riverhawk IM-125 User manual

Repairs – Rentals

Field Service

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

RevisionW

Page1of38

INSTRUCTIONMANUALIM‐125

ForGasTurbineandSteamTurbine

TensionedStudsandNuts

ApplicableBoltingConnections

Fr.7FAGasTurbineto7FH2Generator

Fr.7FAGasTurbinetoLoadCoupling

Fr.7FBGasTurbineto7FH2Generator

Fr.7FBGasTurbinetoLoadCoupling

LoadCouplingorSteamTurbineto7FH2Gen

ApplicableGEOrderingSheetPartNumbers

358A7202P001

358A7202P002

358A7202P012

358A7202P018

358A7202P020

358A7202P031

358A7202P032

361A5218P001

377A9477P001

377A9477P002

377A9477P003

377A9477P004

377A9477P005

377A9477P006

382A6121P003

382A6121P004

382A6121P006

GEPower&Water

GENERALELECTRICCOMPANY

MLI: ____ OF ____

DATE

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

ISSUED:

THISDOCUMENTSHALLBEREVISEDINITSENTIRETY.ALLSHEETSOFTHISDOCUMENTARE

THESAMEREVISIONLEVELASINDICATEDINTHISVENDORSUPPLIEDDRAWINGAPPLIQUE.

REV

373A4000

GEDRAWINGNUMBER

VENDORSUPPLIED

THISDOCUMENTISFILEDUNDERTHEGEDRAWINGNUMBER.

GENOTTOREVISE.GEREVISIONLEVELISSHOWNONTHISAPPLIQUE.

GESIGNATURES

CHECKED:

TheRiverhawk Company reserves the righttoupdatethisdocumentwithout dissemination ornotice.

ThelatestrevisionmaybeobtainedbycontactingRiverhawkCompanyorthruwww.riverhawk.com.

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page2of38

TableofContents

Section Description PageNumber

1.0 CautionsandSafetyWarnings 3

2.0 ScopeandGEPartNumberCross‐Reference 4

3.0 QuickChecklist 6

4.0 GeneralPreparations 9

5.0 HardwareSetPreparations 11

6.0 StudandNutAssembly 14

7.0 HydraulicTensionerEquipmentAssembly 17

8.0 AssemblyofTensioneronStud 20

9.0 StudTensioning 23

10.0 ThreadLocking 25

11.0 StudandNutRemoval 26

12.0 StorageInstructions 30

13.0 FrequentlyAskedQuestions 31

14.0 RevisionHistory 33

AppendixA1 ECDeclarationofConformity 35

AppendixA2 UKCADeclarationofConformity 36

AppendixB1 18‐BoltTensioningPattern(GT‐LC)RecordSheet 37

AppendixB2 16‐BoltTensioningPattern(LC‐GEN)RecordSheet 38

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page3of38

1.0CautionsandSafetyWarnings

WARNING

Impropertooluseandthefailuretofollowthecorrectproceduresaretheprimaryroot

causesoftoolfailuresandpersonalinjuries.Alackoftrainingorexperiencecanleadto

incorrecthardwareinstallationorincorrecttooluse.Onlytrainedoperatorswithcareful,

deliberateactionsshouldusehydraulictensioners.ContactRiverhawkCompanywithany

trainingneeds.

WARNING

Riskofhighpressurehydraulicfluidinjection.Riverhawktoolsoperateunderhighpressure.

Thoroughlyinspectallhosesandconnectionsfordamagepriortousingthisequipment.

CAUTION

Personalinjuryandequipmentdamagecanoccuriftheproperhealthandsafetycodesand

proceduresarenotfollowed.Contactthesite’shealthandsafetyofficetodetermineall

applicablesafetyrulesandregulations.

WARNING

Theproperpersonalprotectiveequipmentmustbewornatalltimes.Riverhawkrecommends

ataminimum,safetyglasses,longsleeveshirt,hardhat,heavyworkgloves,andsteeltoe

shoes.

CAUTION

Itisespeciallyimportanttochecktheconditionoftheconicalthreadusedtotensionthestud.

Threaddamagefrompreviousabusecanleadtofailureofthestudortensioningequipment

CAUTION

RiverhawkrecommendsthatthetensionershouldbereturnedtoRiverhawkforperiodic

inspections.Replacementofobsoletetensionersisrecommended.Functionalupgradesarealso

recommended.TheRiverhawkServiceReturnsCoordinatorshouldbenotified3‐6monthsprior

toaplannedoutagetoscheduleaninspectionservice.

WARNING

Adamagedburstdiscmustbereplacedwithawithaburstdiscofthesamedesignand

pressurerating.Donotsubstituteadamagedburstdiscwithadifferentdisctype,adifferent

pressurerating,oraforeignobject.

