REASSEMBLING THE WINCH

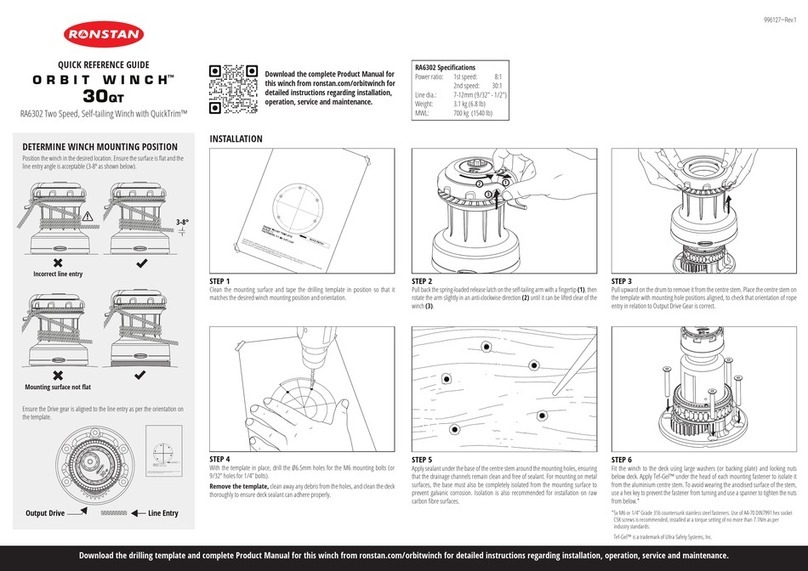

ENABLING QUICKTRIM™ FUNCTION

QUICKTRIM™

A patented innovation in self-tailing winches that allows rapid easing of line tension without having to remove the line from the self-tailer. Orbit Winches™are delivered with the self-tailer locked, operating as a traditional two-speed self-tailing winch.

The QuickTrim™ function is enabled by following the instructions below.

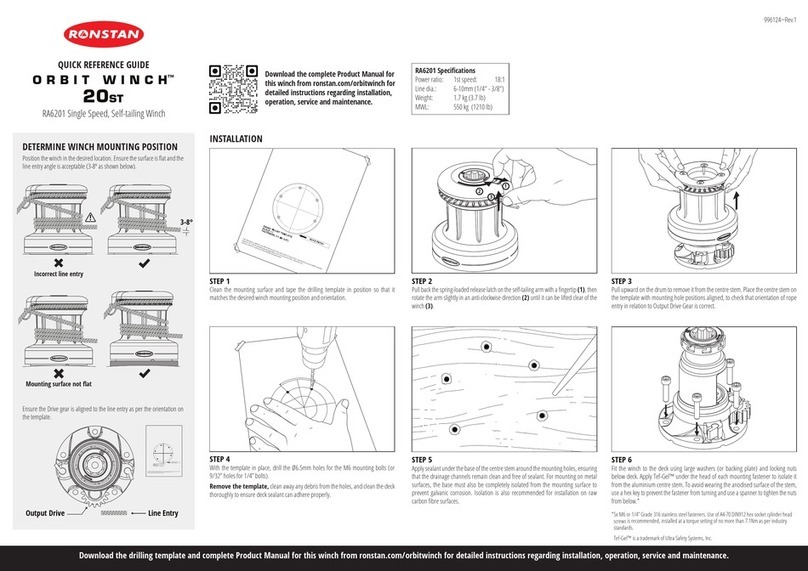

STEP 1

Lift the drum assembly over the centre stem , then slide it fully down into position.

