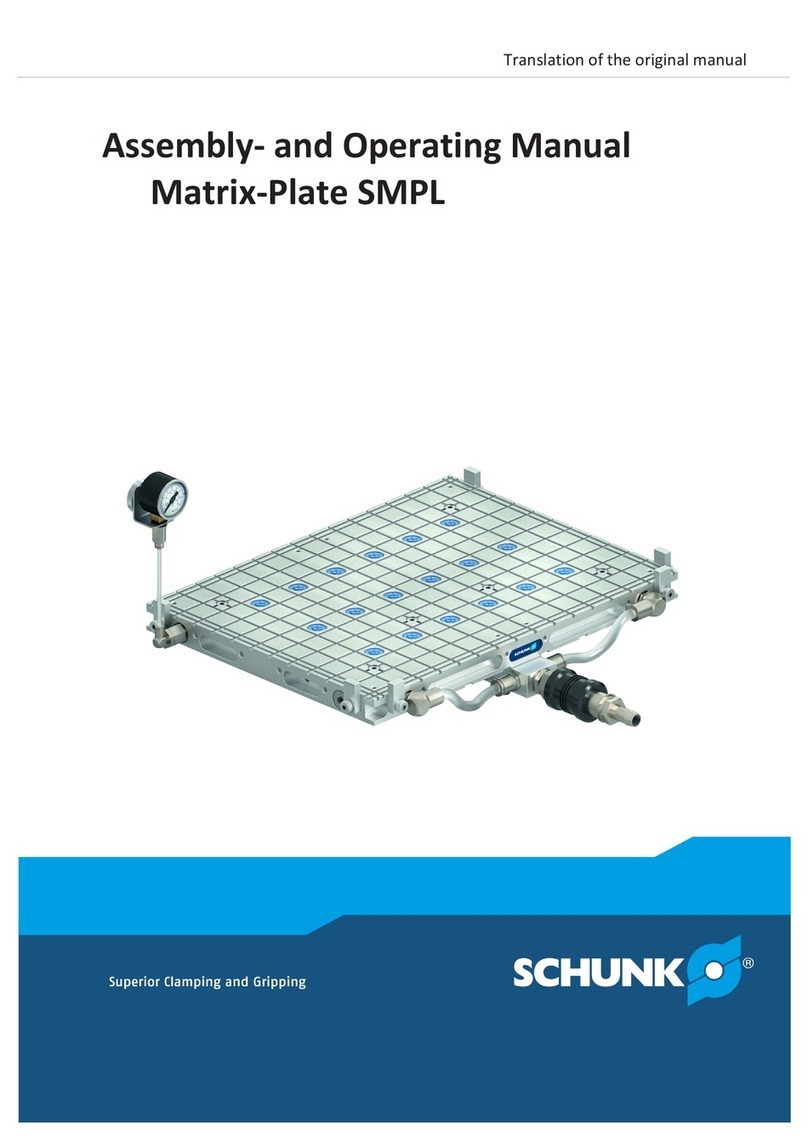

riverhawk IM-278 User manual

Repairs – Rentals

Field Service

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

RevisionA

Page1of32

INSTRUCTIONMANUALIM‐278

ForHydraulicallyTensionedStudsandNuts

ApplicableBoltingConnections

9EGasTurbinetoLoadCoupling

LoadCouplingtoSubstituteShaft

SubstituteShafttoLoadCoupling

LoadCouplingto9A5Generator

ApplicableGEOrderingSheetPartNumbers

102T3330P001

102T3330P002

102T3330P003

102T3330P004

102T3330P005

102T3330P006

102T3330P007

104T5015P001

104T5015P002

104T5015P003

104T5015P004

104T5015P005

104T5015P006

104T5015P007

GEPower&Water

GENERALELECTRICCOMPANY

MLI: ____ OF ____

DATE

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

ISSUED:

THISDOCUMENTSHALLBEREVISEDINITSENTIRETY.ALLSHEETSOFTHISDOCUMENTARE

THESAMEREVISIONLEVELASINDICATEDINTHISVENDORSUPPLIEDDRAWINGAPPLIQUE.

REV

373A4054

GEDRAWINGNUMBER

VENDORSUPPLIED

THISDOCUMENTISFILEDUNDERTHEGEDRAWINGNUMBER.

GENOTTOREVISE.GEREVISIONLEVELISSHOWNONTHISAPPLIQUE.

GESIGNATURES

CHECKED:

TheRiverhawkCompanyreservestherighttomakechangesupdatingthisdocumentwithoutdissemination

ornotice.Thelatestrevisionlevelmaybeobtainedbycontacting Riverhawk Company directly or at our

websitewww.riverhawk.com.

