.........................................................................................................................................................................................................................................................................................................................................................................................................................................................

4. Product Use

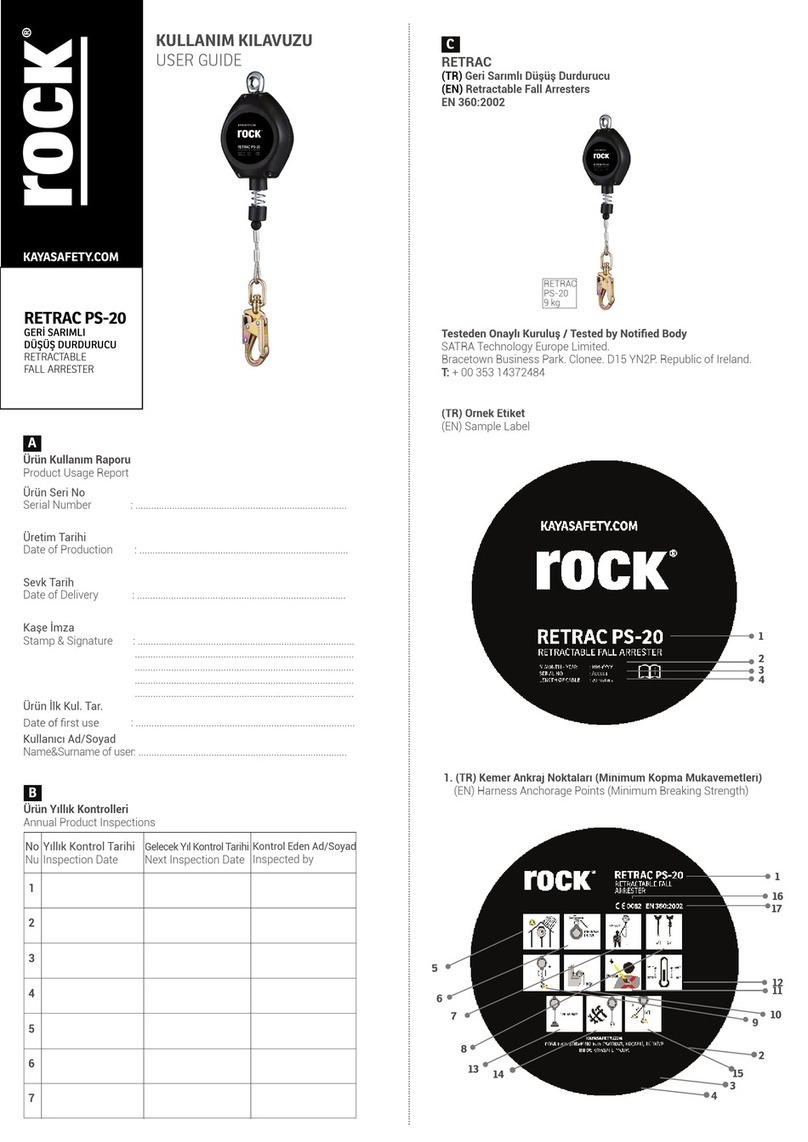

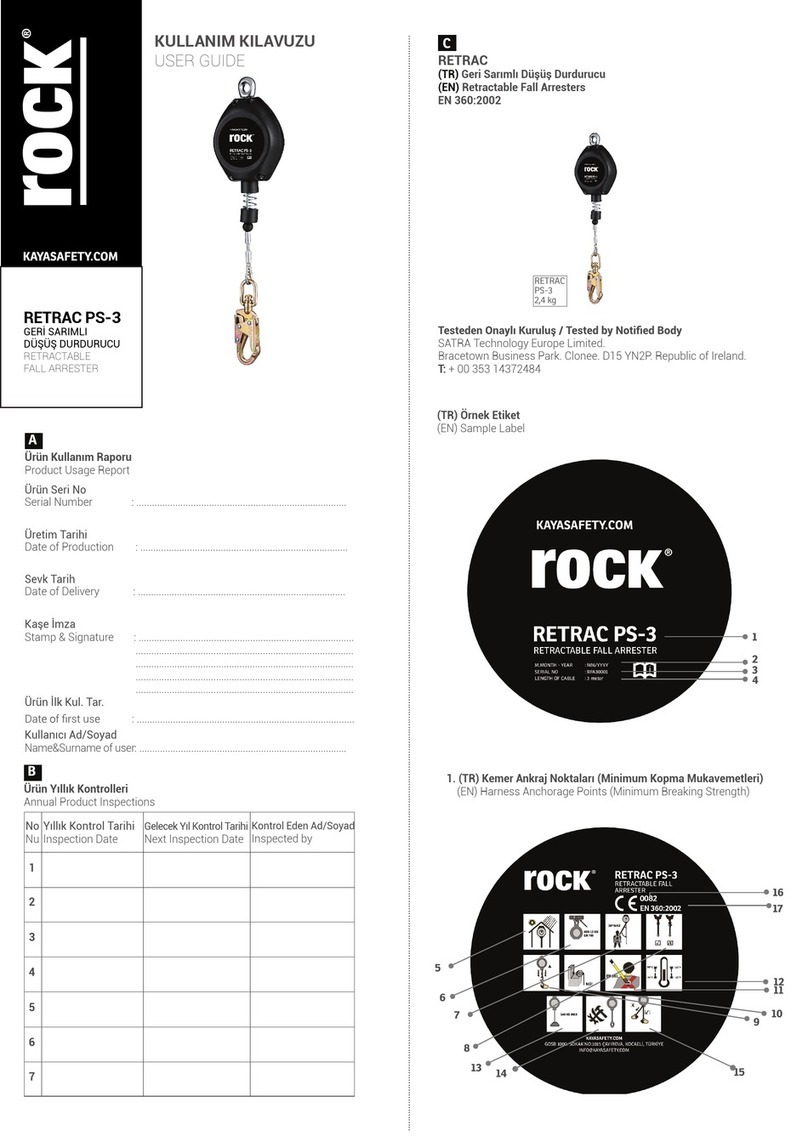

