PRODUCT MANUAL

46/50ST Below Deck Compact Motor™

19

PRODUCT MANUAL

46/50ST Below Deck Compact Motor™

18

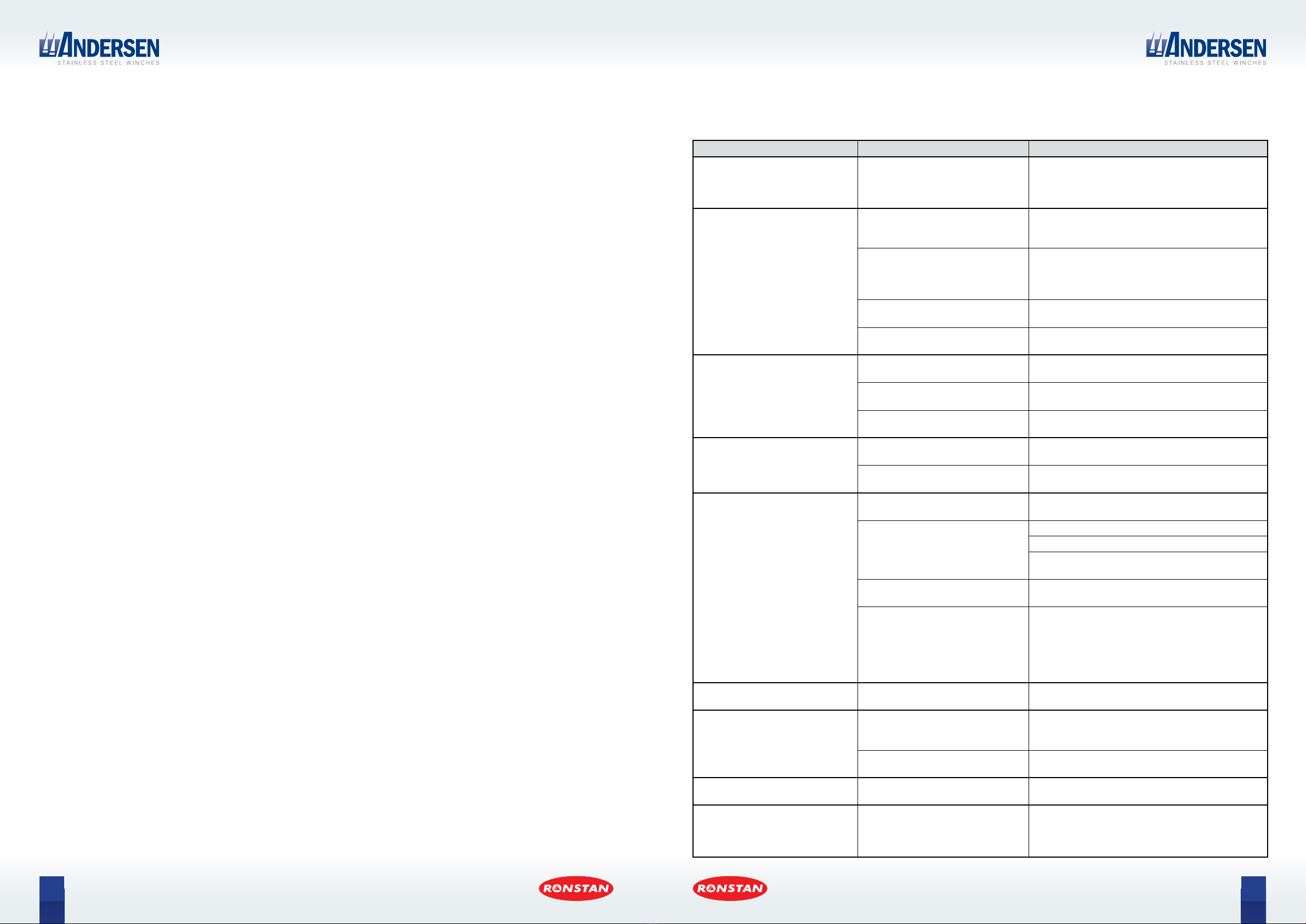

Troubleshooting

Compact Motor™ electric winches have built-in monitoring and protection features to enhance safety and avoid permanent

damage to the electronic and mechanical components of the motor and winch.

