Ricoh MPC 1500sp User manual

Other Ricoh Copier manuals

Ricoh

Ricoh Beluga-C1 Installation guide

Ricoh

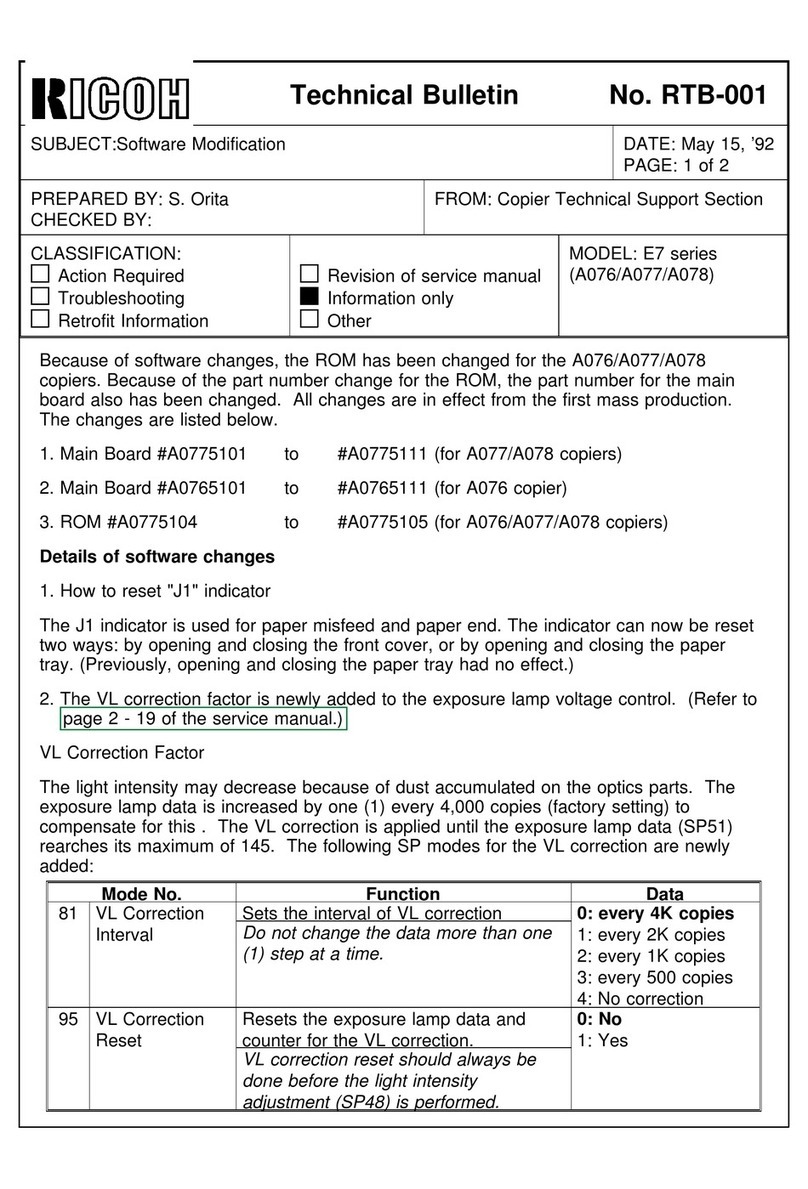

Ricoh E7 Series Service manual

Ricoh

Ricoh D009 User manual

Ricoh

Ricoh Aficio 480W User manual

Ricoh

Ricoh Aficio FT4027 User manual

Ricoh

Ricoh MP C2004 series Instruction sheet

Ricoh

Ricoh Di-C1.5a User manual

Ricoh

Ricoh SWALLOW 2 User manual

Ricoh

Ricoh Di-C1 User manual

Ricoh