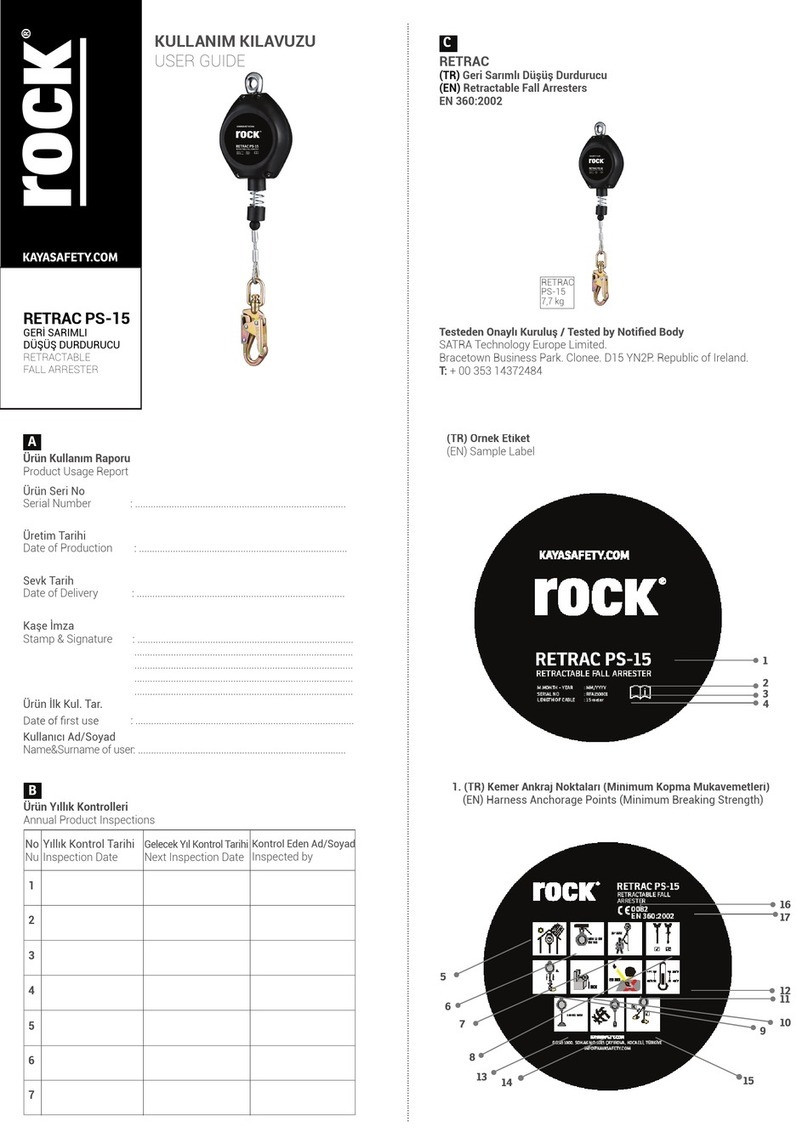

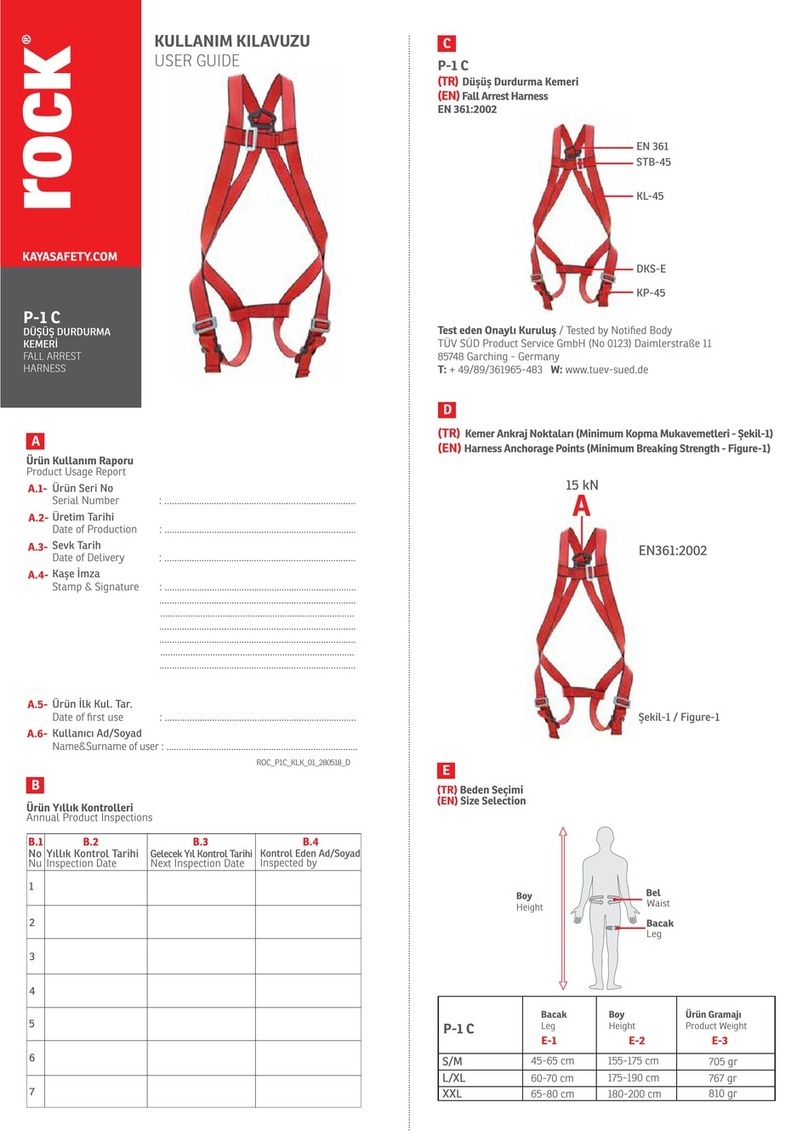

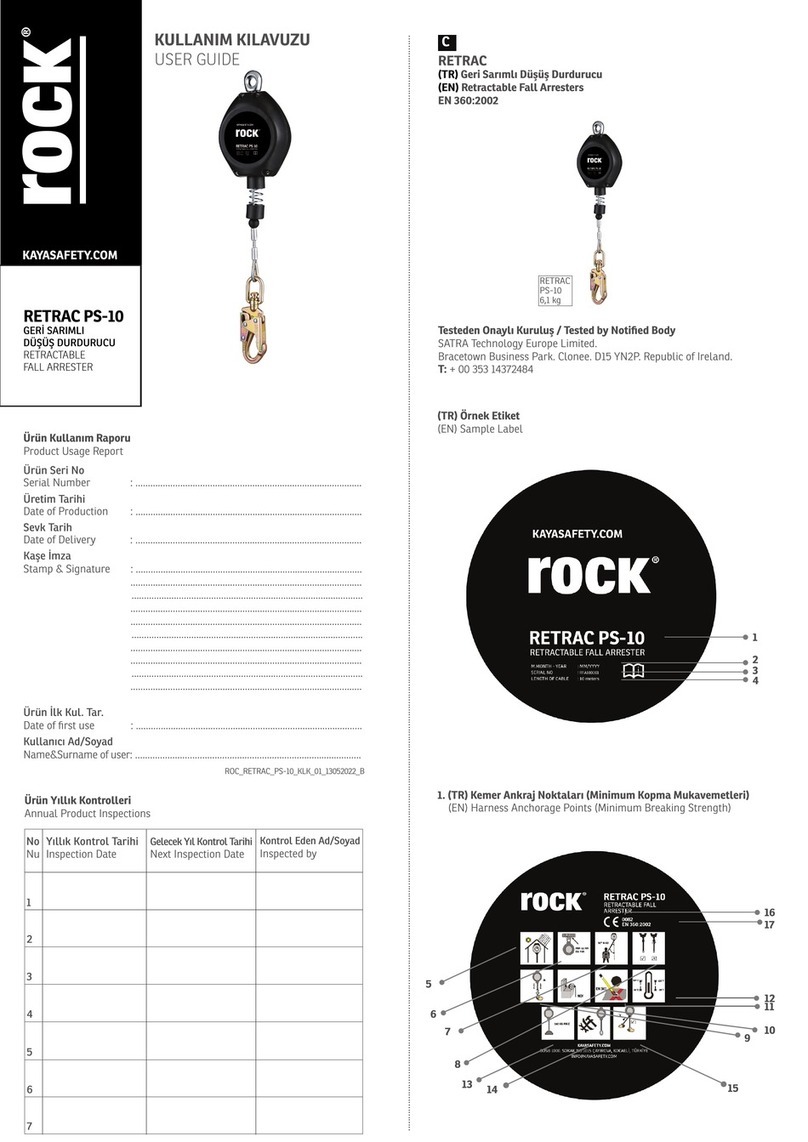

4.1- EN 361:2002 Fall Arrest Harness

* Full Body Fall Arrest Harness

stnenopmoclla,retserrallafsadesusissenrahtserrallafydobllufnehW

of the system should comply with the requirements of EN 363 (full fall arrest

systems). Remaining equipment which are anchoring points of harness must

srebrosbakcohS,453NEhtiwylpmoctsumsdraynaL,597NEhtiwylpmoc

must comply with EN 355, Carabiner must comply with EN 362.

