riverhawk IM-269 User manual

Repairs – Rentals

Field Service

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

RevisionB

Page1of34

INSTRUCTIONMANUALIM‐269

ForGasTurbineTensionedStudsandNuts

Fr.9FATurbinetoHITACHIGeneratorGE102T5689P001

GE102T5689P002

Fr.9FATurbinetoLoadCouplingGE102T5689P004

LoadCouplingtoHITACHIGeneratorGE102T5689P005

GEPower&Water

GENERALELECTRICCOMPANY

MLI: ____ OF ____

DATE

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

ISSUED:

THISDOCUMENTSHALLBEREVISEDINITSENTIRETY.ALLSHEETSOFTHISDOCUMENTARE

THESAMEREVISIONLEVELASINDICATEDINTHISVENDORSUPPLIEDDRAWINGAPPLIQUE.

REV

373A4004

GEDRAWINGNUMBER

VENDORSUPPLIED

THISDOCUMENTISFILEDUNDERTHEGEDRAWINGNUMBER.

GENOTTOREVISE.GEREVISIONLEVELISSHOWNONTHISAPPLIQUE.

GESIGNATURES

CHECKED:

TheRiverhawkCompanyreservestherighttomakechangesupdatingthisdocumentwithout

dissemination or notice. The latest revision level may be obtained by contacting Riverhawk

