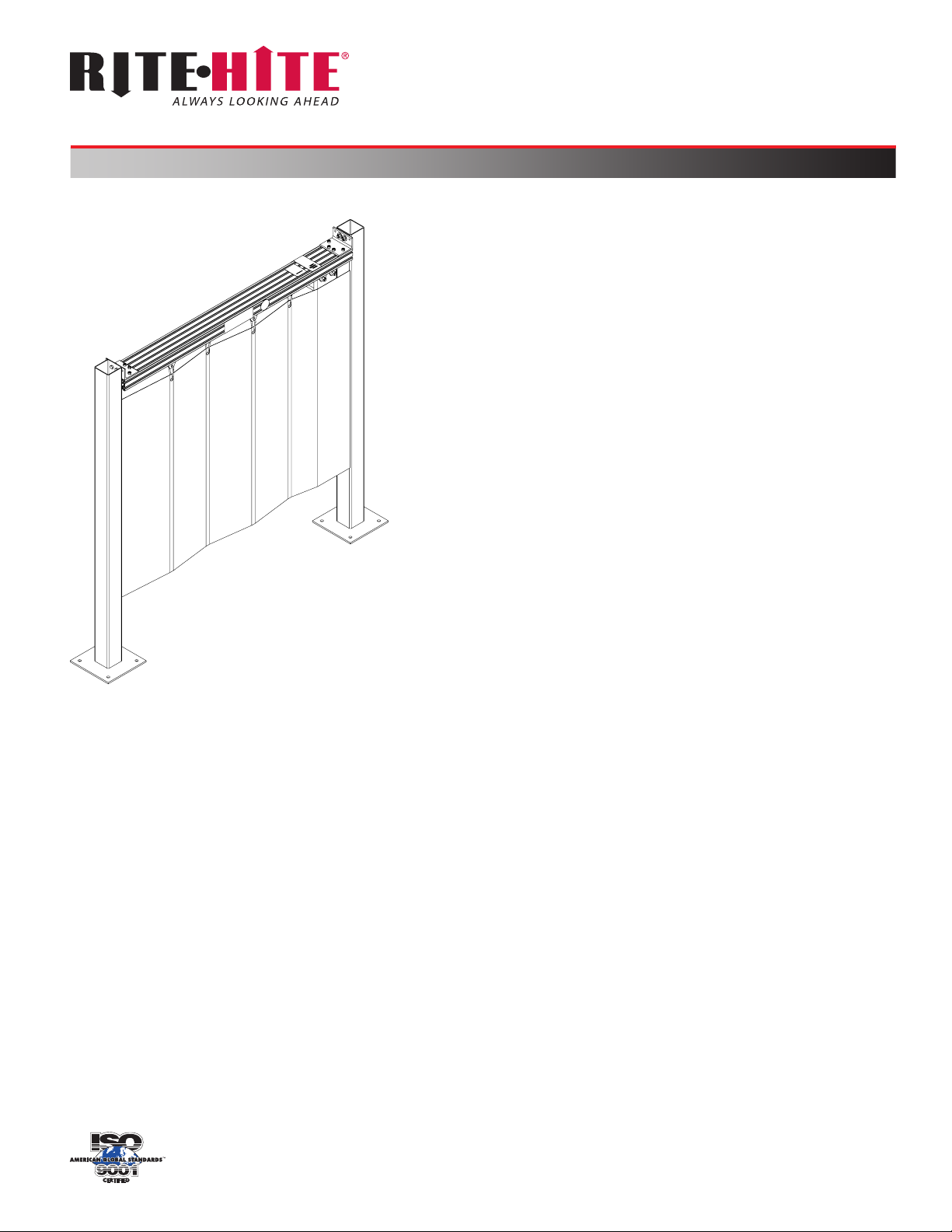

SlideAir™ Pneumatic Safety Curtain Installation/Service/Owner's Manual Rite‑Hite®

2 Publication: AMEN00119 2020-07-06

NOTICE TO USER

Thank you for purchasing a Rite‑Hite product.

The SlideAir pneumatic sliding curtain provides safety

and reduces process driven hazards in manufacturing

applications.

Read and understand manual before beginning the

installation, operation or servicing of this product.

Before work begins, verify space clearance requirements

from architectural drawings.

Complete "Final Checklist" (page 11) before leaving site.

