WARNING

• Read operators manual. Operator must be prop-

erly trained before using tool.

• Wear eye protection.

• Do not exceed pressure and temperature ratings of

the tool and any attachment, valve or fitting. Only

tap into lines that contain specified media.

Model RT 3422 Tapping Tool

Water: 500 psig @ 100°F (40°C)

Air, Steam, Natural Gas: 150 psig @ 370° F (172°C)

Tapping Tool Safety

1. Only trained personnel should use this tapping

tool. Incorrect use of this tool can result in serious

personal injury, environmental damage, and/or prop-

erty damage.

2. Always wear eye protection. Cutters and drills are

hard and can shatter.

3. Do not exceed recommended pressure ratings.

Attempting to tap into main with pressures beyond the

maximum limits of this tool or a fitting may result in

their failure.

4. Only tap into pressurized mains that carry water,

air, steam or natural gas. Other media may attack

the seals of this tool.

5. When using power tools to drive this tapping

tool, understand and follow all the safety in-

structions associated with that power tool. Air

power ratchets are generally a safer choice due to

the inherent explosion and shock hazards asso-

ciated with electrical tools.

• Electrical tools should not be used for natural

gas taps. Only use air or manual ratchets.

Electrical tools cause sparks which may ignite the

gas.

• Grounded electrical tools should be plugged

into a properly grounded outlet. If tool should

electrically malfunction or breakdown, grounding

provides a low resistance path to send electricity

away from the user.

• Electrical tools should be plugged into an outlet

protected with a Ground Fault Circuit Interrupter

(GFCI). Reduces risk of electrical shock.

6. Use only right angle electrical drills or air ratchets

to rotate the cutter. Tool must be fed at a con-

trolled rate. Failure to use a right angle drive or to

carefully control the tool feed rate may result in the

cutter suddenly stopping which will cause the power

tool driver to suddenly twist.

7. Main being tapped must be securely mounted to

prevent any movement. Movement could cause

tool breakage during the tapping operation.

8. Follow all applicable regulations and safety pre-

cautions regarding the work area.

• When working below grade, have an adequate es-

cape route before starting the tap. Such pre-

cautions reduce the risk of injury.

• When working on a scaffold or lift, the operator,

tool, and drive assembly should all be properly

secured. Will prevent injury in the event of a fall or

dropping a tool.

9. Vent pressure bleed valve away from work area

and personnel. When working over equipment

or personnel, use a hose attachment on the

bleeder valve to control fluid discharge. Discharge

directed at personnel could result in serious injury.

10. Do not use this tool to support the operator.

Could result in tool breakage or malfunction.

11. Tool is made to tap into pressurized lines. Follow

instructions in operator’s manual on tool uses.

Other uses may increase the risk of injury

NOTE! Keep this manual in the pocket provided in the

toolbox.

Description, Specifications,

and Equipment

Description

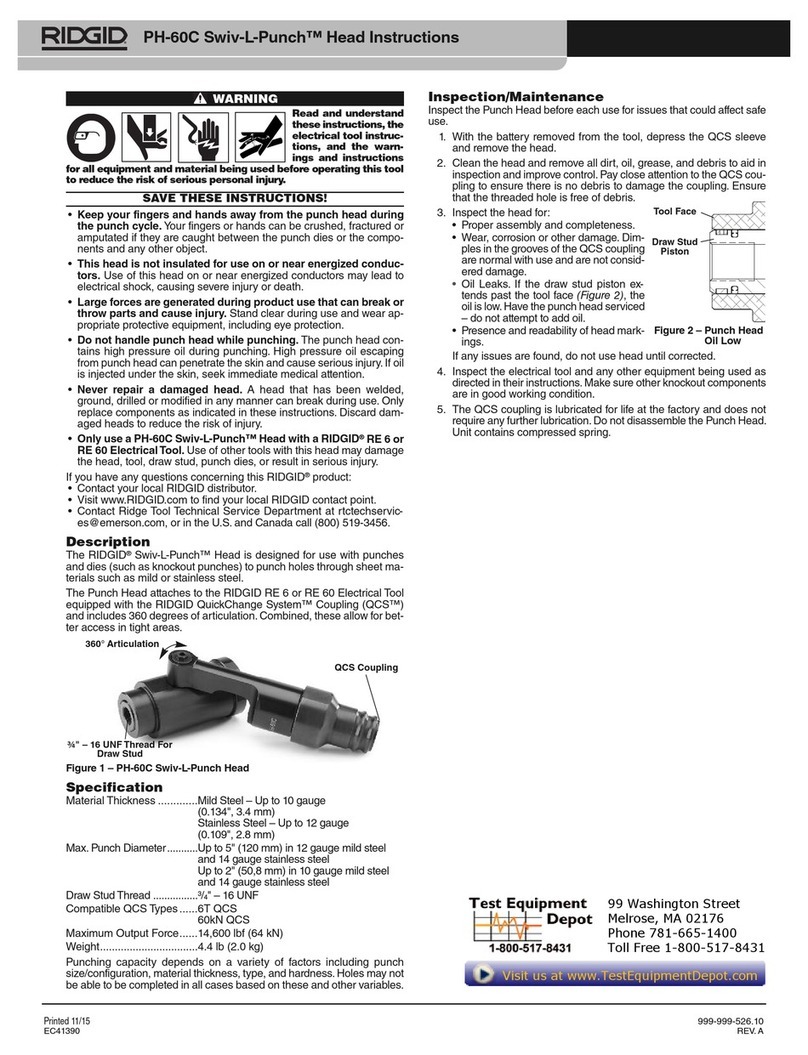

The Model RT3422 Tapping Tool is designed to perform

pressurized taps using a saddle-mounted valve or

welded nipple on steel, plastic, ductile iron and cast

iron pipe. It is capable of tapping water lines under

pressure up to 500 psi and steam, air, and natural gas

mains up to 150 psi. Weighing only 18 lbs, the Model

RT3422 can produce 3/4″ – 2″taps fast and easy. The

cutter is rotated by an 11/16″ hand ratchet or can be op-

erated by an air ratchet or right angle drill if desired. A

self cleaning acme threaded barrel permits easy feeding

of the cutter into the pipe and resists the force of the

pressurized pipe when the cut is made.

Ridge Tool Company 3

RT3422 Tapping Tool