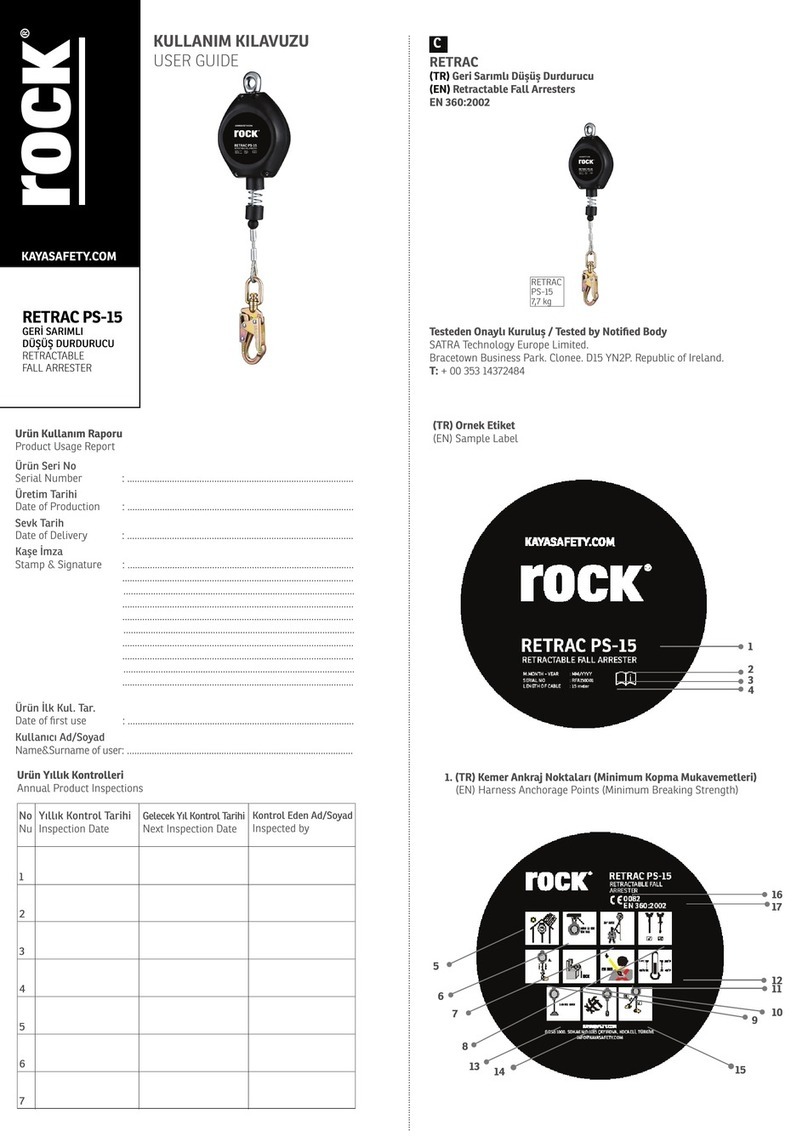

* Back D Ring; ( Figure- 1 )

Use only back D rings of safety harness with other equipment described in

EN 363 ( Shock absorber, lanyard, fall arrest systems). These points were

marked with “A” in order to be recognized easily.)

3- General Specification

Personal Protective Equipment (PPE)

This full body harness enables the user to work safely by making a connection

to a secure point with an appropriate tool. This safety harness is manufactured in

comply with standards of EN 358, EN 361, EN 813.

4.2- EN 358:1999 Work Positioning Harness

Always use side D rings located on the back pad with a lanyard as shown in

Figure - 2Always make sure to place the lanyard at the same level of your

waist or above when positioning is performed.

