Robam CXW-200-A812 User manual

This manual suits for next models

1

Table of contents

Other Robam Ventilation Hood manuals

Robam

Robam CXW-200-A806 User manual

Robam

Robam CXW-220-A900 User manual

Robam

Robam CXW-260-A671 User manual

Robam

Robam CXW-200-A851 User manual

Robam

Robam CXW-220-A670 User manual

Robam

Robam CXW-218-A651 User manual

Robam

Robam CXW-260-A676 User manual

Robam

Robam CXW-200-A831 User manual

Robam

Robam CXW-200-A609 User manual

Robam

Robam CXW-200-A822 User manual

Robam

Robam CXW-210-A520 User manual

Robam

Robam CXW-200-A837 User manual

Robam

Robam CXW-200-A825 User manual

Robam

Robam CXW-200-A808 User manual

Robam

Robam CXW-220-A816 User manual

Robam

Robam CXW-200-A809 User manual

Robam

Robam CXW-260-76H1S User manual

Robam

Robam CXW-200-A830 User manual

Robam

Robam CXW-220-A852 User manual

Robam

Robam CXW-260-A672 User manual

Popular Ventilation Hood manuals by other brands

ChiQ

ChiQ CQHDU30T1T1W instruction manual

Broan

Broan 613004 Series instructions

Whirlpool

Whirlpool UXT2030ADB Installation Instructions and Use & Care Guide

Thermador

Thermador PH PROFESSIONAL PH30 Care and use manual

Foster

Foster FLY 2459930 Care and use manual

CDA

CDA 3L9 Manual for installation, use and maintenance

Küppersbusch

Küppersbusch KD6250.0 Instructions for use and installation instructions

Hoover

Hoover HTS6CBK3XWIFI Installation and user manual

AEG

AEG 330 D operating instructions

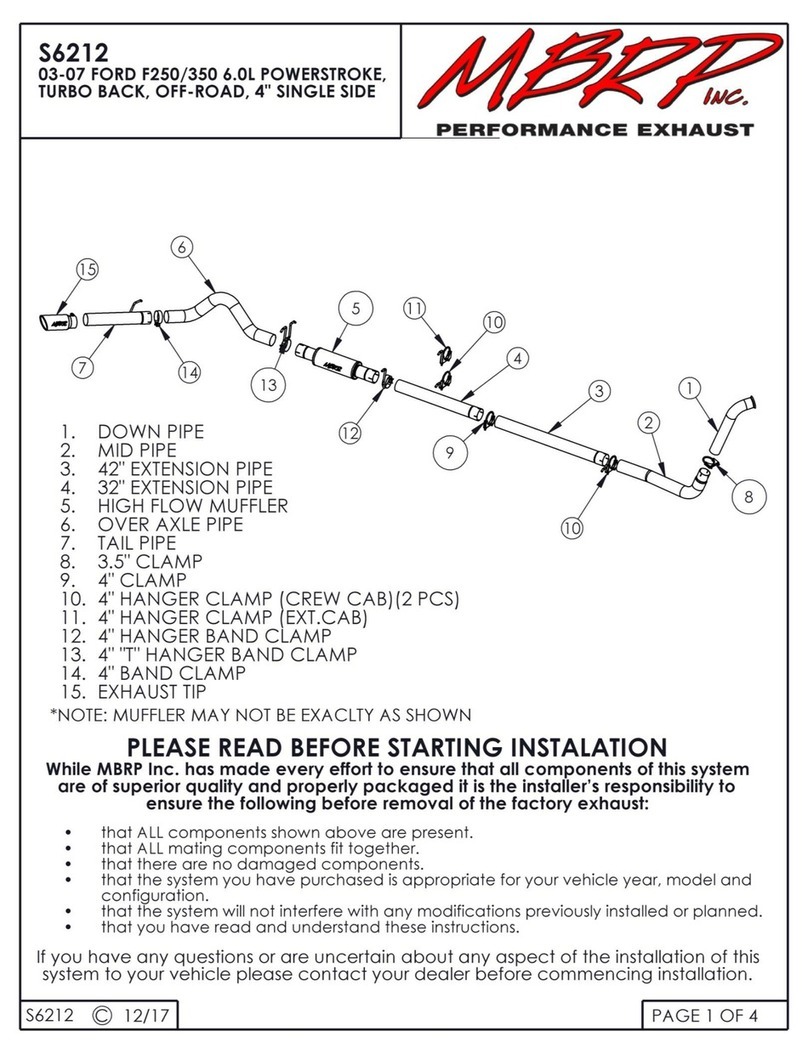

MBRP

MBRP S6212 installation manual

Ancona

Ancona WPP424 User manual and installation instructions

Bosch

Bosch HCP3.651UC use and care manual

Zephyr

Zephyr Verona ZVO-M90AG Use, care and installation guide

Dacor

Dacor DHD30U990WS/DA installation instructions

Franke

Franke Frames by Franke FS DW 866 XS installation manual

Futuro Futuro

Futuro Futuro SILVANA ISLAND installation manual

Vynco

Vynco VEF2B Installation Instructions and Specifications

Gram

Gram EFV 5460-92 X instruction manual