Ricoh G035 User manual

Other Ricoh Copier manuals

Ricoh

Ricoh NC5006 User manual

Ricoh

Ricoh Aficio 1232C User manual

Ricoh

Ricoh MP 401 spf User manual

Ricoh

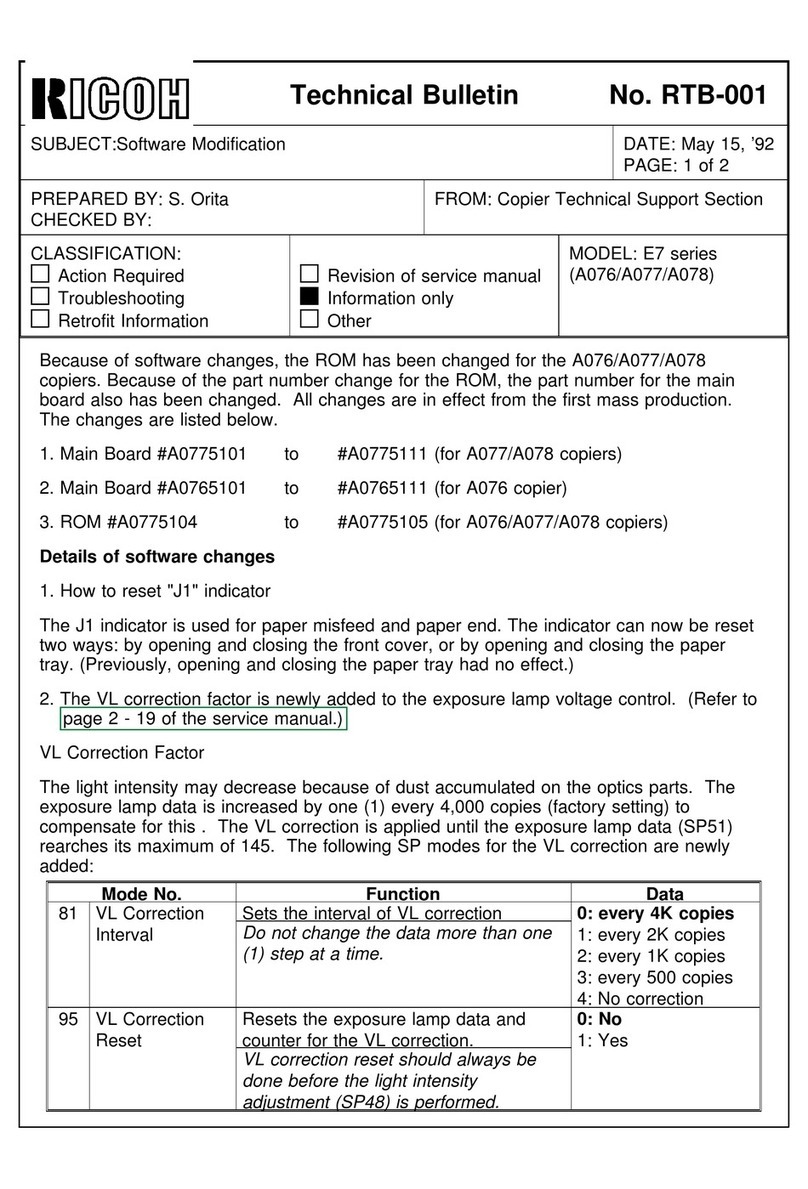

Ricoh E7 Series Service manual

Ricoh

Ricoh FW 810 User manual

Ricoh

Ricoh FT5034 User manual

Ricoh

Ricoh FW830 User manual

Ricoh

Ricoh FW770 User manual

Ricoh

Ricoh Di-C1 User manual

Ricoh

Ricoh FT4220 Installation guide

Ricoh

Ricoh A217 User manual

Ricoh

Ricoh A151 User manual

Ricoh

Ricoh aficio 1013 User manual

Ricoh

Ricoh M5 User manual

Ricoh

Ricoh FT5035 User manual

Ricoh

Ricoh FT8880 User manual

Ricoh

Ricoh Cor-C1 Series Installation guide

Ricoh

Ricoh FT2012+ User manual

Ricoh

Ricoh Aficio SP C400DN User manual

Ricoh

Ricoh 5490 User manual