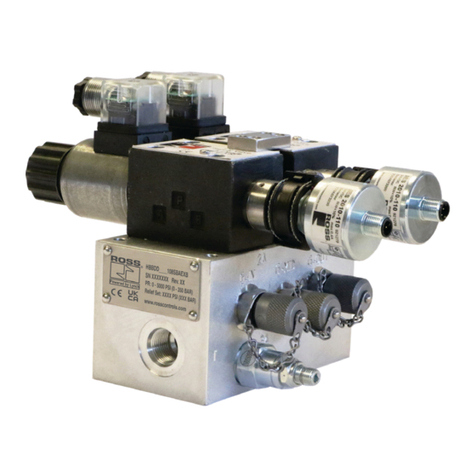

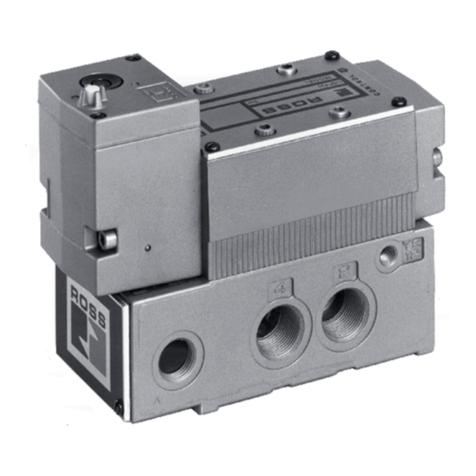

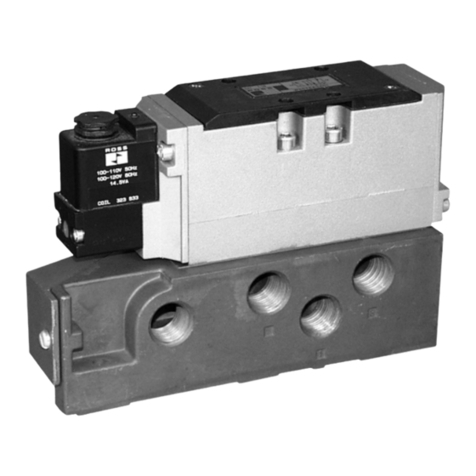

Control Reliable Double Valves Basic Size 4, 12 & 30

Thank You! You have purchased a premium-quality ROSS®pneumatic valve. It is a high

quality DM2® Series C explosion proof double valve with dynamic monitoring and inherent lockout capability for

Category 3 and 4 applications (except press clutch/brake applications). The valve is designed for base mounting

for ease of installation and maintenance. With care in its installation and maintenance you can expect it to have a

long and economical service life. Before you install this valve, read the information in this folder completely, and

save it for future reference.

NOTE: This valve is expressly not intended for use in press clutch/brake applications.

ROSS produces the DM2® Series Dand a number of other double valve configurations specifically for use with

press clutch/brake applications.

ROSS CONTROLS®www.rosscontrols.com

VALVE INSTALLATION

DM

2® Series C Explosion Proof

Size 12

illustrated

Pneumaticequipmentshouldbeinstalledonlybypersonstrainedandexperienced

in such installation.

Application: DM2® Series C double valves are intended for use in Category 3

& 4 applications except press clutch/brake applications.

Air Lines: Before installing this valve in a new or existing system, the air lines

must be blown clean of all contaminants. It is recommended that a 5-micron

rated air filter be installed in the inlet line close to the valve.

Valve Inlet (Port 1): Be sure that the supply line is of adequate size and does

not restrict the air supply because of a crimp in the line, a sharp bend, or a

clogged filter element. The air supply must not only provide sufficient pressure

(see Standard Specifications, page 3), but must also provide an adequate flow

of air on demand. Otherwise, the valve elements will be momentarily starved

for air and the valve may fail to operate.

Valve Outlet (Port 2): For faster pressurizing and exhausting of the mechanism

being operated by the valve, locate the valve as close as possible to the

mechanism. The lines must be of adequate size and be free of crimps and

sharp bends.

Valve Exhaust (Port 3): Do not restrict the air flow from

the exhaust port as this can adversely affect the operation of the valve. The

valves are factory equipped with a properly sized silencer. ROSS silencers

reduce impact noise by as much as 25 dB, and produce little back pressure.

