Maintenance

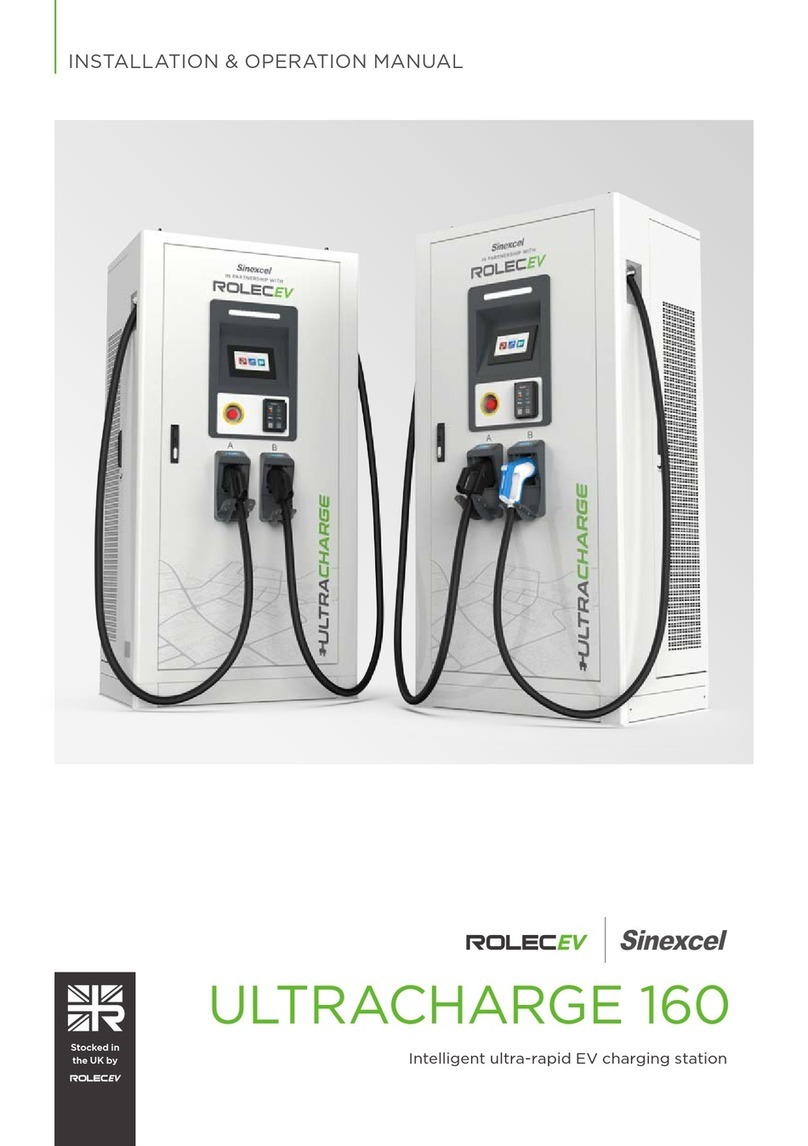

EVUCMM-V01R1 Maintenance Manual UltraCharge 160 DC Charger

October 2023 Page 8of 22

Maintenance

Maintenance of Inactive Charging Stations

xWhen the charger is not in use, the charger should be in a power-off state.

xTo maintain the service life of the charger, unnecessary load should be reduced,

