10 © 2023, ROSS®, All Rights Reserved.

CM26 Series Operating Instructions

www.rosscontrols.com

Package Contents

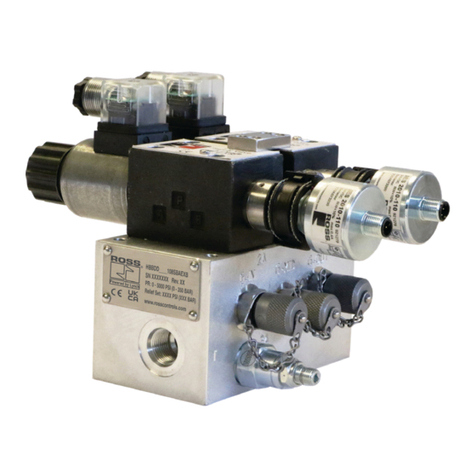

Items included: • CM26 Series valve

• Operating instructions

1. About this Documentation

These instructions contain important information for the safe and appropriate

assembly and commissioning of the product.

fRead these instructions all the way through, particularly section 2. “Notes on

Safety”, before working with the product.

fMake these operating instructions available to the engineer and assembly

technician of the machine/system in which the product will be used.

fKeep these operating instructions for the entire product life cycle.

Additional documentation:

• SISTEMA libraries

• DGUVcerticate:GermanSocialAccidentInsurance

• Product catalog and other technical documents

For more information visit www.rosscontrols.com.

fIn addition, observe all applicable local and national regulations on accident

prevention and on environmental protection.

1.1. Warning Notices in these Operating Instructions

In these operating instructions, warning notices precede sections with handling

requirements which incur risks of personal injury or material damage.

Warnings are structured as follows:

SIGNAL WORD

Type or source of hazard!

Consequences

fMeasures to avert danger

• Warning triangle: Indicates a risk of fatal or severe injuries.

• Signal word: Indicates the severity of the danger.

• Type or source of hazard: States the type of danger or the source of the hazard.

• Consequences: Describes possible consequences of ignoring the warning.

• Measures to avert danger: Indicates how to avoid the danger. It is essential that the

measures to avert danger are complied with.

DANGER

Indicates an imminent and serious danger that will result in

severe or even fatal injury if you fail to avoid it.

WARNING

Indicates a possible danger that could result in severe or even

fatal injury if you fail to avoid it.

CAUTION

Indicates a danger that may result in minor to moderate injuries if

you fail to avoid it.

ATTENTION

Indicates potential property damage that may be incurred by the

product or its surroundings if you fail to avoid it.

2. Notes on Safety

The product has been manufactured according to the accepted rules of current

technology.

There is risk of injury or damage if the following safety instructions and warnings given

in this instruction manual are not observed.

2.1. Intended Use

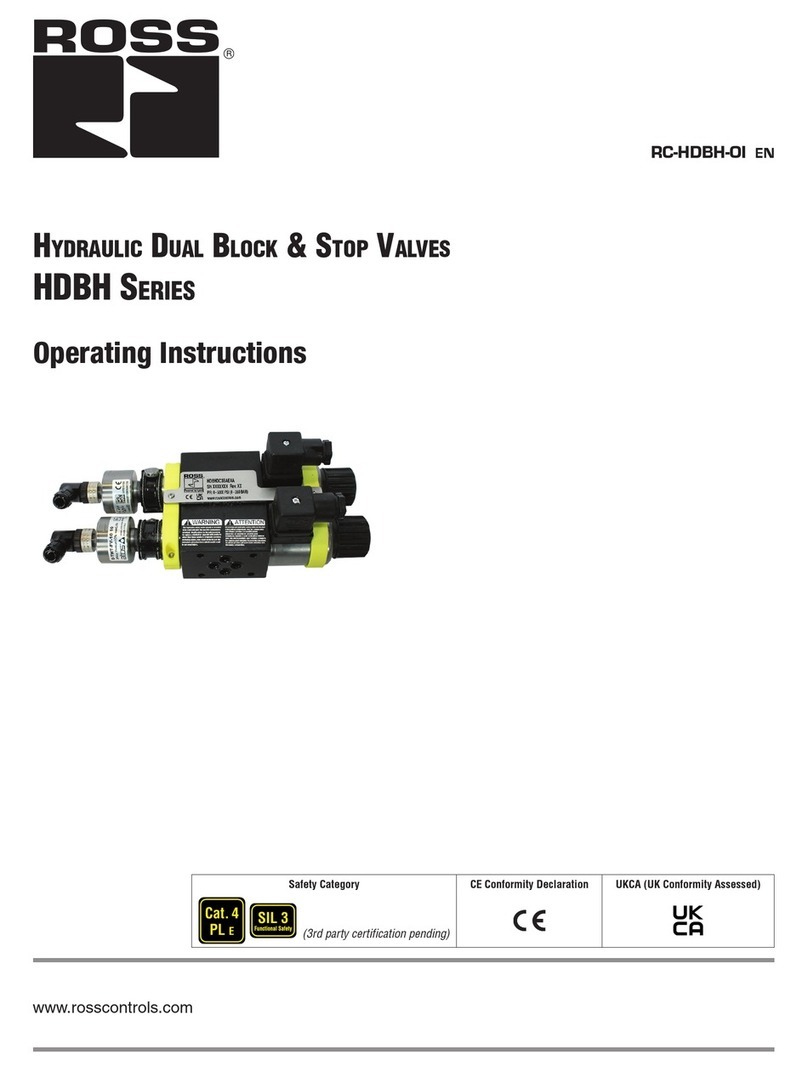

The CM26 Series of double valves are safety components designed and manufactured

in accordance with Machinery Directive 2006/42/EC and bear the CE and UKCA mark.