Companydirectlyorvisitourwebsiteatwww.riverhawk.com

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page2of34

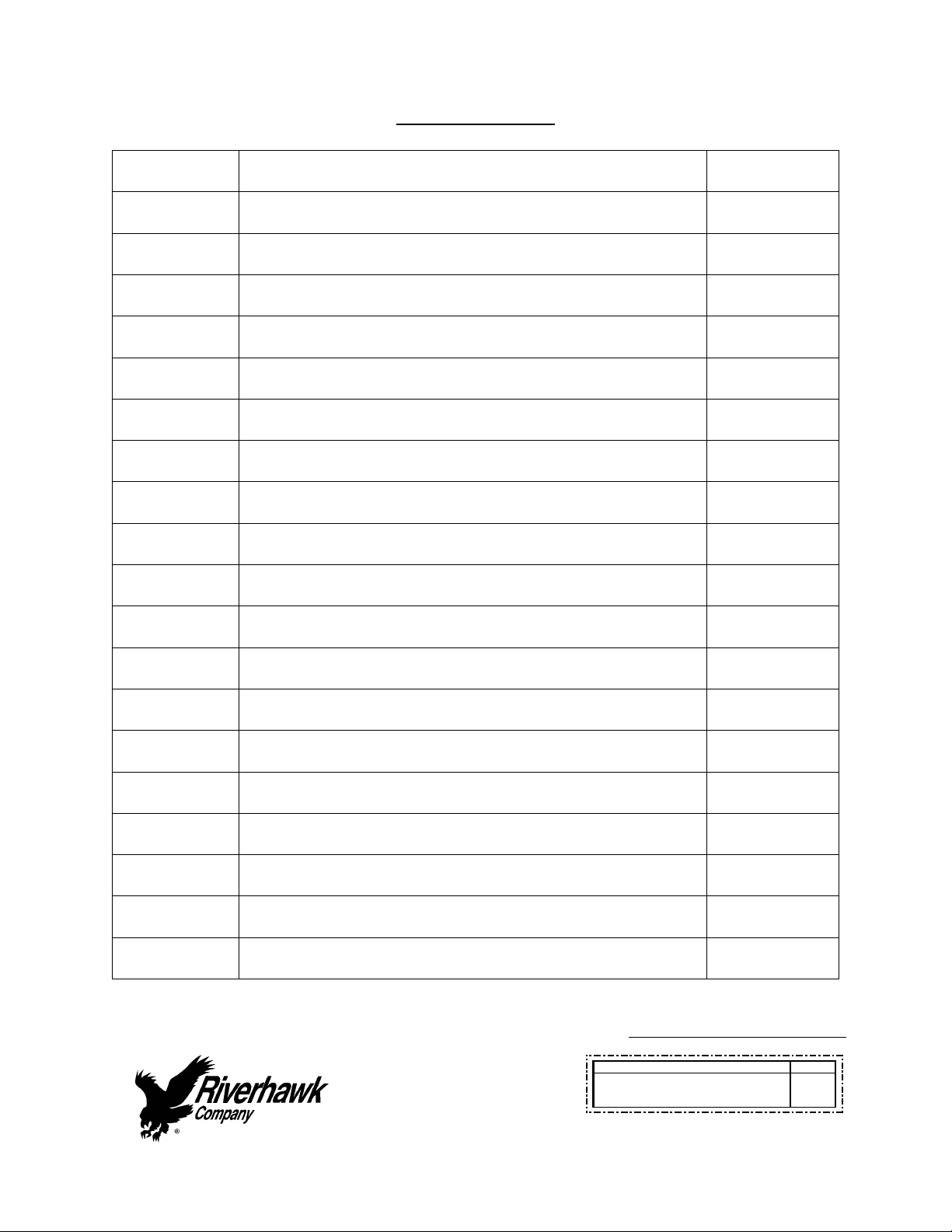

TableofContents

Section Description PageNumber

1.0 CautionsandSafetyWarnings 3

2.0 Scope 3

3.0 QuickCheck‐List 4

4.0 GeneralPreparations 6

5.0 HardwareSetPreparations 8

6.0 StudandNutAssembly 10

7.0 AssemblyofHydraulicTensionerEquipment 12

8.0 AssemblyofTensioneronStud 15

9.0 StudTensioning 20

10.0 ThreadLocking 22

11.0 WindagePlugInstallation 23

12.0 StudandNutRemoval 25

13.0 StorageInstructions 27

14.0 FrequentlyAskedQuestions 29

15.0 RevisionHistory 31

AppendixA1 ECDeclarationofConformity 31

AppendixA2 UKCADeclarationofConformity 32

AppendixB1 TurbineSideStretchRecordSheet 33

AppendixB2 GeneratorSideStretchRecordSheet 34

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page3of34

1.0CautionsandSafetyWarnings

CAUTION

Personalinjuryandequipmentdamagecanoccurifthepullerscrewisnotsecurelyengagedwith

thetaperedthreadofthestud.Properengagementisachievedwhenthepullerscrewistightin

thestudandtheTensionerAssemblyisfreetorotate.

CAUTION

The “9FA gas turbine to the load coupling” flange uses a different tensioner than the “load

couplingtoHITACHIgenerator”flange.Verifythecorrecttensionerisbeingused.

WARNING

ThesafetycageMUSTbeinplaceandhandskeptoutofdesignatedareasatalltimeswhenthe

tensionerispressurizedotherwisepersonalinjurycanoccur.

CAUTION

DO NOT EXCEED THE MAXIMUM PRESSURE VIBROSCRIBED ON THE PULLER BODY. Excessive

pressurecandamagethestudandthepullerscrew.

CAUTION

DO NOT EXCEED THE MAXIMUM PRESSURE VIBROSCRIBED ON THE PULLER BODY. Excessive

pressurecandamagethestudandpullerscrew

Note:Beforethreadingthepullerscrewintothestud,carefullycheckthecleanlinessofboththe

stud'sandthepullerscrew'sconicalthreads.Besuretoremovealldirtfromtherootofthestuds’

conicalthreads.Applyalightcoatofcleanturbineoiloraspraylubricanttothepullerscrew.Do

notuse“NeverSeize”ontheconicalthreads.Thisprocedurewill ease assembly and assure

positivematingofthethreadsbeforetightening.

2.0 Scope

ThisdocumentdescribestheproceduretobeusedtoinstallstudsandnutssuppliedbyRiverhawk

Company in the flanges at the turbine/coupling and coupling/generatorconnections.This

hardwareisdepictedonthefollowingdrawings.ThesedrawingsaswellasToolingdrawingsform

apartofthismanual.

HardwareSets:

HF‐5376 HF‐5458 HF‐5459

HydraulicTensioners:

HT‐0445 HT‐5407

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page4of34

3.0QuickChecklist

The following checklist is intended as a summary of the steps needed to use the Riverhawk‐

suppliedequipment. Newpersonnelor thoseexperiencedpersonnelwhohavenot usedthe

Riverhawkequipmentrecentlyareencouragedtoreadtheentiremanual.

EQUIPMENTINSPECTION

□ Checkoillevelinhydraulicpump.

□ Checkairpressureat80psi[5.5bar]minimum.(Forair‐drivenpumps)

□ Checkhydraulichosefordamage.

□ Testpump.

□ Inspecttensionerforanydamage.

NUTANDSTUDPREPARATION

□ Inspectstudandnutsforanydamage.

□ Measurestudlength.

□ Cleanthestudsandnuts.

□ Installstudsandnuts(off‐center)intotheflange.

□ Setstick‐outdimensiononthecouplingsideoftheflange.

□ Handtightenallstuds.

□ Verifystick‐outmeasurement(VERYIMPORTANT)

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page5of34

Tensioning(Boltinstallation)

□ Matchthetensionersetuptotheflangejoint.

□ Applyalightcoatofcleanturbineoilorspraylubricanttothepullerscrew.DONOTUSE

“NEVERSEIZE”ONTHECONICALTHREADS.

□ Slidespannerringoverthepullerscrew.

□ Mountthetensioneronthestudinflange.

□ Installspannerringontonut.

□ Insert1/2”hexAllenwrenchintothebacksideofthestud.

□ Tightenthepullerscrew.

□ Backoffpullerscrew1/2turn.