Reset Solenoid: DM2® Series C double valves are supplied with a 3/2 normally

closed solenoid valve for reset purposes. Electrical reset signal must be

momentary and of correct voltage.

Electrical Supply: DM2® Series C double valves get electrical power through

plug-in connectors. The electrical supply must correspond to the voltage

and hertz ratings of the solenoids. Otherwise, the solenoids are subject to

early failure. If power is supplied by a transformer, the power supply must

be capable of handling the maximum power. See Valve Specifications on

page 3 for information on maximum power.

Operating Pressures and Temperatures: Allowable ranges for pressure and

temperatures are given in the Standard Specifications on page 3. Exceeding

these values can adversely affect performance and shorten valve life.

Pipe Installation: To install pipe in base ports, engage pipe one turn, apply

pipe thread sealant (tape not recommended), and tighten pipe. This procedure

will prevent sealant from entering and contaminating the valve. To install pipe

with parallel threads (e.g., SAE, ISO 228-G, etc.) do not use sealant. After

installing pipe into the base ports, use compressed air to blow any debris out

of the piping, then install the valve onto the base.

Test: After installation or repair and prior to normal use, the internal lockout

feature of the DM2® Series C double valve must be tested for proper functioning.

Observe normal equipment operation safety precautions during these tests to

avoid personal injury or damage to equipment.

NOTE: Reset may need to be performed prior to beginning the test procedure.

Also, the valve is designed such that both pilot solenoids must be de-energized

prior to reset, and must remain de-energized until after the reset signal is

removed. Otherwise, the valve will not reset.

A) Electrically energize both pilot solenoids simultaneously, then de-energize

one pilot solenoid. This should result in a valve lockout and prevent the valve

from operating.

B) Energize both solenoids and the valve should remain in the lockout condition.

C) De-energize both pilot solenoids and reset the valve.

D) Electrically energize both pilot solenoids simultaneously again. De-energize

the other pilot solenoid this time. Again, this should result in a lockout.

E) Energize both pilot solenoids. The valve should remain in a lockout condition.

F) De-energize both pilot solenoids and then reset the valve.

After satisfying these tests, energizing both pilot solenoids simultaneously

should result in normal operation.

Fault Indication: The built-in status indicator can be used to signal the machine

controls that a fault has occurred. The status indicator utilizes a pressure switch.

The pressure switch has 4 electrical contacts. During normal operation the

pressure switchispressurized. A lockout conditiondepressurizestheswitch until

the valve is reset. Contacts 1 and 2 are closed when the switch is depressurized

(normally closed) and contacts 1 and 3 are closed when an adequate pressure

signal is applied to the switch (normally open).

Please read and make sure you understand all installation instructions before proceeding with the installation.

Additional technical documentation is available for download at www.rosscontrols.com.

If you have any questions about installation or servicing your valve, please contact ROSS or your authorized ROSS distributor, see contact

information listed at the back of this document, or visit www.rosscontrols.com to find your distributor.

VALVE OPERATION

On first operation, or after repair, the pilot valve supply circuit and inherent

monitoring elements may need to be reset. This reset is accomplished by

applying a momentary air signal to the RESET port or by energizing the

optional reset solenoid momentarily on the valve. After reset, the valve will

then be ready for operation.

The air supply to each pilot valve is controlled by the position of the inlet

poppets. In the ready-for-operation position these poppets are held on their

seats and maintain pilot air flow. During shifting of the valve elements the

poppets move off seat and momentarily allow pilot air to escape to exhaust.

If either valve element fails to operate correctly, the pilot supply to the other

valve element will remain connected to exhaust causing the valve to lockout.

The internal monitoring system will lock out the valve if the time difference

between both elements shifting fully is longer than approximately 125

milliseconds. This timing is preset by restricting-orifices and chambers in

the pilot air circuit.

The main airflow from port 1 to port 2 is via crossflow passages between

both main valves, so that both valve elements must be fully shifted in order

for port 2 to be pressurized.

If the valve locks out, further operation is prevented until the valve has been

reset. Electrical signals to the solenoids must be "off" to allow the valve to

be reset.

The DM2® Series C valve is completely self-contained and does not need

an external monitoring system.