WARNING

Toavoidfailure,ensuresafety,andproperoperation,thetensionerassemblymustbeinstalled

onastudintheflangebeforebleedingandpressurizingthetensioner.Donotusethetensioner

atanypressureunlessthetoolisinstalledonastudinaflange.

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page4of38

CAUTION

Donotoverextendthetensioner.Overextensioncancausethepistontoloseitssealandleak

oil.

CAUTION

Personalinjuryandequipmentdamagecanoccurifthepullerscrewisnotsecurelyengaged

withthetaperedthreadsofthestud.Properengagementisachievedwhenthepullerscrewis

tightinthestudandthetensionerassemblyisfreetoturn.

WARNING

Thesafetycagemustbeinplaceatalltimes.Whenthetensionerispressurizedhandsmustbe

keptoutofdesignatedareastoavoidanypotentialforpersonalinjury.

CAUTION

Beforethreadingthepullerscrewintothestud,carefullycheckthecleanlinessofboththe

stud'sandthepullerscrew'sconicalthreads.Applyalightcoatofcleanturbineoiloraspray

lubricanttothepullerscrew.Thisprocedurewilleaseassemblyandassurepositivematingof

thethreadsbeforetightening.Donotuse“NeverSeize”ontheconicalthreads.

CAUTION

Donottightenthenutwhilethetooliscominguptopressure;waituntilpressureisachieved

beforeattemptingtotightenthenutwiththespannerring.Ifthetoolisnotproperlyinstalled,

thetoolcouldjumpoffthestudwhilecominguptopressure.

CAUTION

Donotexceedthemaximumpressuremarkedonthetensioner.Excessivepressurecandamage

thestudandpullerscrew.

WARNING

FIREHAZARD:DONOTheatwhenpullerassemblyisinplace.Personalinjuryorequipment

damagemayoccur.UseofanOxy‐Acetylenetorchisnotrecommended

2.0Scope

Thisdocumentdescribestheproceduretobeusedtoinstallthestudandnutsetssuppliedby

theRiverhawkCompanyintheflangesattheTurbine/Coupling,Coupling/Generator,andSteam

Turbine/Generatorconnections.

ThevariousframeconfigurationscoveredinthismanualarelistedinSections2.1through2.6

withdifferencesasrelatedtoconnectivehardwaredefined.Listedalsoarethepertinent

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page5of38

hardwaredrawings(HF‐xxxx).Thesedrawingsaswellastoolingdrawings(HT‐xxxx)formpartof

thismanual.

2.1Frame7FAGasTurbineto7FH2Generator

GEPARTNUMBER RIVERHAWKP/N GEVENDOCP/N

GE358A7202P001

GE358A7202P002

GE358A7202P012

HF‐0771

HF‐0771

HF‐0771

GE359B2514

GE359B2514

GE359B2514

ThehydraulictoolusedforinstallationandremovalisRiverhawkHT‐0342.

ThesehardwaredrawingsdepictthecompletestudandnutpackagefortheGasTurbineto

LoadCoupling(2‐1/4”size,Qty18)aswellastheLoadCouplingtoGenerator(2‐3/4”size,Qty

16).

2.2Frame7FAGasTurbinetoLoadCoupling

GEPARTNUMBER RIVERHAWKP/N GEVENDOCP/N

GE358A7202P031

GE358A7202P032

GE361A5218P001

HF‐2447

HF‐2447

HF‐2447

GE359B2539

GE359B2539

GE359B2539

ThehydraulictoolusedforinstallationandremovalisRiverhawkHT‐0342.

ThesehardwaredrawingsdepictthecompletestudandnutpackagefortheGasTurbineto

LoadCoupling(2‐1/4”size,Qty18).

2.3Frame7FBGasTurbineto7FH2Generator

GEPARTNUMBER RIVERHAWKP/N GEVENDOCP/N

GE377A9477P001

GE377A9477P002

HF‐0771

HF‐0771

GE359B2514

GE359B2514

ThehydraulictoolusedforinstallationandremovalisRiverhawkHT‐0342.

ThesehardwaredrawingsdepictthecompletestudandnutpackagefortheGasTurbineto

LoadCoupling(2‐1/4”size,Qty18)aswellastheLoadCouplingtoGenerator(2‐3/4”size,Qty

16).

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page6of38

2.4Frame7FBGasTurbinetoLoadCoupling

GEPARTNUMBER RIVERHAWKP/N GEVENDOCP/N

GE377A9477P006 HF‐2447 GE359B239

ThehydraulictoolusedforinstallationandremovalisRiverhawkHT‐0342.

ThesehardwaredrawingsdepictthecompletestudandnutpackagefortheGasTurbineto

Load.

