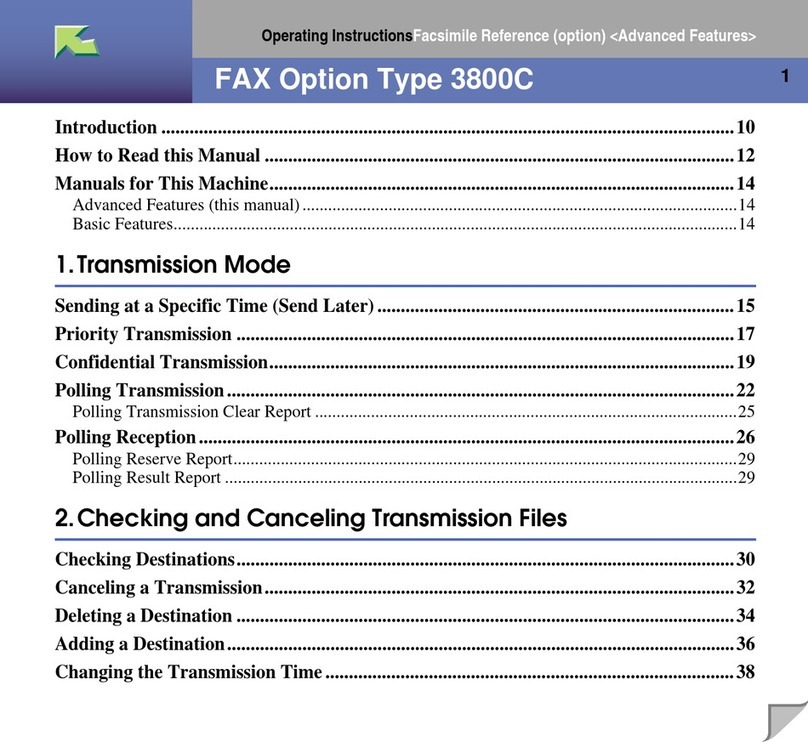

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION............................................1-1

1.1 SPECIFICATIONS..................................................................................... 1-1

1.2 FEATURES................................................................................................ 1-2

1.2.1 FAX FEATURES............................................................................... 1-2

1.2.2 PC INTERFACE FEATURES............................................................ 1-3

1.2.3 SERVICE MODE FEATURES........................................................... 1-3

1.3 COMPONENT LAYOUT............................................................................ 1-4

1.4 OVERALL MACHINE CONTROL.............................................................. 1-6

1.5 DATA PATH............................................................................................... 1-7

1.6 POWER DISTRIBUTION........................................................................... 1-8

2. DETAILED DESCRIPTIONS...........................................................2-1

2.1 SCANNER................................................................................................. 2-1

2.1.1 DOCUMENT FEED MECHANISM.................................................... 2-1

2.1.2 SCANNING....................................................................................... 2-1

2.2 PRINTER................................................................................................... 2-2

2.2.1 PAPER FEED MECHANISM............................................................. 2-2

2.2.2 CARRIAGE DRIVE MECHANISM..................................................... 2-3

2.2.3 INKJET CARTRIDGE....................................................................... 2-3

2.2.4 PRINT HEAD MAINTENANCE UNIT................................................ 2-3

2.2.5 INK LOW CONDITION..................................................................... 2-4

2.2.6 PRINTING FAXES AT 300 DPI RESOLUTION................................ 2-5

2.2.7 PROTOCOL REFERENCE............................................................... 2-6

2.3 PC INTERFACES..........................................................................2-6

2.3.1 PC PRINTER: CENTRONICS INTERFACE........................................... 2-6

2.3.2 PC FAX MODEM: RS232C SERIAL INTERFACE.................................. 2-8

2.4 PCBs........................................................................................................ 2-10

2.4.1 FCU................................................................................................ 2-10

2.4.2 NCU................................................................................................ 2-11

3. INSTALLATION PROCEDURE.......................................................3-1

3.1 PRECAUTIONS......................................................................................... 3-1

3.2 INSTALLING THE MACHINE.................................................................... 3-1

3.3 INITIAL PROGRAMMING.......................................................................... 3-1

3.3.1 PROGRAM AND SETUP ITEMS (SERVICE MODE)........................ 3-1

3.3.2 PROGRAM AND SETUP ITEMS (USER MODE)............................. 3-1

3.4 REMARKS................................................................................................. 3-1

4. SERVICE TABLES..........................................................................4-1

4.1 USER MODE............................................................................................. 4-1

4.2 SERVICE MODE....................................................................................... 4-2

4.2.1 HOW TO ACCESS THE SERVICE FUNCTIONS............................. 4-2

4.2.2 COUNTER DISPLAY (FUNCTION 80)............................................. 4-2