The CM26 Series line of double valves are redundant 5/2 valves that are designed to

meet the needs and requirements of Safe Return

Cylinder/Actuator (5/2 valves) applications for machinery with pneumatic controls.

Typically, these valves are implemented to meet the Category 4 and/or Performance

Level e requirements of a machine’s (or system’s) safety circuit as determined by a

risk assessment of the hazards and tasks required of employees that interact with the

machine/system.

fSee section 3 “Technical Data” for the standards and test values complied with and

adhered to by the product. See the declaration of conformity for product-relevant

directives. The 5/2 CM26 Series valves are designed to control the direction of

airowintoandoutofadouble-actingcylinderorotherpneumaticactuatorin

order to drive the cylinder forward or backward to suit the requirements of the

machine operation. However, the CM26 Series does this with the same level of

control expected of the machine’s system’s safety circuit. The safety function

of the CM26 Series valve is to return the cylinder/actuator to its home “safe”

position whenever a fault occurs within the valve.

NOTE: Maintenance tasks require following full lock-out/tag-out procedures to

relieve hazardous energy and prevent unexpected startup.

2.1.1. Safety Function According to ISO 13849

The CM26 Series valves are designed in accordance with the requirements listed

in ISO 13849-1 and -2. Their “fail-to-safe” safety function is ensured even in case of

a fault within the valve (e.g., caused by wear, contamination, or similar situations).

The safety function of the 5/2 CM26 Series valve is to drive a double-acting cylinder

or other pneumatic actuator forward when the two valve elements are actuated

simultaneously, but to drive the cylinder or other actuator back to its home “safe”

position when both valve elements are shut off or if only one of the two valves is

actuated. A fault in the system where only one valve actuates when switching on or

only one de-actuates when shutting off causes the CM26 Series valve to supply air

to port 2 of the valve and to simultaneously open port 4 to exhaust (port 5). This, in

turn, causes the cylinder or other actuator to return to its home “safe” position.

In the event of loss of air pressure at the inlet port a check valve (may be removed

oncustomerrequest)isinstalledtotrapthedownstreamair,asmallbleedorice

slowly relieves the trapped air

Attention: There may be some movement because of gravity or pressure balance,

whiletheairwillbeventedviathebleedorice

The CM26 Series valves feature additional Memory (fault memory) and reset

functions.

The CM26 valves are self-testing, redundant systems in accordance with the

requirements listed in ISO 13849-1 and -2.

The control outputs of the safety system must be designed and constructed to

meet the Category and/or Performance Level requirements of the safety system,

as determined by the risk assessment of the machine. Normally, the outputs to the

solenoids are dual-channel outputs from a safety relay or safety PLC.

2.1.2. Common Cause Failure – CCF

The product has been engineered and manufactured according to the fundamental

and proven safety principles of ISO 13849-1 and -2.

Critical failure modes and causes:

• Failure of the safety function - caused by simultaneous incomplete return of both

solenoid valves (A and B).

• Common Cause Failures (CCF) are failures of different components, resulting

from a single event. CCF are not to be confused with cascading faults or common

mode faults. Common cause failures can cause loss of the safety function,

especially in dual channel circuits where both channels could fail simultaneously

due to a single event.

• Maintaincompressedairquality,i.e.,ltration,pressureregulation,.

• Avoid oils that can cause valve seals to swell, soften, or otherwise deteriorate.

• Operating outside of prescribed temperature limits.

• Install the valve such that the normal stroke travel of the valve elements are

perpendicular to the main direction of machine vibration and/or mechanical shock.

• DonotuseatestpulselongerthanallowedbytheTechnicalSpecications.

• Avoidexternalmagneticelds.

• Do not plug the valve exhaust port.

• Useonlyhigh-ow,non-cloggingsilencers,with similarorhigher specications

as ROSS®silencers.

2.1.3. Diagnostic Coverage

A diagnostic coverage of 99% is achievable through appropriate integration of the

CM26 Series valve into the safety control system.

WARNING: In the event of loss of pressure during a fault could cause unexpected

movement of a cylinder that is being controlled by the valve.

2.1.4. Foreseeable Misuse

WARNING

Risk of Injury!

Misuse may result in injury or damage.

fThe product must be used exclusively as intended.

The product must be used exclusively as intended.

ENGLISH