4.3- EN 813:1997 , EN 1227: 2007 Seat Harness

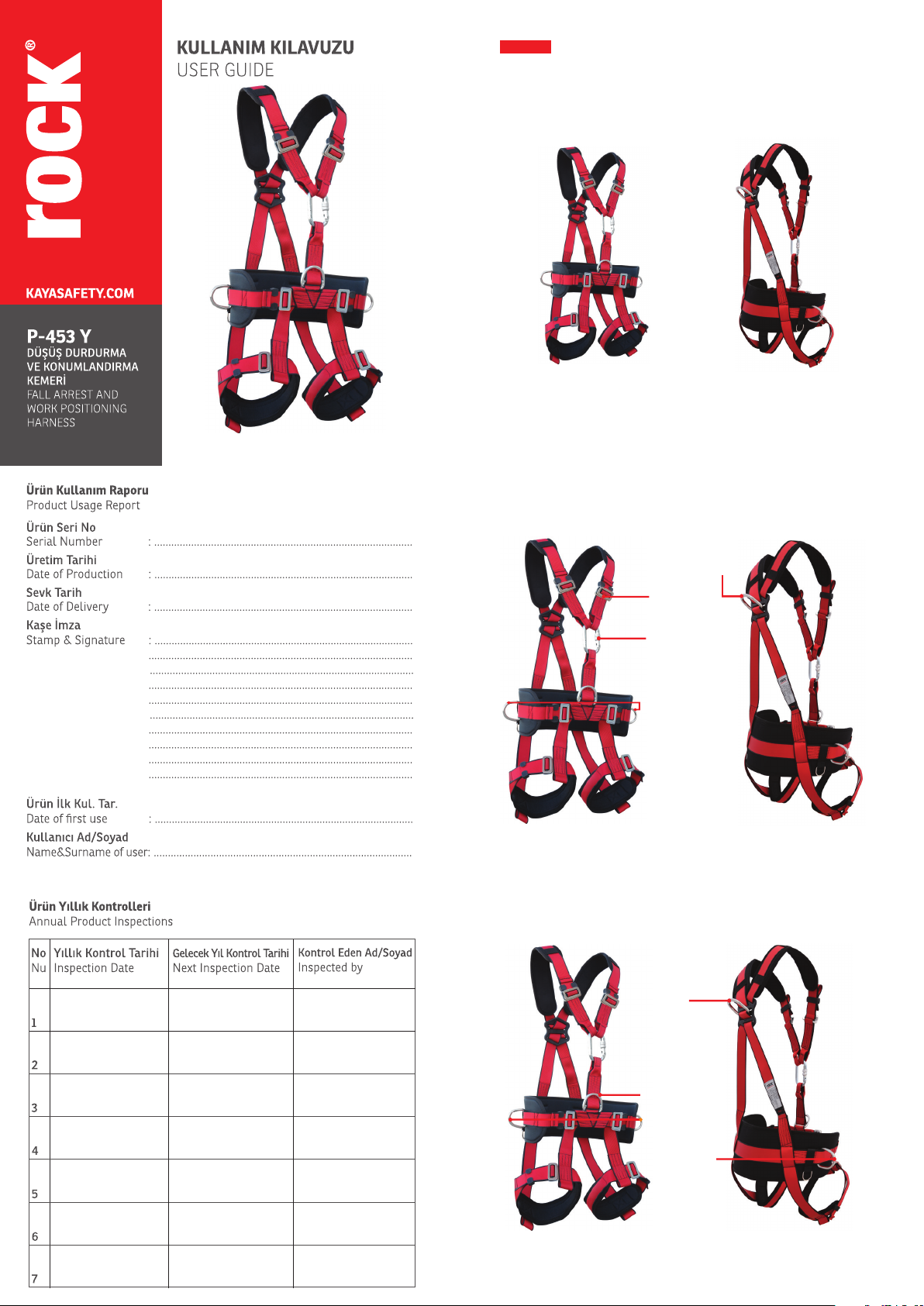

4.4- Fall Clearance = A+B+C+D

Figure - 3 seat harness is used when a lower point in rope access technique

or work positioning is needed. D ring in the seat harness can be used with

descenders, positioning lanyards and work area restriction lanyards.

Figure - 4 ; Fall Clearance ( Calculation of fallclearance distance)

Clearance distance should be calculated in the working area for a possible fall.

In case of fall from height, user should be able to adjust the clearence distance

in order not to hit any object or ground.

Fall clearance is the height at which a worker must attach to an anchorage to

avoid contact with a lower level. In order to calculate required fallclearance

distance the following measurements must be kept in mind.