2.5LoadCouplingorSteamTurbineto7FH2Generator

GEPARTNUMBER RIVERHAWKP/N GEVENDOCP/N

GE358A7202P018

GE382A6121P003

GE382A6132P004

GE377A9477P003

GE377A9477P005

HF‐0803

HF‐0803

HF‐0803

HF‐0803

HF‐0803

GE359B2520

GE359B2520

GE359B2520

GE359B2520

GE359B2520

ThehydraulictoolusedforinstallationandremovalisRiverhawkHT‐0342.

ThesehardwaredrawingsdepictthecompletestudandnutpackagefortheLoadCouplingor

SteamTurbinetoGenerator(2‐3/4”size,Qty16).

2.6HydraulicTooling

GEPARTNUMBER RIVERHAWKP/N GEVENDOCP/N

GE358A7202P020

GE382A6121P006

GE377A9477P004

HT‐0342

HT‐0342

HT‐0342

GE359B2500

GE359B2500

GE359B2500

3.0QuickChecklist

ThefollowingchecklistisintendedasasummaryofthestepsneededtousetheRiverhawk‐

suppliedequipment.Newpersonnelorthoseexperiencedpersonnelwhohavenotusedthe

Riverhawkequipmentrecentlyareencouragedtoreadtheentiremanual.

EQUIPMENTINSPECTION

□Checkoillevelinhydraulicpump.

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page7of38

□Checkairpressureat80psi[5.5bar]minimum.(Forair‐drivenpumps)

□Checkhydraulichosefordamage.

□Testpump.

□nspecttensionerforanydamage.

NUTANDSTUDPREPARATION

□Inspectstudsandnutsforanydamage.

□Cleanthestudsandnuts.

□Measurestudlengths.(VERYIMPORTANT)

□Installstudsandnutsintotheflange.

□Setstick‐outdimensiononthecouplingsideoftheflange.

□Handtightennutsonturbine/generatorsideofflange.

□Verifystick‐outmeasurement(VERYIMPORTANT)

TENSIONING(BoltInstallation)

□Checktensionerdrawingforcorrectpartsandpartnumbers.

□Applyalightcoatofcleanturbineoilorspraylubricanttothepullerscrew.DONOTUSE

“NEVERSEIZE”ONTHECONICALTHREADS.

□Slidespannerringoverthepullerscrew.

□Installthetensioneronthestudinflangeandslidespannerringontonut.

□Insert1/2”hexAllenwrenchintothebacksideofthestud.

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page8of38

□Tightenthepullerscrew.Thenbackoffpullerscrew1/2aturn.

□Retightenthepullerscrewandleavetight.DONOTBACKOFFPULLERSCREW.

□Bleedthetensioner.DoNOTbleedtensioneroffofastud!Damagetothetoolwill

result!

□Tensionto50%.Consultmanualforcorrectpressure.

□Usethepinwrenchinspannerringtotightennut.

□Releasepressure,movetonextstudinpattern.

□Repeatabovestepsatfinalpressure.

□Measurefinalstudlengthandrecordonstretchdatasheets.Calculatestretch.

□Torquethenuts'setscrews.

DETENSIONING(StudRemoval)

□Loosennuts'setscrews

□

Inspectandcleanstuds'conicalthreads.DonotcontinueuntilALLdebrisisremoved

fromthethreads!SeeinstructionmanualIM‐220.Donottrytousethetensionerto

removeadamagedstud!

□Applyalightcoatofcleanturbineoilorspraylubricanttothepullerscrew.DONOTUSE

“NEVERSEIZE”ONTHECONICALTHREADS.

□Slidespannerringoverthepullerscrew.

□Installthetensioneronthestud.

□Installspannerringintonut.

□Tightenthepullerscrew.Thenbackoffpullerscrew1/2aturn.

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page9of38

□Retightenthepullerscrewandleavetight.DONOTBACKOFFPULLERSCREW.

□Bleedthetensioner.DoNOTbleedtensioneroffofastud!Damagetothetoolwill

result!

□Applyfinalpressure.

□Loosennutwiththespannerringandpinwrench.

□Movetonextstudinpattern

4.0GeneralPreparations

Readandunderstandallinstructionsbeforeinstallingandtensioningstuds.

OperatorsshouldbetrainedorhavepreviousexperienceusingRiverhawktensioning

equipment.Trainingwillminimizethechanceofimproperuseoftheequipment.

Thehydraulictoolingincludingthehydraulichosesshouldbeinspectedpriortouse.Inspection

guidelinesarelistedinthefollowingsub‐sections.

Thisequipmentproducesveryhighhydraulicpressuresandveryhighforces.Operatorsmust

exercisecautionandweartheappropriatepersonalprotectiveequipmentwhenhandlingand

operatingthehydraulictooling.

High‐pressureoilfromthehydraulicpumppressurizesthetensionerwhichgeneratesavery

largeforcethatactuallystretchesthestud.Asthestudisstretchedthenutliftsofftheflange.