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page2of32

TableofContents

Section Description PageNumber

1.0 CautionsandSafetyWarnings 3

2.0 ScopeandGEPartNumberCross‐Reference 4

3.0 QuickCheck‐List 5

4.0 GeneralPreparations 9

5.0 HardwareSetPreparations 11

6.0 NutandStudAssembly 14

7.0 AssemblyofTensioneronStud 17

8.0 StudPullingandTensioning 19

9.0 ThreadLocking 22

10.0 Stud/NutRemoval 23

11.0 Storage 24

12.0 FrequentlyAskedQuestions 24

13.0 RevisionHistory 26

AppendixA1 ECDeclarationofConformity 27

AppendixA2 UKCADeclarationofConformity 28

AppendixB1 16‐BoltTensioningPatternRecordSheet 29

AppendixB2 14‐BoltTensioningPatternRecordSheet 30

AppendixB3 14‐BoltTensioningPatternRecordSheet 31

AppendixB4 14‐BoltTensioningPatternRecordSheet 32

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page3of32

1.0CautionsandSafetyWarnings

NOTICE

Asofsummer2011,thismanualistobeusedinrelationtotheinterlockingstyletensioner.This

new tensioner can be identified buy its ORANGE safety guard. Note: yellow guarded tensioner

requirestheuseofdifferentsetofinstructions,consultRiverhawkforassistance

TOAVOIDFAILURE,ENSURESAFETYANDPROPEROPERATIONTHETENSIONERANDINTERLOCK

SAFETYGUARDMUSTINSTALLEDONTHEFLANGEBEFORETENSIONINGBEGINS.DONOTUSETHE

TENSIONERASSEMBLYATANYPRESSUREUNLESSTHETOOLISINSTALLEDONTHEFLANGE.

WARNING

Impropertooluseandthefailuretofollowthecorrectproceduresaretheprimaryrootcausesoftool

failuresandpersonalinjuries.Alackoftrainingorexperiencecanleadtoincorrecthardware

installationorincorrecttooluse.Onlytrainedoperatorswithcareful,deliberateactionsshoulduse

hydraulictensioners.ContactRiverhawkCompanywithanytrainingneeds.

WARNING

Riskofhighpressurefluidinjection.Riverhawktoolsoperateunderhighpressure.Thoroughlyinspect

allhosesandconnectionsfordamageorleakspriortousingthisequipment.

CAUTION

Personalinjuryandequipmentdamagecanoccurifthepullerscrewisnotsecurelyengagedwith

thecleanconicalthreadofthestud.Properengagementisachievedwhenthepullerscrewistight

inthestudandisnotcross‐threadedintotheconicalthread.(ReferenceIM‐220)

WARNING

Theproperpersonalprotectiveequipmentmustbewornatalltimes.Riverhawkrecommendsata

minimum,safetyglasses,longsleeveshirt,hardhat,heavyworkgloves,andsteeltoeshoes.

WARNING

ThesafetyguardMUSTbeinplaceandhandskeptoutofdesignatedareasatalltimeswhenthe

tensionerispressurizedotherwisepersonalinjurycanoccur.

CAUTION

DONOTEXCEEDTHEMAXIMUMPRESSUREMARKEDONTHETENSIONER.Excessivepressurecan

damagethestudandthepullerscrew.

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page4of32

WARNING:

Keephandsclearofthetoolwhilethepressureisbuildingup.Thisincludesthepinwrenchfor

tighteningthespannerring(nut).Oncethetoolisstabilizedatpressurethenandonlythencanthe

nutbetightened.Thisreducesthepotentialofpersonalinjury.

Note:Beforethreadingthepullerscrewintothestud,carefullycheckthecleanlinessofboththe

stud's and the puller screw's conical threads. Apply a light coat of clean turbine oil or a spray

lubricanttothepullerscrew.Donotuse“NeverSeize”ontheconicalthreads.Thisprocedurewill

easeassemblyandassurepositivematingofthethreadsbeforetightening.

2.0Scope

Thisdocumentdescribesthestepstoinstallasetofhardwarecontainingthestudsandnuts

suppliedbyRiverhawkCompanyattheturbine/coupling;coupling/substituteshaft;substitute

shaft/couplingandcoupling/generatorconnections.Thishardwareisdepictedonthefollowing

drawings.Thesedrawingsaswellastoolingdrawingsformpartofthismanual.

Riverhawk

HardwareSetPart

Number

GEDrawing

Numberfor

HardwareSet

GEOrderingSheet

PartNumber

HardwareSet

Description

HF‐5369 269B8701

102T3330P001

102T3330P002#

104T5015P001

104T5015P002#

2‐3/4"hardwareforAll4bolted

joints.

- - 102T3330P003#

104T5015P003#

Hydraulicinstallationtoolingonly

HF‐5578 269B8737 102T3330P004

104T5015P004

2‐3/4"hardwarefortheturbine

endtoloadcouplingconnection.

HF‐5579 269B8738 102T3330P005

104T5015P005

2‐3/4"loadcouplingto

substituteshaftconnection.

HF‐5580 269B8739 102T3330P006

104T5015P006

2‐3/4"substituteshafttoload

couplingconnection.

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page5of32

HF‐5581 269B8740 102T3330P007

104T5015P007

2‐3/4"loadcoupling9A5

generatorconnection.

