riverhawk IM-477 User manual

Other riverhawk Industrial Equipment manuals

riverhawk

riverhawk IM-186 User manual

riverhawk

riverhawk IM-257 User manual

riverhawk

riverhawk IM-164 User manual

riverhawk

riverhawk IM-150 User manual

riverhawk

riverhawk IM-125 User manual

riverhawk

riverhawk IM-116 User manual

riverhawk

riverhawk IM-139 User manual

riverhawk

riverhawk IM-255 User manual

riverhawk

riverhawk IM-269 User manual

riverhawk

riverhawk IM-278 User manual

Popular Industrial Equipment manuals by other brands

Milnor

Milnor 6450TG1L/R Installation

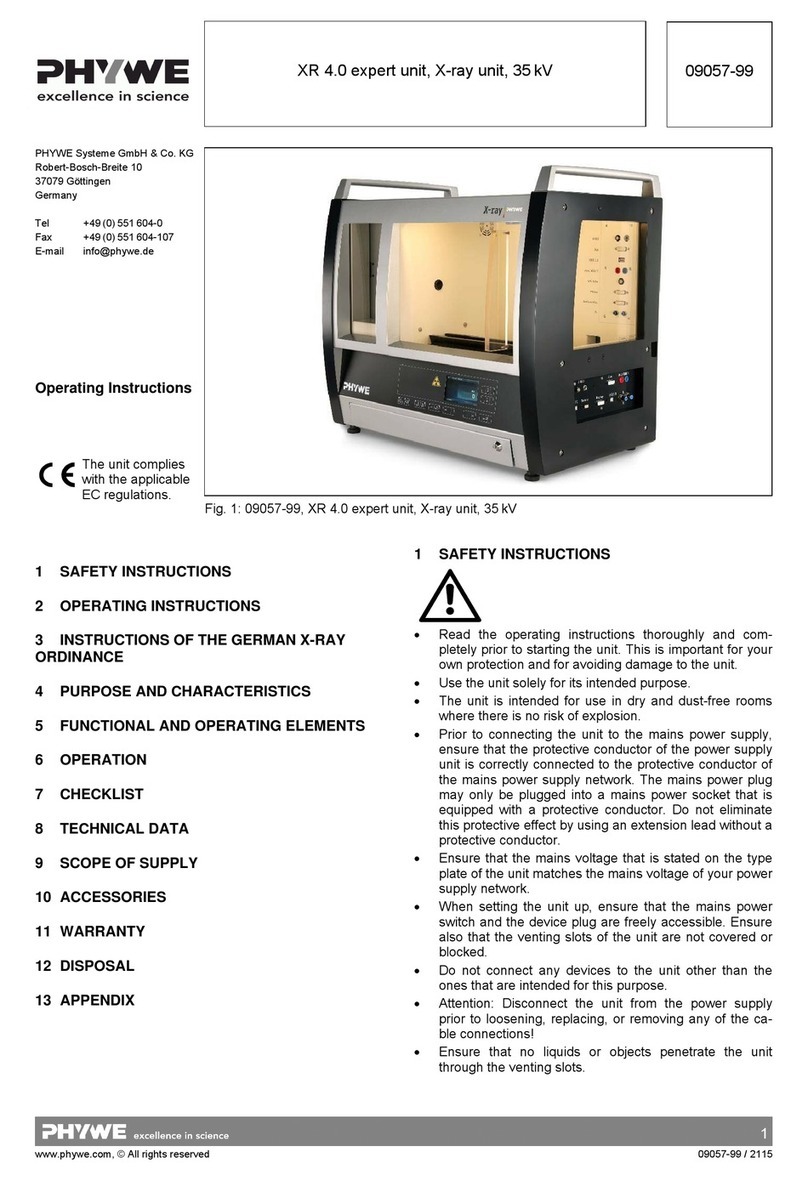

PHYWE

PHYWE XR 4.0 operating instructions

Larson Electronics

Larson Electronics EPLRL-100-HR quick start guide

DANA

DANA SPICER Axle 123 Service manual

SMC Networks

SMC Networks JMHZ2-16D-X7500AC-KA Series Operation manual

Youngman

Youngman Lightweight Staging 33050800 instruction manual