Thenutisthenturnedbyhandusingthesuppliedspannerring.Oncethenutistightagainstthe

flange,thepressureinthetensionerisreleased.Thehardwareisnowclampingtheflange

together.

4.1MachinePreparation

Theflangetobetensionedmustbefullyclosedpriortopositioningofstudsintheflanges.

Turningtheturbineandgeneratorshaftsisnotrequired,butmaybeuseful.Also,itwillbe

advantageoustoremoveasmanyobstructionsaspossiblefromtheflangearea,suchasspeed

probes,shippingplates,andconduit.

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page10of38

4.2Hardware–Balance

Hardwareissuppliedasweightbalancedsets.StudsandNutsareinterchangeablewithinsets.

Donotintermixsets.

Savetheweightcertificationsuppliedwitheachset.Itwillbeneededforthepurchaseof

replacementhardware.

4.3Tensioner–CareandHandling

Whennotinuse,thetensionershallbemaintainedinacleanenvironmentandallcapsand

plugsforhydraulicopeningsandfittingsmustbeinplace.

UseISO32gradeoil.

Wheninuse,thetensionershallbeprotectedfromsandandgrit.

Seesection12forlongtermstoragerequirements.

4.4HandTools

Severalhandwrenchesandmicrometerswillberequiredtoperforminstallationand

measurementofthestuds:

5/8”wrench AsetofAllenWrenches 9”to10”micrometer

1”wrench 3’–4’BreakerBar 10”to11”micrometer

4.5SpecialTools

HydraulicTensionerKit: HT‐0342HydraulicTensioner

(referenceGEVENDOC359B2500)

ObsoleteHydraulicTensionerKits: HT‐0835HydraulicTensioner

(OBSOLETE,replacedbyHT‐0342)

HydraulicPumpKit: AP‐0532Air‐OperatedHydraulicPump

(recommended)

(referenceGEVENDOC359B2502)

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:info@riverhawk.com

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page11of38

MP‐0130ManualHand‐OperatedHydraulicPump

(referenceGEVENDOC359B2506)

CAUTION

RiverhawkrecommendsthatthetensionersbereturnedtoRiverhawkforperiodic

inspections.Replacementofobsoletetensionersisrecommended.Functionalupgradesare

alsorecommended.TheRiverhawkServiceReturnsCoordinatorshouldbenotified3‐6

monthspriortoaplannedoutagetoscheduleaninspectionservice.

5.0HardwareSetPreparations

5.1NutPreparation

Picture1.RiverhawkLocknut

Ifthereisanyvisibledamageonanut,donotusethenutandcontacttheRiverhawkCompany

forareplacementnut.Pleasebepreparedtosupplytheturbinenumber,weightcertification,

anddigitalphotographsforevaluation.

5.1.1NutCleaning‐NewInstallations

Fornewinstallations,thenutsshouldcomesealedfromthefactoryandwillneednocleaning.

Set Screw

1 of 2

Spanner

Ring Holes

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page12of38

5.1.2NutCleaning‐OldInstallations

Previouslyinstallednutsrequirecleaningasfollows:Wirebrushusingapetroleum‐based

solventtoremoveanyforeignmaterialontheexternalsurfacesandthreads.

5.1.3NutCleaning‐VeryOldInstallations

Ifpreviousinstallationsemployedathread‐lockingcompound,whichwillbevisibleasagrayish‐

greenresidue,removeasmuchofthiscompoundaspossible.Finishthecleaningprocessby

rinsinginavolatilesolventsuchasacetoneandallowtodry.

RiverhawkCompanystronglyrecommendsreplacingthisstyleofnutwiththecurrentnutwith

are‐useablemechanicallockingfeature.

5.2StudPreparation

Checkthestudforanyvisibledamage.Ifthereisanyvisibledamage,donotusethestudand

contacttheRiverhawkCompanyforareplacementstud.Pleasebepreparedtosupplythe

turbinenumber,weightcertification,anddigitalphotographsforevaluation.

CAUTION

Itisespeciallyimportanttochecktheconditionoftheconicalthreadusedtotensionthe

stud.Threaddamagefrompreviousabusecanleadtofailureofthestudortensioning

equipment.

Theconicalthreadsofeachstudmustbecleanofgritanddirtbeforeinstallationorremoval.

Thisensurestheproperseatingofthepullerscrew.

5.2.1StudCleaning‐NewInstallations

Fornewinstallations,thestudsshouldcomesealedfromthefactoryandwillneednocleaning.

5.2.2StudCleaning‐OldInstallations

Previouslyinstalledstudsmayrequirecleaning.Cleanconicalthreadsshouldhaveabrightand

shinyappearance.