#denotesGEpartnumbersthatincludehydraulictooling

OtherImportantReferenceDocumentation:

IM‐293(GE373A4058) InstructionManualforGEHydraulicPumpKit

IM‐220(GE373A4025) CleaningProcedureoftheConicalThreadsonRiverhawkStuds

3.0QuickChecklist

ThefollowingchecklistisintendedasasummaryofthestepsneededtousetheRiverhawk‐supplied

equipment. New personnel or those experienced personnel who have not used the Riverhawk

equipmentrecentlyareencouragedtoreadtheentiremanual.

EQUIPMENTINSPECTION

□ Checkhydraulichoseforanydamage.

□ Testpump,seepumpinstructionmanualIM‐293forprocedure.

□ Inspecttensionerforanydamage.

NUTANDSTUDPREPARATION

□ Inspectstudsandnutsforanydamage.

□ Cleanthestudsandnuts(ReferenceIM‐220).

□ Measurestudlengthsandrecordonstretchdatasheets.

(VERYIMPORTANT)

□ Installstudsandnutsintotheflange.

□ Setstick‐outdimensionontheconicalthreadendofstud.

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page6of32

□ Handtightennutsonbacksideofstud.

□ Verifystick‐outmeasurement(VERYIMPORTANT)

Tensioning(Studinstallation)

□ Checktensioner’sdrawingforcorrectpartsandpartnumbers.

□ Applyalightcoatofcleanturbineoilorspraylubricanttothepullerscrew.DONOTUSE

“NEVERSEIZE”ONTHECONICALTHREADS.

□ Installspannerringontonut.

□ Threadpullerscrewontothestud.

□ InsertAllenwrenchintothebacksideofthestudtostopthestudfromrotatingwhen

installingpullerscrew.

□ UsinganAllenwrench,tightenthepullerscrew.Thenbackoffpullerscrew1/2aturn.

□ Retightenpullerscrewbyhanduntilitisfullyinserted.DONOTBACKOFFPULLERSCREW.

□ Slidefootoverpullerstudandorientateintoposition.

□ Threadthetensionerontopullerscrew.Lightlyturnthetensionerontothepullerscrew,

untilitstops.Thegapbetweenthefootandtensionerisabout1/16”to3/16”.

□ Placeguardovertensionerandpositionguidepinintotheholeinthebacksideofthestud.

□ Tightenknurledinterlockfittingbyhanduntilitpressesfirmlyagainsttensioner.(nogap)

□ Slideandengagecustomconnectorfromrearofguardtolocktensionerintoplace.

□ Tensionto50%.Consultmanualforcorrectpressure.

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page7of32

□ Usethepinwrenchinspannerringtotightennut.

□ Releasepressure,allowtensionertofullyretract.

□ Disconnecthosefromtensioner.

□ Loosenknurledfittingandremoveguard.

□ Unscrewtensionerfrompullerscrew.Usecautiontoinsurethathandsarenotbetween

tensionerandcouplingwhentensionerbecomesdisengagedfrompullerscrew.

□ Removefoot.

□ Removepullerscrewfromstud.

□ Removespannerringfromnut,movetonextstudinpattern.

□ Tensionallstudsto50%beforeproceedingtofinalpressure.

□ Repeatabovestepsatfinalpressure.

□ Measurefinalstudlengthandrecordonstretchdatasheets.Calculatestretchandverify

persection8.2

□ Torquenuts’setscrewspersection10.

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page8of32

Detensioning(Studremoval)

□ Loosennuts'setscrews

□

Inspectandcleanstuds'conicalthreads.DonotcontinueuntilALLdebrisisremoved

fromthethreads!ReferenceinstructionmanualIM‐220.Donottrytousethetensioner

toremoveadamagedstud!

□ Applyalightcoatofcleanturbineoilorspraylubricanttothepullerscrew.DONOTUSE

“NEVERSEIZE”ONTHECONICALTHREADS.

□ Installspannerringontonut.

□ Threadpullerscrewontothestud.

□ UsingAllenwrenchtightenthepullerscrew.Thenbackoffpullerscrew1/2aturn.

□ Lightlyretightenpullerscrewbyhanduntilitisfullyinserted.DONOTBACKOFFPULLER

SCREW.

□ Slidefootoverpullerstudandorientateintoposition.

□ Threadthetensionerontopullerscrew.Lightlyturnthetensionerontothepullerscrew

untilitstops.Thegapbetweenthefootandtensionerisabout1/16”to3/16”.

□ Placeguardovertensionerandpositionguidepinintotheholeinbacksideofstud.

□

Tightenknurledinterlockfittingbyhanduntilitfirmlypressesagainsttensioner.(no

gap)

□ Slideandengagecustomconnectorfromrearofguardtolocktensionerintoplace.

□ Applyfinalpressure.

□ Loosennutwiththespannerringandpinwrench.

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page9of32

4.0GeneralPreparations

Readandunderstandallinstructionsbeforeinstallingandtensioningstuds

Thisequipmentproducesveryhighhydraulicpressuresandveryhighforces.Operatorsmust

exercisecaution,andproperpersonalsafetyequipmentmustbewornatalltimes.Contactthe

site’shealthandsafetyofficetodetermineallapplicablesafetyrulesandregulations.