□ Retightenthepullerscrewandleavetight.DONOTBACKOFFPULLERSCREW.

□ Bleedthetensioner.DoNOTbleedtensioneroffofastud!Damagetothetoolwill

result!

□ Tensionto50%.Consultmanualforcorrectpressure.

□ Usethepinwrenchinspannerringtotightennut.

□ Releasepressure,movetonextstudinpattern.

□ Repeatabovestepsatfinalpressure.

□ Measurefinalstudlengthandrecordonstretchdatasheets.Calculatestretch.

□ Torquenuts'setscrews.

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page6of34

Detensioning(Studremoval)

□ Loosennuts'setscrews

□ Inspectandcleanstuds'conicalthreads.DonotcontinueuntilALLdebrisisremoved

fromthethreads!Donottrytousethetensionertoremoveadamagedstud!

□ Applyalightcoatofcleanturbineoilorspraylubricanttothepullerscrew.DONOTUSE

“NEVERSEIZE”ONTHECONICALTHREADS.

□ Slidespannerringoverthepullerscrew.

□ Mountthetensioneronthestud.

□ Installspannerringintonut.

□ Tightenthepullerscrew.

□ Backoffpullerscrew1/2aturn.

□ Retightenthepullerscrewandleavetight.DONOTBACKOFFPULLERSCREW.

□ Bleedthetensioner.DoNOTbleedtensioneroffofastud!Damagetothetoolwill

result!

□ Applyfinalpressure.

□ Loosennutwiththespannerringandpinwrench.

□ Movetonextstudinpattern

4.0GeneralPreparations

Readandunderstandallinstructionsbeforeinstallingandtensioningstuds.

Thisequipmentproducesveryhighhydraulicpressuresandveryhighforces.Operatorsmust

exercisecaution,wearsafetyglassesandhardhatswhenusingthisequipment.

HighpressurefluidfromtheHydraulicPressureKitsystempressurizesthetensionerwhich

generatesastretchingforcethatactuallystretchesthestud.Asthestudisstretchedthenut

liftsofftheflange.Thenutisthenreseatedintopositionontheflangebyturninganutdriver

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page7of34

byhand.Whenthenutistightagainsttheflange,thepressureinthetensionerisreleased

leavingthestudloadedtoitspredeterminedvalue.

4.1MachinePreparation

Theflangetobetensionedmustbefullyclosedpriortopositioningthestudsintheflanges.

Also,itwillbeadvantageoustoremoveasmanyobstructionsaspossiblefromtheflangearea,

suchasspeedprobesandconduit.

4.2Hardware–Balance

Hardwareissuppliedasweightbalancedsets

Studsandnutsareinterchangeablewithinsets

Donotintermixwithothersets

Saveweightcertificationsuppliedwitheachsetforthepurchaseofspareparts

4.3Tensioner–CareandHandling

Whennotinuse,thetensionershallbemaintainedinacleanenvironmentandallcapsand

plugsforhydraulicopeningsandfittingsmustbeinplace.

Wheninuse,thetensionershallbeprotectedfromsandandgrit.

Longtermstorage–coattensionerwithoil,returntooriginalcontainer,sealcontainerand

protectfrommoisture.DONOTSTOREOUTSIDE

Shipment–coattensionerwithoilandshipinoriginalcontainer.

4.4 HandTools

Severalhandwrenchesandmicrometerswillberequiredtoperforminstallationand

measurementofthestuds:

5/8”wrench

1"wrench

1”SocketandImpactWrench

AsetofAllenWrenches

3’–4’BreakerBar

12”to13”micrometerorcaliper

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page8of34

4.5SpecialTools

HydraulicTensionerKit: HT‐0445HydraulicTensioner

GASTURBINESIDEONLY

(referenceGE359B2507)

HT‐5407HydraulicTensioner

GENERATORSIDEONLY

(referenceGE269B8709)

HydraulicPumpKit: AP‐0532Air‐OperatedHydraulicPump

(recommended)

(referenceGE359B2502)

MP‐0130ManualHand‐Operated

HydraulicPump

(referenceGE359B2506)

5.0HardwareSetPreparations

5.1NutPreparation

Fornewinstallations,thenutsshouldcomesealedfromthefactoryandwillneednocleaning.

Previouslyinstallednutsrequirecleaning:Wirebrushusingapetroleum‐basedsolventto

removeanyforeignmaterialontheexternalsurfacesandthreads.

Donotapplythreadlubricantstothethreads.

Finishthecleaningprocessbyrinsinginavolatilesolventsuchasacetoneandallowtodry.

5.2StudPreparation

Fornewinstallations,thestudsshouldcomesealedfromthefactoryandwillneednocleaning.

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page9of34

5.2.1StudCleaning‐OldInstallations

Previouslyinstalledstudsmayrequirecleaning.Cleanconicalthreadsshouldhaveabrightand

shinyappearance.

