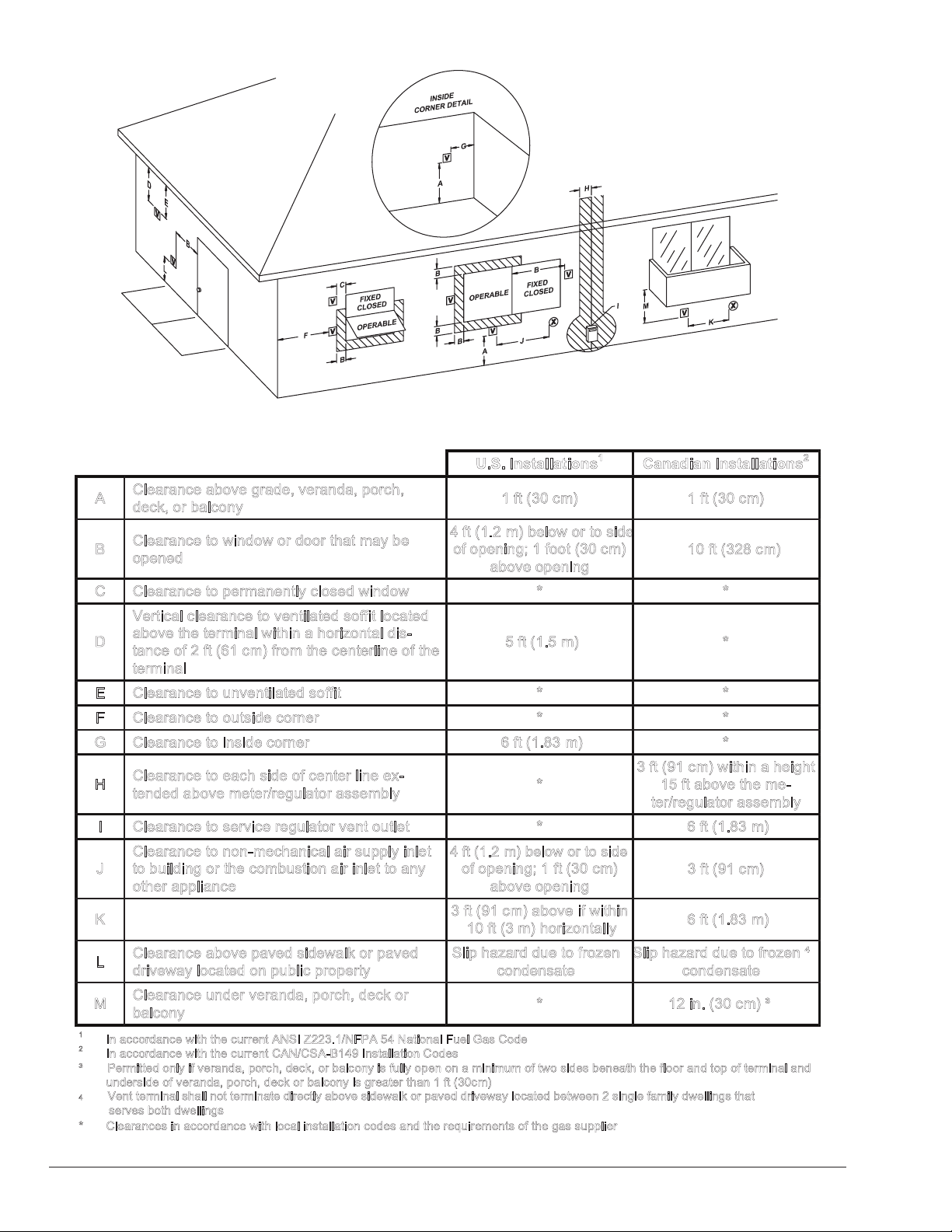

The equipment must be installed in accordance with local

codes, or in the absence of local codes with the latest

edition of the National Fuel Gas Code, ANSI Z223.1, the

National Electrical Code, ANSI/NFPA 70.

The equipment shall be installed in accordance with those

installation regulations in force in the local area where

the installation is to be made. These shall be carefully

followed in all cases. Authorities having jurisdiction shall

be consulted before installations are made.

Adding the D-2 power vent to the unit does not change

the service clearance requirements. Consult the manual

for the unit.