High‐pressurefluidfromtheHydraulicPressureKitsystempressurizesthetensionerwhich

generatesastretchingforcethatactuallystretchesthestud.Asthestudisstretchedthenutlifts

offtheflange.Thenutisthenreseatedintopositionontheflangebyturningspannerringwiththe

pinwrench.Whenthenutistightagainsttheflange,thepressureinthetensionerisreleased

leavingthestudloadedtoitspredeterminedvalue.

4.1MachinePreparation

Theflangetobetensionedmustbefullyclosedpriortopositioningofstudsintheflanges.Turning

theshaftsoftheturbineandthegeneratorwillberequired.Also,itwillbeadvantageousto

□ Releasepressure,allowtensionertofullyretract.

□ Disconnecthosefromtensioner.

□ Loosenknurledfittingandremoveguard.

□ Unscrewtensionerfrompullerscrew.

□ Removefoot.

□ Removepullerscrewfromstud.ItmaybenecessarytoinsertanAllenwrenchintothe

backsideofstudtoremovepullerscrew.

□ Removespannerringfromnut.

□ Movetonextstudinpattern.

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page10of32

removeasmanyobstructionsaspossiblefromtheflangearea,suchasspeedprobes,shipping

plates,andconduit.

4.2Hardware–Balance

Hardwareissuppliedasweightbalancedsets.StudsandNutsareinterchangeablewithinaset.Do

notmixstudandnutsfrommultiplesets.

Savetheweightcertificationthatissuppliedwitheachset.Itwillbeneededforthepurchaseof

replacementhardware

4.3Tensioner–CareandHandling

Whennotinuse,thetensionershallbemaintainedinacleanenvironmentwithallcapsandplugs

forhydraulicopeningsandfittingsinplace.

UseISO32gradeoil.

Wheninuse,thetensionershallbeprotectedfromsandandgrit.

4.4 HandTools

Severalhandwrenchesandmicrometersmayberequiredtoperforminstallationand

measurementofthestuds:

5/8”wrench

AsetofAllenWrenches

3’–4’BreakerBar

10”to11”micrometerorcaliper

4.5SpecialTools

HydraulicTensionerKit: HT‐5506HydraulicTensioner

(referenceGE269B8736)

HT‐5506‐ITHydraulicTensioner

(Italian)

(referenceGE269B8749)

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:info@riverhawk.com

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page11of32

HydraulicPumpKit: AP‐0532Air‐OperatedHydraulic

Pump(recommended)

(referenceGE359B2502)

AP‐0523‐ITAir‐OperatedHydraulic

Pump(Italian)

(referenceGE269B8750)

MP‐0130ManualHand‐Operated

HydraulicPump

(referenceGE359B2506)

5.0PreparationofHardware

5.1NutPreparation

SamplePictureofaRiverhawkLocknut

Ifthereisanyvisibledamageonanut,donotusethenutandcontacttheRiverhawkCompanyfor

areplacementnut.Pleasebepreparedtosupplytheturbinenumber,weightcertification,and

digitalphotographsforevaluation.

Set Screw

1 of 2

Spanner

Ring Holes

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page12of32

5.1.1NutCleaning‐NewInstallations

Fornewinstallations,thenutsshouldcomesealedfromthefactoryandwillneednocleaning.

5.1.2NutCleaning‐OldInstallations

Previouslyinstallednutsrequirecleaningasfollows:

Wirebrushusingapetroleumbasedsolventtoremoveanyforeignmaterialontheexternal

surfacesandthreads.

5.2StudPreparation

Checkthestudforanyvisibledamage.Ifthereisanyvisibledamage,donotusethestudand

contacttheRiverhawkCompanyforareplacementstud.Pleasebepreparedtosupplytheturbine

number,weightcertification,anddigitalphotographsforevaluation.

Theconicalthreadsofeachstudmustbecleanbeforeinstallationorremoval.Thisensuresthe

properseatingofthepullerscrew.

5.2.1StudCleaning‐NewInstallations

Fornewinstallations,thestudsshouldcomesealedfromthefactoryandwillneednocleaning.

5.2.2StudCleaning‐OldInstallations

Previouslyinstalledstudswillrequirecleaning.Cleanconicalthreadsshouldhaveabrightand

shinyappearance.UseinstructionmanualIM‐220formoredetailedinstructions.

Notice:

Failuretoproperlycleanthestudscouldresultinimpropermatingofthreads.Personalinjuryand

equipmentdamagecanoccurifthepullerscrewisnotsecurelyengagedwiththetaperedthread

ofthestud.

Ifcleaningisrequired,followthesesteps:

1. Blowoutthethreadswithcompressedairtoremoveloosedebrisanddryconicalthreads.

ReferenceinstructionmanualIM‐220formoredetailedinstructions.Donotapplyasolvent

orothercleaningsolutiontothethreadsasthismaychemicallyattackthestud.

2. UseStudCleaningKit,GT‐4253orasimilar1"diameterBrasspowerbrush.

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page13of32

PictureofBrassPowerBrush

3. Insertthebrushintoanelectricdrillandsetdrilltoruninacounterclockwisedirectionat

highspeed.