Ifcleaningisrequired,followthesesteps:

1. Blowoutthethreadswithcompressedairtoremoveloosedebrisanddryconical

threads.Donotapplyasolventorothercleaningsolutiontothethreadsasthismay

chemicallyattackthestud.

2. UseStudCleaningKit,GT‐4253orasimilar1"diameterBrasspowerbrush.

PictureofBrassPowerBrush

3. Insertthebrushintoanelectricdrillandsetdrilltoruninacounterclockwisedirection

athighspeed.

4. Workthedrillinacircularmotionwhilemovingthebrushinandouttocleanallofthe

threads.Trynottoholdthebrushinoneplacetoolong,soasnottoremovethestud's

protectivecoating.

5. Blowoutthethreadswithcompressedairtoremovelooseneddebris.

6. Visuallyinspectthreadsforcleanliness.Threadsshouldbebrightandshiny.

7. Repeatifanydirtcanbeseeninthethreads.

8. Inspectthreadsforanydamagethatmayhavebeencausedbypreviousinstallation.

Donotapplythreadlubricantstothethreads.

Finishthecleaningprocessbyrinsinginavolatilesolventsuchasacetoneandallowtodry.

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page10of34

5.3StudLengthMeasurement

Studmeasurementwillrequireamicrometerorcaliper,whichwillmeasure12”to13”(304.8

mmto330.2mm).

Measureandrecordtheinitiallengthofthestuds.Thefollowingsuggestionswillimproveyour

results:

Plantostartandfinishanyflangeinthesameday.

Studsandflangemustbeatthesametemperature.

Numbereachstudwithamarker.

Markthelocationofmeasurementonstudendwithapermanentmarker.

Measureeachstudtonearest0.001”(.02mm).

Recordeachmeasurementonthesuppliedcharts.

Donotallowthemicrometertosetinthesun.

