2PUB. NO. DFNDRB JANUARY 2013

DEFENDER™

TABLE OF CONTENTS

INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

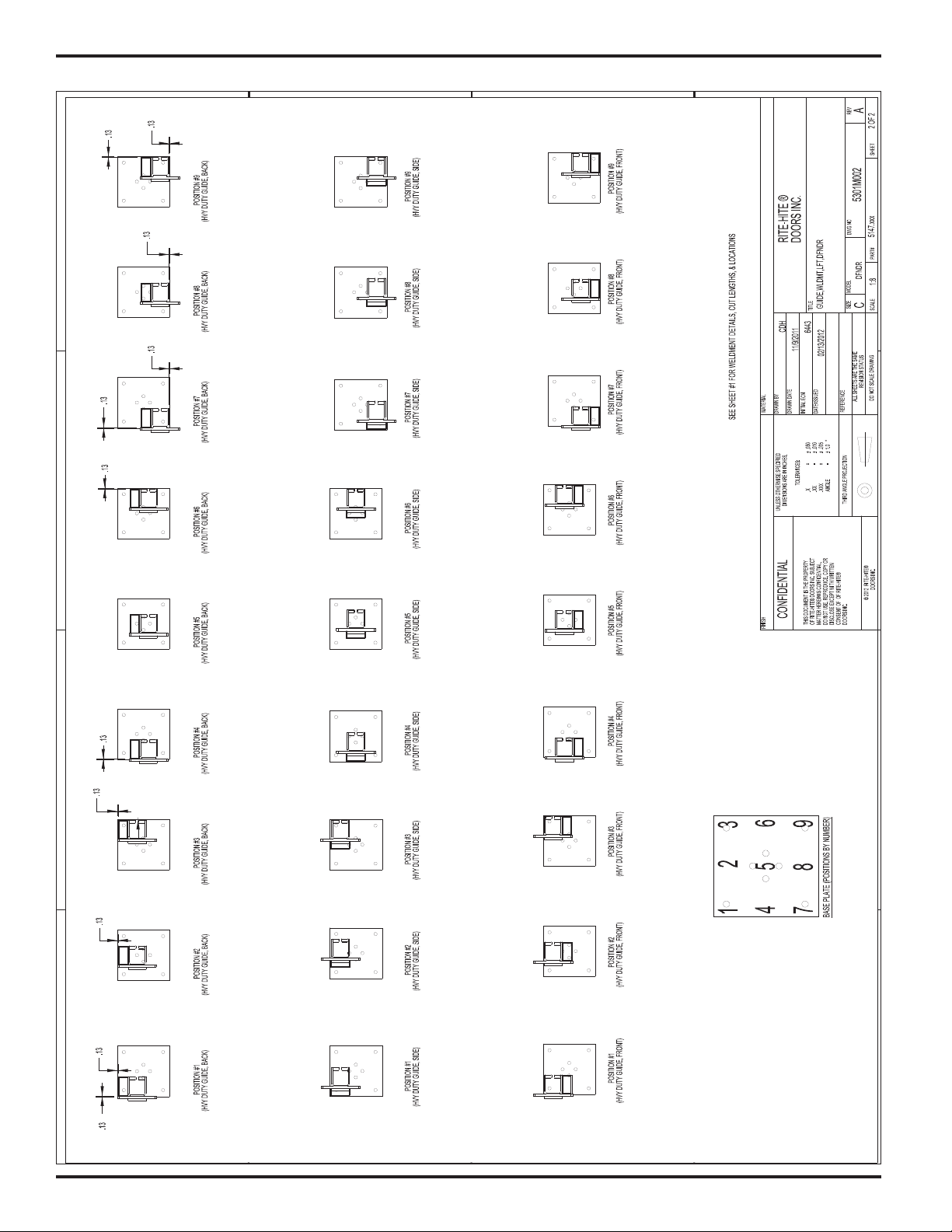

GUIDE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

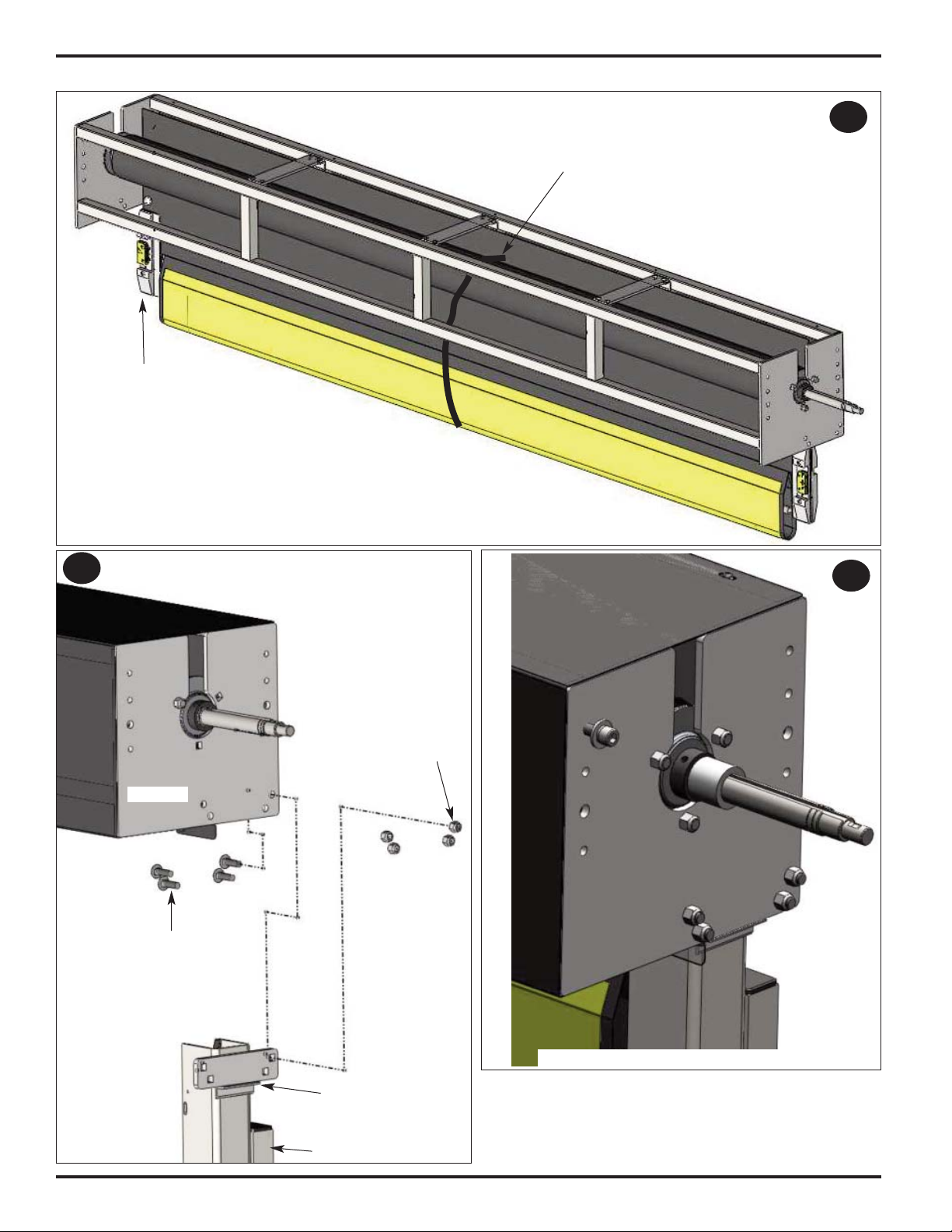

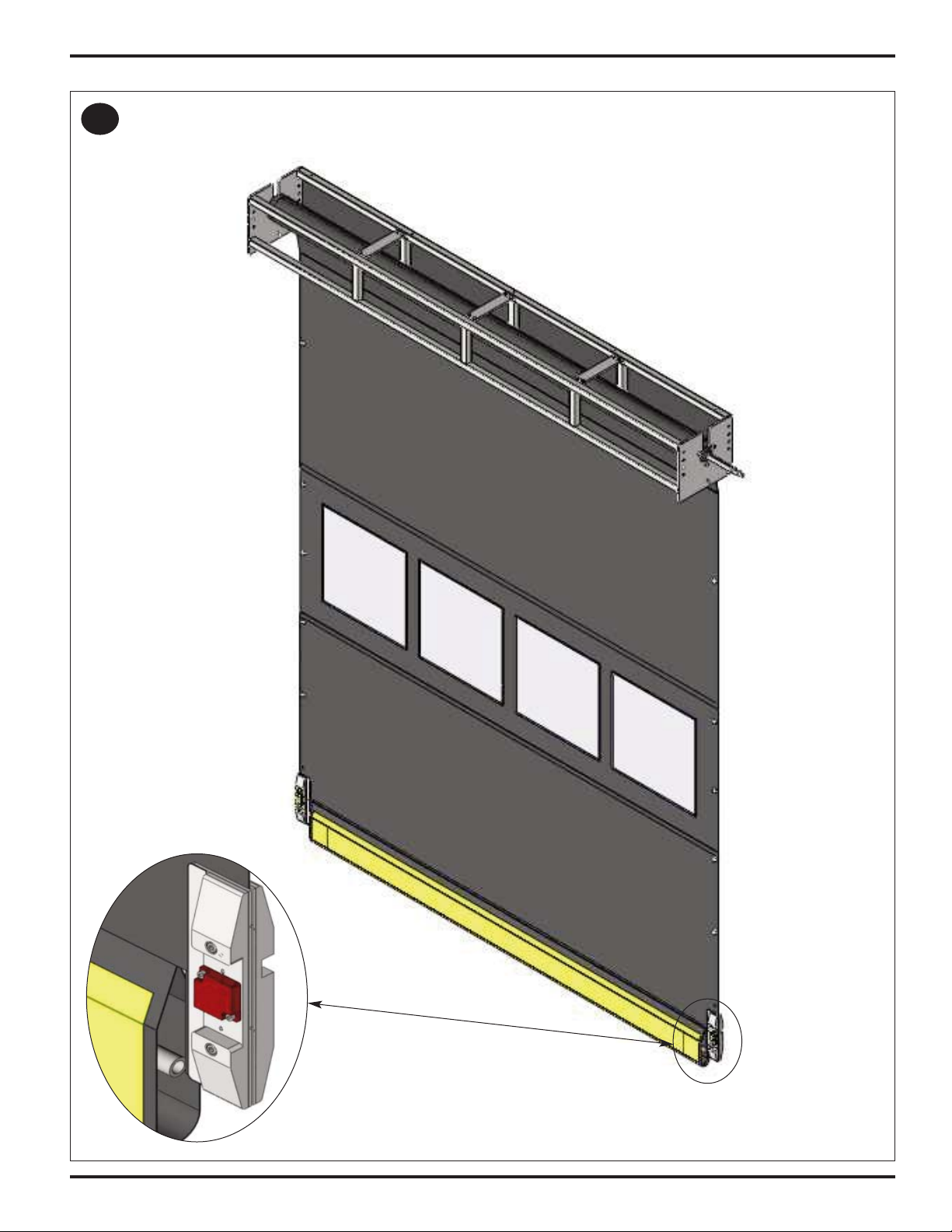