4. Workthedrillinacircularmotionwhilemovingthebrushinandouttocleanallofthe

threads.Trynottoholdthebrushinoneplacetoolong,soasnottoremovethestud's

protectivecoating.

5. Blowoutthethreadswithcompressedairtoremovelooseneddebris.

6. Visuallyinspectthreadsforcleanliness.Threadsshouldbebrightandshiny.

7. Repeatifanydirtcanbeseeninthethreads.

8. Inspectthreadsforanydamagethatmayhavebeencausedbypreviousinstallation.

Donotapplythreadlubricantstothethreads.

Finishthecleaningprocessbyrinsinginavolatilesolventsuchasacetoneandallowtodry.

5.3StudLengthMeasurement

MeasureandrecordtheinitiallengthsofthestudsonthesuppliedstretchdatasheetinAppendix

Bofthismanual.

Thefollowingrecommendationswillimproveyourresults.

Plantostartandfinishanyflangeinthesameday.

Studsandflangemustbeatthesametemperature.

Keepthemeasuringinstrumentsoutofthesunlight.

Numbereachstudwithamarkerforlaterstretchmeasurementtracking.

Markthelocationofmeasurementonstudendwithapermanentmarker.

Thesamepersonshouldmakeallmeasurements.

Measureeachstudtonearest0.001inch(.01mm)orbetter.

Recordeachmeasurementonthestretchrecordsheetsinthismanual'sappendix.

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:info@riverhawk.com

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page14of32

6.0StudandNutAssembly

RefertoHardwareSetPartNumberdrawinglistedinSection2.0ofthismanual.Ifyoudon’thave

ahardwaresetdrawing,itcanbefoundintheGEdrawingsystemorcontactRiverhawkCompany.

Assemblethenuttotheconicaltensioningthreadend(frontside)ofthestud.

SlidetheassemblyintotheflangefromthecouplingsideasshowninFigures1thru4theninstall

theothernutonthebackside.

Ensurethatbackside’snutorientationiscorrectwiththreadlockingscrewsfacingoutwardofthe

flange.