Ifcleaningisrequired,followthesesteps:

1. Blowoutthethreadswithcompressedairtoremoveloosedebrisanddryconical

threads.Donotapplyasolventorothercleaningsolutiontothethreadsasthismay

chemicallyattackthestud.

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page13of38

2. UseStudCleaningKit,GT‐4253orasimilar1"diameterBrasspowerbrush.

Picture2.BrassPowerBrush

3. Insertthebrushintoanelectricdrillandsetdrilltoruninacounterclockwisedirection

athighspeed.

4. Workthedrillinacircularmotionwhilemovingthebrushinandouttocleanallofthe

threads.Trynottoholdthebrushinoneplacetoolong,soasnottoremovethestud's

protectivecoating.

5. Blowoutthethreadswithcompressedairtoremovelooseneddebris.

6. Visuallyinspectthreadsforcleanliness.Threadsshouldbebrightandshiny.

7. Repeatifanydirtcanbeseeninthethreads.

8. Inspectthreadsforanydamagethatmayhavebeencausedbypreviousinstallation.

9. Donotapplythreadlubricantssuchas“NeverSeize”tothestud’sthreads.

10. Finishthecleaningprocessbyrinsinginavolatilesolventsuchasacetoneandallowto

dry.

5.2.3StudCleaning‐VeryOldInstallations

Ifpreviousinstallationemployedathreadlockingcompound,whichwillbevisibleasagrayish‐

greenresidue,removeasmuchofthiscompoundaspossiblefromthestud’sthreads.

Finishthecleaningprocessbyrinsinginavolatilesolventsuchasacetoneandallowtodry.

5.3StudLengthMeasurement

Measureandrecordtheinitiallengthsofthestuds.Thefollowingsuggestionswillimproveyour

results.

Plantostartandfinishanyflangeinthesameday.

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page14of38

Studsandflangemustbeatthesametemperature.

Numbereachstudwithamarkerforlaterstretchmeasurementtracking.

Markthelocationofmeasurementonstudendwithapermanentmarker.

Measureeachstudtonearest0.001inch(.01mm).

Recordeachmeasurementonthesuppliedrecordsheets.

Donotallowthemeasuringinstrumentstositinthesun.

Thesamepersonshouldmakeallmeasurements.

6.0StudandNutAssembly

RefertoHardwareSetPartNumberdrawinglistedinSection2.0ofthismanual.

Assemblethenuttotheconicalthreadend(TensioningEnd)ofthestud.

