FORM NO: 5908247 REV: A 8

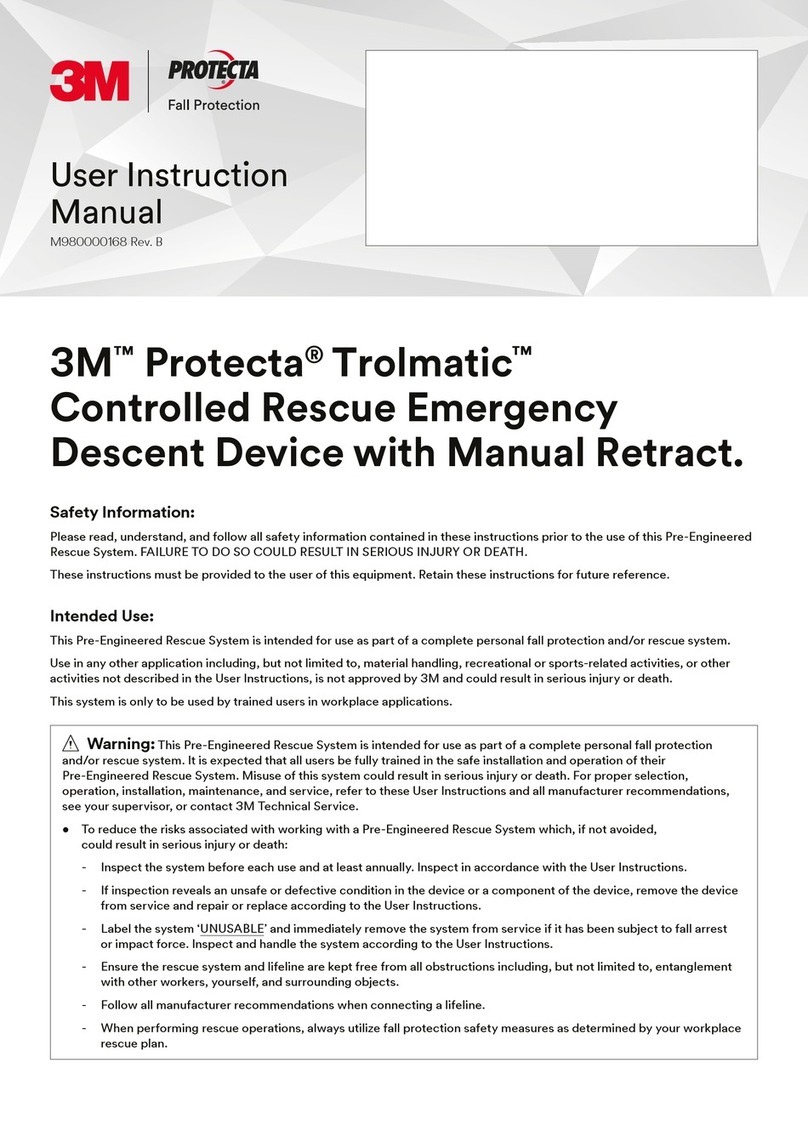

SAFETY INFORMATION

Please read, understand, and follow all safety information contained in these instructions prior to the use of this Vertical

System. FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY OR DEATH.

These instructions must be provided to the user of this equipment. Retain these instructions for future reference.

Intended Use:

This Vertical System is intended for use as part of a complete personal fall protection system.

Use in any other application including, but not limited to, material handling, recreational or sports related activities, or other activities not

described in the Product Instructions, is not approved by 3M and could result in serious injury or death.

This device is only to be used by trained users in workplace applications.

!WARNING

This Flexible Cable/Rigid Rail System is part of a personal fall protection system. It is expected that all users be fully trained in the

safe installation and operation of their personal fall protection system. Misuse of this device could result in serious injury or

death. For proper selection, operation, installation, maintenance, and service, refer to these Product Instructions and all manufacturer

recommendations, see a supervisor, or contact 3M Technical Service.

• To reduce the risks associated with working with a Flexible Cable/Rigid Rail System which, if not avoided, could result

in serious injury or death:

- Inspect all components of the system before each use, at least annually, and after any fall event. Inspect in accordance with the

Product Instructions.

- If inspection reveals an unsafe or defective condition in a component of the system, remove the component from service and

destroy it.

- Any Flexible Cable/Rigid Rail System that has been subject to fall arrest or impact force must be immediately removed from

service and all components must be inspected by a Competent Person prior to being used again.

- Do not connect to the system while it is being installed.

- Ensure the system is appropriately rated for the number of simultaneous users.

- When unpacking the cable it may rapidly uncoil. Use proper safety procedures and appropriate personal protective equipment

when unpacking cable.

- Only use approved connectors to attach body harness to the system. Do not use any additional connecting devices.

- Use only cable specied and approved in the Product Instructions.

- Do not interfere with the locking action of the shuttle/sleeve device. Only manipulate the device to attach and detach from the

system.

- Always maintain three points of contact while climbing. Refer to the Product Instructions for further information on proper

climbing technique.

- Ensure that fall protection systems/subsystems assembled from components made by different manufacturers are compatible

and meet the requirements of applicable standards, including the ANSI Z359 or other applicable fall protection codes, standards,

or requirements. Always consult a Competent and/or Qualied Person before using these systems.

• To reduce the risks associated with working at height which, if not avoided, could result in serious injury or death:

- Ensure your health and physical condition allow you to safely withstand all of the forces associated with working at height.

Consult with your doctor if you have any questions regarding your ability to use this equipment.

- Never exceed allowable capacity of your fall protection equipment.

- Never exceed maximum free fall distance of your fall protection equipment.

- Do not use any fall protection equipment that fails pre-use or other scheduled inspections, or if you have concerns about the use

or suitability of the equipment for your application. Contact 3M Technical Services with any questions.

- Some subsystem and component combinations may interfere with the operation of this equipment. Only use compatible

connections. Consult 3M prior to using this equipment in combination with components or subsystems other than those described

in the User Instructions.

- Use extra precautions when working around moving machinery (e.g. top drive of oil rigs), electrical hazards, extreme

temperatures, chemical hazards, explosive or toxic gases, sharp edges, or below overhead materials that could fall onto you or

your fall protection equipment.

- Use Arc Flash or Hot Works devices when working in high heat environments.

- Avoid surfaces and objects that can damage the user or equipment.

- Ensure there is adequate fall clearance when working at height.

- Never modify or alter your fall protection equipment. Only 3M or parties authorized in writing by 3M may make repairs to the

equipment.

- Prior to use of fall protection equipment, ensure a rescue plan is in place which allows for prompt rescue if a fall incident occurs.

- If a fall event occurs, immediately seek medical attention for the worker who has fallen.

- Do not use a body belt for fall arrest applications. Use only a Full Body Harness.

- Minimize swing falls by working as directly below the anchorage point as possible.

- If training with this device, a secondary fall protection system must be utilized in a manner that does not expose the trainee to

an unintended fall hazard.

- Always wear appropriate personal protective equipment when installing, using, or inspecting the device/system.

EN

DISTRIBUTED

BY

CAI

SAFETY

SYSTEMS

|

Phone:

(888)

246

6999

|

Web:

caisafety.com

|

Email:

[email protected]