Table of Contents

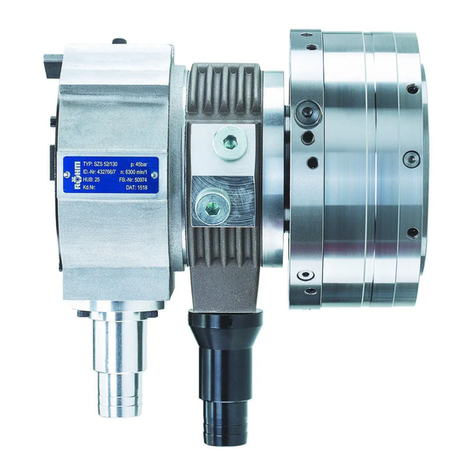

DURO-A RC III

Table of Contents

1 About this Operating Manual..................................................................... 5

1.1 Manufacturer Details................................................................................. 5

1.2 Copyright.................................................................................................. 5

1.3 Warranty and Liability ............................................................................... 6

1.4 Conventions of Presentation ..................................................................... 7

1.4.1 Text Display........................................................................................7

1.4.2 Display of Safety and Warning Instructions..........................................7

2 Safety ......................................................................................................... 8

2.1 Intended Use ............................................................................................ 9

2.2 Improper Use.......................................................................................... 10

2.3 Obligations of the Owner......................................................................... 11

2.4 Qualification of Operating and Specialist Personnel................................. 12

2.5 Personal Protective Equipment and Personnel Qualification .................... 13

2.6 General Dangers .................................................................................... 13

2.6.1 Dangers due to Flying Parts.............................................................. 13

2.6.2 Skin Irritation due to Operating Materials........................................... 14

2.6.3 Eye Injuries due to Metal Chips.........................................................14

2.6.4 Risk of Burns due to Hot Surfaces.....................................................14

2.6.5 Dangers due to Imbalanced Workpieces............................................ 14

2.6.6 Dangers due to Power Failure...........................................................15

2.6.7 Danger of Crushing...........................................................................15

2.6.8 Procedure in the Event of Danger and Accidents............................... 16

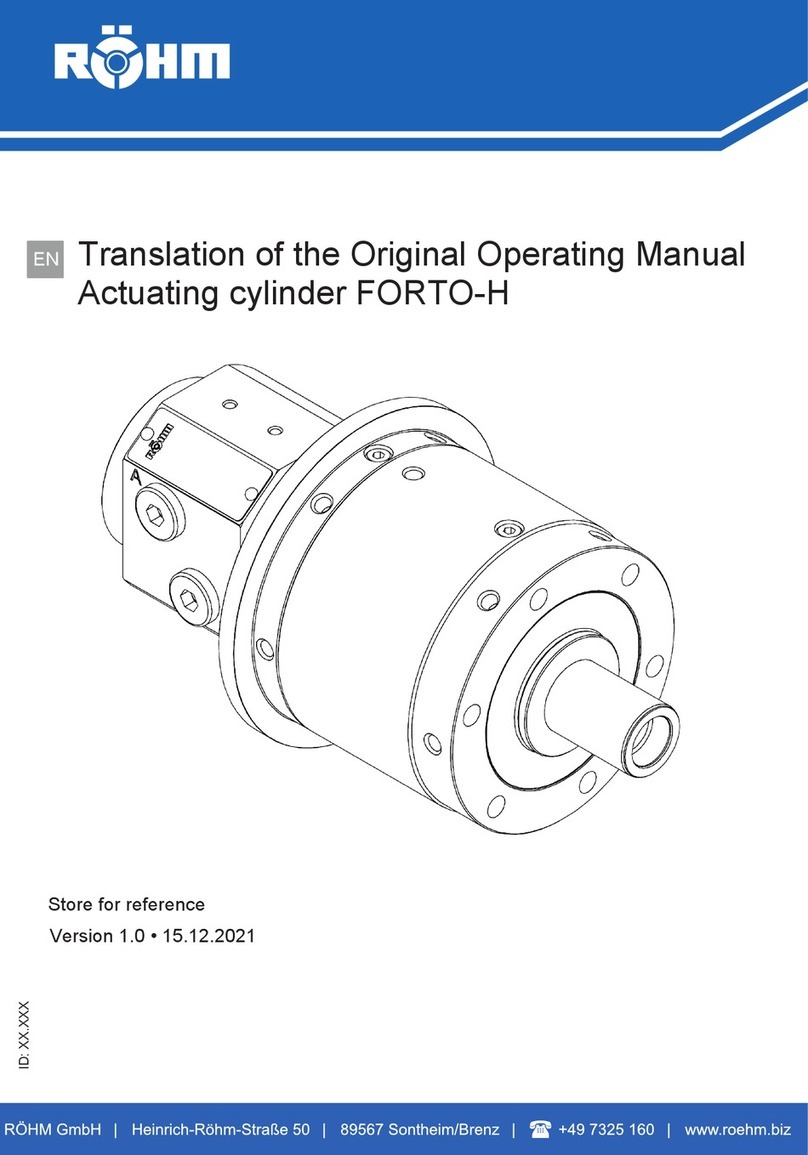

3 Product Description................................................................................. 17

3.1 About this Power Chuck.......................................................................... 17

3.2 Technical Specifications ......................................................................... 19

3.2.1 Overview of Construction Sizes......................................................... 19

3.2.2 Environmental and Operational Conditions........................................ 20

3.2.3 Clamping Force-Speed Diagram........................................................ 21

3.2.4 Permissible Operating Materials........................................................ 22

4 Transport.................................................................................................. 22

4.1 Personal Protective Equipment and Personnel Qualification .................... 22

4.2 Tapped Holes for Transport Purposes ..................................................... 23

5 Assembly ................................................................................................. 23

5.1 Personal Protective Equipment and Personnel Qualification .................... 24

5.2 Assembly on Intermediate Disk ............................................................... 24