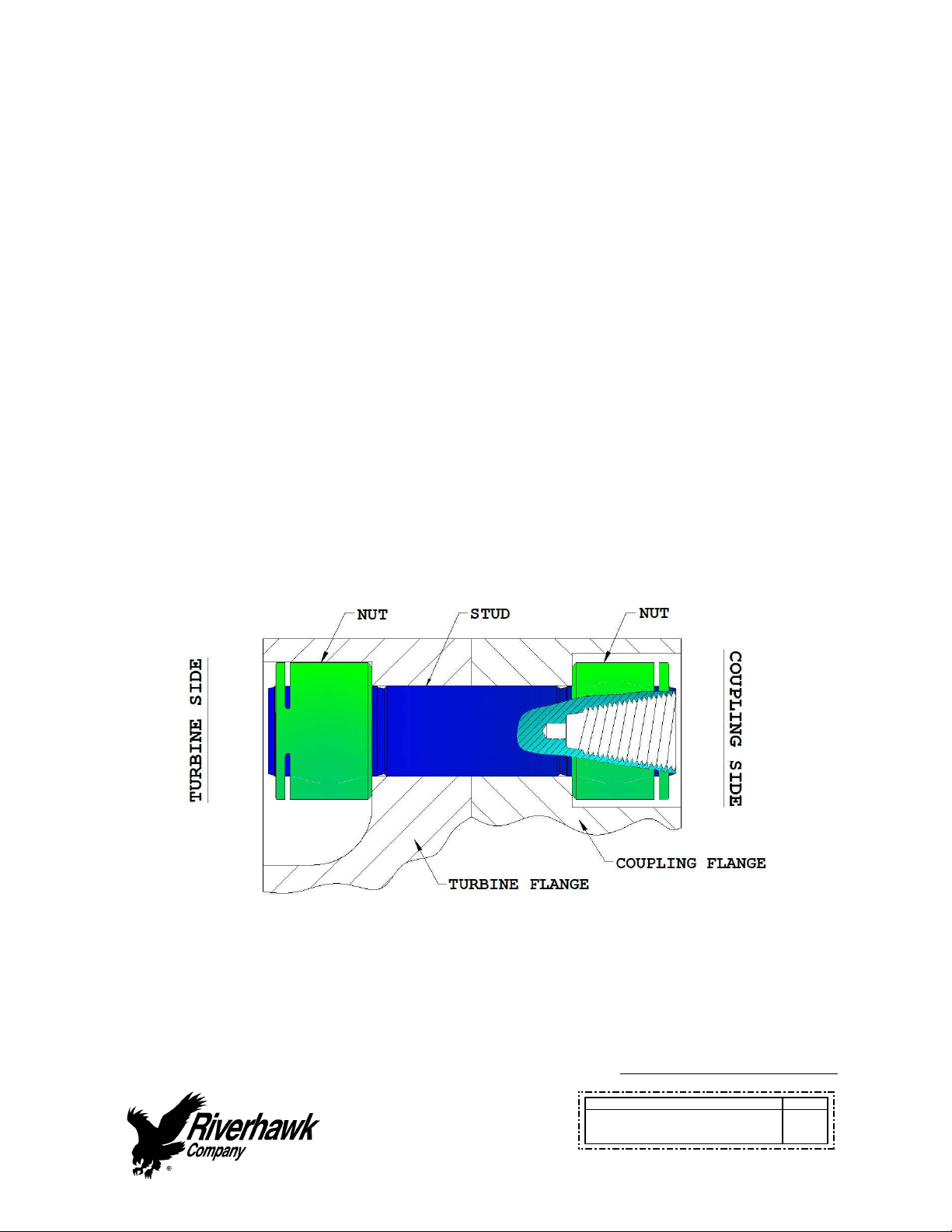

SlidetheassemblyintotheflangefromthecouplingsideasshowninFigures1&2(onthenext

page)theninstalltheothernutonthebackside.

ThenutsarethesameontheTurbineend(2.25”).ThenutsaredifferentontheGeneratorend

(2.75”);theshorternutgoesonthe“backside”orthesideclosesttotheGenerator.

Figure1–CutawayViewofTurbineFlange

andCouplingFlangeBoltedJoint

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page15of38

Figure2–CutawayViewofGeneratorFlange

andCouplingFlangeBoltedJoint

Adjustthestud/nutassemblysothatthestudsticksoutfromthefaceofthenuttheamount

shownonthehardwaresetdrawing.Ifyoudon’thaveahardwaresetdrawing,itcanbe

foundintheGEVendocssystemorcontactRiverhawkCompany.(Seesection2)

SETTINGTHESTICK‐OUTLENGTHISCRITICALFORTHEHYDRAULICTENSIONERTOWORK

CORRECTLY.

THESTICK‐OUTLENGTHISALWAYSSETFROMTHECOUPLINGSIDEOFTHEFLANGE.

Thestick‐outlengthcanbecheckedthreedifferentways.

Stick‐OutGageDropGage

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page16of38

DigitalCalipers

SamplePicturesofaStick‐OutMeasurement

Handtightentheassemblytoasnugfit.SeePhotos1&2foraviewoftheassemblyofstuds

andnutsintheflangepriortotensioning.

CouplingSideTurbine/GeneratorSide

Photo1 Photo2

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page17of38

7.0HydraulicTensionerEquipmentAssembly

7.1HydraulicEquipmentInspection

7.1.1HydraulicTensionerInspection

CAUTION

RiverhawkrecommendsthatthetensionerbereturnedtoRiverhawkforperiodicinspections.

Replacementofobsoletetensionersisrecommended.Functionalupgradesarealso

recommended.TheRiverhawkServiceReturnsCoordinatorshouldbenotified3‐6months

priortoaplannedoutagetoscheduleaninspectionservice.

Donotbleedtheairfromthehydrauliclinesandtensioneratthistime.Seesection8for

bleedinginstructionsonwhentobleedtheairfromthehydrauliclines.

WARNING

Toavoidfailure,ensuresafety,andproperoperation,thetensionerassemblymustbe

installedonastudintheflangebeforebleedingandpressurizingthetensioner.Donotuse

thetensioneratanypressureunlessthetoolisinstalledonastudinaflange.

CheckpullerscrewusagelifewithRiverhawkservicebulletinSB‐08001.

Cleanpullerscrewandcheckforanydebrisanddents.

Pullerscrewshouldbefreetorotateandmovebackandforth.

Seambetweencylindersclosedtightly.

Inspectthetensionerguardforanysignsofdamageincludingcrackedwelds.Anyguards

modifiedinthefieldshouldbereplaced.Bentguardsshouldbereplaced.Also,besurethe

rubberpadisinplaceontheendoftheguard,ifmissing,replace.

Inspecttheoutsideofthetensionerfordiscolorationpatternsthatmayindicatesubmersion

andinternaldamage.

Performaninventoryofthelooseequipmentsuppliedwiththetensioner.Aninventorylistis

providedonthetensioner’stechnicaldrawing(forexampleRiverhawkHT‐xxxx).Replacement

partsareavailablefromRiverhawk.

