31

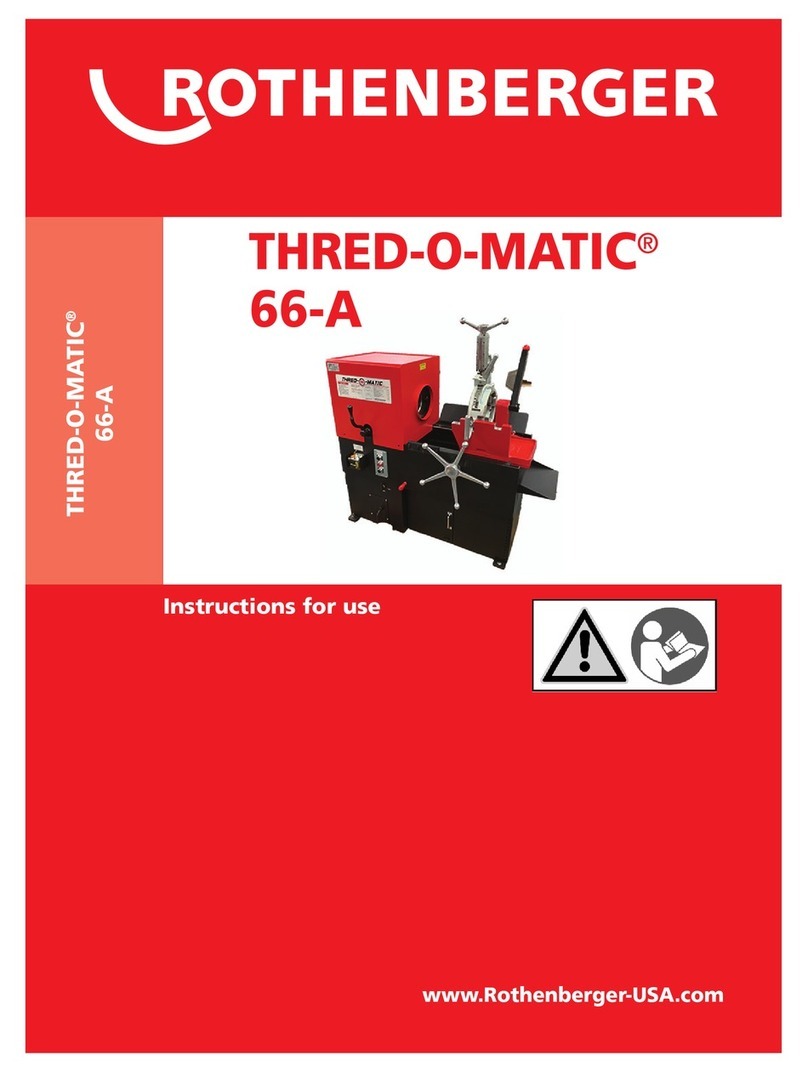

3 Functions of the thread-tapping machine

3.1 Overview / accessories / description

3.1.1 Overview, thread-tapping machine

Overview, control elements (> see front fold-out page):

1 Pipe cutter 5 Oil drainage screw

2 Thread-tapping jaws 6 Feeder hand wheel

3 Internal deburrer 7 Centring chuck

4 Tool carriage 8 Clamping chuck

3.1.2 Overview, automatic thread-tapping head

Overview, control elements (> see front fold-out page):

10 T-handle 13 Selector block

11 Locking lever 14 Cam plate

12 Selector pin 15 screw

3.1.3 Accessories

Use only suitable accessories recommended by ROTHENBERGER Werkzeuge GmbH!

Pipe stand, Height-adjustable, with ball guide, for pipes up to 6”

NIPPEL MAX Spare cutting wheel

For internally clamping D=41 mm, L=19 mm, DA=9 mm

short pipe sections hardened special steel for

manufacturing für machine type

nipples and double nipples - PANDA 40, PANDA 90

size 1/2“…2“, - PISET 3 SG, No. 6

Recycling pipe waste pieces - SUPERTRONIC 2S, 3S, 4S, 2SE,

saves time and money 3SE, 4SE, ROPOWER 50 R

automatic fast clamping

and centring of the RONOL

SYN

pipe pieces for right-hand High-performance thread-tapping fluid

and left-hand thread mineral oil-free, synthetic-based specially

for fast, rational working, developed and approved for drinking

automatic release after water and sanitary installation.

completion of the nipple, 100 % water-soluble, physiologically

hardened, ground harmless.

clamping jaws - in 5-litre plastic canisters

- NIPPEL MAX-Set, complete in sheet RONOL

steel carrying case High-performance thread-tapping fluid

1/2“ • 3/4“ • 1“ • 1 1/4“• 1 1/2“ mineral oil-based, very well suited

for thread-tapping work on all

- Nipple holder materials including stainless steel.

1/2“ • 3/4“ • 1“ • 1 1/4“ • 1 1/2“ • 2“ - in 5-litre plastic canisters

- Sheet steel case

- Plastic inlay