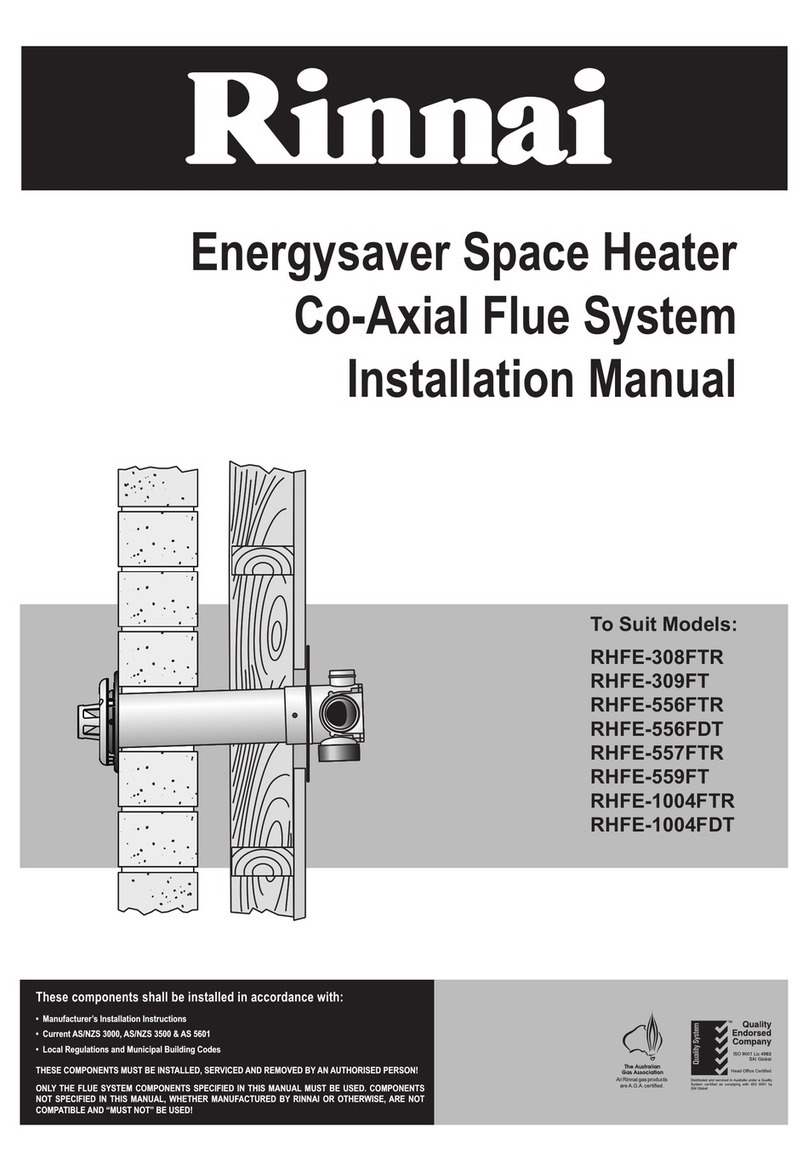

Rinnai Energysaver RHFE-1004FDT Operating instructions

Other Rinnai Heater manuals

Rinnai

Rinnai RHFE-556FTR User manual

Rinnai

Rinnai ENERGYSAVER RHFE-308FTR Operating instructions

Rinnai

Rinnai Energysaver RHFE-556FM User manual

Rinnai

Rinnai FC510 User manual

Rinnai

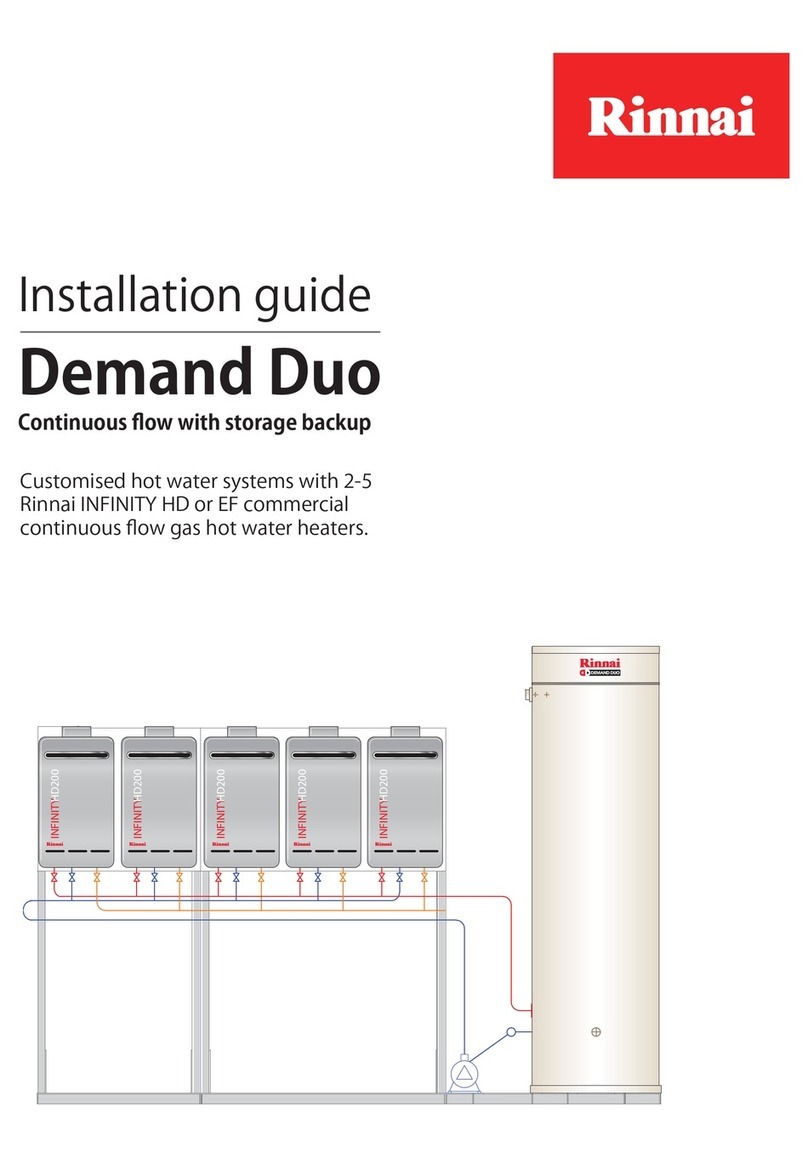

Rinnai Demand Duo User manual

Rinnai

Rinnai 1001T User manual

Rinnai

Rinnai DD180 Specification sheet