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page18of38

NOTE:PriortoSerialNumberS/N721theHT‐0342wassuppliedwithtwoadapterfeet.The

feetweremarked“TURBINE”and“GENERATOR”.Mounttheappropriatefootbefore

attemptinguseofthetensioner.

7.1.1.1HydraulicTensioner’sBurstDiscReplacement

Thehydraulictensioner’sburstdiscisakeyelementintheoverallsafeuseofthehydraulic

tensioner.

Eachtensionerisshippedfromourfactorywithoneburstdiscalreadyinstalledinthetensioner

andwithanothersparediscforfieldreplacement.Extraburstdiscsareavailablefrom

Riverhawkforreplacementpurposes.

Toreplaceadamagedburstdisc:

1. Removethehydraulicport’sdispersionnut,compressionring,anddamagedburstdisc.

2. Discardthedamagedburstdisc.

3. Cleanthedispersionnut,compressionring,newburstdisc,andthehydraulicportwitha

solventtoensureadirt‐freeinstallation.

4. Reassemblenewburstdisc,compressionring,anddispersionnutintothesame

hydraulicport.

Warning

Adamagedburstdiscmustbereplacedwithawithaburstdiscofthesamedesignand

pressurerating.Donotsubstituteadamagedburstdiscwithadifferentdisctype,adifferent

pressurerating,oraforeignobject.

7.1.2HydraulicPumpKitInspection

RefertotheHydraulicPumpKitInstructionManual,IM‐293(GEVENDOC373A4058).Thelatest

revisionmaybeobtainedbycontactingRiverhawkCompanyorthruwww.riverhawk.com.

