14 August 1997 ELECTRICAL COMPONENT DESCRIPTIONS

7

A217 Copier

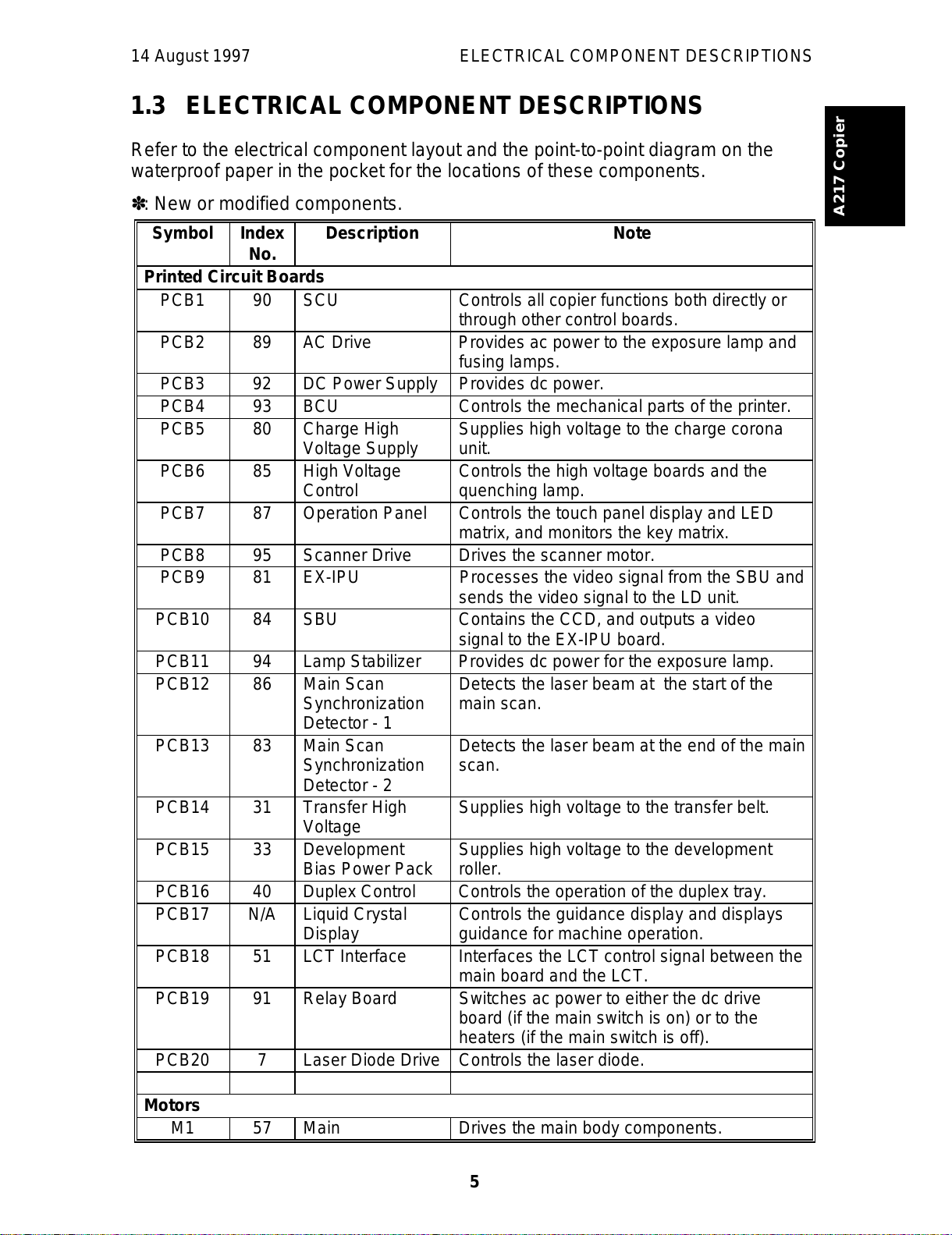

Symbol Index

No. Description Note

S10 19 Registration Detects the leading edge of the copy paper to

determine the stop timing of the paper feed

clutch, and detects misfeeds.

S11 29 Image Density

(ID) Detects the density of various patterns on the

drum during process control.

S12 30 Toner Density

(TD) Detects the amount of toner inside the

development unit.

S13 1 Scanner HP Informs the CPU when the 1st and 2nd

scanners are at the home position.

S14 8 Original Length-1 Detects the length of the original. This is one

of the APS (Auto Paper Select) sensors.

S15 9 Original Length-2 Detects the length of the original. This is one

of the APS (Auto Paper Select) sensors.

S16 24 Fusing Exit Detects misfeeds.

S17 6 Platen Cover Informs the CPU whether the platen cover is

up or down (related to APS/ARE functions).

ARE: Auto Reduce and Enlarge

S18 32 Toner End Instructs the CPU to add toner to the toner

supply unit, and detects toner end conditions.

S19 28 Auto Response Returns the operation panel display and exits

from the energy saver mode.

S20 10 Transfer Belt

Position Informs the CPU of the current position of the

transfer belt unit.

S21 2 Original Width Detects the width of the original. This is one

of the APS (Auto Paper Select) sensors.

S22 34 Duplex Paper End Detects paper in the duplex tray.

S23 35 Duplex Turn Detects the trailing edge of the copy paper to

determine the jogging timing, and detects

misfeeds.

S24 42 Duplex Entrance Detects misfeeds.

S25 37 Side Fence

Jogger HP Detects the home position of the duplex side

fence jogger.

S26 41 End Fence

Jogger HP Detects the home position of the duplex end

fence jogger.

S27 23 Toner Overflow Detects when the used toner collection bottle

is full.

S28 14 By-pass Relay Detects misfeeds.

Switches

SW1 11 By-pass Feed

Table Detects whether the by-pass feed table is

open or closed.

SW2 53 Tray Down Sends a signal to the CPU to lower the LCT

bottom plate.

SW3 20 Tray Paper Size Determines what size of paper is in the paper

tray.

SW4 54 LCT Cuts the dc power line and detects whether

the LCT is open or not.

SW5 52 LCT Cover Cuts the dc power line of the LCT lift motor.