HEADER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

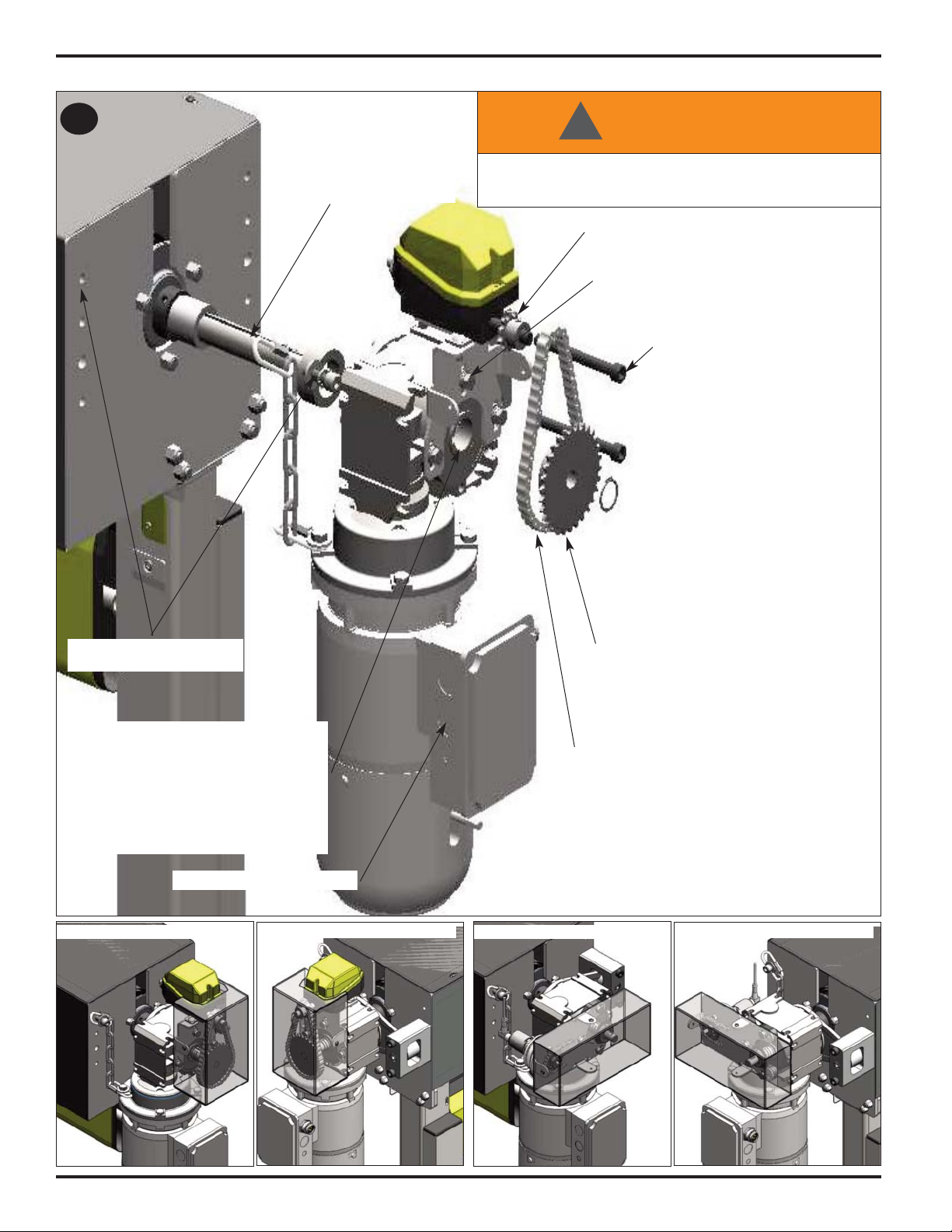

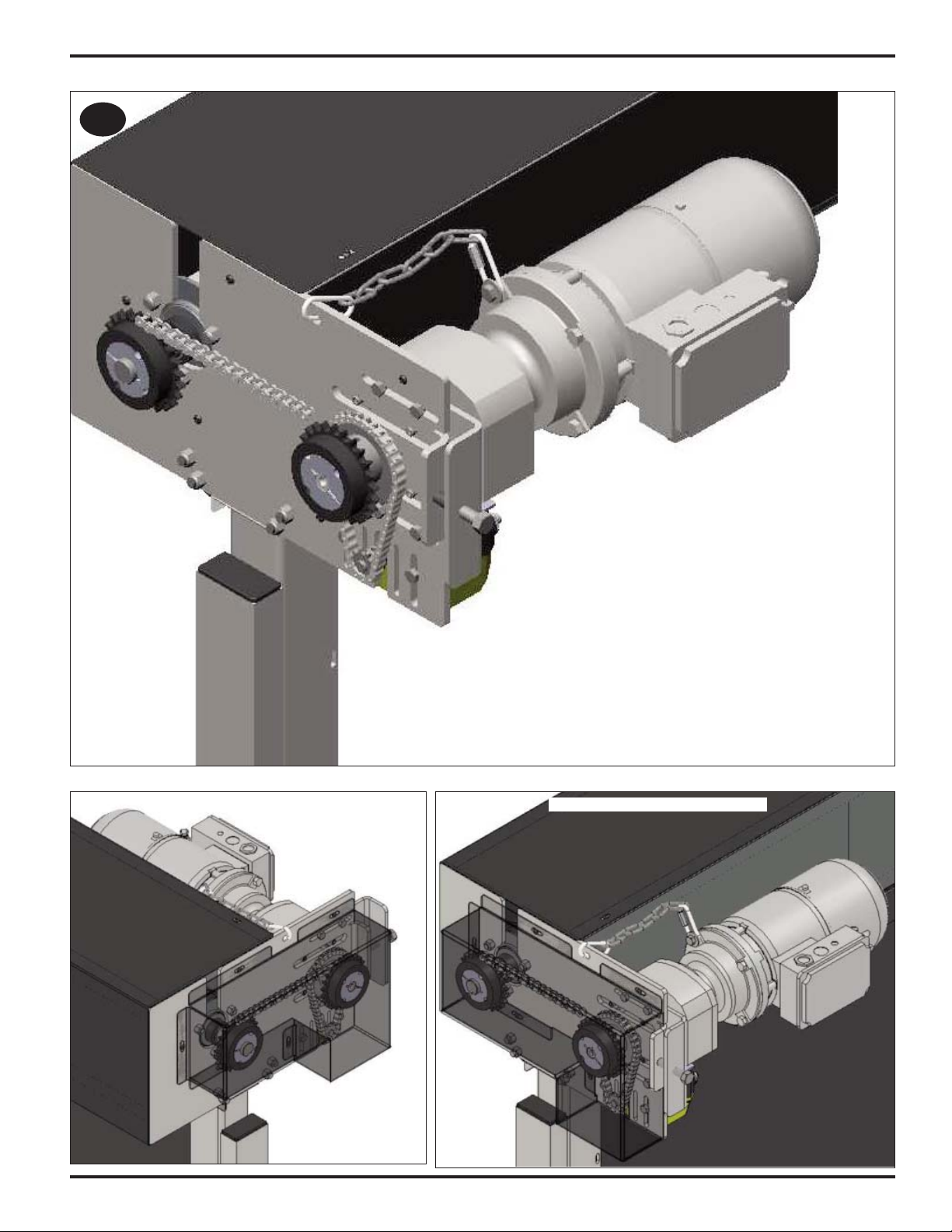

MOTOR / LIMIT SWITCH INSTALLATION . . . . . . . . . . . . . . . . . . . . .8

ENCODER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

LIMIT SWITCH WIRING / ADJUSTMENTS . . . . . . . . . . . . . . . . . . . .13

INTERLOCK / HOLD DOWN INSTALLATION . . . . . . . . . . . . . . . . . .15

PE LIGHT STRIP INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . .16

SHROUD INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

FEATURE RICH CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

SEQUENCE OF OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

MAINTENANCE CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

ELECTRICAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

PARTS LIST EXPLOSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

ARCHITECTURAL DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

NOTICE TO USER

Our mission is to “Improve Industrial Safety, Security and

Productivity Worldwide Through Quality and Innovation.”