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page19of38

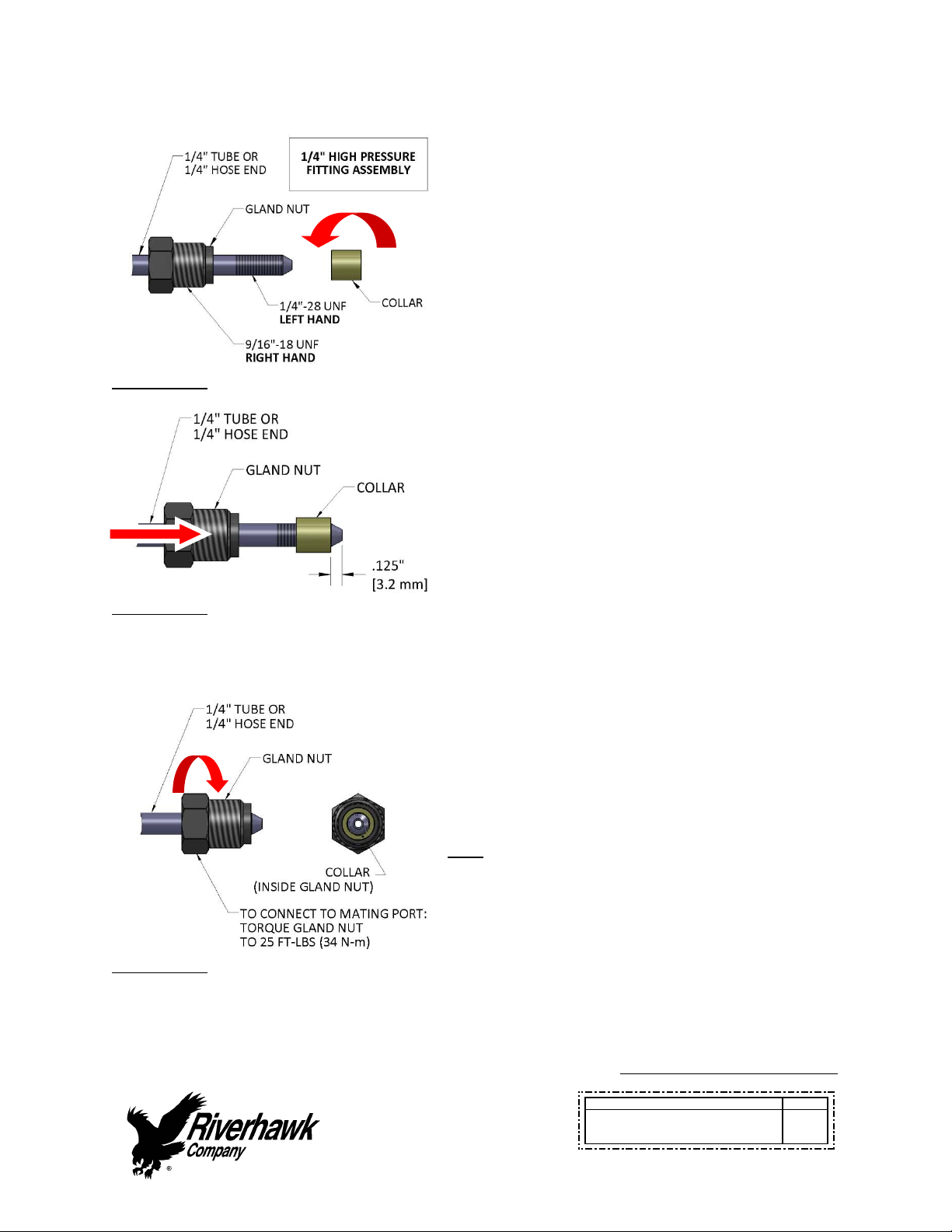

7.2HydraulicFittings

Illustration1

Riverhawktensionersusea1/4”HighPressure

porttoconnectitshydraulichoses.Thehose

connectorismadefromathreepieceassembly:a

glandnut,acollar,anda1/4”tubeor1/4”hose

end.(SeeIllustration1)

Toassemblythefitting,slidetheglandnutover

the1/4”tubeor1/4”hoseend.Turnthecollar

counter‐clockwise(lefthandthread)ontothe

tubeorhoseendasshowninIllustration1.

Illustration2

Thecollarshouldbeplaced.125”(3.2mm)from

thetipofthecone.(SeeIllustration2)Itmaybe

necessarytoadjustthiscollarwithasetofvise‐

grippliers.Becarefultonotstripthethreadsoff

thetubeorhoseend.

Illustration3

Slidetheglandnutdownoverthecollar.(See

Illustration3)Insertthe1/4”tubeor1/4”hose

endintotensionerorhydraulicpump.Whilefirmly

holdingthetubeorhoseendtostopitfrom

rotating,turntheglandnutclockwise(righthand

thread)andtorquetheglandnutto25FT‐LBS(34

N‐m).

Tips:

Makesureallpartsarecleanandfreefrom

debris.

Protecttheconeontheendofthe1/4”tube

or1/4”hoseendfromscratchesasthisisthe

sealingsurface.

Replaceredplasticcapswhenfinishedto

protectthethreadsandcone.

InstructionManualIM‐125

CUSTOMER'SINFORMATIONBOX

CONTENTSAREINDEPENDENTOFRIVERHAWKDOCUMENTCONTROL

215ClintonRoad

NewHartford,NY13413

Tel:+13157684855

Fax:+13157684941

Email:[email protected]

REV

373A4000

GEDRAWINGNUMBER

RevisionW

Page20of38

8.0AssemblyofTensioneronaStud

8.1HandlingoftheTensioner

Restthetensionerontopofthecouplingshaft.Usingastrapjustlongenoughtogoaroundthe

couplingshaft,attacheachendtothehandlesofthetensioner.Onewaytodothisistoattach

thestrapbyloopingthestrapthroughitselfaroundthehandleofthetensionerononeside

thenaroundthecouplingshaftandfinallyattachedtothehandleontheothersidewithaD‐

shackle.Thiswillhelpholdthetensionerinplaceshoulditfalloffoftheshaft.Thestrapalso

helpstheoperatorsmovethetensioneraroundtheshaftwhiletensioning.

Ifpossible,usea‘Come‐along’orchainfallfromtheceilingofthecouplingroomandattachit

tothetensionerusingashortstrapwrappedthroughthehandlesandaroundthetopofthe

tensioner.Thiswillallowtheoperatorstoeasilymovethetensioneraroundthecouplingshaft

bysupportingtheweightofthetool.

8.2KitAssembly

Assemblethehydraulicpumpwithitshosetothetensionerandbleedouttheairperfollowing

instructionsinsection8.3.

Note:Beforethreadingthepullerscrewintothestud,carefullycheckthecleanlinessofboth

thestud'sandthepullerscrew'sconicalthreads.Applyalightcoatofcleanturbineoilora

spraylubricanttothepullerscrew.Donotuse“NeverSeize”ontheconicalthreads.This

procedurewilleaseassemblyandassurepositivematingofthethreadsbeforetightening.

RefertoTensionerAssemblydrawingandphotoforviewsofthetensionertoflangemounting.

Alltensioningwillbeperformedonthecouplingsideoftheflangeconnections.

Table of contents

Other riverhawk Industrial Equipment manuals

riverhawk

riverhawk IM-269 User manual

riverhawk

riverhawk IM-150 User manual

riverhawk

riverhawk IM-139 User manual

riverhawk

riverhawk IM-257 User manual

riverhawk

riverhawk IM-116 User manual

riverhawk

riverhawk IM-255 User manual

riverhawk

riverhawk IM-164 User manual

riverhawk

riverhawk IM-477 User manual

riverhawk

riverhawk IM-278 User manual

riverhawk

riverhawk IM-186 User manual