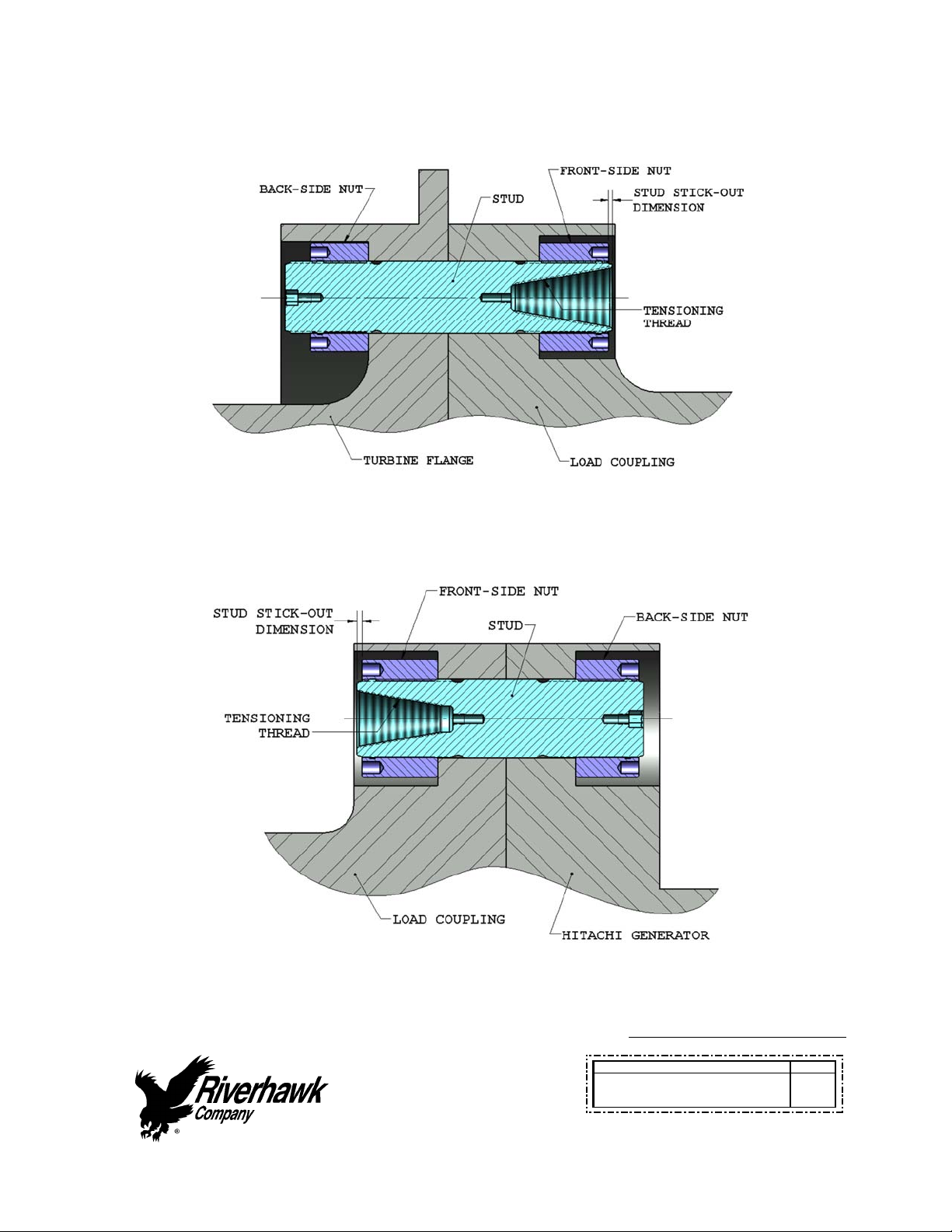

6.0 Stud and Nut Assembly

RefertoHardwareAssemblyDrawing(HF‐)listedinSection2.0ofthismanual.

1. Beforethreadingthenutontothestudchecktobecertainthatthesetscrewsarefree

toturn.

2. Assemblefront‐sidenuttothetaperedthreadend(PullEnd)ofthestud.Pleasenote

thatthefrontandbacksidenutsaredifferent.

3. Slidethestudandnutassemblyintotheflangefromthecouplingsideasshownin

Figures1and2.

4. Installthenutontheback‐sideoftheflange.Pleasenotethatthefrontandbackside

nutsaredifferent.

5. Adjustthenut/studassemblysothatthestudprotrudesfromthefaceofthe

cylindricalnutbytheamountdepictedonthehardwaredrawing(fromsection2)and

showninFigures1and2.SETTINGTHISPROTRUSION(orstick‐out)OFSTUDTONUT

ISCRITICALFORPROPERTENSIONEROPERATION.Ametalstick‐outgageisprovided

withthetensionertoassisttheoperatorinsettingtheprotrusiondimension(See

Figure3forthisandothermethods).

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:info@riverhawk.com

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page11of34

6. Handtightentheback‐sidenut,withoutturningthestudorfront‐sidenut,toasnugfit.

Figure1–CutawayViewofTurbineFlangeto

LoadCouplingBoltedJoint

Figure2–CutawayViewofLoadCouplingto

HitachiGeneratorBoltedJoint

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:info@riverhawk.com

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page12of34

Stick‐OutGageDropGage

DigitalCalipers

Figure3–PicturesofaStick‐OutMeasurementMethods

7.0AssemblyofHydraulicTensionerEquipment

7.1CheckHydraulicEquipment

7.1.1CheckHydraulicTensioners

Cleanpullerscrewandcheckforanydebrisanddents.

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page13of34

Pullerscrewshouldbefreetorotateandmovebackandforth.

Seambetweencylindersclosedtightly.

Inspecttensionerguardforanysignsofdamage.Bentguardsshouldbereplaced.Also,besure

therubberpadisinplaceontheendoftheguard,ifmissing,replace.

7.1.2CheckHydraulicPumpKit

Thepumpkitisshippedfullofhydraulicoil.Thepumpreservoircapissealedforshipment.

Replacethegreyshippingcapwiththeredplasticreservoircap.

Tousethepump,turncaptotheventpositionandfollowtheoperatinginstructionsonthe

insidecover.

Topreventoilspillage,closecapwhennotinuse.LostoilshouldbereplacedwithEnerpac

HydraulicOil.ISO32orequivalenthydraulicoilmaybesubstituted.

Testpumpbydead‐heading(leaveportpluginplace)andrunpump–shouldholdsteady

pressure.