Thank you for purchasing the GUARDIAN™ DEFENDER™

barrier door from FROMMELT™ SAFETY PRODUCTS. The

DEFENDER is a unique fabric door that can be transformed to

fit most opening configurations while helping to keep different

atmospheres separate.

FROMMELT SAFETY PRODUCTS reserves the right to modify

the electrical and architectural drawings in this manual as well

as the actual parts used on this product are subject to

manufacturing changes and may be different than shown in this

manual. Due to unique circumstances with varying

requirements, separate prints may be included with the unit.

This manual should be thoroughly read and understood before

beginning the installation, operation or servicing of this door.

Complete final checklist prior to leaving site.

This owners manual MUST be stored near the door.

The information contained in this manual will allow you to

operate and maintain the door in a manner which will insure

maximum life and trouble free operation.

The serial # for your door is on a label located on each lower

guide and/or on at the back of the header on the drive side or

on underside of center shroud, Figure 5.2.

If any procedures for the installation, operation or maintenance

of the DEFENDER have been left out of this manual or are not

complete, contact Technical Support at 1-563-589-2722.

RECOMMENDED SERVICE PARTS

Kit, Spheres (Qty 10) - 53700561

Encoder - 43800005

SPECIAL FEATURES

- Contains: Fumes, sparks, smoke, mist, debris and noise

- Flame resistant material

- Optional Variable Frequency Drive

(speed controls, smoother operation)

- Soft Bottom Edge (SBE) technology (impact protection)

- Multiple Safety Switch Options

- Multiple Guide/Base Plate configurations

- Minimal Installation Time

- Sizes ranging from 2’x3’ [610x915] to 16’x16’ [4877x4877]

DOOR OPTIONS PER ORDER FORM

Header Seal: No or Yes

Vision: None, 1 Row or 2 Rows and distance from bottom

Vision color: None, Clear, Amber, Dark Green, Orange

Motor Location: Right or Left

Motor Orientation: Down, Up, Front, Back or Chain driven

Motor Cable Length: None, 5M, 10M, 15M

Voltage: 220, 208, 230, 400, 460, 575

Control Box: None, Integrator, Relay or Feature Rich

Interlock Switch Type: Consult order

Interlock/Hold Down Switch Cables: None, 5M, 10M, 15M

Hold Down: No or Yes

Safety Controller: By others, Shipped Loose or in C-Box

Guide Location: Left side and Right side - consult order

Stop Photoeyes: None, 1 or 2

Stop Photoeye Strip: No or Yes

Stop Photoeye Strip Cables: None, 5M, 10M, 15M

INSTALLATION TOOLS REQUIRED

- Drill (cordless or electric) - Anti Seize

- 25’ [7620] Tape measure - Hydro level

- “C” Clamps - Hammer Drill

- Drill Bits - Phillips Bit for Drill

- Retaining Ring Pliers - Allen Wrench Set (1/8”) [2]

- Wire Strippers - Straight Edge

- “T” Handle Metric Allen Wrench

- 7/16” [11], 3/4” [19] Socket/wrench

- Small Straight / Phillips Screwdrivers

- Ladder (6’-8’) [1829-2438]

