3

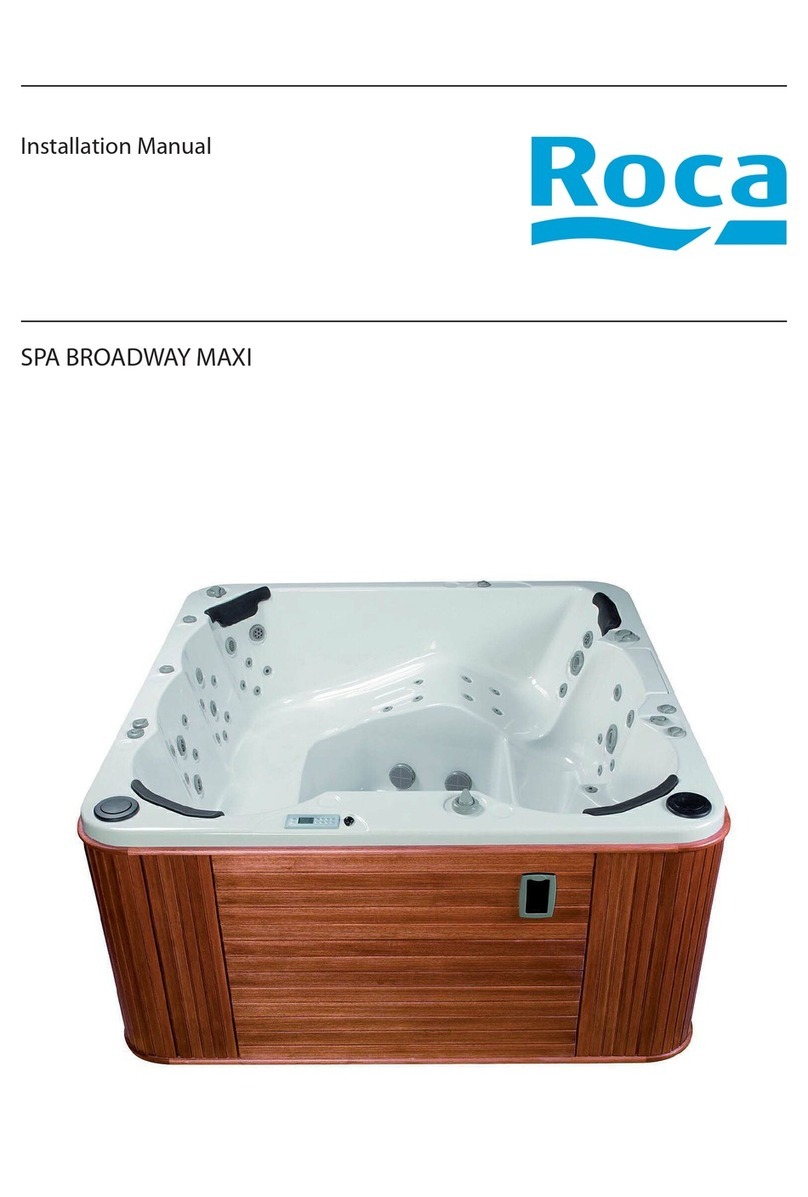

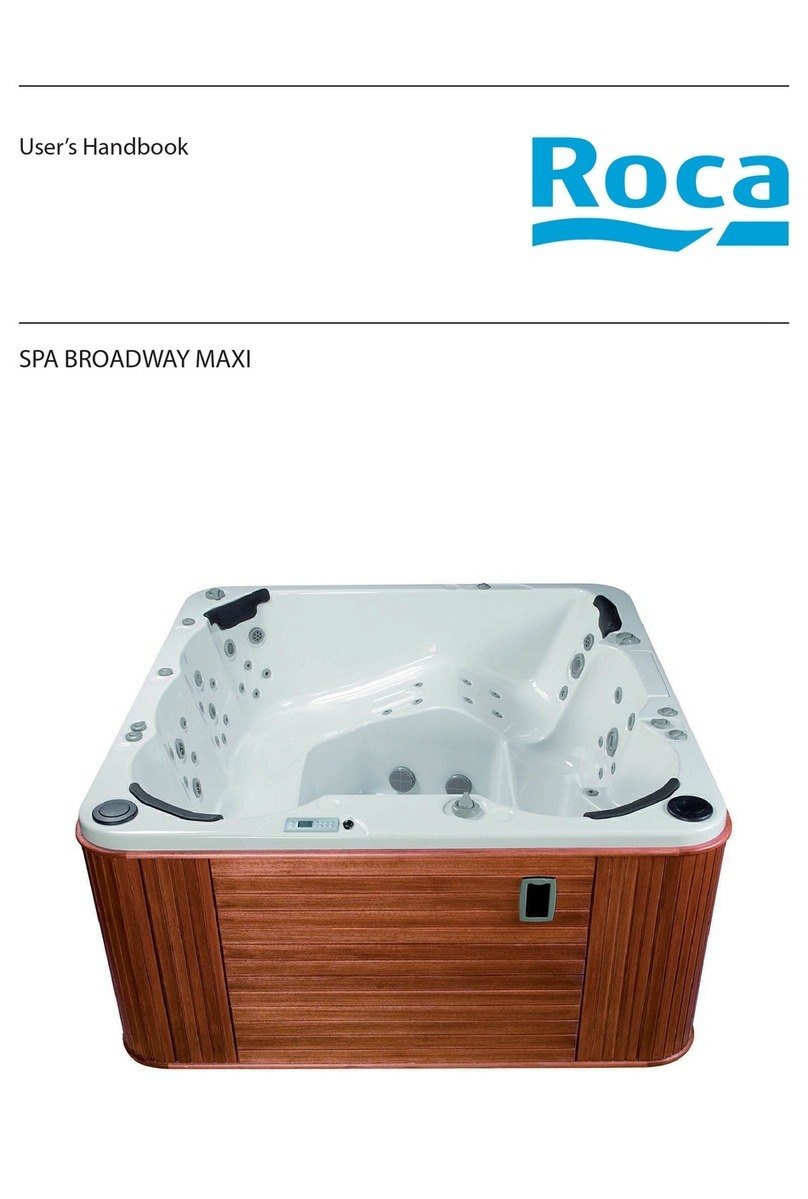

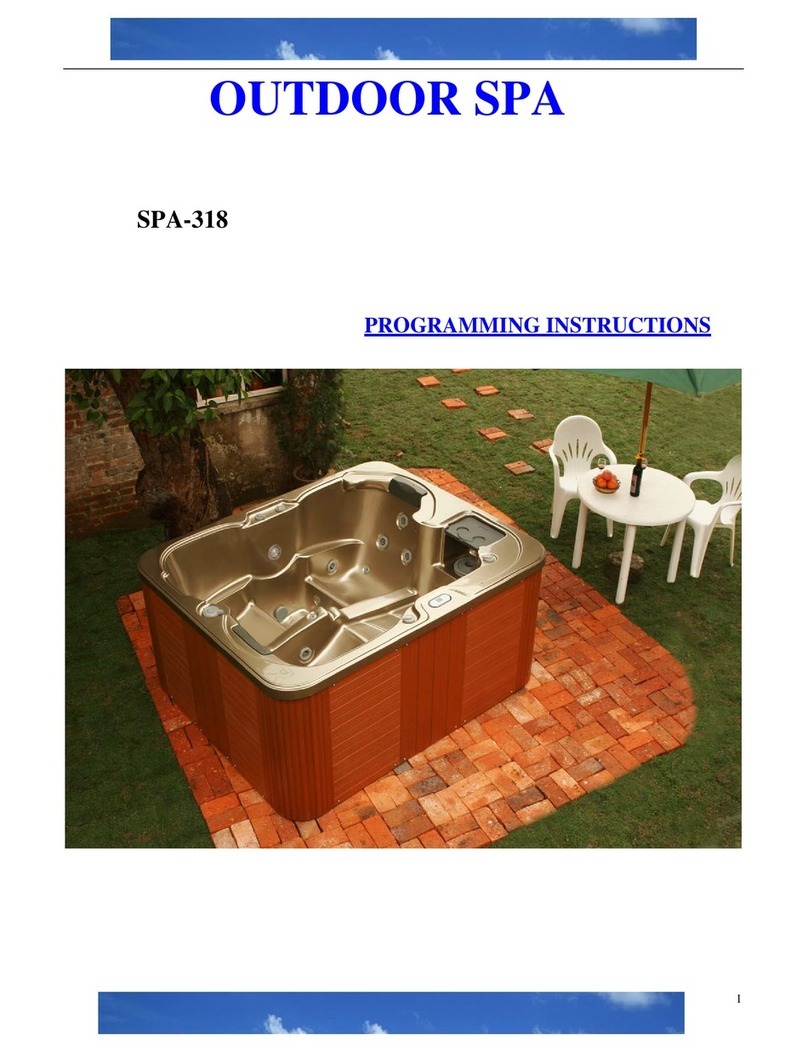

This spa has been designed, manufactured and checked by

our technical staff. It must be fitted in compliance with the

regulations in force, and the corresponding instructions should

be followed.

BREACH OF THIS CONDITION RENDERS THE PRODUCT

WARRANTY NULL AND VOID.

This spa has been designed for private use.