Automatic cut-out and reset

The integrated controller will cause the motor to stop without tripping the circuit breaker if one of the following conditions is

detected:

• Maximum pulling load exceeded. The motor will cut out if the pre-set maximum pulling load of the winch for electrical

operation is exceeded. Operation can resume within a few seconds when the load returns below the limit.

• Overheating. The motor will cut out if the temperature of the motor circuit reaches 60˚C (140˚F). Operation can resume

when the temperature returns to normal, which may take some time.

• Maximum continuous run time exceeded. The motor will cut out after running continuously for 4 minutes and 15

seconds. Operation can resume after releasing the push button for a pause of at least 30 seconds.

In these cases, the illuminated push button will ash, indicating that the controller will reset automatically when operating

conditions return to normal.

Fault detection and identication

If a fault occurs that requires investigation or intervention, the LED indicators on the circuit breaker can assist with

troubleshooting and diagnostics. These indicators are located along the edge of the PCB, at the rear of the circuit breaker as

shown in step 9 of this manual.

FAULT POSSIBLE CAUSE ACTION

Excessive vibration or noise

from motor/gearbox unit.

Drive shaft housing not mating

properly with octagonal recess

in deck plate, clamping ring not

tightened properly.

Ensure proper assembly with deck plate, and

sucient clearance with through-deck hole – see

step 3. Ensure clamping ring is fully tightened

before inserting and tightening locking grub screw.

Motor stops;

push button LED ashes

The motor has cut out after

reaching the pre-set maximum load

for electrical operation of the winch.

Release the push button and run the winch with

reduced load.

Motor circuit overheated;

temperature above 60˚C (140˚F).

When the motor has cooled down suciently (this

may take some time), status will automatically

reset to normal and the winch will be ready for use.

Ensure adequate ventilation around the motor.

Running time has exceeded +/- 4

minutes.

Release the push button and start again after

30 seconds.

Damaged control cable (push

button to motor). Replace cable if necessary.

Motor will not start; push button

LED not illuminated.

Circuit breaker and/or battery

switch may be “OFF”. Check and switch to “ON”.

No power supply to motor. Check power cables are properly connected to the

battery and circuit breaker.

Push button disconnected. Check control cables for push button and motor

are connected.

Motor will not start; push button

LED is illuminated.

Incorrect or insucient voltage in

power supply to motor. Restore normal voltage to power supply.

Damaged control cable (push

button to motor). Replace cable if necessary.

Circuit breaker trips and switches

to OFF after being reset.

Refer to LED Status Code table in

this section of the manual.

Address fault identied in LED Status Code table

and reset the circuit breaker.

Incorrect or insucient voltage in

power supply to motor.

Charge or change battery.

Check terminal connections.

Restore normal voltage to power supply and reset

the circuit breaker.

Thermal sensor wires disconnected

or damaged.

Re-connect thermal sensor wiring or replace if

damaged.

Motor circuit severely overheated;

temperature above 70°C (158˚F)

trips circuit breaker to OFF.

When the motor has cooled down suciently (this

may take some time), status will automatically

reset to normal and the winch will be ready for use.

Ensure adequate ventilation around the motor.

If problem persists or re-occurs contact your

Andersen dealer.

Circuit breaker trips and switches

to OFF while operating the winch.

Refer to Status Code Table in this

section of the manual.

Address fault identied in LED Status Code table

and reset the circuit breaker.

Green LED on circuit breaker does

not illuminate when circuit breaker

switched to ON, or ashes every

20 seconds in normal use.

MINUS wire from circuit breaker to

battery terminal is disconnected or

damaged.

Check cable and terminal connections at circuit

breaker and battery.

PCB or its terminals may be

damaged.

Contact your Andersen dealer, replace PCB if

necessary.

Circuit breaker trips, switches to

OFF and no status code ashes.

Current draw exceeds maximum

rating of circuit breaker.

Check electrical installation and ensure connections

to circuit breaker are correct.

Water drips from drain holes near

the base of drive shaft housing,

just above the motor/gearbox

unit.

May indicate water ingress through

drive shaft lip seal.

Follow the instructions in the service kit for lip

seal replacement provided with your Compact

Motor™, or contact your Andersen dealer for

assistance.

Troubleshooting Guide