Figure1–CutawayViewofTurbineFlange

andCouplingFlangeBoltedJoint

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page15of32

Figure2–CutawayViewofTurbineLoadCoupling

andSubstituteShaftBoltedJoint

Figure3–CutawayViewofSubstituteShaft

andGeneratorLoadCouplingBoltedJoint

Figure4–CutawayViewofGeneratorLoadCoupling

andGeneratorFlangeBoltedJoint

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page16of32

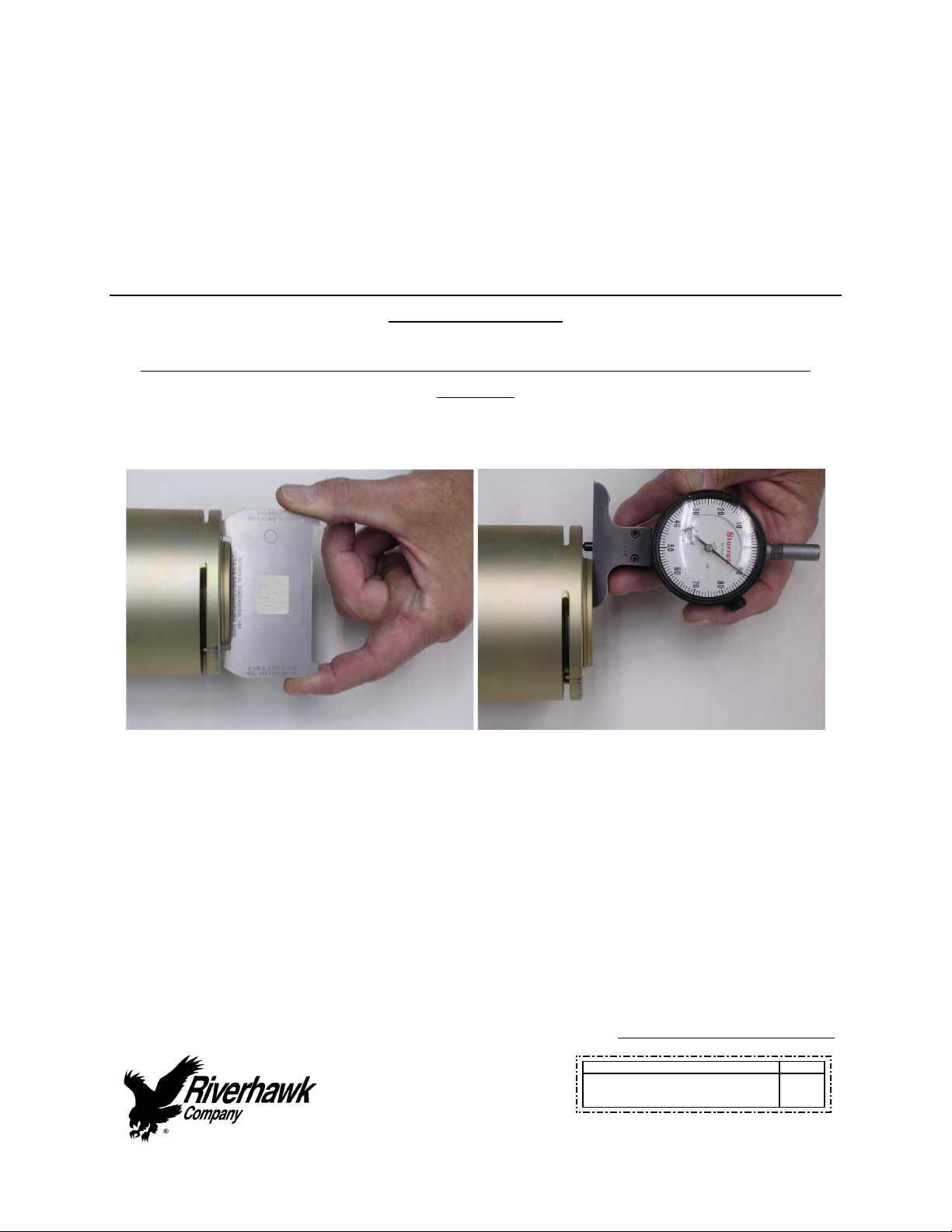

Adjustthefrontsidestud/nutassemblysothatthestudsticksoutfromthefaceofthenutthe

amountshownonthehardwaresetdrawing.Ifyoudon’thaveahardwaresetdrawing,itcanbe

foundintheGEdrawingsystemorcontactRiverhawkCompany.

(Seesection2)

SETTINGTHESTICK‐OUTLENGTHISCRITICALFORTHEHYDRAULICTENSIONERTO

WORKCORRECTLY.

THESTICK‐OUTLENGTHISALWAYSSETFROMTHECOUPLINGSIDEOFTHE

FLANGE.

Thestick‐outlengthcanbecheckedthreedifferentways.

Stick‐OutGageDropGage

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page17of32

DigitalCalipers

SamplePicturesofaStick‐OutMeasurement

7.0AssemblyofTensioneronStud

Alltensioningwillbeperformedfromtheconicaltensioningthreadendofthestudwith

orientationofthestudtotheflangeasshowninFigures1thru4.

7.1AssemblyofTensionerKitwithORANGESafetyGuard

RefertoTensionerdrawingandFigure6fortensionertoflangemounting.Assemblysequenceisas

follows:

1. Carefullycheckthecleanlinessofboththestud'sandthepullerscrew'sconicalthreads.

2. Ensurestudlengthmeasurementisdocumented.

3. Verifystickoutlengthofstudtonut.

4. Applyalightcoatofcleanturbineoiloraspraylubricanttothepullerscrew.Donotuse

“NeverSeize”ontheconicalthreads.

5. Placethespannerringontothenut

6. Insertthepullerscrewintothetaperedthreadofthestudandhandtighten.Besurenotto

cross‐threadtheassembly

7. UsinganAllenwrenchtightenpullerscrew,thenbackoffpullerscrew1/2aturn.

8. Retightenpullerscrewbyhanduntilitisfullyinserted.DONOTBACKOFFPULLERSCREW.

9. Placethefootoverpullerscrew,orientateintoposition.

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page18of32

10. Threadtensionerontopullerscrew.Note:Internalstopintensionerwillresultingapwith

foot.DONOTTIGHTENTENSIONERAGAINSTFOOT.(GAPSHOULDBE1/16”to3/16”)

11. Placeguardovertensionerandpositionguidepinintohexendofstud.

12. Tightenknurledinterlockfittingbyhanduntilitfirmlypressesagainsttensioner.(nogap)

13. Activatecustomconnectorfromrearofguardbypushingonthecenterwithyourthumband

pullingthetabswithyourforefingerandmiddlefinger.Pushtheassemblyforwarduntilit

locksontothetensioner.Releasefingersfromtabsandthenremovethumb.Ensure

connectionisfirmlyengagedorelsethetensionerwillnotbeconnectedtopump.(Figure5)

Figure 5 – Activation of

custom connector

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page19of32

CAUTION

Personalinjuryandequipmentdamagecanoccurifthepullerscrewisnotsecurelyengaged

withtheconicalthreadsofthestud.Properengagementisachievedwhenthepullerscrewis

tightinthestudandisnotcross‐threadedintotheconicalthread.

8.0StudPullingandTensioning

Thestudswillbetensionedintwosteps,at50%pressureandatfinalpressure.Followthe

tensioningsequenceforeachflangejointasdefinedonthedatasheetsfoundattheendofthis

manual.

Note:Beforethreadingthepullerscrewintothestud,carefullycheckthecleanlinessofboththe

stud'sandthepullerscrew'sconicalthreads.Applyalightcoatofcleanturbineoiloraspray

lubricanttothepullerscrew.Donotuse“NeverSeize”ontheconicalthreads.Thisprocedurewill

easeassemblyandassurepositivematingofthethreadsbeforetightening.