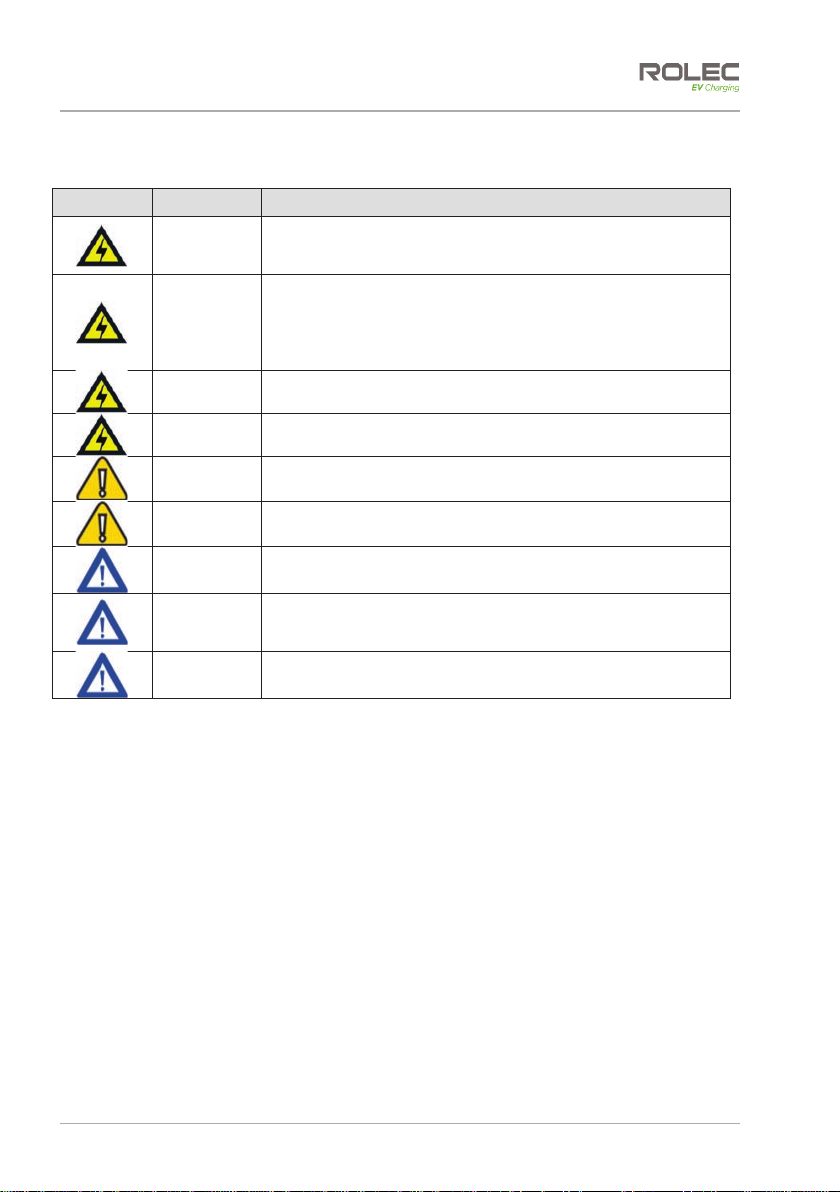

Charger Checks and Maintenance Cycle

Item Period Details Action

Front-end

distribution

box Every 3 months

Each item is checked in accordance with the

maintenance manual of the distribution box.

(Note: The maintenance manual of the distribution box

is provided by the supplier of distribution box.)

Maintenance

and repairing

Appearance Every 12

months

Check the appearance of the cabinet for any stains.

Check whether the cabinet shell has any rust,

scratches, deformation, paint damage or other

defects.

Cleaning and

paint repair

Interior Every 12

months

Make sure the interior of the cabinet is clean and tidy.

Make sure the air inlet and outlet of the power module

are not blocked with debris or dust.

xClean air ways allow more effective cooling and

prevent premature failure of the power module.

Cleaning

Lightning

protector Every 12

months

Check whether the module is securely connected, and

the status indicator is normal. If the status indicator

changes to red, the dry contact NC-COM of alarm

becomes open or the NC-COM becomes short-

circuited, the surge protector has failed.

Replacement

Fan Every 6 months Make sure the fan is working correctly. Maintenance

and repairing

Signal lamp Every 6 months Make sure the signal lamp is working correctly. Make

sure it is fixed tightly and in a normal state. Maintenance

and repairing

Components Every 6 months

Check whether components of the electric circuit

have discoloration, deformation, overheating, or other

defects, and make sure all accessible components are

secure.

If any abnormality is found, parts must be replaced in

a timely manner.

Maintenance

and repairing

Charging

connector Every 6 months

Make sure the fixing clasp is not damaged.

the needle of the charging connector is oxidized and

discoloured or obviously worn and deformed, whether

any foreign body has entered the hole on the head of

the connector, and whether the charging connector

cable is damaged.

Cleaning and

repairing

Power

module Every 6 months Check that the power module is normal and there is a

trouble-free display on the module screen. Maintenance

and repairing

Human Every 6 months Check the display screen to see if it is cracked or not Maintenance