Rinnai

Rinnai ORH15SR User manual

Rinnai

Rinnai REH-10T User manual

Rinnai

Rinnai RHFE-557FT User manual

Rinnai

Rinnai RCE-606A User manual

Rinnai

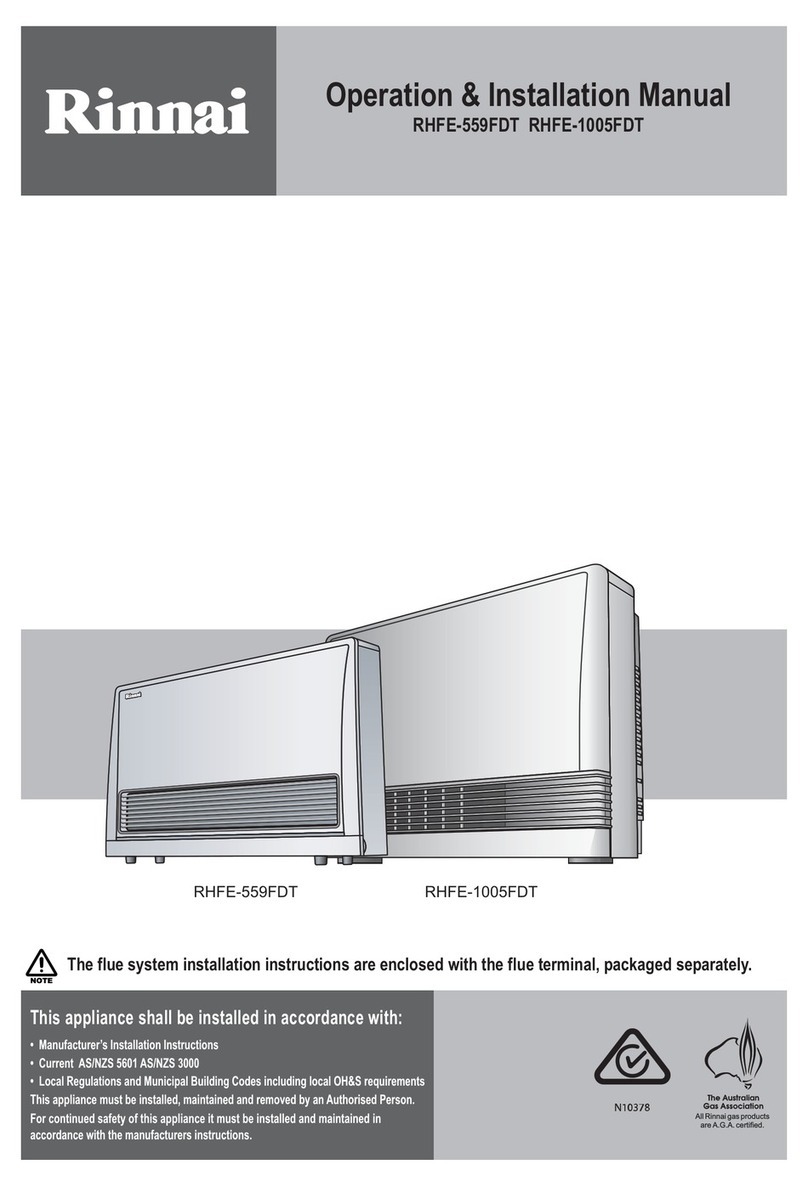

Rinnai RHFE-559FDT / FT User manual

Rinnai

Rinnai ASPIRATION RHFE-750ETR User manual

Rinnai

Rinnai FM10NA User manual

Rinnai

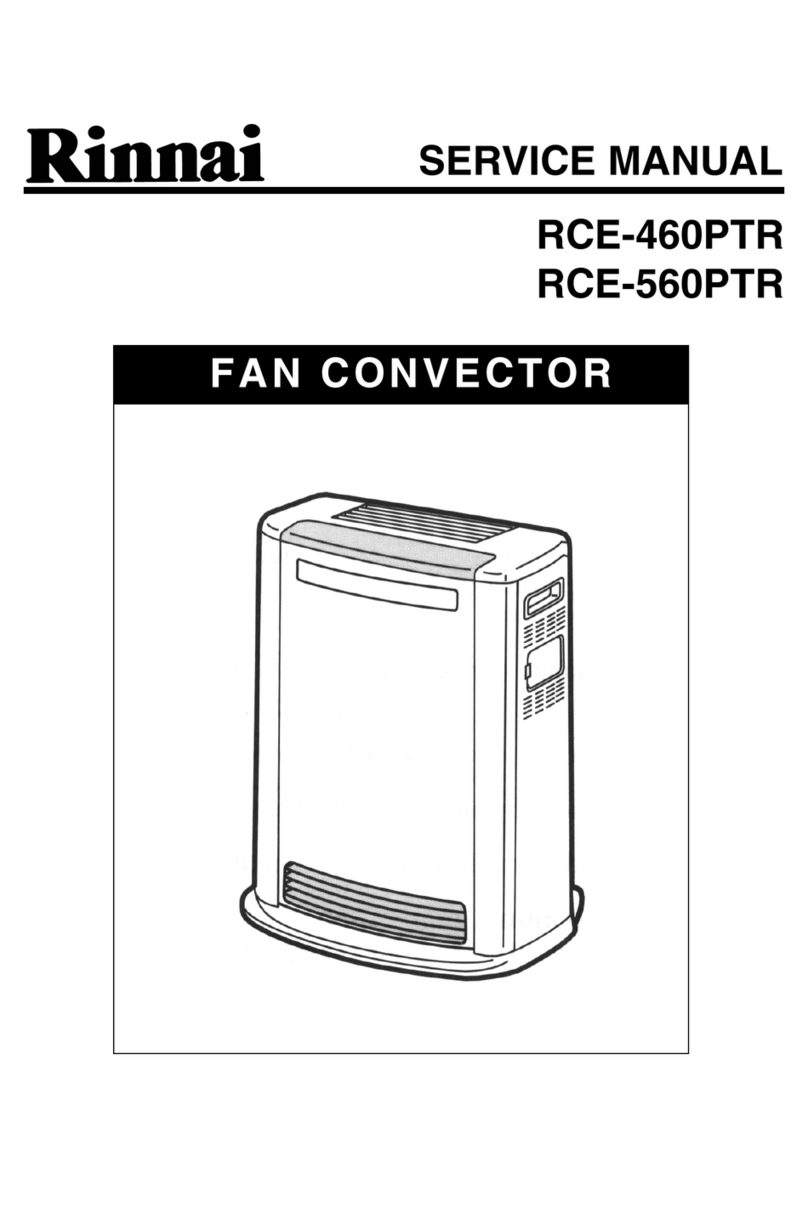

Rinnai RCE-460PTR User manual

Rinnai

Rinnai RHFE-309FT Specification sheet

Rinnai