A :Length of Fall Arrest System (Lanyard)

B :Length of the Lanyard after afall

C :Height of Suspended Worker

D : Safety Factor

Fall Clearance

Working at height equipment must beused as personalized. These products

must be controled on regular basis before and after each single use and

findings must be recorded into product control form. On an adequate lighted

environment apply following controls by lying the product down on a flat

surface;

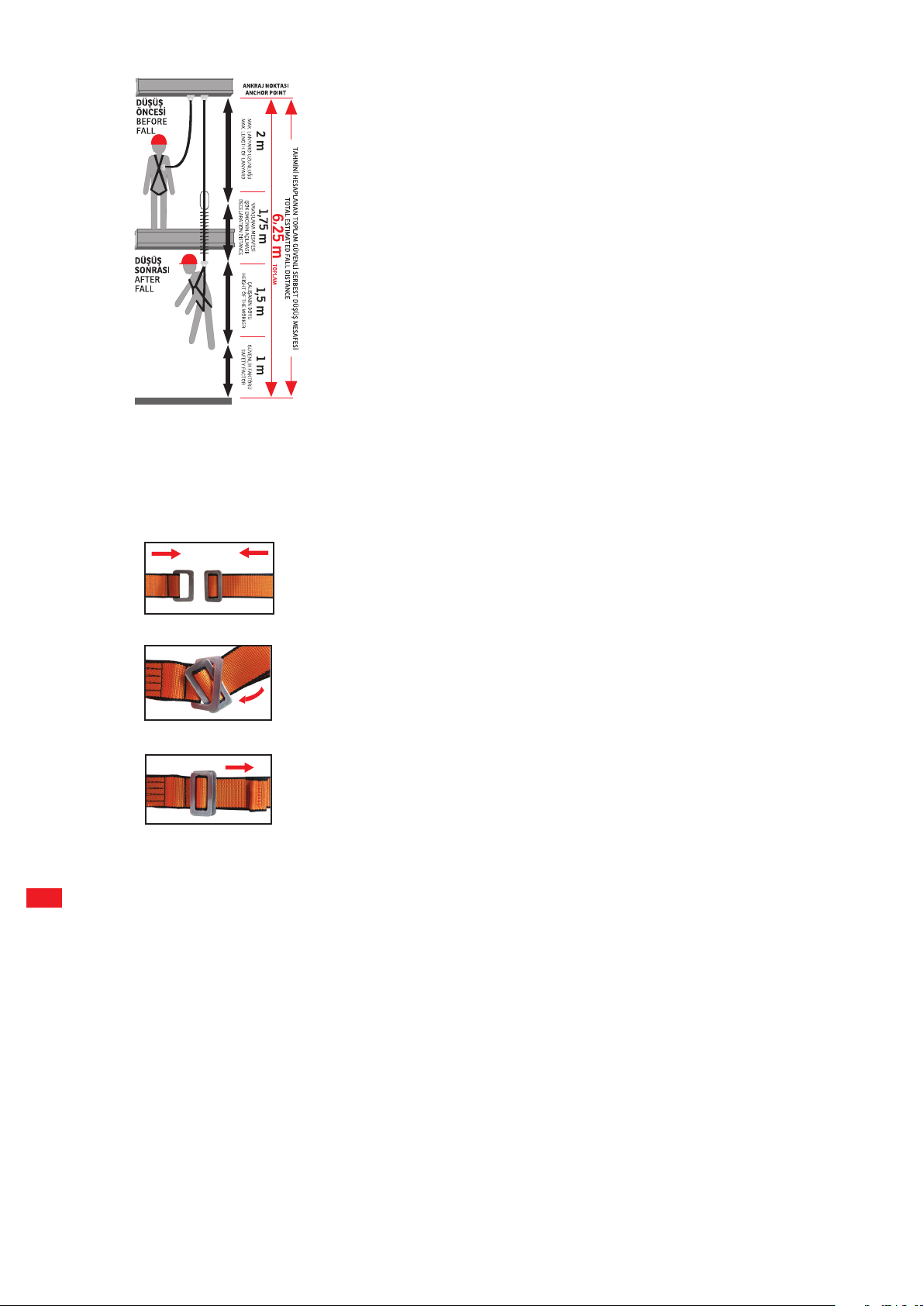

• Webbings should be checked for cuts, abrasions, color change, broken stitches

and undue stretching.

