Rhein-Nadel Automation GmbH 2

VT-BA-ESR2000_EN-2019 / 05.08.2019 SJ

Table of Contents

1. About this document ..............................................................................................................4

2. Safety directives.....................................................................................................................4

2.1. Design of safety directives..................................................................................................4

2.2. Fundamental safety directives ............................................................................................4

2.3. Personnel............................................................................................................................4

2.4. Intended use.......................................................................................................................5

2.5. Residual hazards................................................................................................................5

2.5.1. Device ..........................................................................................................................5

2.5.2. Drive protection............................................................................................................5

2.5.3. Degree of protection - Protection of persons and equipment .......................................6

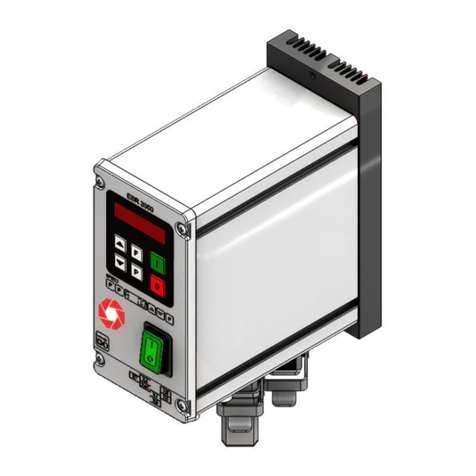

3. Product information................................................................................................................6

3.1. Characteristic features........................................................................................................6

3.2. EC conformity .....................................................................................................................6

3.3. Technical data.....................................................................................................................6

3.4. Accessories ........................................................................................................................7

3.5. Starting preparations...........................................................................................................7

3.5.1. Commissioning.............................................................................................................8

3.5.2. Controller set-up to suit a vibratory feeder ...................................................................8

3.6. Sensor inputs and sensor linkages.....................................................................................9

3.7. Sensor connection............................................................................................................10

3.8. Status outputs and relays .................................................................................................11

4. Operation .............................................................................................................................11

4.1. General.............................................................................................................................11

4.2. Starting-up the controller...................................................................................................12

4.3. Main menu / Setpoint entry and display............................................................................12

4.4. Description of individual codes for controller programming...............................................13

4.5. Application-specific change of default settings .................................................................14

4.5.1. Code C001 for feed rate output..................................................................................14

4.5.2. Code C003 Seal setpoint ...........................................................................................14

4.5.3. Code C004 sensor input 1 and code C005 sensor input 2.........................................14

4.5.4. Code C006 Sensor linkage.........................................................................................15

4.5.5. Code C008 cycle monitoring ......................................................................................16

4.5.6. Code C009 Show status / Reset ERROR message...................................................16

4.5.7. Code C200 Inhibiting all code entries.........................................................................17

4.5.8. Code C100 Setting the feed rate by external voltage input. .......................................17

4.5.9. Code C143 Saving parameters..................................................................................17

4.5.10. Code C210 Retrieving parameters..........................................................................18

4.5.11. Error messages.......................................................................................................18

5. Dimensional drawing............................................................................................................19

6. Connection diagram.............................................................................................................20