SamplePictureofAP‐0532HydraulicPumpwithhydraulicconnectionpluggedfortesting

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page14of34

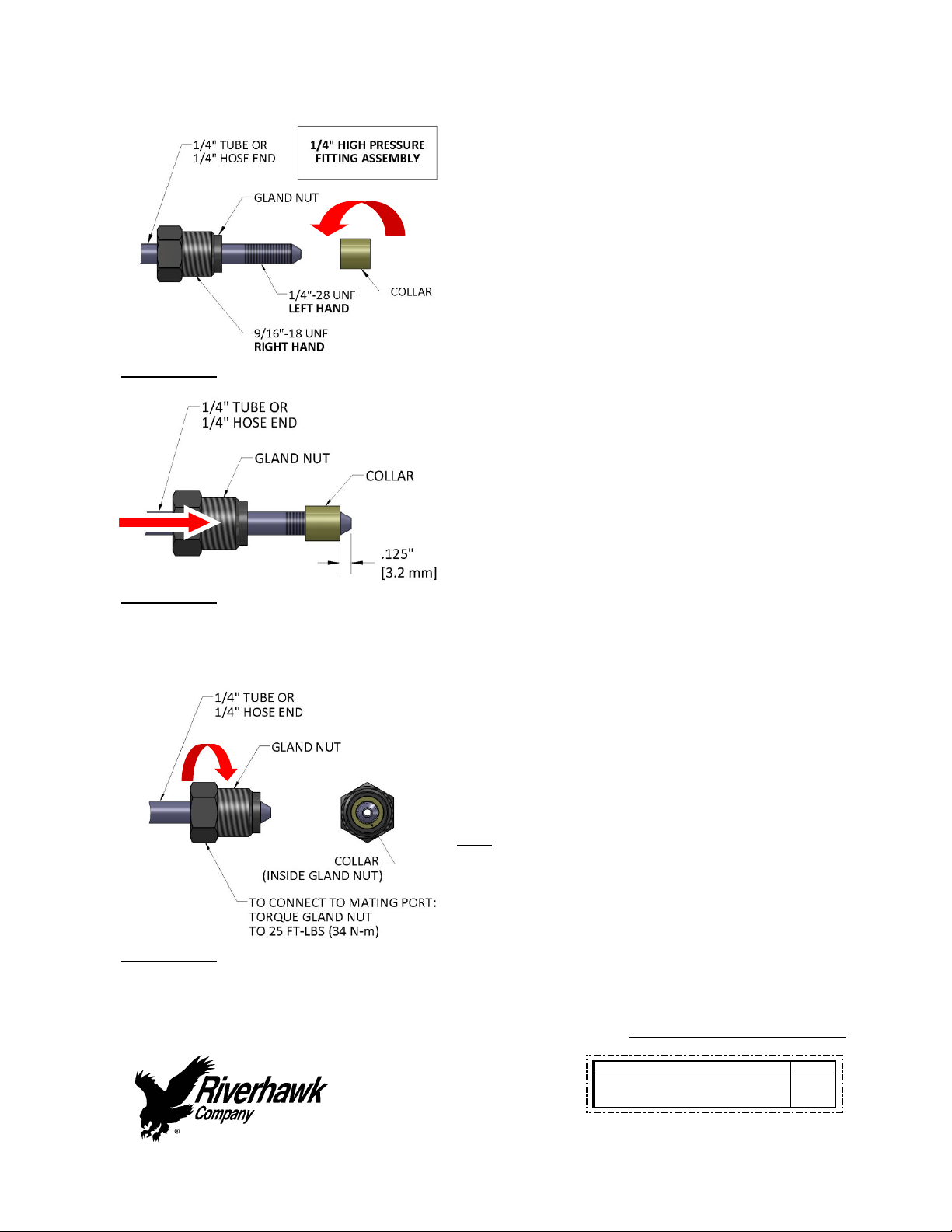

7.2HydraulicFittings

Illustration1

Riverhawkhydraulicpumpsusea1/4”High

Pressureporttoconnectitshydraulichoses.The

hoseconnectorismadefromathreepiece

assembly:aglandnut,acollar,anda1/4”tubeor

1/4”hoseend.(SeeIllustration1)

Toassemblythefitting,slidetheglandnutover

the1/4”tubeor1/4”hoseend.Turnthecollar

counter‐clockwise(lefthandthread)ontothe

tubeorhoseendasshowninIllustration1.

Illustration2

Thecollarshouldbeplaced.125”(3.2mm)from

thetipofthecone.(SeeIllustration2)Itmaybe

necessarytoadjustthiscollarwithasetofvise‐

grippliers.Becarefultonotstripthethreadsoff

thetubeorhoseend.

Illustration3

Slidetheglandnutdownoverthecollar.(See

Illustration3)Insertthe1/4”tubeor1/4”hose

endintothetensioner’squickcoupler.While

firmlyholdingthetubeorhoseendtostopitfrom

rotating,turntheglandnutclockwise(righthand

thread)andtorquetheglandnutto25FT‐LBS(34

N‐m).

Tips:

Makesureallpartsarecleanandfreefrom

debris.

Protecttheconeontheendofthe1/4”tube

or1/4”hoseendfromscratchesasthisisthe

sealingsurface.

Replaceredplasticcapswhenfinishedto

protectthethreadsandcone.

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page15of34

8.0AssemblyofTensioneronStud

CAUTION

The “9FA gas turbine to the load coupling” flange uses a different tensioner than the “load

couplingtoHITACHIgenerator”flange.Verifythecorrecttensionerisbeingused

RiverhawktensionerHT‐0445isfortheGASTURBINESIDEONLY.

RiverhawktensionerHT‐5407isfortheGENERATORSIDEONLY.

8.1HandlingoftheTensioner

Restthetensionerontopofthecouplingshaft.Usingastrapjustlongenoughtogoaroundthe

couplingshaft,attacheachendtothehandlesofthetensioner.Onewaytodothisistoattach

thestrapbyloopingthestrapthroughitselfandaroundthehandleofthetensionerononeside

thenaroundthecouplingshaftandfinallyattachedtothehandleontheothersidewithaD‐

shackle.Thiswillhelpholdthetensionerinplaceshoulditfalloffoftheshaft.Thestrapalso

helpstheoperatorsmovethetensioneraroundtheshaftwhiletensioning.