Rothenberger

Rothenberger Rofrost Turbo II operating instructions

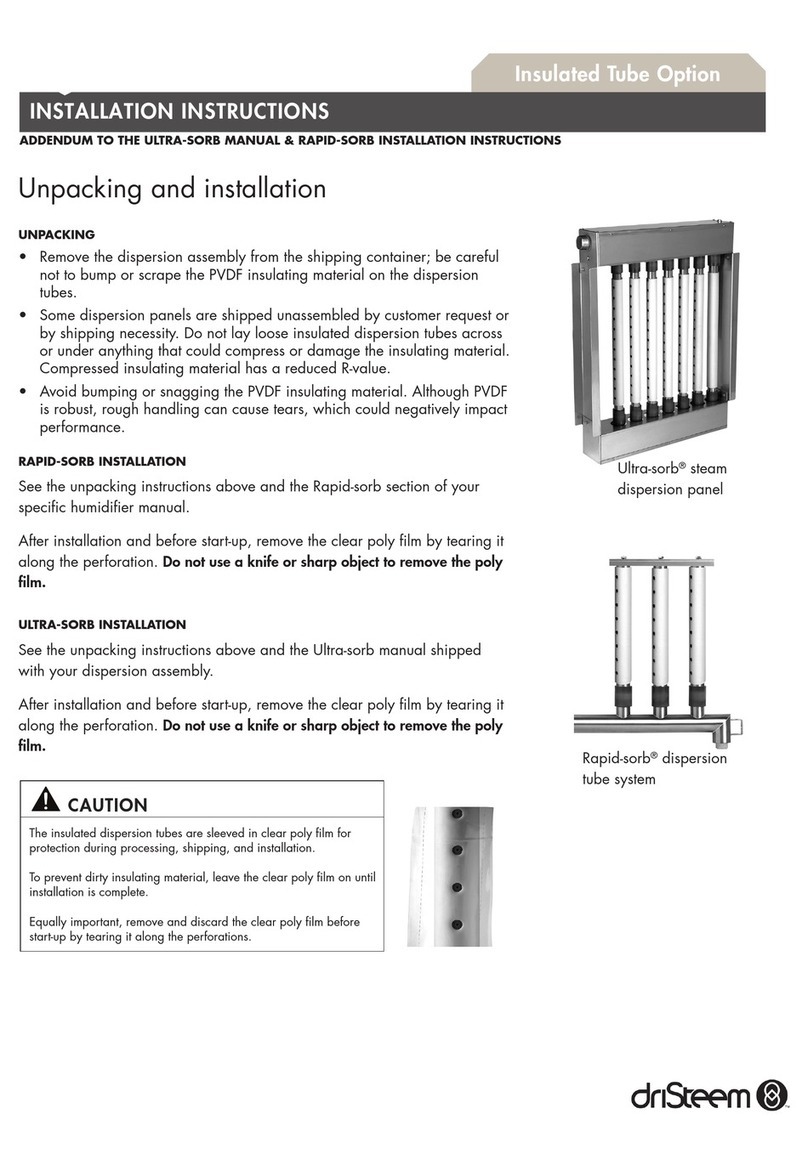

DriSteem

DriSteem ULTRA-SORB installation instructions

KTR

KTR RADEX-NC Operating & assembly instructions

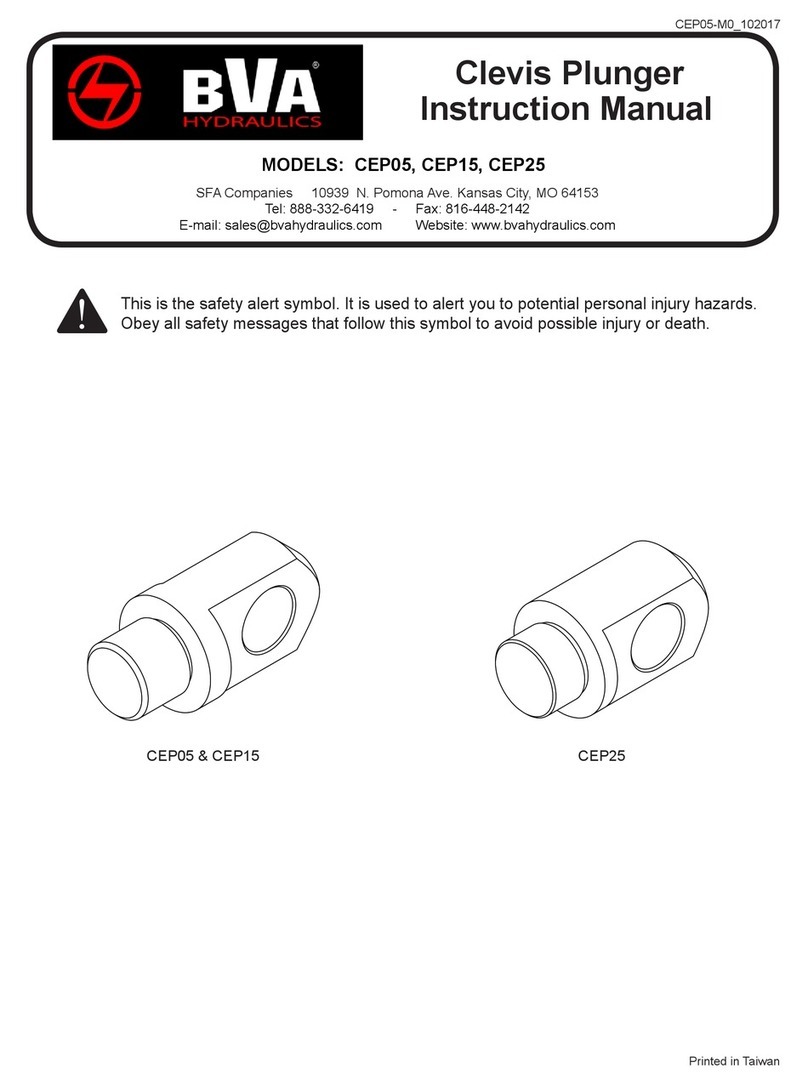

BVA Hydraulics

BVA Hydraulics CEP05 instruction manual

Nitronic

Nitronic ST215W operating instructions

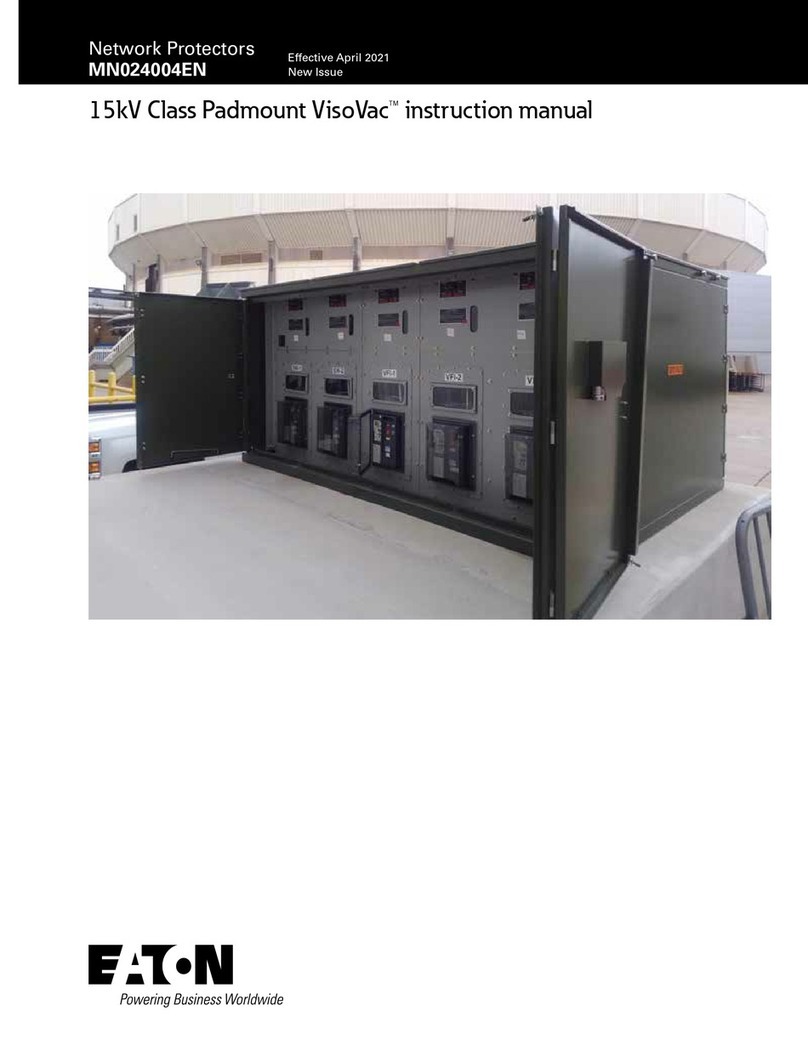

Eaton

Eaton VisoVac instruction manual