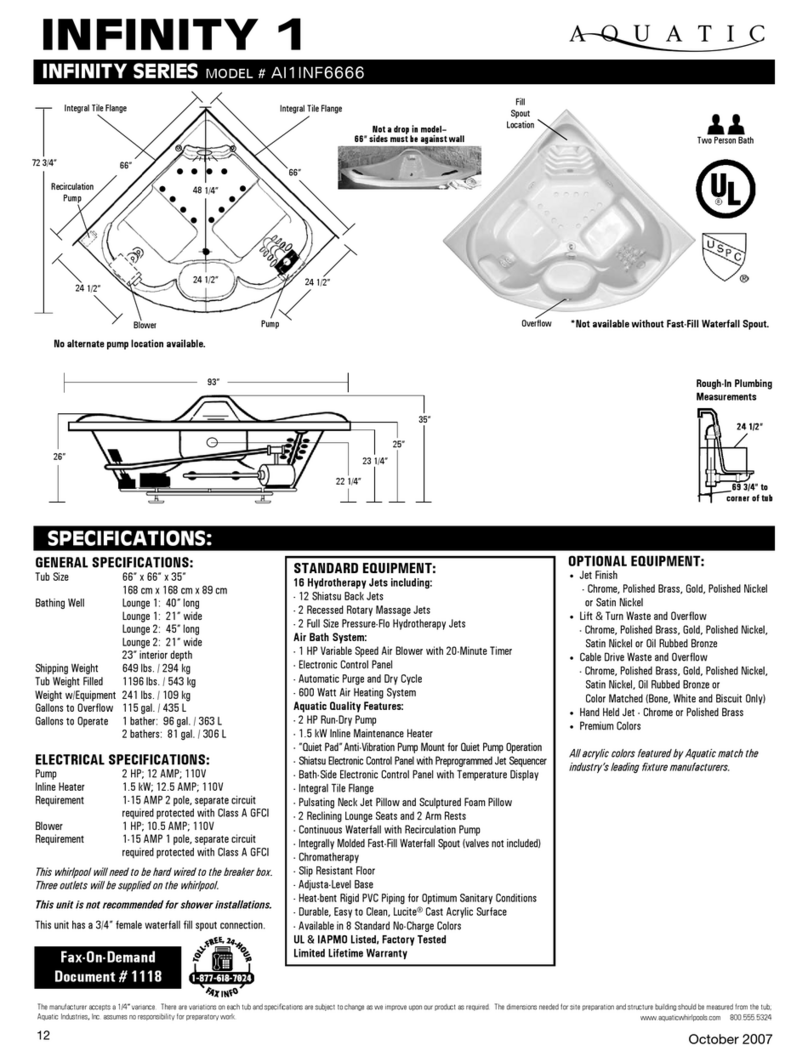

GENERAL SPECIFICATIONS

AIR MASSAGE:

- 1 Blower with heater (800 W + 300 W). 1x230V.

- 40 bottom holes.

WATER MASSAGE:

- 1 pump (hydro [high speed] and filter [low speed])

1.1 kW 1x230V.

- Jets:

- 2 directional 3.5” jets.

- 4 rotating 3.5” jets.

- 13 rotating minijets.

- 2 air regulators:

- 1 for the seat area.

- 1 for the lying down area.

DISINFECTION:

- 1 ozone generator (10W) 250mg/h.

FILTERING AND HEATING:

- Filter cartridge.

WATER HEATING ELEMENT:

- 2 kW, 1 x 230 V

SPECIFICATIONS:

- Capacity - 580 litres.

- Dimensions -1880/1330/750 mm.

- Weight - 150 kg (without water).

- No. of people -2-3.

- Single-phase 230 V mains.

- Maximum power consumption: 4.2 Kw (230 V single

phase)

1. RECEIVING THE EQUIPMENT

The spa should reach its destination in its original packaging.

Once the packaging has been removed, check the spa fully before

it is installed and report any anomaly.

Do not lift the spa using the filter equipment or the pipes.

Do not stand the spa on its edge. Always stand it on its legs.

During the installation, check that the interior of the spa is pro-

tected by the covering included with the equipment.

The electrical installation and pipe connections must be carried

out by authorised installers.