Ifpossible,usea‘Come‐along’orchainfallfromtheceilingofthecouplingroomandattachit

tothetensionerusingashortstrapwrappedthroughthehandlesandaroundthetopofthe

tensioner.Thiswillallowtheoperatorstoeasilymovethetensioneraroundthecouplingshaft

bysupportingtheweightofthetool.

8.2KitAssembly

Assemblethehydraulicpumpwithitshosetothetensionerandbleedouttheairperfollowing

instructionsinsection8.3.

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page16of34

Samplepictureshowinghoseattachedtoatensioner

Note:Beforethreadingthepullerscrewintothestud,carefullycheckthecleanlinessofboth

thestud'sandthepullerscrew'sconicalthreads.Applyalightcoatofcleanturbineoilora

spraylubricanttothepullerscrew.Donotuse“NeverSeize”ontheconicalthreads.This

procedurewilleaseassemblyandassurepositivematingofthethreadsbeforetightening.

RefertoTensionerAssemblydrawingandphotoforviewsofthetensionertoflangemounting.

Alltensioningwillbeperformedonthecouplingsideoftheflangeconnections.

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:info@riverhawk.com

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page17of34

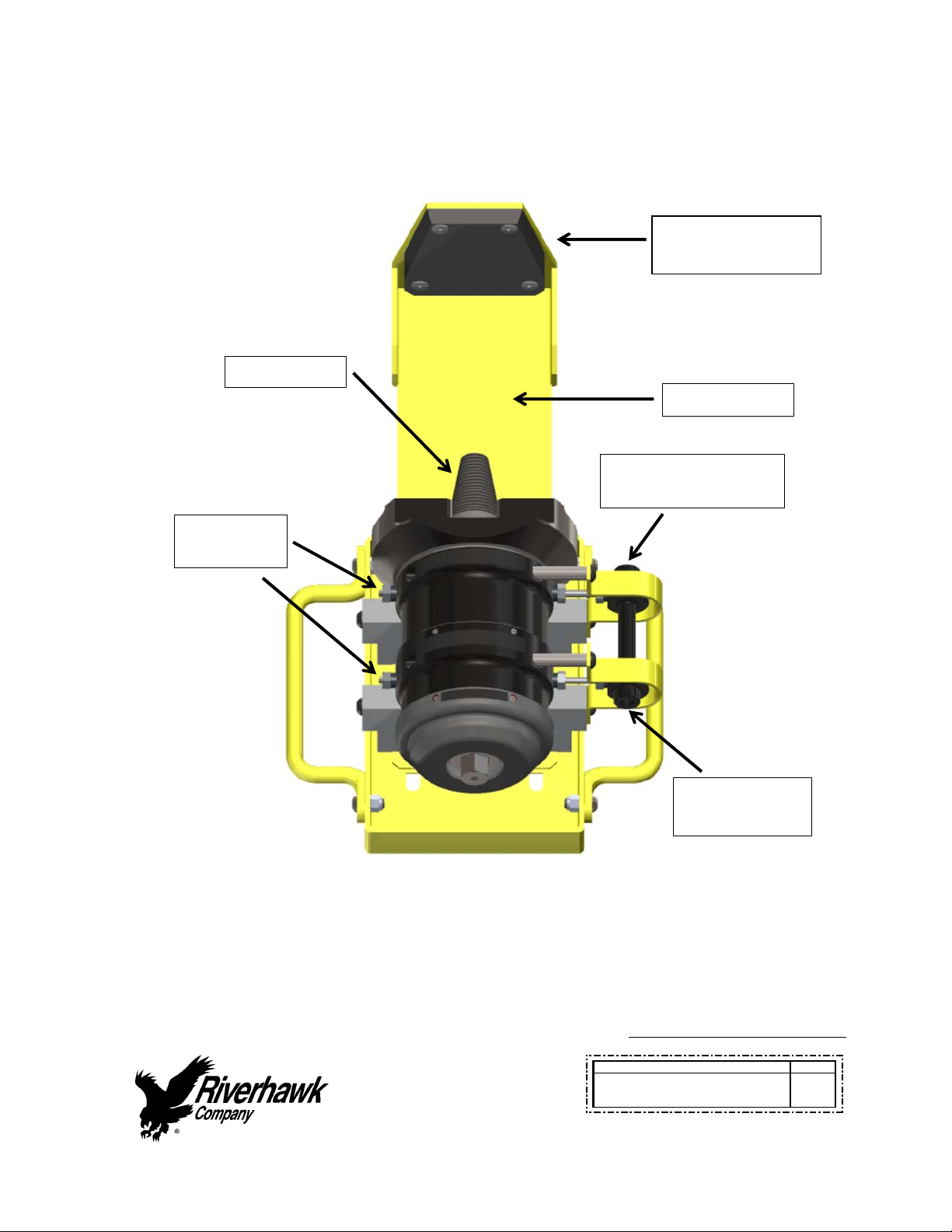

FigureofHT‐0445Tensioner

RubberPad

(DONOTREMOVE)