- 6’ [1829] Carpenters level

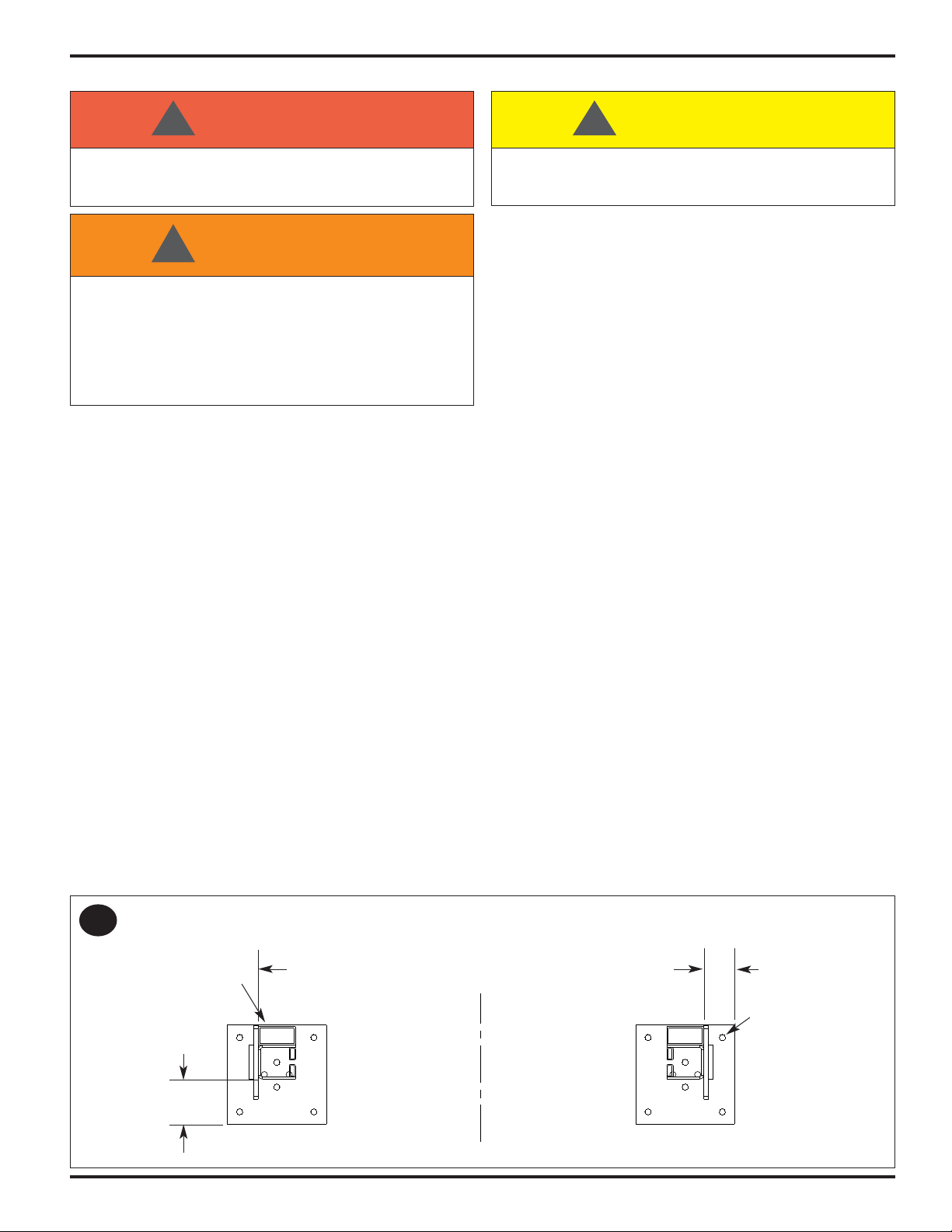

LOCKOUT/TAGOUT PROCEDURES

The Occupational Safety and Health Administration requires

that, in addition to posting safety warnings and barricading the

work area, the power supply has been locked in the OFF

position or disconnected. It is mandatory that an approved

lockout device is utilized. An example of a lockout device is

illustrated. The proper lockout procedure requires that the

person responsible for the repairs is the only person who has

the ability to remove the lockout device.

In addition to the lockout device, it is also a requirement to tag

the power control in a manner that will clearly note that repairs

are under way and state who is responsible for the lockout

condition. Tagout devices have to be constructed and printed so

that exposure to weather conditions or wet and damp locations

will not cause the tag to deteriorate or become unreadable.

FROMMELT SAFTEY

PRODUCTS does not

recommend any particular

lockout device, but recommends

the utilization of an OSHA

approved device (refer to OSHA

regulation 1910.147). RITE-HITE

Corporation also recommends

the review and implementation of

an entire safety program for the

Control of Hazardous Energy

(Lockout/Tagout). These

regulations are available through

OSHA publication 3120.

PRODUCT INTRODUCTION