2. PREPARING THE PLACE FOR THE

INSTALLATION

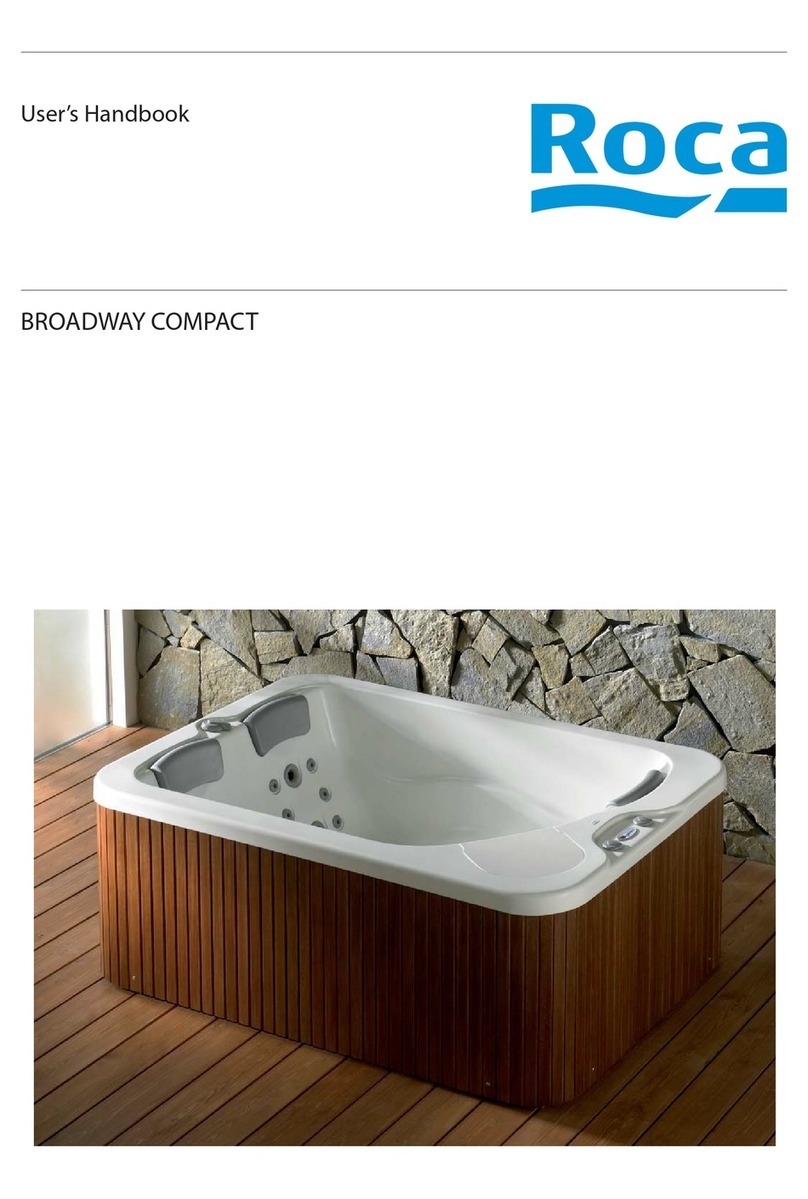

The Compact Broadway spa can function indoors and outdoors.

It must be installed on a firm base to prevent it from sinking.

When choosing the location for the spa, a series of requirements

must be taken into account:

- If you have decided to install the spa indoors, bear in mind the

thoroughfares required for transporting it to its final location.

- The electrical connection of the equipment must be carried out

with a 3 conductor cable with a section of 4 mm2and ready for 230

VAC (the nominal power consumed by the standard equipment is

equal to 4.2 Kw).

- An earth connection compliant with current legislation is

essential.

- Access to interior components through the side panels for

post-installation maintenance.

- You must also bear in mind how you are going to fill and empty

the spa. The floor must be level.

- There must be adequate ventilation in closed interior loca-

tions.

- You must bear in mind the materials used on the wall and

ceilings, since the humidity generated by the spa requires

steam-resistant materials.

- Due to unavoidable splashing, the floor must be highly-resis-

tant to water, such as tiles or plastic coverings. If carpets are

used, they must be treated to avoid bacteria from damp. Use

special sailing carpets or rugs. Parquet or wooden floors are

not advisable unless they have been duly treated for this kind

of use, such as wood for gardens or outdoor buildings. In any

case, make sure that the floor has a gradient of 2% towards a

drain installed in the room.

3. POSITIONING THE SPA

- For appropriate operating conditions, the spa must be posi-

tioned on a carefully levelled, firm base.

- The weight of the full spa and with three people in it is approxi-

mately 1000 kg. This weight is supported on 9 points - the legs

- with a load on the floor of 400 kg/m2.

- Level the spa by adjusting the legs (see fig. 1).

- Position the spa in a way that best enables maintenance

through the wooden panels.

- When installing the spa in a corner or next to a side wall,

remember to leave 0.5 metres or connection or installation

work or fit trap doors with a minimum size of 1700x700 mm for

accessing all the sides for post-installation maintenance.

- This spa cannot be embedded. Do not obstruct access to

the side panels.

The following diagrams show the distribution of the support

points (fig. 1) and the position of the spaces inside the spa

(fig. 2).