5

Picture 11-1

6.Installation of aluminum foil's air duct:

Installation of without check valve:Firstly,insert the aluminum foil's air duct with fixed bar between the inner and

external rings of check valve vent, fasten it by ST3x10 tapping screw. Then fasten another side of aluminum foil's air

duct with adhesive tap outside of room.When the wall's hole is bigger than air duct, the air duct can be pulled out of

room directly;when the wall's pipe is smaller than air duct, there are four specifications for the interface of air duct, such

as 140mm,150mm,160mm and 170mm.The operator can select reasonable specification according to wall's hole. The

additional part can be cut with forfex.(The detail as following picture),if the duct should connect with public smoke

flue,please first straighten out the duct,then connect with flue.

Φ175 alu min um fo il 's air duct

Φ180

Φ170

Φ160

Φ150

Φ140

Picture 11-2

Check valve

Seal ring of check valve

ST4X18 screws

Installation of with check valve:Firstly,insert the aluminum foil's air duct into the external rings of check valve vent,

fasten it seal tape. Then put 4 buckles in the check valve into the slots,turn with clockwise and fix the duct with the check

valve vent. Then fasten another side of aluminum foil's air duct with adhesive tap outside of room.When the wall's hole is

bigger than air duct, the air duct can be pulled out of room directly;when the wall's pipe is smaller than air duct, there are

four specifications for the interface of air duct, such as 140mm,150mm,160mm and 170mm.The operator can select

reasonable specification according to wall's hole. The additional part can be cut with forfex.(The detail as following

picture),if the duct should connect with public smoke flue,please first straighten out the duct,then connect with flue.

Body of machine

Check valve

Check valve interface

ST4X18 screws

Seal ring of check valve

Φ175 aluminum foil's air duct

Adhesive tape Φ175 air duct's interface

Φ180

Φ170

Φ160

Φ150

Φ140

Adhesive tape

Slot

Body of machine

Fixed bar of air duct

ST3X10 screw

Adhesive tape Φ175 air duct's interface

cut additional part which smaller than wall's hole

Notice: Please straighten the aluminum foil's air duct when installing

this product to avoid noise under incompletely straight condition. The

additional air duct can be cut by wire-cutter.

Notice: Please straighten the aluminum foil's air duct when installing

this product to avoid noise under incompletely straight condition. The

additional air duct can be cut by wire-cutter.

cut additional part which smaller than wall's hole

Buckle

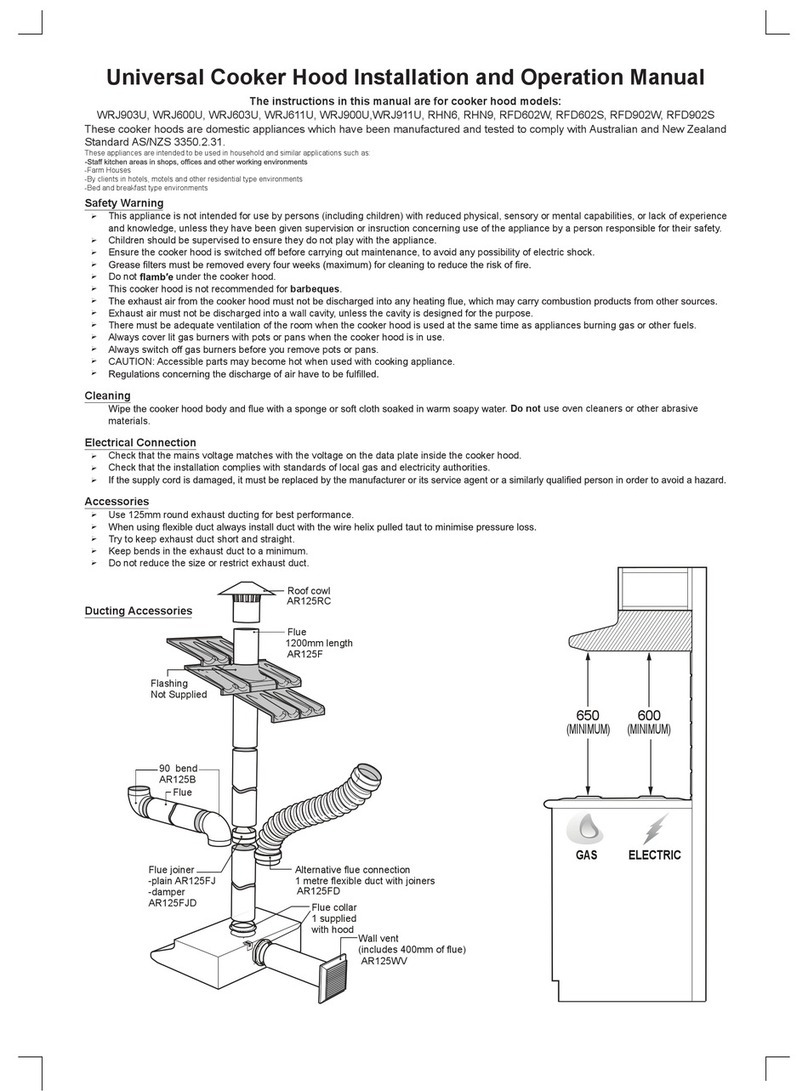

7. Installing other end of exhaust duct (for reference)

Installing with exhaust tube and range hood against the window:

replace a piece of window glass with plywood with ventilation holes or drill holes directly on the glass.

In case range hood kept away from the window:

Choose the window nearest to the hood and with outdoor access for installing the exhaust tube; or drill holes

on the wall nearest to the hood and with outdoor access to install the exhaust tube through the wall.

Drilling holes through wall:

Align properly the positions of exhaust tube against the wall and scribe the holes on the wall (circles slightly

larger than the exhaust tube diameter),then drill the wall by long drill bit.Please take care of the wall

structure and materials to prevent damage of wall other than the wall holes.

The hole diameter on the wall shall be near to that of the exhaust tube and shall not be too small. Otherwise,

it will lead to obstructed exhaust, higher noise and lower air flow rate,noisy.The connection part from the

duct and the flue should be well sealed,make sure the duct,check valve vent and the flue well fixed,and

check the valve from the check valve or flue switched smoothly;

吸油烟机

Range Hood