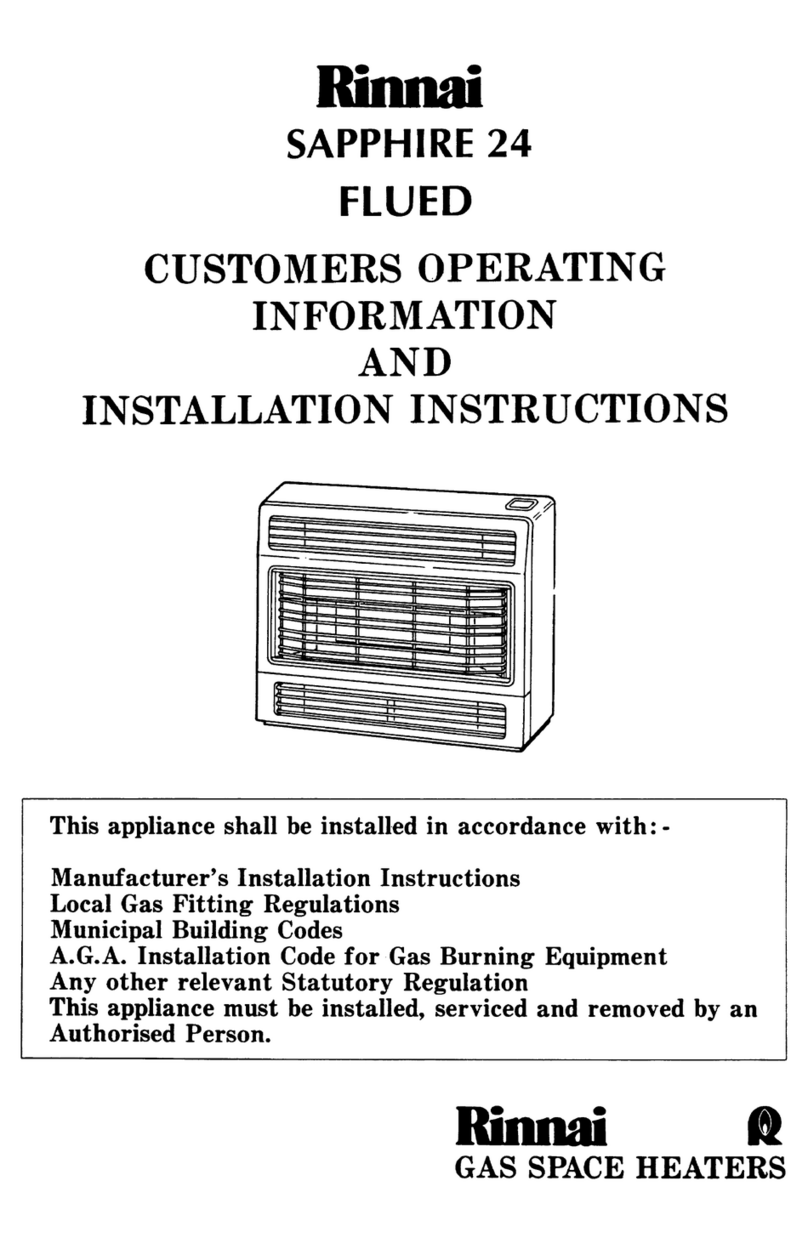

Rinnai Sapphire User manual

Rinnai

Rinnai ENERGYSAVER RHFE-308FTR User manual

Rinnai

Rinnai ES17 User manual

Rinnai

Rinnai RCE-229A Quick start guide

Popular Heater manuals by other brands

oventrop

oventrop Regucor Series quick start guide

Blaze King

Blaze King CLARITY CL2118.IPI.1 Operation & installation manual

ELMEKO

ELMEKO ML 150 Installation and operating manual

BN Thermic

BN Thermic 830T instructions

KING

KING K Series Installation, operation & maintenance instructions

Empire Comfort Systems

Empire Comfort Systems RH-50-5 Installation instructions and owner's manual

Well Straler

Well Straler RC-16B user guide

EUROM

EUROM 333299 instruction manual

Heylo

Heylo K 170 operating instructions

Eterna

Eterna TR70W installation instructions

Clarke

Clarke GRH15 Operation & maintenance instructions

Empire Heating Systems

Empire Heating Systems WCC65 Installation and owner's instructions