WARNING

ThesafetyguardMUSTbeinplaceandhandskeptoutofdesignatedareasatalltimeswhenthe

tensionerispressurizedotherwisepersonalinjurycanoccur.

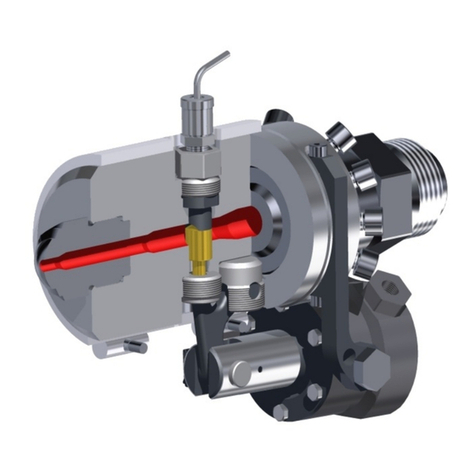

Figure 6 – Cutaway View of

Tensioner Installed on Flange

Instruction Manual IM-278

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4054

GEDRAWINGNUMBER

RevisionA

Page20of32

8.1Tensioningat50%pressure

Afterthetensionerisproperlyinstalledapplyhydraulicpressuretothetool.Bringthepressureto

the50%levelinaccordancewiththefollowingtable.

FlangePosition StudSize 50%Pressure 50%Stretch

TurbinetoCoupling 2‐3/4"

[71mm]

10000psi

[690bar]

Donotmeasure

Donotuse

CouplingtoSubstitute

Shaft

2‐3/4"

[71mm]

10000psi

[690bar]

Donotmeasure

Donotuse

SubstituteShaftto

Coupling

2‐3/4"

[71mm]

10000psi

[690bar]

Donotmeasure

Donotuse

CouplingtoGenerator 2‐3/4"

[71mm]

10000psi

[690bar]

Donotmeasure

Donotuse

8.1.1TighteningofNuts

Tightenthecylindricalnutshandtightusingthepinwrenchandspannerring,asdepictedinFigure

4.Turnthenutuntilitbottomsontheflange.Thenapplytorquetoturnthenutanadditional5

degrees.Thiswillaidinachievingthedesiredstretch.

WARNING:

Keephandsclearofthetoolwhilethepressureisbuildingup.Thisincludesthepinwrenchfor

tighteningthespannerring(nut).Oncethetoolisstabilizedatpressurethenandonlythencan

thenutbetightened.Thisreducesthepotentialofpersonalinjury.

8.2RemovingtheTensionerfromanInstalledStud

Thetensionerremovalistobeaccomplishedbythefollowssteps:

1. Releasethetensionertoolpressurebyopeningthevalveonthepump.Leavevalveopen.(This

isautomaticontheair‐operatedhydraulicpump)Allowapproximately20secondsfor

tensionertofullyretract,thenremovehosefromtensioner.

2. Unscrewknurledfittingattheendoftheguardandremoveguard.

3. Unscrewtensionerfrompullerscrew.Usecautiontoensurethathandsarenotbetween

tensionerandcouplingwhentensionerbecomesdisengagedfrompullerscrew.