SafetyGuard

PullerScrew

PressureReliefValve

withBurstDisc

HydraulicHose

Connection

Hydraulic

Bl

eed

P

o

r

ts

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:info@riverhawk.com

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page18of34

FigureofHT‐5407Tensioner

RubberPad

(DONOTREMOVE)

SafetyGuard

PressureReliefValve

withBurstDisc

HydraulicHose

Connection

PullerScrew

Hydraulic

Bl

eed

P

o

r

ts

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:info@riverhawk.com

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page19of34

Assemblysequenceisasfollows:

Placethespannerring(differentforeachendturbineorgenerator)overthepuller

screwonthetensioner.

Placeandholdthetensionerassemblyovertheendofthestudtobetightened.

Slidethepullerscrewintothetaperedthreadofthestudandhandtighten.Besurenot

tocrossthreadassembly.

Holdthestudsteadywitha1/2”hexkeywrenchandlightlytightenthepullerscrewinto

theconicalthreadofthestudwithawrench.

Placethespannerringonthecylindricalnutlocatedonthestud.

AtthispointtheTensionerAssemblyMUSTBEFREETOROTATE,thepullerscrewmust

betightinthestud.DONOTBACKOFFPULLERSCREW.

Ifthetensionerisnotfreetorotatewhenthepullerscrewistightthen,either(1)thestudis

notproperlypositionedintheflangeandrecheckthestick‐outlengthandrepositionthenuts,

or(2)Thetensionerisdamagedandmustbereturnedforrepair.

CAUTION

Personalinjuryandequipmentdamagecanoccurifthepullerscrewisnotsecurelyengaged

withthetaperedthreadofthestud.Properengagementisachievedwhenthepullerscrewis

tightinthestudandtheTensionerAssemblyisfreetorotate.

8.3BleedingHydraulicSystem

FollowthetensionerassemblyinstructionsofSection8.0

Instruction Manual IM-269

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4004

GEDRAWINGNUMBER

RevisionB

Page20of34

TOAVOIDFAILURE,ENSURESAFETYANDPROPEROPERATIONTHETENSIONERASSEMBLY

MUSTBEMOUNTEDONTHESTUDBEFOREBLEEDINGTHESYSTEMANDTENSIONINGBEGINS.

Thetensionerhasfourports,oneforpressurizing,twoforbleedingthesystemandafourth

pressurereliefport.Tofacilitatebleeding,startbyfirstmountingthetensioneratthe9o’clock

studposition.Also,makesurethatthepumpisalwayssituatedbelowthetensionerassembly.

Thetensionerisequippedwith5/8"hexconedstembleederfittingsinstalledinthebleeder

ports.Withthesetwofittingsloosenedsimultaneously,strokethepumprepeatedlyuntilthe

streamsofoilexitingthetoolfromeachportarefreeofair,thenretightenthefittings.

Note:Thehoseisstiff;useofthistoolingcanbesimplifiedbytemporarilymountingthe

tensionerononestudpriortofinaltighteningoffittings.Thiswillreducethetendency

forthefittingstoloosenduringuse.

9.0StudTensioning

Thestudswillbetensionedintwosteps,at50%pressureandatfinalpressure.Followthe

tensioningsequenceforeachflangejointasdefinedonthedatasheetsfoundattheendofthis

manual

WARNING

ThesafetycageMUSTbeinplaceandhandskeptoutofdesignatedareasatalltimeswhenthe

tensionerispressurizedotherwisepersonalinjurycanoccur.

9.1Tensioningat50%pressure

Afterthetensionerisproperlyinstalledapplyhydraulicpressuretothetool.Bringthepressure

tothe50%levelinaccordancewiththefollowingtable.

FlangePosition StudSize 50%Pressure 50%Stretch

TurbinetoCoupling 2‐3/4"

[71mm]

10000psi

[690bar]

Donotmeasure

Donotuse

CouplingtoGenerator 2‐3/4"

[71mm]

8000psi

[550bar]

Donotmeasure

Donotuse

Table of contents

Other riverhawk Industrial Equipment manuals

riverhawk

riverhawk IM-186 User manual

riverhawk

riverhawk IM-125 User manual

riverhawk

riverhawk IM-164 User manual

riverhawk

riverhawk IM-255 User manual

riverhawk

riverhawk IM-477 User manual

riverhawk

riverhawk IM-150 User manual

riverhawk

riverhawk IM-139 User manual

riverhawk

riverhawk IM-278 User manual

riverhawk

riverhawk IM-257 User manual

riverhawk

riverhawk IM-116 User manual