Store manual near the unit.

The English version of this manual shall prevail over any

error in, or conicting interpretation of, any translations.

Rite‑Hite reserves the right to substitute and/or modify

parts and drawings (electrical and architectural) from

those contained in this manual. Separate prints may be

included with the unit.

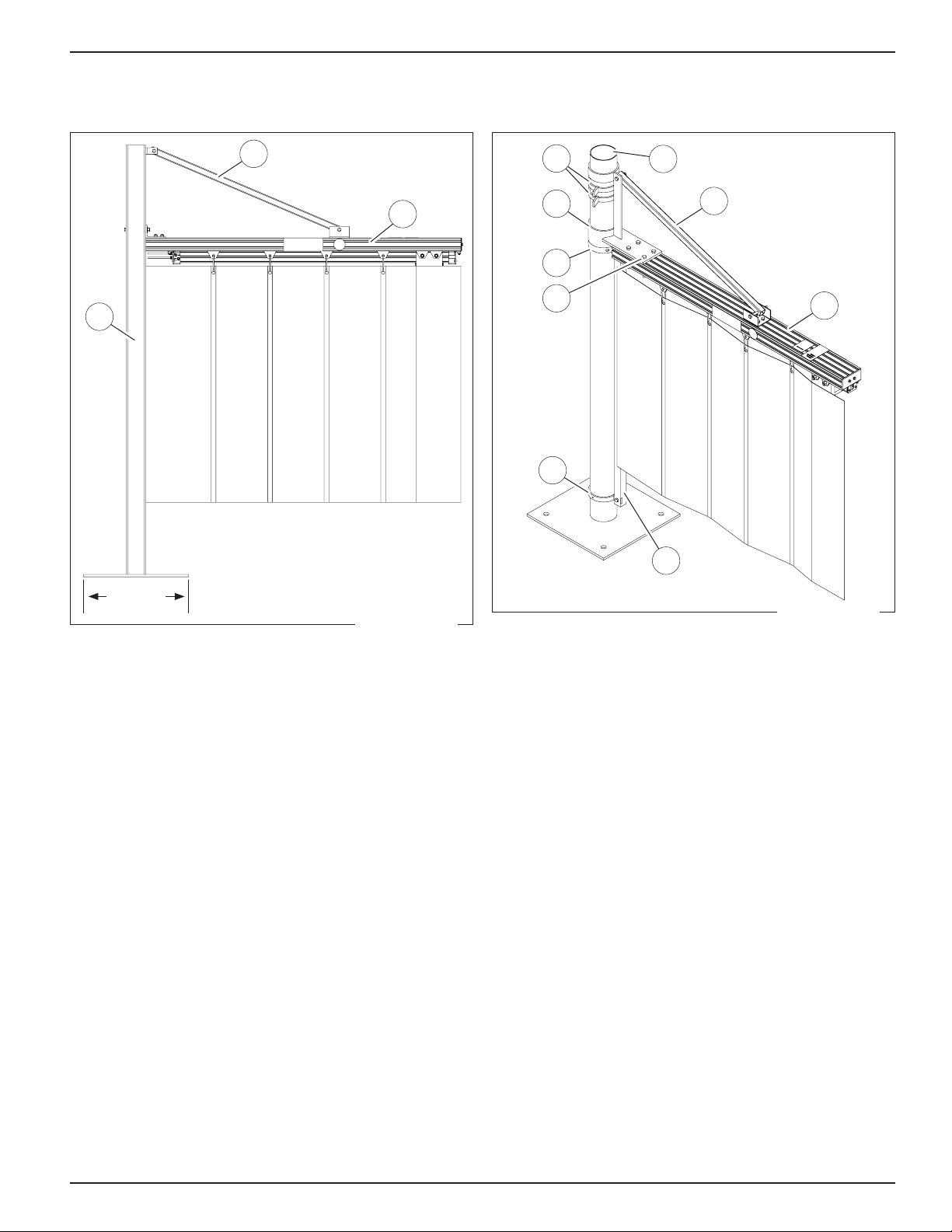

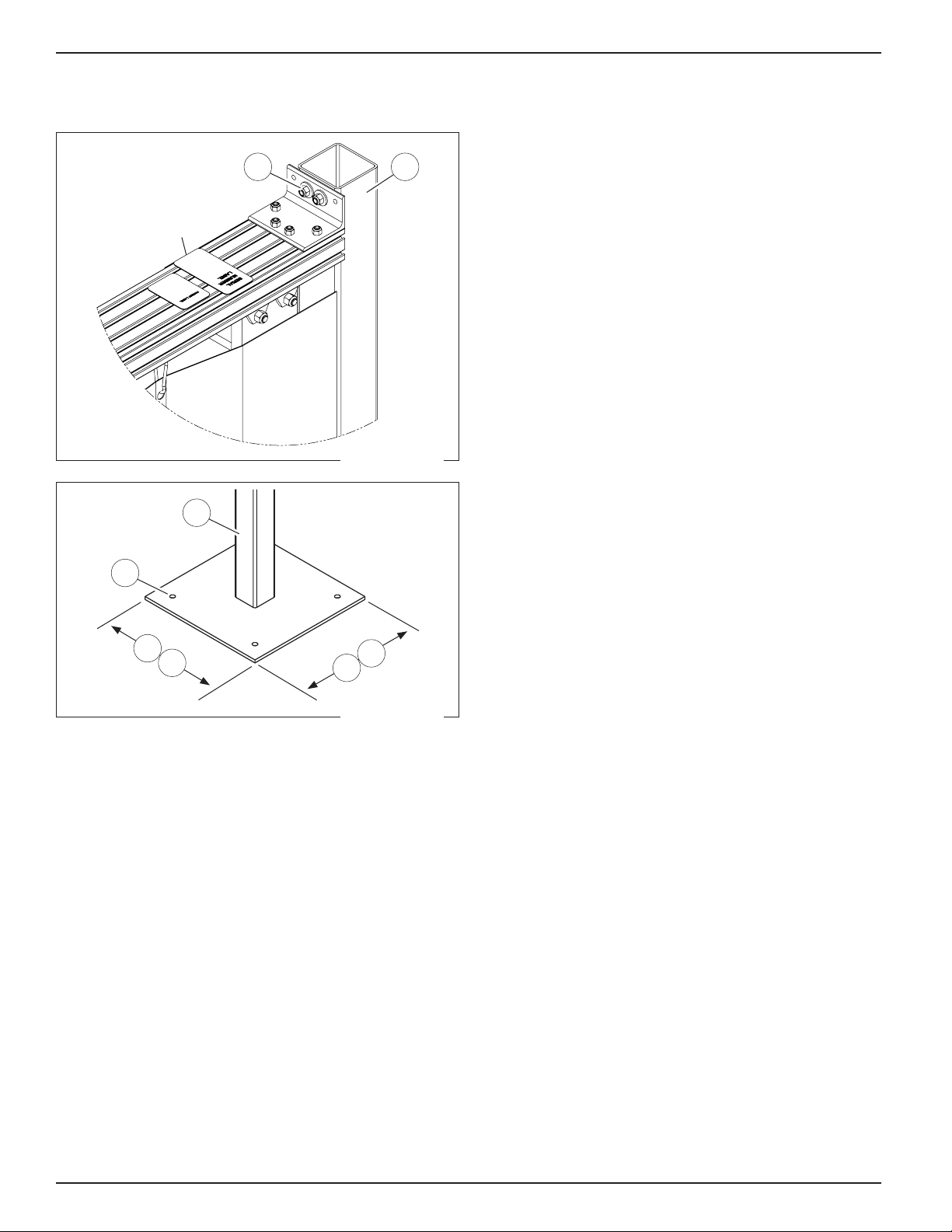

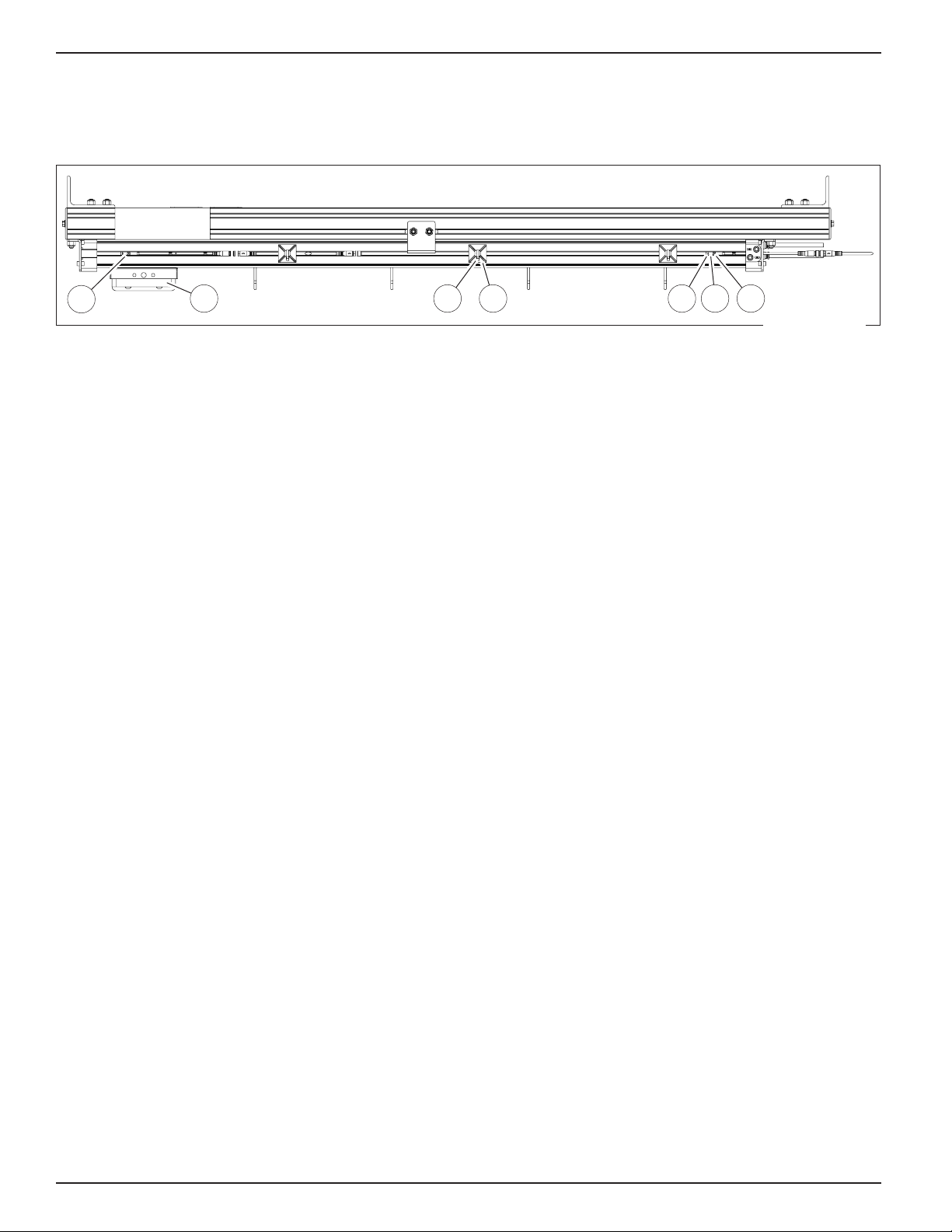

When ordering parts, include your unit serial or RHC

number located on the label located on the top of the main

header extrusion (Figure 3 on page 8).

For best results, have this product serviced by an

authorized Rite‑Hite representative.

A Planned Maintenance Program (P.M.P.), customized to

your specic operation is available and recommended.

For a P.M.P., contact your local Rite‑Hite representative

or Rite‑Hite technical support at (U.S.) 1‑563‑589‑2722,

1‑888‑456‑3625, (S.A.) +55 21 99616 4421,

(E.U.) +49‑5693 98700.

NOTICE

Store dry between 40° and 80° F, (4° and 27° C).

The Rite‑Hite®products in this manual are covered by one or more

of the following U.S. patents: 6192960, 6212826, 6330763, 6360487,

6481487, 6560927, 6598648, 6615898, 6688374, 6837296, 6901703,

6964289, 7034682, 7045764, 7111661, 7114753, 7151450, 7578097,

7699089, 7748431, 7757437, 8037921, 8167020, 8113265, 8863815,

8857498, 9222304, 9388634, 9309717, 9493984, 9556672, 9631427,

9771754 and may be covered by additional pending U.S. and foreign

patent applications.

Rite‑Hite®, SlideAir™ are trademarks of Rite‑Hite.

Manufactured by Rite‑Hite Doors, Inc.