Table of contents

Other riverhawk Industrial Equipment manuals

riverhawk

riverhawk IM-164 User manual

riverhawk

riverhawk IM-269 User manual

riverhawk

riverhawk IM-257 User manual

riverhawk

riverhawk IM-150 User manual

riverhawk

riverhawk IM-116 User manual

riverhawk

riverhawk IM-139 User manual

riverhawk

riverhawk IM-477 User manual

riverhawk

riverhawk IM-125 User manual

riverhawk

riverhawk IM-186 User manual

riverhawk

riverhawk IM-255 User manual

Popular Industrial Equipment manuals by other brands

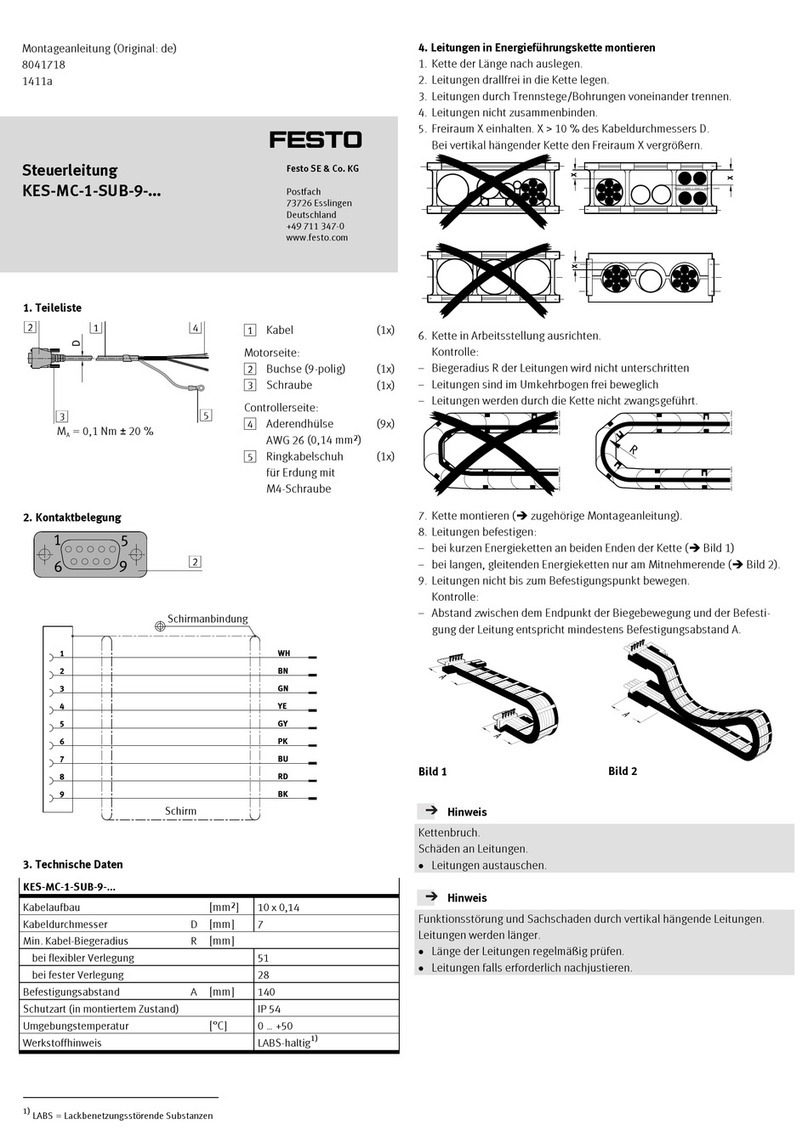

Festo

Festo KES-MC-1-SUB-9 Series Assembly instructions

Herzog

Herzog BHP Installation & service instructions

ABB

ABB HT582327 Operation manual

ABB

ABB Power2 550-M44 Operation manual

Parker

Parker Bestobell Valves IOM 002 Installation, operation and maintenance manual

Eaton

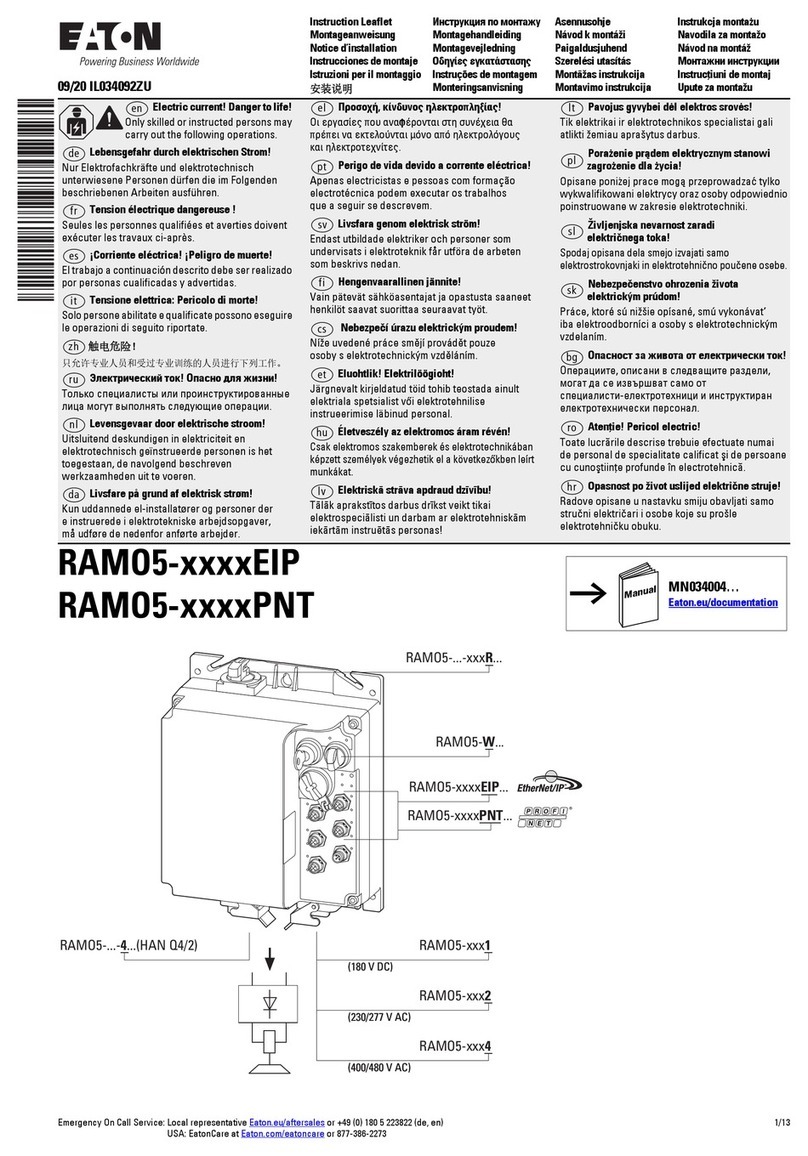

Eaton RAMO5 EIP Series Instruction leaflet