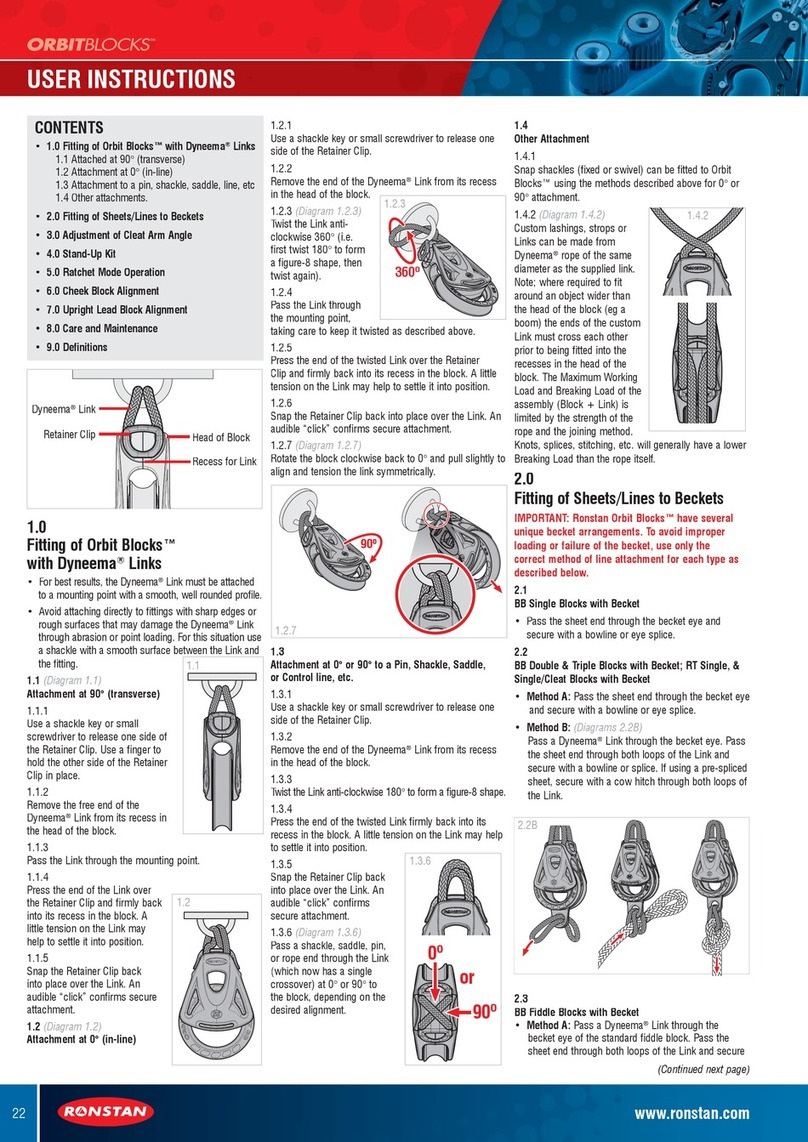

ARM ORIENTATION

The image above can be used as a guide to the orientation of the self-tailing arm in

typical locations on the deck.

STEP 2

Rotate the self-tailing arm to its desired position, ensuring that the rope splitter is in

position. Pull back the spring-loaded release latch on the self-tailing arm with a

fingertip (1), then rotate the arm slightly in a clockwise direction (3), and listen for

the audible "click" indicating it is locked in position (2).

STEP 3

Check that the drum turns smoothly when rotated by hand in a clockwise direction,

and is not able to turn in an anti-clockwise direction. Insert a winch handle in the

socket of the central drive shaft. Turning the handle in a clockwise direction should

drive the drum in fast speed; turning the handle in an anti-clockwise direction should

drive it in slow speed.

STEP 2

Locate and remove the countersunk cross-head screw.

STEP 1

Remove the self-tailer arm, closing plate and closing washer and set these parts aside

for now.

STEP 3

Reassemble the winch as per instructions above.

Read All Safety Notices and Product Manuals

Do not install or operate this winch before reading and fully understanding the

contents of the Product Manual.

Stay Alert When Operating

Winches are very powerful and have the potential to cause significant damage

and/or serious injury if used improperly or without due caution and vigilance.

Operators Must Be Trained

Help prevent significant damage and/or serious injury by ensuring any person

operating a winch has a thorough understanding of its proper operation and is

aware of the potential hazards involved. As a minimum, all winch operators

must read and understand the Safety Notices included in this Quick

Installation Guide and the Product Manual.

Particular attention is drawn to the following points:

• Children and others not qualified to operate a winch must be kept at a safe

distance from the winch and any rigging or fittings that are under load.

• Long hair and/or loose clothing must be tied back to avoid being caught in

the winch.

• In the event of a line override or other fault with an electric winch, stop the

winch and turn off power before attempting to resolve the problem.

Avoid Accidental Operation

Remove winch handles when not in use, and turn off power to electric winches

to help avoid unsupervised

or unintentional operation. Failure to do so could

result in significant damage and/or serious injury.

Maintenance

Turn off power to an electric winch before performing any maintenance or

service tasks. Failure to do so could result in significant damage and/or serious

injury.

SAFETY NOTICES

Slow

Fast

Download the complete Product Manual for this winch from ronstan.com/orbitwinch for detailed instructions regarding installation, operation, service and maintenance.

!

0°

90°

180°

270°

0°

90°

180°

270°

0°

90°

180°

270°

0°

90°

180°

270°

REMOVE SCREW TO

ACTIVATE QUICKTRIM

™

1

2

3

1

3

2

1

3

2

USING QUICKTRIM™

To release line tension, first hold the tail of the rope in one hand whilst placing your

other hand on the top cover of the self-tailer.

Use the palm of your hand to grip and rotate the top cover anti-clockwise against the

spring pressure and maintain it in that position. The self-tailer is now able to turn

beneath the cover, allowing the line to be eased off the drum in a controlled manner.

For more information and a demonstration on using QuickTrim

TM

visit:

ronstan.com/winches