• Buckles should be checked for signs of wear, cracks, deformation, corrosion

or other damages. They should function correctly and smoothly.

• D Rings and other metal parts should be checked for signs of wear,

cracks, deformation, corrosion or other damage.

• Connectors should be checked for sign of wear, cracks, deformation, corrosion,

dirt. The gate and the locking mechanisms should work easily and without

any problem. The gate should open and close completely.

• Labels should be secure and legible.

During the controls if at least one of these deviation is found, usage of the

equipment should be suspended or retired and immediately send back to

producer for detailed inspection. No repair is allowed by unauthorised person.

Only manufacturer directions should be applied.

When use product with a system , make sure that all pieces of equipment in

the system are correctly positioned with respect to each other.

5. Product Control and Validation

5.1 Before Every Single Use

5.2 During Each Use

A worker who has been incapacitated by an injury or medical condition and

who is suspended by the full body harness must be rescued immediately.

So you must always have a rescue plan for such emergency situations. For

this adequately trained personnel and rescue equipment must be on hand.

6.1 Rescue Plan

6.2 Anchor Point

6. Supplementary İnformation Regarding Standard; EN 365

The anchor point of the system comprises this product should preferably be

located above the user or should at least at the waist level of the user. An

attachment point below this level will cause a serious injury or death. The

anchor point must conform to the requirements of the EN 795 standard and

the minimum strength of it must be 12 kN.

6.3 Various Situation

- A fall arrest harness is the only device allowable for supporting the body in

a fall arrest system.

- In a fall arrest system, it is essential to check the required clearance under

the user before each use, to avoid any impact with the ground or an obstacle

in case of a fall.

- Make sure that the anchor point is correctly positioned, in order to limit the

risk and the height of afall.

- When using multiple pieces of equipment together, a dangerous situation

can result if the safety function of one piece of equipment is affected by the

safety function of another piece of equipment.

- Users must be medically fit for activities at height. Warning, inert suspension

in a harness can result in serious injury or death.

Product is sold with storage bag and user guide. Additionally model and

applied standards are provided with the product. During the storage keep

the product in it’s own bag. Storage area of the product should meet fol

lowing requirements;

- Dry, no direct sun light, room temperature

- Do not store together with acids, solvents etc.

- Keep away from direct heat sources.

- If the product gets humidity during the storage, dry the product in room

temperature before usage.

7.2 Storage

7.3 Maintenance

Personal protection equipment should be checked regularly to make sure

that the equipment will operate properly whenever it is used Harness can

be wiped with a wet sponge, for cleaning. A mild soap and warm water not

exceeding 30ºC can be used for difficult stains. After cleaning, it should

be thoroughly rinsed in clean cold water, hung out in a dry, dark and cool

place and kept away from the direct heat sources. Harnesses should be

hung out or placed loosely in a bag or another container in order to protect

it from harmful fumes, corrosive agent or light (artificial or sunlight). Do

not use acidic or solvent chemicals!

If the product has one of the deviations below it should be withdrawn from

service immediately and should be destroyed to prevent further usage.

• It has suffered a heavy shock load or has had a load dropped onto it.

• There are discoloration, stiffness, cuts and tears, glazed or fused areas

on the webbingg.

• There are cracks, deformation, corrosion or excessive wear on the metal parts.

• It fails to pass inspection (before usage or detailed inspection)

• Labels (markings) are illegible or absent

• It is extremely dirty and does not respond to normal washing.

• It has come into contact with chemicals and especially acids or is even

suspected.

• Its history is unknown.

• Its life time stated in the user’s manual has expired or even it has never

been used.

.elbailerdnaytefaseromonsistcudorpehttahttbuodtsethgilsasierehT•

7.1 Life Time

7.Kaya General Information

Although the potential life time is 3 years from the date of production, it is

very difficult to define the exact service life of it as it varies according to the fre

quency and intense of use, environmental conditions, correct maintenance and

storage. Recommended life expectancy of this Lanyard with energy absorber is

5 years from date of first use.