Ricoh FT4480 Quick start guide

Ricoh

Ricoh Afico 3030 User manual

Ricoh

Ricoh MP 401 spf User manual

Ricoh

Ricoh Aficio MP 171 Quick start guide

Ricoh

Ricoh MP 2014 Series User manual

Ricoh

Ricoh MD-P2 Quick start guide

Ricoh

Ricoh A193 User manual

Ricoh

Ricoh LDD745 User manual

Ricoh

Ricoh Pro C900s Quick start guide

Ricoh

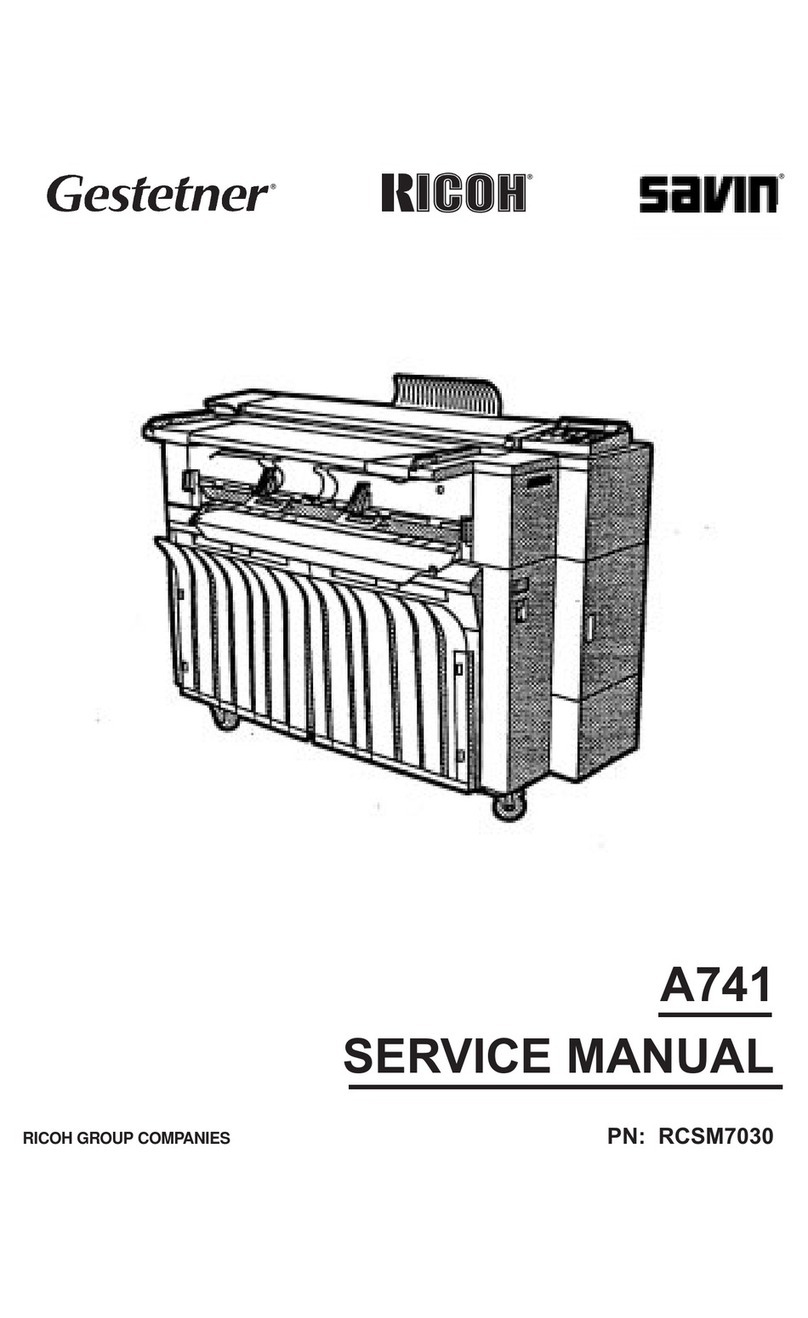

Ricoh SAVIN A741 User manual

Ricoh

Ricoh Priport JP5800 User manual