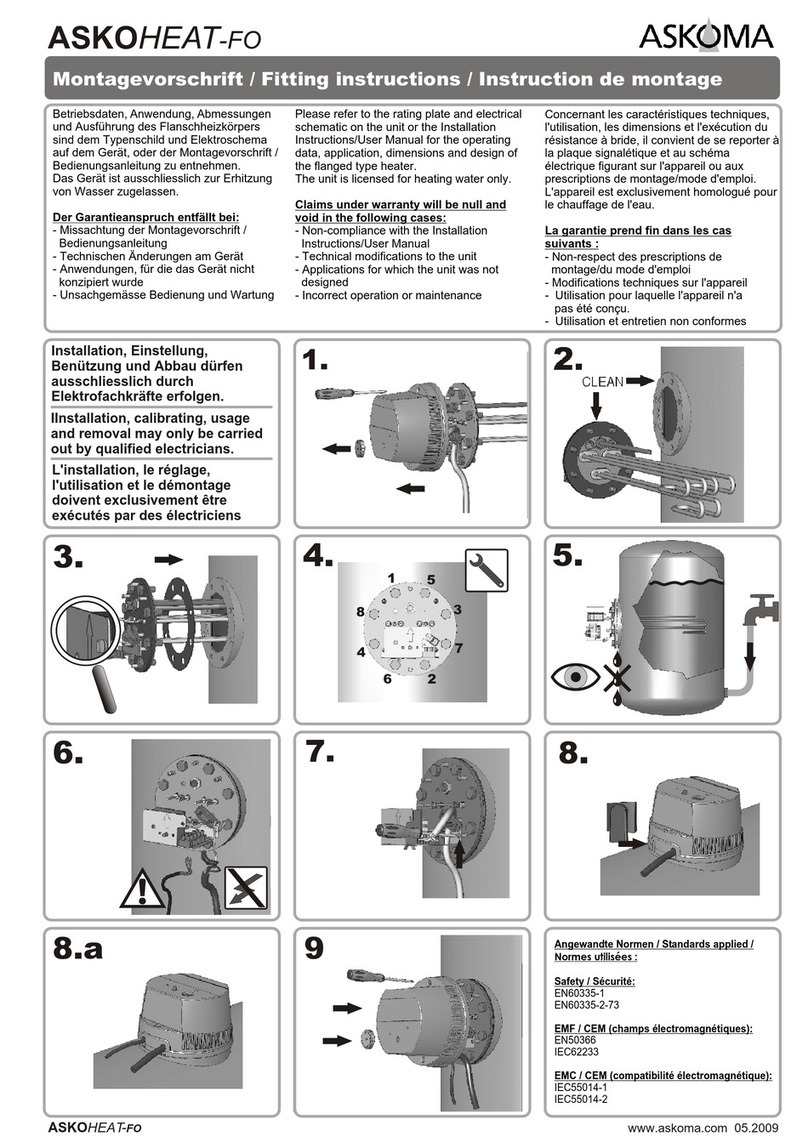

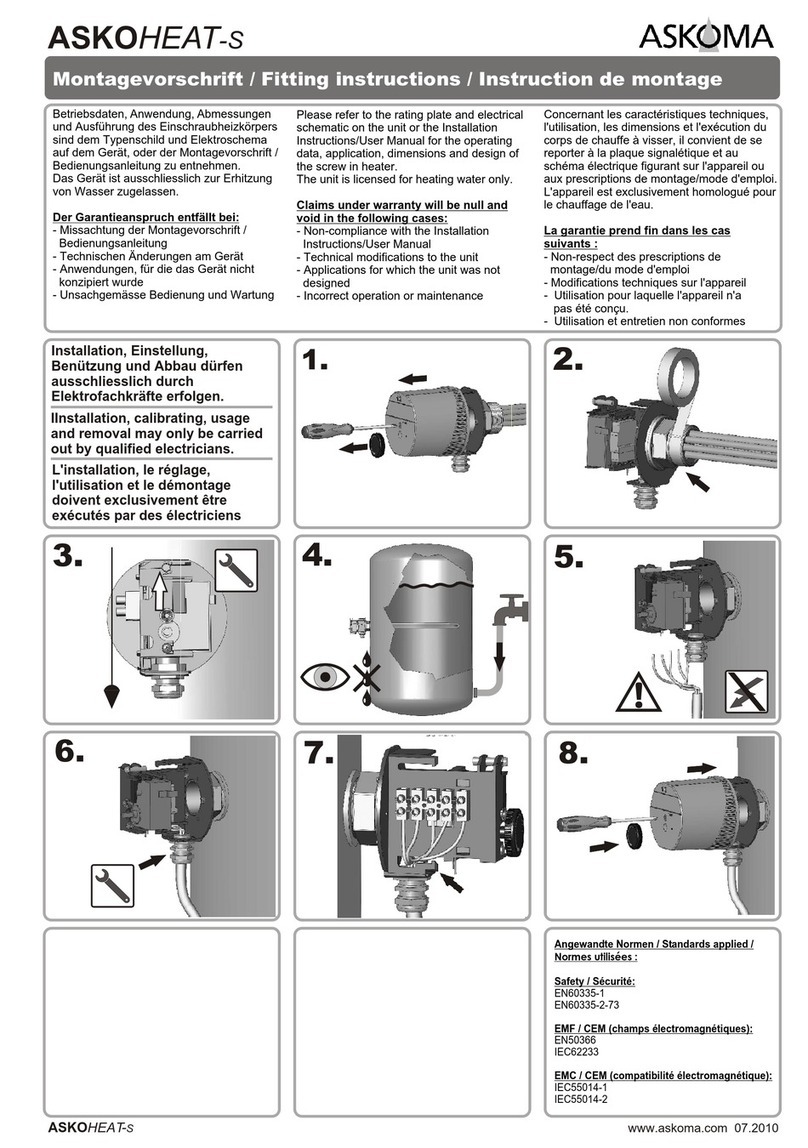

Mounting the Assembly

Follow these instructions if the Power Vent venting

system was purchased as an optional assembly kit.

1. Remove existing pagoda top (outdoor units) or

drafthood (indoor units). To remove the pagoda top,

push the four brackets inward and pull up the pagoda

top. The pagoda may then be discarded.

2. Unscrew the four screws holding the outer top using

a Phillips screw driver. Remove the jacket top.

3. Replace the inner stack adapter. If the heater had

a drafthood installed previously, remove the inner

stack adapter and replace it with the Power Vent

stack adapter. Otherwise, install the Power Vent

stack adapter.

4. Unscrew the access panel on the right side of the

appliance. Set aside the screws with the access

panel.

5. Remove the knurled screw holding the front door

and set it aside with the door.

6. Mount the jacket top above the unit. Note: Do not

install at this point.

7. Mount the Power Vent on the outer top.

8. Route the conduit harness of the Power Vent thru

the outer top hole, around the adapter towards the

back of the unit. Continue routing the harness thru

the corner slot, which leads to open area behind the

access panel. Finally, route only the wire harness

thru the 7/8" grommet hole located on the sway

brace. Follow instructions on page 7 to wire the

Power Vent.

NOTE: Newer units have a 7/8" grommet located on the

rain shield, which would eliminate routing the harness

around the back corner.